Beruflich Dokumente

Kultur Dokumente

U-Shaped Reinforced Bellows (Austenitic Steel)

Hochgeladen von

met-calc0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

170 Ansichten10 SeitenU-shaped Reinforced Bellows (Austenitic Steel)

Originaltitel

U-shaped Reinforced Bellows (Austenitic Steel)

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenU-shaped Reinforced Bellows (Austenitic Steel)

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

170 Ansichten10 SeitenU-Shaped Reinforced Bellows (Austenitic Steel)

Hochgeladen von

met-calcU-shaped Reinforced Bellows (Austenitic Steel)

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 10

14.

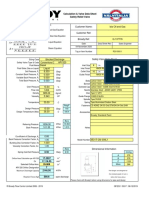

6 U-shaped reinforced bellows (Austenitic steel)

The calculation pressure: P 1,5 [Mpa]

The test pressure: Ptest 2 [Mpa]

The minimum yield strength or 1,0% proof strength at

calculation temperature (bellows): Rp1,0T 450 [Mpa]

The minimum tensile strength (bellows): Rm 800 [Mpa]

The minimum yield strength or 1,0% proof strength at

calculation temperature (collar): Rp1,0Tc 355 [Mpa]

The minimum tensile strength (collar): Rmc 470 [Mpa]

The minimum yield strength or 1,0% proof strength at

calculation temperature (reinforcing rings): Rp1,0Tr 350 [Mpa]

The minimum tensile strength (reinforcing rings): Rmr 470 [Mpa]

The minimum yield strength or 1,0% proof strength at

calculation temperature (reinforcing fastener): Rp1,0Tf 350 [Mpa]

The minimum tensile strength (reinforcing fastener): Rmf 470 [Mpa]

The crest convolution radius: ric 30 [mm]

The root convolution radius: rir 30 [mm]

The nominal thickness of one ply: ep 8 [mm]

The number of plies: np 1 []

The number of convolutions: N 4 []

The off-set angle of the sidewalls: α 15 [°]

The inside diameter of bellows convolution and end

tangents: Di 1200 [mm]

The convolution height: w 250 [mm]

The end tangent reinforcing collar thickness: ec 10 [mm]

The end tangent length: Lt 35 [mm]

The bellows collar length: Lc 40 [mm]

Fixing flange width: Lf 40 [mm]

The modulus of elasticity of bellows material at design

temperature: Eb 210000 [Mpa]

The modulus of elasticity of bellows material at room

temperature: E0 195000 [Mpa]

The Poisson's ratio of the bellows material: νb 0,3 []

The modulus of elasticity of collar material at design

temperature: Ec 210000 [Mpa]

The modulus of elasticity of reinforcing fastener

material at design temperature: Ef 210000 [Mpa]

The modulus of elasticity of reinforcing ring member

material at design temperature: Er 210000 [Mpa]

The cross sectional metal area of one reinforcing

fastener: Af 300 [mm2]

The cross sectional metal area of one bellows

reinforcing ring member: Ar 400 [mm2]

𝑚𝑖𝑛 𝑟 ; 𝑟

≥ 0,9

𝑚𝑎𝑥 𝑟 ; 𝑟 1,000 yes

The internal radius of torus at the crest and root of U-

shaped convolutions:

𝑟 +𝑟

𝑟 =

2

ri 30 [mm]

𝑟 ≥ 3𝑒 24,0 yes

−15° ≤ 𝛼 ≤ +15° yes

𝐷

𝑤≤

3 400,0 yes

𝑛 ≤5 yes

The bellows nominal thickness:

𝑒 =𝑛 ∗𝑒

e 8 [mm]

𝐿 − 𝐿 ≤ 0,5 𝑒 ∗ 𝐷 yes

The nominal design stress for normal operating cases

(bellows):

𝑅 , 𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ; 𝑚𝑖𝑛 ;

1,5 1,2 3

f 300,0 [Mpa]

The nominal design stress for test cases (bellows):

𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ;

1,05 2

ftest 428,6 [Mpa]

The nominal design stress for normal operating cases

(collar):

𝑅 , 𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ; 𝑚𝑖𝑛 ;

1,5 1,2 3

fc 236,7 [Mpa]

The nominal design stress for test cases (collar):

𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ;

1,05 2

ftestc 338,1 [Mpa]

The nominal design stress for normal operating cases

(reinforcing rings):

𝑅 , 𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ; 𝑚𝑖𝑛 ;

1,5 1,2 3

fr 233,3 [Mpa]

The nominal design stress for test cases (reinforcing

rings):

𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ;

1,05 2

ftestr 333,3 [Mpa]

The nominal design stress for normal operating cases

(reinforcing fastener):

𝑅 , 𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ; 𝑚𝑖𝑛 ;

1,5 1,2 3

ff 233,3 [Mpa]

The nominal design stress for test cases (reinforcing

fastener):

𝑅 , 𝑅

𝑓 = 𝑚𝑎𝑥 ;

1,05 2

ftestf 333,3 [Mpa]

The mean diameter of end tangent reinforcing collar:

𝐷 = 𝐷 + 2𝑒 + 𝑒

Dc 1226 [mm]

The mean diameter of bellows convolution:

𝐷 =𝐷 +𝑤+𝑒

Dm 1458 [mm]

The thickness of one ply, corrected for thinning during

forming:

𝐷

𝑒∗ = 𝑒

𝐷

ep* 7,258 [mm]

The bellows thickness, corrected for thinning during

forming:

𝑒∗ = 𝑛 ∗ 𝑒∗

e* 7,258 [mm]

The factor considering the stiffening effect of the

attachment weld and the end convolution on the

pressure capacity of the end tangent:

𝐿

𝑘 = 𝑚𝑖𝑛 ; 1,0

1,5 𝐷 ∗ 𝑒

k 0,238 []

The convolution pitch:

𝑞 = 4𝑟 + 2𝑒

q 136 [mm]

The cross sectional area of one convolution:

𝜋−2

𝐴= 𝑞 + 2𝑤 ∗ 𝑒 ∗

2

2

A 4192,3 [mm ]

Coefficient:

𝑞

𝐶 =

2𝑤

C1 0,272 []

Coefficient:

𝑞

𝐶 =

2,2 𝐷 ∗ 𝑒 ∗

C2 0,601 []

The convolution height factor for reinforced bellows

for calculation pressure:

100

𝐶 𝑃 = 0,3 −

1048𝑃 , + 320

Cr(P) 0,298 []

The convolution height factor for reinforced bellows

for test pressure:

100

𝐶 𝑃 = 0,3 − ,

1048𝑃 + 320

Cr(Ptest) 0,299 []

The resultant total internal pressure force acting on

the bellows and reinforcement for calculation

pressure:

𝐻 𝑃 = 𝑃𝐷 𝑞

H(P) 2,97E+05 [N]

The resultant total internal pressure force acting on

the bellows and reinforcement for test pressure:

𝐻 𝑃 =𝑃 𝐷 𝑞

H(Ptest) 3,97E+05 [N]

The ratio of the internal pressure force resisted by the

bellows on the internal pressure force resisted by the

reinforcement:

- For integral reinforcing ring members:

𝐴𝐸

𝑅=𝑅 = →𝐿 =0

𝐴 𝐸

R1 10,5 []

- For reinforcing ring members joined by fasteners:

𝐴𝐸 𝐿 𝐷

𝑅=𝑅 = +

𝐷 𝐴 𝐸 𝐴 𝐸

R2 10,9 []

R 10,9 []

Coefficient: α0 0,955 []

Coefficient: α1 -2,708 []

Coefficient: α2 7,279 []

Coefficient: α3 14,212 []

Coefficient: α4 -104,242 []

Coefficient: α5 133,333 []

Coefficient:

𝐶 =∝ +∝ 𝐶 +∝ 𝐶 +∝ 𝐶 +∝ 𝐶 +∝ 𝐶

Cp 0,671 []

Coefficient: β0 1,003 []

Coefficient: β1 1,338 []

Coefficient: β2 -1,717 []

Coefficient: β3 1,908 []

Coefficient: β4 0,020 []

Coefficient: β5 -0,550 []

Coefficient:

𝐶 = 𝛽 +𝛽 𝐶 +𝛽 𝐶 +𝛽 𝐶 +𝛽 𝐶 +𝛽 𝐶

Cf 1,278 []

Coefficient: γ0 1,005 []

Coefficient: γ1 1,263 []

Coefficient: γ2 5,184 []

Coefficient: γ3 -13,929 []

Coefficient: γ4 13,828 []

Coefficient: γ5 -4,83 []

Coefficient:

𝐶 =𝛾 +𝛾 𝐶 +𝛾 𝐶 +𝛾 𝐶 +𝛾 𝐶 +𝛾 𝐶

Cd 1,520 []

The meridional bending stress for calculation pressure:

0,85 𝑤 − 𝐶 𝑃 𝑞

𝜎 , 𝑃 = ∗ ∗𝐶 ∗𝑃

2𝑛 𝑒∗

σm,b(P) 356,3 [Mpa]

The meridional bending stress for test pressure:

0,85 𝑤 − 𝐶 𝑃 𝑞

𝜎 , 𝑃 = ∗ ∗𝐶 ∗𝑃

2𝑛 𝑒∗

σm,b(Ptest) 474,4 [Mpa]

The circumferential membrane stress due to pressure

for calculation pressure (the end tangent):

1 𝐷 +𝑒 ∗𝐿 ∗𝐸 ∗𝑘

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝑒∗ 𝐷 +𝑒 ∗𝐿 ∗𝐸 +𝑒 ∗𝐷 ∗𝐿 ∗𝐸 ∗𝑘

σθ,t(P) 20,0 [MPa]

The circumferential membrane stress due to pressure

for test pressure (the end tangent):

1 𝐷 +𝑒 ∗𝐿 ∗𝐸 ∗𝑘

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝑒∗ 𝐷 +𝑒 ∗𝐿 ∗𝐸 +𝑒 ∗𝐷 ∗𝐿 ∗𝐸 ∗𝑘

σθ,t(Ptest) 26,7 [MPa]

The circumferential membrane stress due to pressure

for calculation pressure (collar):

1 𝐷 ∗𝐿 ∗𝐸 ∗𝑘

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝑒∗ 𝐷 +𝑒 ∗𝐿 ∗𝐸 +𝑒 ∗𝐷 ∗𝐿 ∗𝐸 ∗𝑘

σθ,c(P) 20,6 [MPa]

The circumferential membrane stress due to pressure

for test pressure (collar):

1 𝐷 ∗𝐿 ∗𝐸 ∗𝑘

𝜎 , 𝑃 = ∗ ∗𝑃 ≤𝑓

2 𝑒∗ 𝐷 +𝑒 ∗𝐿 ∗𝐸 +𝑒 ∗𝐷 ∗𝐿 ∗𝐸 ∗𝑘

σθ,t(Ptest) 27,5 [MPa]

The circumferential membrane stress for calculation

pressure:

𝐻 𝑃 𝑅

𝜎 𝑃 = ≤𝑓

2𝐴 𝑅+1

σθ(P) 32,5 [MPa]

The circumferential membrane stress for test pressure:

𝐻 𝑃 𝑅

𝜎 𝑃 = ≤𝑓

2𝐴 𝑅+1

σθ(Ptest) 43,3 [MPa]

The meridional membrane stress for calculation

pressure:

𝑤−𝐶 𝑃 𝑞

𝜎 , 𝑃 = 0,85 ∗𝑃

2𝑒 ∗ σm,m(P) 18,4 [MPa]

The meridional membrane stress for test pressure:

𝑤−𝐶 𝑃 𝑞

𝜎 , 𝑃 = 0,85 ∗𝑃

2𝑒 ∗

σm,m(Ptest) 24,5 [MPa]

Effective stress concentration factor:

for annealed bellows (without cold work) 3

for as-formed bellows (with cold work) 1,5

Effective stress concentration factor: Kf 3 []

𝜎 , 𝑃 +𝜎 , 𝑃 ≤𝐾 ∗𝑓 374,7 yes

𝜎 , 𝑃 +𝜎 , 𝑃 ≤ 𝐾 ∗𝑓 498,9 yes

The circumferential membrane stress for calculation

pressure: - reinforcing rings:

𝐻 𝑃 1

𝜎´ , 𝑃 = ≤𝑓

2𝐴 𝑅 +1

σ´θ,r(P) 32,4 [MPa]

The circumferential membrane stress for test pressure:

- reinforcing rings:

𝐻 𝑃 1

𝜎´ , 𝑃 = ≤𝑓

2𝐴 𝑅 +1

σ´θ,r(Ptest) 43,2 [MPa]

The circumferential membrane stress for calculation

pressure: - reinforcing fastener:

𝐻 𝑃 1

𝜎´´ , 𝑃 = ≤𝑓

2𝐴 𝑅 +1

σ´´θ,f(P) 41,8 [MPa]

The circumferential membrane stress for test pressure:

- reinforcing fastener:

𝐻 𝑃 1

𝜎´´ , 𝑃 = ≤𝑓

2𝐴 𝑅 +1

σ´´θ,f(Ptest) 55,7 [MPa]

The bellows axial rigidity:

𝜋 𝑛 𝑒∗ 1

𝐾 = ∗𝐸 ∗ ∗𝐷 ∗ ∗

2 1−𝜈 𝑁 𝑤−𝐶 𝑃 𝑞 𝐶

Kb 4301,7 [N/mm]

Column squirm:

𝜋𝐾

𝑃 , = 0,3 ≥𝑃

𝑁∗𝑞

Ps,c 7,5 [MPa]

The total stress range due to cyclic loading for

calculation pressure: Δq 10 [mm]

The total stress range due to cyclic loading for test

pressure: Δqtest 10 [mm]

The specified number of fatigue cycles for calculation

pressure: Nspe 100000 []

The specified number of fatigue cycles for test

pressure: Nspetest 500 []

The meridional membrane stress for calculation

pressure:

𝐸 ∗ 𝑒∗

𝜎 , ∆𝑞 = ∆𝑞

2 𝑤−𝐶 𝑃 𝑞 ∗𝐶

σm,m(Δq) 4,7 [MPa]

The meridional membrane stress for test pressure:

𝐸 ∗ 𝑒∗

𝜎 , ∆𝑞 = ∆𝑞

2 𝑤−𝐶 𝑃 𝑞 ∗𝐶

σm,m(Δqtest) 4,7 [MPa]

The meridional bending stress for calculation pressure:

5𝐸 ∗ 𝑒 ∗

𝜎 , ∆𝑞 = ∆𝑞

3 𝑤−𝐶 𝑃 𝑞 ∗𝐶

σm,b(Δq) 380,8 [MPa]

The meridional bending stress for test pressure:

5𝐸 ∗ 𝑒 ∗

𝜎 , ∆𝑞 = ∆𝑞

3 𝑤−𝐶 𝑃 𝑞 ∗𝐶

σm,b(Δqtest) 381,3 [MPa]

The total stress range due to cyclic loading for

calculation pressure:

𝑄 = 0,7 ∗ 𝜎 , 𝑃 +𝜎 , 𝑃 + 𝜎 , ∆𝑞 + 𝜎 , ∆𝑞

σeq 647,8 [MPa]

The total stress range due to cyclic loading for test

pressure:

𝑄 = 0,7 ∗ 𝜎 , 𝑃 +𝜎 , 𝑃 + 𝜎 , ∆𝑞 +𝜎 , ∆𝑞

σeqtest 735,3 [MPa]

The allowable number of fatigue cycles for calculation

pressure:

,

𝐸 24452,5

𝜎 ≥ 630,4𝑀𝑃𝑎: 𝑁 =

𝐸 𝐸

𝜎 − 288,2

𝐸

,

𝐸 28571,9

𝜎 < 630,4𝑀𝑃𝑎: 𝑁 =

𝐸 𝐸

𝐸 𝜎 − 230,6

𝐸

𝜎 ≤ 230,6𝑀𝑃𝑎: 𝑁 = 10

𝐸

𝑁 ≥𝑁

Nalw 296039 []

The allowable number of fatigue cycles for test

pressure:

,

𝐸 24452,5

𝜎 ≥ 630,4𝑀𝑃𝑎: 𝑁 =

𝐸 𝐸

𝐸 𝜎 − 288,2

,

𝐸 28571,9

𝜎 < 630,4𝑀𝑃𝑎: 𝑁 =

𝐸 𝐸

𝐸 𝜎 − 230,6

𝐸

𝜎 ≤ 230,6𝑀𝑃𝑎: 𝑁 = 10

𝐸

𝑁 ≥𝑁

Nalwtest 157565 []

The cumulative fatigue damage index:

𝑁 𝑁

𝐷= + ≤1

𝑁 𝑁

D 0,34 []

Das könnte Ihnen auch gefallen

- U-Shaped Unreinforced Bellows (Austenitic Steel)Dokument9 SeitenU-Shaped Unreinforced Bellows (Austenitic Steel)met-calc100% (1)

- Figure 9.4-13 Conical Shell With Isolated Opening. Combined Reinforcement From Shell and Nozzle en 13445-3 - Figure 9.4-13Dokument4 SeitenFigure 9.4-13 Conical Shell With Isolated Opening. Combined Reinforcement From Shell and Nozzle en 13445-3 - Figure 9.4-13met-calcNoch keine Bewertungen

- Spherical Shells en 13445-3 - 7.4.3Dokument3 SeitenSpherical Shells en 13445-3 - 7.4.3met-calc100% (1)

- Optimization Design of The U-Shaped Metal BellowsDokument5 SeitenOptimization Design of The U-Shaped Metal BellowsdaymonNoch keine Bewertungen

- Expansion Bellows Design CalculationDokument1 SeiteExpansion Bellows Design CalculationvvpvarunNoch keine Bewertungen

- "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Dokument4 Seiten"Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriNoch keine Bewertungen

- PVengDokument3 SeitenPVengDiana SoareNoch keine Bewertungen

- Threaded Holes (11.4.3.3) EN 13445-3Dokument1 SeiteThreaded Holes (11.4.3.3) EN 13445-3met-calcNoch keine Bewertungen

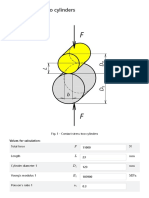

- Contact Stress Two CylindersDokument3 SeitenContact Stress Two Cylindersmet-calcNoch keine Bewertungen

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Dokument5 SeitenFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNoch keine Bewertungen

- ThickAndThin JointsDokument31 SeitenThickAndThin JointsHùng Mạnh NguyễnNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Dokument24 SeitenHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNoch keine Bewertungen

- Flexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Dokument2 SeitenFlexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriNoch keine Bewertungen

- Butterfly Valve Hydrodynamic Calculation Sheet: S D Max 3Dokument6 SeitenButterfly Valve Hydrodynamic Calculation Sheet: S D Max 3Ly Thanh HaNoch keine Bewertungen

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Dokument4 SeitenFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Spherical ValveDokument40 SeitenHydrodynamic Calculation Spherical Valvemet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Dokument31 SeitenHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNoch keine Bewertungen

- Butter Valve Thickness PDFDokument10 SeitenButter Valve Thickness PDFAnand KumarNoch keine Bewertungen

- Expansion Bellow Tech ComparisonDokument10 SeitenExpansion Bellow Tech ComparisonSabariMechyNoch keine Bewertungen

- Analisis of Stress in BellowsDokument101 SeitenAnalisis of Stress in BellowsOswaldo GuerraNoch keine Bewertungen

- Contact Stress of Cylinder On Flat SurfaceDokument3 SeitenContact Stress of Cylinder On Flat Surfacemet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D$ 0.16Dokument30 SeitenHydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D$ 0.16Eng-CalculationsNoch keine Bewertungen

- Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsDokument9 SeitenPressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsJoemarie MartinezNoch keine Bewertungen

- Hydrodynamic Calculation Howell-Jet ValveDokument17 SeitenHydrodynamic Calculation Howell-Jet Valvemet-calcNoch keine Bewertungen

- Spherical Shells (7.4.3) EN 13445-3Dokument3 SeitenSpherical Shells (7.4.3) EN 13445-3met-calcNoch keine Bewertungen

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDokument5 SeitenASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNoch keine Bewertungen

- Dimensions of Restriction Orifice Plates For ASME b16Dokument5 SeitenDimensions of Restriction Orifice Plates For ASME b16Mohamed Salah SolimanNoch keine Bewertungen

- Optimization and Standardization of Flanged and Flued Expansion Joint DesignDokument32 SeitenOptimization and Standardization of Flanged and Flued Expansion Joint DesignPankaj SinglaNoch keine Bewertungen

- NozzlePRO 14.1NewFeatures-2019ReleaseDokument13 SeitenNozzlePRO 14.1NewFeatures-2019ReleasedelitesoftNoch keine Bewertungen

- Hydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The PistonDokument23 SeitenHydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The Pistonmet-calcNoch keine Bewertungen

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDokument1 SeiteChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNoch keine Bewertungen

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Dokument21 SeitenCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Welding Neck Flanges 1Dokument3 SeitenWelding Neck Flanges 1bikkelbobNoch keine Bewertungen

- Keystone Butterfly Valve F 631Dokument4 SeitenKeystone Butterfly Valve F 631Robi KeiNoch keine Bewertungen

- Conical Shells (7.6.4) EN 13445-3Dokument3 SeitenConical Shells (7.6.4) EN 13445-3met-calcNoch keine Bewertungen

- Sizing CalcDokument1 SeiteSizing CalcHilary AbaratuNoch keine Bewertungen

- PV Elite ResultDokument239 SeitenPV Elite ResultChaitanya Sai TNoch keine Bewertungen

- Ivc Valves PDFDokument4 SeitenIvc Valves PDFNaveen ReddyNoch keine Bewertungen

- Test Report Long-Term Ring Bending Strain (SB)Dokument4 SeitenTest Report Long-Term Ring Bending Strain (SB)Diana QuinteroNoch keine Bewertungen

- Flange CouplingDokument17 SeitenFlange CouplingROCKY DUBEYNoch keine Bewertungen

- (DIN 28050 - 2009-09) - Behà Lter Und Apparate - Maximal Zulã Ssiger Druck - 1, 0 Bar Bis +0, 5 Bar - Technische Lieferbedingungen - 0001.de - enDokument8 Seiten(DIN 28050 - 2009-09) - Behà Lter Und Apparate - Maximal Zulã Ssiger Druck - 1, 0 Bar Bis +0, 5 Bar - Technische Lieferbedingungen - 0001.de - enNaveen Suresh KumarNoch keine Bewertungen

- External Pressure Pipe Thickness CalcDokument3 SeitenExternal Pressure Pipe Thickness Calcreach_arindomNoch keine Bewertungen

- ASME UG 37 Nozzles PDFDokument6 SeitenASME UG 37 Nozzles PDFlatif.deNoch keine Bewertungen

- Investigations of Butterfly Control Valve Flow CharacteristicsDokument16 SeitenInvestigations of Butterfly Control Valve Flow CharacteristicsKalimuthu Ps100% (1)

- Calculo Brida Ejemplo PV - EliteDokument8 SeitenCalculo Brida Ejemplo PV - ElitePedro Montes MarinNoch keine Bewertungen

- CAESAR II-Applications GuideDokument302 SeitenCAESAR II-Applications GuideTakChi_LamNoch keine Bewertungen

- Hydrodynamic Calculation Gate Valve (Through Conduit)Dokument14 SeitenHydrodynamic Calculation Gate Valve (Through Conduit)met-calcNoch keine Bewertungen

- Mechanical Specifications For Fiberbond ProductDokument8 SeitenMechanical Specifications For Fiberbond ProducthasnizaNoch keine Bewertungen

- Blind Flange (10 Bar)Dokument7 SeitenBlind Flange (10 Bar)SyedZainAliNoch keine Bewertungen

- Double Piston EffectDokument1 SeiteDouble Piston EffectaiaudcoNoch keine Bewertungen

- Nozzle StressDokument25 SeitenNozzle StressvamsiNoch keine Bewertungen

- 0.0bolt Torque Calculation - R0Dokument9 Seiten0.0bolt Torque Calculation - R0Darshan PanchalNoch keine Bewertungen

- PSV Reaction Force CalculationDokument2 SeitenPSV Reaction Force CalculationSuthanNoch keine Bewertungen

- Design of Compact Flange JointsDokument15 SeitenDesign of Compact Flange JointsAkhil JoseNoch keine Bewertungen

- Figure 9.4-5 Cylindrical Shell With Isolated Opening and Reinforcing Ring, With External Blind Flange B en 13445-3 - Figure 9.4-5Dokument4 SeitenFigure 9.4-5 Cylindrical Shell With Isolated Opening and Reinforcing Ring, With External Blind Flange B en 13445-3 - Figure 9.4-5met-calcNoch keine Bewertungen

- Cylindrical Compression Helix Springs For Suspension SystemsVon EverandCylindrical Compression Helix Springs For Suspension SystemsNoch keine Bewertungen

- Hydrodynamic Calculation Howell-Jet ValveDokument17 SeitenHydrodynamic Calculation Howell-Jet Valvemet-calcNoch keine Bewertungen

- Nuts (11.4.3.2) EN 13445-3Dokument1 SeiteNuts (11.4.3.2) EN 13445-3met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Dokument24 SeitenHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Dokument19 SeitenHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNoch keine Bewertungen

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDokument3 SeitenRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Spherical ValveDokument40 SeitenHydrodynamic Calculation Spherical Valvemet-calcNoch keine Bewertungen

- Threaded Holes (11.4.3.3) EN 13445-3Dokument1 SeiteThreaded Holes (11.4.3.3) EN 13445-3met-calcNoch keine Bewertungen

- Spherical Shells (7.4.3) EN 13445-3Dokument3 SeitenSpherical Shells (7.4.3) EN 13445-3met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Howell-Bunger ValveDokument34 SeitenHydrodynamic Calculation Howell-Bunger Valvemet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The PistonDokument23 SeitenHydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The Pistonmet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Needle ValveDokument23 SeitenHydrodynamic Calculation Needle Valvemet-calcNoch keine Bewertungen

- Multi-Stage ValveDokument2 SeitenMulti-Stage Valvemet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Lenticular Disc)Dokument28 SeitenHydrodynamic Calculation Butterfly Valve (Lenticular Disc)met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Gate Valve (Through-Conduit)Dokument23 SeitenHydrodynamic Calculation Gate Valve (Through-Conduit)met-calcNoch keine Bewertungen

- Contact Stress Two CylindersDokument3 SeitenContact Stress Two Cylindersmet-calcNoch keine Bewertungen

- Contact Stress of The Cylinder in The Cylindrical SocketDokument3 SeitenContact Stress of The Cylinder in The Cylindrical Socketmet-calcNoch keine Bewertungen

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Dokument5 SeitenFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Dokument31 SeitenHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Dokument31 SeitenHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNoch keine Bewertungen

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Dokument4 SeitenFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNoch keine Bewertungen

- Allowable Stress: R Mpa C SDokument1 SeiteAllowable Stress: R Mpa C Smet-calcNoch keine Bewertungen

- Contact Stress of Cylinder On Flat SurfaceDokument3 SeitenContact Stress of Cylinder On Flat Surfacemet-calcNoch keine Bewertungen

- Conical Shells (7.6.4) EN 13445-3Dokument3 SeitenConical Shells (7.6.4) EN 13445-3met-calcNoch keine Bewertungen

- Allowable Hertz PressureDokument1 SeiteAllowable Hertz Pressuremet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Dokument18 SeitenHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNoch keine Bewertungen

- BucklingDokument2 SeitenBucklingmet-calcNoch keine Bewertungen

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Dokument18 SeitenHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNoch keine Bewertungen

- Hydrodynamic Calculation Gate Valve (Through Conduit)Dokument14 SeitenHydrodynamic Calculation Gate Valve (Through Conduit)met-calcNoch keine Bewertungen

- Multi-Hole CageDokument7 SeitenMulti-Hole Cagemet-calcNoch keine Bewertungen

- The Flow Characteristic On The Position of The DriveDokument7 SeitenThe Flow Characteristic On The Position of The Drivemet-calcNoch keine Bewertungen

- Bend Test and Ductility TestDokument24 SeitenBend Test and Ductility TestNovie Dave EstremaduraNoch keine Bewertungen

- Electroarc - Insulation Enhancement ProductsDokument17 SeitenElectroarc - Insulation Enhancement ProductsVenkata Reddy100% (2)

- BMW Colorsystem 2015 16Dokument17 SeitenBMW Colorsystem 2015 16Esaú MonNoch keine Bewertungen

- Alloy 34MnB5Dokument2 SeitenAlloy 34MnB5Javo RodriguezNoch keine Bewertungen

- Structural Lightweight Concrete in Hong Kong: Now, New, NextDokument6 SeitenStructural Lightweight Concrete in Hong Kong: Now, New, NextSteven F. S. BruniNoch keine Bewertungen

- Quad Roll CrushDokument5 SeitenQuad Roll Crushstatus wa kerenNoch keine Bewertungen

- European Steel and Alloy Grades: 42crmo5-6 (1.7233)Dokument2 SeitenEuropean Steel and Alloy Grades: 42crmo5-6 (1.7233)farshid KarpasandNoch keine Bewertungen

- Review Article: Nanomaterial by Sol-Gel Method: Synthesis and ApplicationDokument21 SeitenReview Article: Nanomaterial by Sol-Gel Method: Synthesis and ApplicationPam S. PowellNoch keine Bewertungen

- MIL-B-81934 2C Bearings, Self LubricatingDokument5 SeitenMIL-B-81934 2C Bearings, Self LubricatingthomasNoch keine Bewertungen

- Petroleum Research: R.V.V.Ramana Murthy, Murthy Chavali, Faruq MohammadDokument9 SeitenPetroleum Research: R.V.V.Ramana Murthy, Murthy Chavali, Faruq MohammadErica MagnagoNoch keine Bewertungen

- QW-424 Asme Ix 2023Dokument1 SeiteQW-424 Asme Ix 2023CARLOS OLIVEROSNoch keine Bewertungen

- Nexans Power Accessories - Oil and Gas (ATEX) - 2013Dokument44 SeitenNexans Power Accessories - Oil and Gas (ATEX) - 2013jose augustoNoch keine Bewertungen

- Cable Tray Manual: Appendix PagesDokument14 SeitenCable Tray Manual: Appendix PagesMarvinNoch keine Bewertungen

- FireStone EPDMDokument2 SeitenFireStone EPDMAlaaGaballaNoch keine Bewertungen

- Pending Call ReportDokument46 SeitenPending Call ReportVandana YadavNoch keine Bewertungen

- Anderol 555Dokument1 SeiteAnderol 555rewindingidsNoch keine Bewertungen

- SWS Data SheetDokument4 SeitenSWS Data SheetBanupriya BalasubramanianNoch keine Bewertungen

- Concrete Work Implementation MethodDokument9 SeitenConcrete Work Implementation MethodMonehoi ZechalyNoch keine Bewertungen

- Data NYAF 4mm SupremeDokument1 SeiteData NYAF 4mm SupremeHans JayaNoch keine Bewertungen

- Failure Analysis of A Half Shaft of A Formula SAE Racing Car PDFDokument7 SeitenFailure Analysis of A Half Shaft of A Formula SAE Racing Car PDFhayyanadmaNoch keine Bewertungen

- Byk - P 4102 - TDS - 1643511993Dokument2 SeitenByk - P 4102 - TDS - 1643511993swapon kumar shillNoch keine Bewertungen

- Siemens Power Cables & Their ApplicationsDokument240 SeitenSiemens Power Cables & Their Applicationsagsparx67% (6)

- Concrete Technology-BitsDokument5 SeitenConcrete Technology-Bitsabhiram ramNoch keine Bewertungen

- Ultrachem Bitumen WPDokument1 SeiteUltrachem Bitumen WPAde KurniawanNoch keine Bewertungen

- BS 8218-1998 Mastic Asphalt RoofingDokument38 SeitenBS 8218-1998 Mastic Asphalt Roofingconst1Noch keine Bewertungen

- Caesarr Ii-Liqueo de Bridas Asme Viii Div 1 Appendix 2Dokument9 SeitenCaesarr Ii-Liqueo de Bridas Asme Viii Div 1 Appendix 2Juan VillavicencioNoch keine Bewertungen

- Btech Project Report Template-1Dokument38 SeitenBtech Project Report Template-1OMShivRajaBabuNoch keine Bewertungen

- Ball Bearing Lubrication in Centrifugal PumpsDokument4 SeitenBall Bearing Lubrication in Centrifugal Pumpsyousafsappal795Noch keine Bewertungen

- Pengaruh Suhu Penyimpanan Terhadap Kedalaman Pengerasan Dan Kekuatan Resin KompositDokument5 SeitenPengaruh Suhu Penyimpanan Terhadap Kedalaman Pengerasan Dan Kekuatan Resin KompositRani WulandariNoch keine Bewertungen

- Design of Reinforced Concrete Structures (DRCS) Concrete Manufacturing ProcessDokument2 SeitenDesign of Reinforced Concrete Structures (DRCS) Concrete Manufacturing ProcessBlen tesfayeNoch keine Bewertungen