Beruflich Dokumente

Kultur Dokumente

Ieee Paper PDF

Hochgeladen von

Suresh ThillaiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ieee Paper PDF

Hochgeladen von

Suresh ThillaiCopyright:

Verfügbare Formate

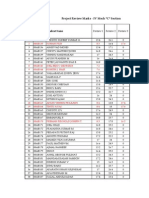

IEEE Africon 2011 - The Falls Resort and Conference Centre, Livingstone, Zambia, 13 - 15 September 2011

Comparative Performance Analysis of Marula comparable to that of conventional diesel fuel while reducing

engine emissions of particulates, hydrocarbons and carbon

Oil and Petrodiesel fuels on a Variable monoxide [1]. Other advantages include reduced emission of

Compression Ratio Engine carbon monoxide, particulate matter and polycyclic aromatic

hydrocarbons; physical and chemical properties that are very

similar to those of petroleum based diesel fuel in terms of

Jerekias Gandure, Clever Ketlogetswe operation in compression ignition engines (diesel engines);

biodegradability; non-toxic and essentially free of sulphur and

Department of Mechanical Engineering

aromatics, making it safer to handle and transport; ability to

University of Botswana

run in any conventional, unmodified diesel engine; improved

Gaborone, Botswana

lubricity and high cetane number. The best advantage is the

gandurej@mopipi.ub.bw, ketloget@mopipi.ub.bw fact that biodiesel is a renewable fuel source, while petroleum

fuel is limited. This alone will be the reason for its ever

increasing popularity. Biodiesel, however, has its disadvantage

Abstract - The quest for biofuel production and use in and these include lower energy content, Engine operation

Botswana is driven by factors including volatile oil prices,

need for fuel security, potential for job creation, potential

problems such as fuel filter plugging, injector coking (carbon

reduction in greenhouse gas emissions, and economic deposits), piston ring sticking and breaking, and severe engine

diversification. In line with national efforts to come up with lubricant degradation. Biodiesel can be produced from any

energy sources that are both environmentally friendly and material that contains fatty acids, be they bonded to other

sustainable, this work was carried out to compare molecules or present as free fatty acids. As a result various

performance properties of native marula seed oil and vegetable fats and oils, animal fats, waste greases, and edible

petrodiesel fuels on a variable compression engine test rig with oil processing wastes can be used as feedstocks for biodiesel

automatic data acquisition set up. Parameters such as engine production. The choice of feedstock is based on such variables

torque, brake power and specific fuel consumption were as local availability, cost, government support and performance

measured at different loads for the two fuels. The results

indicated that engine performance when powered with marula

as a fuel [2].

oil as fuel was very close to that when powered with

petrodiesel. The engine performance was also analysed for This work sought to establish performance properties of

same parameters of engine torque, brake power and specific marula oil as a potential feedstock for biodiesel production

fuel consumption when powered by the same two fuels over in Botswana. The results are expected to provide indicators

varying compression ratios at a fixed load of 80%. The results which can be used to stimulate rapid development of

indicated that compression ratio of 16:1 yields optimum

biodiesel using indigenous feedstocks in Botswana. Marula

performance in terms of engine torque and brake power for

both petrodiesel and marula oil fuels; marula oil fuel has a

tree is indigenous to most parts of the Southern African

smooth rising performance profile across all compression Development Community. In Botswana, for example, it is

ratios which out-performs petrodiesel on lower compression widely distributed all over the country, but it is

ratios for engine torque and brake power, and is largely better concentrated in the north eastern part of the country.The

than petrodiesel on fuel consumption. tree grows in warm and dry climatic conditions, and

produce oval fruits that turn pale yellow when ripe.

Key words: Performance, marula oil, petrodiesel

1. Introduction

• The expedition for biofuel production and use in Botswana is

driven by factors including volatile oil prices, need for fuel

security, potential for job creation, potential reduction in

greenhouse gas emissions, and economic diversification. The

ambition to establish national energy self-reliance and to

develop alternatives to finite fossil fuel resources have resulted

in the development of fuel technologies that are based on the

use of renewable agriculture based materials as feedstocks. In

the case of renewable fuels for compression ignition (diesel)

engines, the majority of efforts to date have focused on

biodiesel, which consists of alkyl esters of fatty acids found in

agricultural acylglycerol - based fats and oils. Biodiesel has

been shown to give engine performance that is generally Figure 1: Ripe marula fruit

978-1-61284-993-5/11/$26.00 ©2011 IEEE

IEEE Africon 2011 - The Falls Resort and Conference Centre, Livingstone, Zambia, 13 - 15 September 2011

The fruit consists of a hard woody seed covered by pulp 680C to remove water. The fuel was then used to power a

and juice which makes the fleshy part of the fruit.The hard variable compression ignition engine to test the engine

seed contains mostly two oil rich nuts (kernel) which can be performance prior to transesterification. The results were

eaten as a snack. The kernel oil is currently being used to compared with the results for petroleum diesel under

make cosmetic ointments. The fact that the marula tree similar conditions on the basis of engine torque, engine

grows in drier parts where common oil seeds cannot thrive brake power, and specific fuel consumption for

has stirred interest in it as a valuable source of oil. This has compression ratio 16:1. The experimental data were

led to the evaluation of marula nut oil as a potential source collected as discussed in section 2.2, leading to the results

of vegetable oil for biodiesel production. In evaluating the presented in figures 2 to 4.

potential of oil for use, the fatty acid profile plays an

important role. Oil with a high content of oleic acid makes

ideal frying oil because of the stability offered by the acid

[3]. Engine Torque (Nm)

2. Materials and methods 30

Engine Torque (Nm)

2.1 Marula oil 20

The marula oil for the current study was purchased from 10

B100

Kgetsi Ya Tsie, a Community Trust promoting the 0 D100

economic and social empowerment of rural women in the

Tswapong Hills of Eastern Botswana, who extracts marula 20 30 40 50 60 70 80 90 100

oil mostly for cosmetic markets in Europe and America. Load (%)

2.2 Engine performance analysis

Legend: B100 = Marula oil fuel; D100 = Petrodiesel

The engine performance test was conducted on a TD43F

engine test rig. The test rig is water cooled, four-stroke Figure 2: Engine torque profile for marula oil and

diesel engine that is directly coupled to an electrical petroleum diesel fuel.

dynamometer. In addition to the conventional engine

design, the engine incorporates variable compression design

feature which allows the compression ratio to be varied

from 5:1 to 18:1.

Brake Power (W)

To establish that engine operating conditions were 8

Brake Power (W)

reproduced consistently as any deviation could exert an

6

overriding influence on performance and emissions results,

the reproducibility of the dynamometer speed control set 4

points were maintained within ±4 revs/min of the desired 2 B100

engine speed. The experimental work began with engine D100

0

run on pure petrodiesel fuel. This was done to determine the

engine’s operating parameters which constitute the baseline 20 30 40 50 60 70 80 90 100

that was compared with the subsequent case when the Load (%)

marula oil was used as fuel. At the point of fuel change, the

engine was left to operate with the fuel under test for about

15 minutes to stabilize at its new condition before readings Legend: B100 = Marula oil fuel; D100 = Petrodiesel

were recorded.

Figure 3: Engine brake power profile for marula oil and

3. Results and discussions petroleum diesel fuel.

3.1 Engine performance analysis with varying load

The viscosity of crude marula oil was found to be in the

range specified by international biodiesel standards. As

direct results, the oil was neutralised using NaOH to

remove acidity and minimise chances of corrosion of

engine parts. The oil was also heated to a temperature of

978-1-61284-993-5/11/$26.00 ©2011 IEEE

IEEE Africon 2011 - The Falls Resort and Conference Centre, Livingstone, Zambia, 13 - 15 September 2011

3.2 Engine performance analysis with varying

Specific Fuel Consumption (g/kWh) compression ratio

1

Consumption (g/kWh)

0.8 The engine performance analysis with varying load carried

0.6 out included collection of data for engine torque, brake

Specific Fuel

0.4 power and specific fuel consumption for compression ratios

0.2 B100 13:1 through 17:1 though results in this manuscript are for

0 D100 compression ratio 16:1 only. This section presents results

for engine performance at a fixed load of 80% with

20 30 40 50 60 70 80 90100 compression ratio varying from 13:1 through 17:1 as shown

Load (%) in figures 5 to 7. The results are a comparison between

petroleum diesel and marula oil fuel under similar

conditions on the basis of engine torque, engine brake

Legend: B100 = Marula oil fuel; D100 = Petrodiesel power, and specific fuel consumption. The experimental

data were collected as discussed in section 2.2, leading to

Figure 4: Engine specific fuel consumption profile for the results presented in figures 5 to 7.

marula oil and petroleum diesel fuel.

There are several clear findings to be drawn from the data

presented in figures 2 to 4. Firstly, the results indicate that

Engine Torque (Nm)

the engine torque, brake power, and specific fuel

consumption recorded for D100 and B100 for operation 28

condition (compression ratio 16:1) compares favorably 27

Engine Torque (Nm)

well. The data in figure 2 show a steady increase in engine 26

torque for both D100 and B100 with increase in engine load 25

between 30 and 60%. However between the same operating 24 B100

23

window, B100 recoded relatively high engine torque 22 D100

compared with D100. However, it is clear from the data

presented in figure 2 that as the engine load increase from 12 13 14 15 16 17 18

60% the data recorded for D100 shows a steady increase in Compression Ratio

engine torque while the data for B100 shows a slight

decrease with increase in engine load.

Legend: B100 = Marula oil fuel; D100 = Petrodiesel

The results in figures 3 and 4 also show that the data

recorded for B100 compares favorable well with that for Figure 5: Engine torque profile for marula oil and

D100. The maximum variation in brake power of 0.63W petroleum diesel fuel.

was recorded at 90% engine load, while the minimum

variation of 0.06W was recorded at 60% of engine load,

with D100 recording 5.06W. The trends shown in figure 3

suggest that the optimum compression ignition engine

performance using raw marula oil occurs at 60% engine Brake Power (W)

load. The data shown in figure 4 reinforces this observation,

Brake Power (W)

which shows the specific fuel consumption recorded for 3.7

D100 and B100. One of the most discernible trends 3.5

connected to figure 4 is that the variations in specific fuel

consumption recorded for D100 and B100 between 30% 3.3 B100

and 60% do not show any significant difference for the D100

3.1

fuels under review. The minimum variation of specific fuel

consumption between 30% and 60% engine load is 12 13 14 15 16 17 18

0.01g/kWh, while a maximum of 0.17g/kWh was recorded

Compression Ratio

at the engine load of 90%. Overally, the result in figure 4

points out that marula oil is a potential feedstock for

biodiesel production in Botswana. Legend: B100 = Marula oil fuel; D100 = Petrodiesel

Figure 6: Engine brake power profile for marula oil and

petroleum diesel fuel.

978-1-61284-993-5/11/$26.00 ©2011 IEEE

IEEE Africon 2011 - The Falls Resort and Conference Centre, Livingstone, Zambia, 13 - 15 September 2011

b) The compression ratio of 16:1 yields optimum

performance results for engine torque and brake

power for petrodiesel and marula oil fuels.

Specific Fuel Consumption (g/kWh)

0.7 c) The performance of variable compression diesel

Consumption (g/kWh)

engine using raw marula oil is close to that using

0.6

petrodiesel fuel, suggesting that marula oil is a

Specific Fuel

0.5 potential indigenous feedstock for biodiesel

0.4 B100 production in Botswana.

0.3 D100

12 13 14 15 16 17 18

Acknowledgements

Compression Ratio

We acknowledge support of the University of Botswana,

and the Ministry of Wildlife, Tourism and Environment

Legend: B100 = Marula oil fuel; D100 = Petrodiesel who granted a research permit for this work.

Figure 4: Engine specific fuel consumption profile for

marula oil and petroleum diesel fuels.

The results indicate that profiles for engine torque and References

brake power are largely similar. The best performance for

marula oil fuel was found to be at compression ratio of 17:1 [1] Graboski, M.S., McCormick, R.L. Combustion of

for engine torque with a value of 26.3 Nm, and fat and vegetable oil derived fuels in diesel

compression ratio of 16:1 for brake power with a value of engines. Prog. Energy Combust. Sci. 24, 1998,

3.61W. Similarly, best performance for petrodiesel was 125–164.

found to be at compression ratio of 16:1 for both engine [2] Haas M. J, McAloon A. J., Yee W. C., Foglia T.

torque and brake power with a values of 27.2 Nm 3.7 W A. A process model to estimate biodiesel

respectively. These results imply in part that compression production costs; Bioresource Technology 97

ratio 16:1 yields optimum performance results for engine (2006) 671–678

torque and brake power for petrodiesel and marula oil fuels. [3] Haumann B. F. Frying fats. INFORM, 1996,

Petrodiesel is marginally better than marula oil at this pp320-334.

compression ratio. For lower compression ratios

particularly 14:1 and 15:1, marula oil fuel is significantly

better than petrodiesel for both engine torque and brake

power. Moreover, unlike petrodiesel, marula oil fuel has a

smooth rising performance profile across all compression

ratios which ensures smooth running of the engine at any

set compression ratio. Figure 4 indicates that engine

specific fuel consumption of marula oil fuel is largely lower

than that of petroleum diesel. The fuel consumption at the

optimum compression ratio of 16:1 is almost the same for

the two fuels, with petrodiesel being very marginally better

by 0.1g/KWh.

4. Conclusions

A comparative experimental study to analyse the

performance of marula oil fuel and petroleum diesel was

carried out. From the experimental results, it can be

concluded that:

a) Marula oil has properties that can enable it to

function as a biofuel in variable compression

diesel engines. This implies that transesterifying

marula oil under standard conditions may produce

biodiesel of international quality standard.

978-1-61284-993-5/11/$26.00 ©2011 IEEE

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Er3165 2Dokument27 SeitenEr3165 2Suresh ThillaiNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Q 01132122129Dokument8 SeitenQ 01132122129Suresh ThillaiNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Qi 2009 Renewable-EnergyDokument8 SeitenQi 2009 Renewable-EnergySuresh ThillaiNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Qi 2009 Renewable-EnergyDokument8 SeitenQi 2009 Renewable-EnergySuresh ThillaiNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Project FINALDokument4 SeitenProject FINALSuresh ThillaiNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Biodiesel BenefitsDokument1 SeiteBiodiesel BenefitsSuresh ThillaiNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Studying The Effect of Compression Ratio On An Engine Fueled With Waste Oil Produced Biodiesel/diesel FuelDokument11 SeitenStudying The Effect of Compression Ratio On An Engine Fueled With Waste Oil Produced Biodiesel/diesel FuelSuresh ThillaiNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Thesis Format 2012Dokument4 SeitenThesis Format 2012Suresh ThillaiNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Journal Publication FormatDokument37 SeitenJournal Publication FormatAbreo Dan Vincent AlmineNoch keine Bewertungen

- Notes On Lesson: Faculty Name Code Subject Name CodeDokument108 SeitenNotes On Lesson: Faculty Name Code Subject Name CodeJeba ChristoNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Advance Bio-Photon Analyzer ABPA A2 Home PageDokument5 SeitenAdvance Bio-Photon Analyzer ABPA A2 Home PageStellaEstel100% (1)

- LPM 52 Compar Ref GuideDokument54 SeitenLPM 52 Compar Ref GuideJimmy GilcesNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- SAP PS Step by Step OverviewDokument11 SeitenSAP PS Step by Step Overviewanand.kumarNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Railway RRB Group D Book PDFDokument368 SeitenRailway RRB Group D Book PDFAshish mishraNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- ABS Rules for Steel Vessels Under 90mDokument91 SeitenABS Rules for Steel Vessels Under 90mGean Antonny Gamarra DamianNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Weibull Statistic and Growth Analysis in Failure PredictionsDokument9 SeitenWeibull Statistic and Growth Analysis in Failure PredictionsgmitsutaNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Tata Chemicals Yearly Reports 2019 20Dokument340 SeitenTata Chemicals Yearly Reports 2019 20AkchikaNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- OBHR Case StudyDokument8 SeitenOBHR Case StudyYvonne TanNoch keine Bewertungen

- Proposal Semister ProjectDokument7 SeitenProposal Semister ProjectMuket AgmasNoch keine Bewertungen

- Introduction To Elective DesignDokument30 SeitenIntroduction To Elective Designabdullah 3mar abou reashaNoch keine Bewertungen

- Prestressing ProductsDokument40 SeitenPrestressing ProductsSakshi Sana100% (1)

- Tech Letter-NFPA 54 To Include Bonding 8-08Dokument2 SeitenTech Letter-NFPA 54 To Include Bonding 8-08gl lugaNoch keine Bewertungen

- Part I-Final Report On Soil InvestigationDokument16 SeitenPart I-Final Report On Soil InvestigationmangjuhaiNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Milwaukee 4203 838a PB CatalogaciónDokument2 SeitenMilwaukee 4203 838a PB CatalogaciónJuan carlosNoch keine Bewertungen

- EFM2e, CH 03, SlidesDokument36 SeitenEFM2e, CH 03, SlidesEricLiangtoNoch keine Bewertungen

- Dinsmore - Gantt ChartDokument1 SeiteDinsmore - Gantt Chartapi-592162739Noch keine Bewertungen

- 28 Government Service Insurance System (GSIS) vs. Velasco, 834 SCRA 409, G.R. No. 196564 August 7, 2017Dokument26 Seiten28 Government Service Insurance System (GSIS) vs. Velasco, 834 SCRA 409, G.R. No. 196564 August 7, 2017ekangNoch keine Bewertungen

- Milton Hershey's Sweet StoryDokument10 SeitenMilton Hershey's Sweet Storysharlene sandovalNoch keine Bewertungen

- Sample Property Management AgreementDokument13 SeitenSample Property Management AgreementSarah TNoch keine Bewertungen

- ECON Value of The FirmDokument4 SeitenECON Value of The FirmDomsNoch keine Bewertungen

- 2JA5K2 FullDokument22 Seiten2JA5K2 FullLina LacorazzaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Cars Should Be BannedDokument3 SeitenCars Should Be BannedIrwanNoch keine Bewertungen

- Leases 2Dokument3 SeitenLeases 2John Patrick Lazaro Andres100% (1)

- Code Description DSMCDokument35 SeitenCode Description DSMCAnkit BansalNoch keine Bewertungen

- Social EnterpriseDokument9 SeitenSocial EnterpriseCarloNoch keine Bewertungen

- Khadi Natural Company ProfileDokument18 SeitenKhadi Natural Company ProfileKleiton FontesNoch keine Bewertungen

- Fundamentals of Marketing NotebookDokument24 SeitenFundamentals of Marketing NotebookMorrisa AlexanderNoch keine Bewertungen

- Dairy DevelopmentDokument39 SeitenDairy DevelopmentHemanth Kumar RamachandranNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)