Beruflich Dokumente

Kultur Dokumente

PDT101 Datasheet B211082EN E PDF

Hochgeladen von

Andrey ValeroOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PDT101 Datasheet B211082EN E PDF

Hochgeladen von

Andrey ValeroCopyright:

Verfügbare Formate

Differential Pressure Transmitter

PDT101

Features

• Easy mounting on wall, DIN rail or

panel

• 2 pressure ranges (Pa and in H2O)

• Accessible zero and span

adjustment potentiometers

• ¼” brass tubing connections

• LED status indicator

• Specially designed for critical and

regulated environments

• Euro style detachable connector

• NIST traceable (certificate

included)

Vaisala Differential Pressure Transmitter PDT101 offers precise measurement and

control of very low pressures.

Operating Environment uses a micro-machined, ultra-thin silicon Applications

PDT101 is designed especially for diaphragm which provides inherent PDT101 is suitable for high performance

demanding life science and high sensor repeatability and stability. The cleanroom environments in the life

technology cleanroom applications. The sensor enables precise measurement and science, semiconductor and electronics

transmitter is ideal for incorporating into control in high performance cleanrooms. industries. As part of a continuous

the Vaisala Veriteq Continuous The PDT101 transmitter is available with monitoring system, it is highly suitable

Monitoring System to measure and voltage output (3-wire) or current output for regulated environments where

monitor the critical environmental (2-wire). continuous, documented and redundant

parameters as required in regulated Zero and span adjustment screws are data is a requirement to meet FDA

environments. available on every PDT101 model. Both regulations. The compact design is well

adjustments are accessible from the front suited for mounting in a cleanroom or in

Performance of the unit. the adjacent corridor with LED indicator

PDT101 offers high accuracy, sensitivity lights for quick and easy power status

and stability with accuracy 0.40 % of spot check.

span providing a highly reliable and

repeatable measurement. The sensor

Technical Data

Measurement Performance 37

9.4

Measurement ranges (bidirectional) ±60 Pa 33.6

±0.25 in H2O ø5

Accuracy (incl. non-linearity, hysteresis, 0.4 % span

repeatability and zero/span calibration P OWE R

settings)

Long-term stability ≤0.5 % span/year

HI LO

Response time (10 ... 90 %) 250 ms

Warm-up time 15 s

Compensated temperature range +2 ... +54 °C ZERO SPAN

74 84.6

(+35.6 ... +129.2 °F)

Temperature dependence ±(0.065 Pa + 0.054 % of reading) / °C

or ±(0.00015 in H2O + 0.03 %

of reading) / °F

(reference 21 °C or 70 °F)

ø4

Pressure type Differential, gauge, vacuum and 48

compound

Dimensions in mm

Overpressure

Proof pressure 1.0 bar

Burst pressure 1.7 bar Inputs and Outputs

Static pressure 1.7 bar

Process connection 1/4" barbed fittings

Mounting Position

Max. loop resistance for 4 ... 20 mA ≤ (Supply voltage - 12V)/0.022 A

Error (zero adjustable) ≤1 %/g (calibration in vertical position

is standard) Supply current Max. 20 mA for 4 ... 20 mA output

signal

Adjustments (Front Accessible)

Optical process diagnostics LED visual indicator

Zero ±5 % span

Span ±3 % span Electrical connection Euro style pluggable terminal block

accepts 12 ... 26 AWG wire

(0.13 up to 3.31 mm2)

Operating Environment Output Signal

2-wire 4 ... 20 mA

Operating temperature -18 ... +70 °C (-0.4 ... +158 °F)

3-wire 0 ... 5 VDC

Storage temperature -40 ... +82 °C (-40 ... +179.6 °F)

(user selectable 0 ... 10 VDC)

EMC compliance EN 61326-1, Basic immunity test

Operating Voltage

requirements

2-wire output 4 ... 20 mA 12 ... 36 VDC

Note: If used in an electromagnetic field of 3 V/m, with narrow frequency area of 80 - 120 Mhz, it is

3-wire output 0 ... 5 VDC 11.5 ... 36 VDC

possible that the current output of PDT101 can deviate max. 0.8 % (with accuracy specified 0.4 %) 3-wire output 0 ... 10 VDC 14 ... 36 VDC or 24 VAC

Mechanical Specifications Order Information for PDT101

Medium (measured gas) Clean and dry air, non-conducting and

non-corrosive gases

Mounting Threaded fastener for wall mounting

or DIN rail type EN50022

IP rating IP40

Weight 0.07 kg

Material

Process connection Brass

Sensor element Silicon, aluminium, glass

Case NEMA type 1 fire-retardant ABS 1

(meets UL94-5VA)

Published by Vaisala | B211082EN-E © Vaisala 2017

All rights reserved. Any logos and/or product names are trademarks of

Vaisala or its individual partners. Any reproduction, transfer, distribution

or storage of information contained in this document is strictly

prohibited. All specifications — technical included — are subject to

www.vaisala.com change without notice.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- PowerPoint VBA TutorialDokument17 SeitenPowerPoint VBA TutorialKalai selvanNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- SiC EpitaxyDokument48 SeitenSiC EpitaxyRamakrishnan RamNoch keine Bewertungen

- Trace and Draw: Created by A Teachable TeacherDokument18 SeitenTrace and Draw: Created by A Teachable TeacherNicoleta Dragan100% (1)

- F330B 23Dokument110 SeitenF330B 23ניקולאי איןNoch keine Bewertungen

- Operating Instructions Cleanfit CPA871Dokument56 SeitenOperating Instructions Cleanfit CPA871Andrey ValeroNoch keine Bewertungen

- Operating Instructions Micropilot FMR51, FMR52 Hart: Free Space RadarDokument180 SeitenOperating Instructions Micropilot FMR51, FMR52 Hart: Free Space RadarAndrey ValeroNoch keine Bewertungen

- BA00108DENDokument192 SeitenBA00108DENAndrey ValeroNoch keine Bewertungen

- Cerabar M PMC51: 71086208 Pmc51-Aa11Ja1PgfgcjjDokument1 SeiteCerabar M PMC51: 71086208 Pmc51-Aa11Ja1PgfgcjjAndrey ValeroNoch keine Bewertungen

- Ba01354cen 0417 PDFDokument160 SeitenBa01354cen 0417 PDFAndrey ValeroNoch keine Bewertungen

- PDT101 Datasheet B211082EN E PDFDokument2 SeitenPDT101 Datasheet B211082EN E PDFAndrey ValeroNoch keine Bewertungen

- Operating Instructions Memograph M, RSG40: Advanced Graphic Data ManagerDokument154 SeitenOperating Instructions Memograph M, RSG40: Advanced Graphic Data ManagerAndrey ValeroNoch keine Bewertungen

- Unix FundamentalsDokument47 SeitenUnix Fundamentalsdjay sharmaNoch keine Bewertungen

- Association RulesDokument20 SeitenAssociation RulesAnik1005Noch keine Bewertungen

- Anti-Reflux System User ManualDokument6 SeitenAnti-Reflux System User ManualGillianne Mae VargasNoch keine Bewertungen

- Coding Form Data SiswaDokument5 SeitenCoding Form Data SiswaVicky SplitfireNoch keine Bewertungen

- Sams Teach Yourself Regular Expressions in 10 MinutesDokument334 SeitenSams Teach Yourself Regular Expressions in 10 MinutesDdNoch keine Bewertungen

- Unit 4 MadDokument29 SeitenUnit 4 MadVeeresh NikeeNoch keine Bewertungen

- (Template) Google Slides: PresentationDokument23 Seiten(Template) Google Slides: PresentationloginajaNoch keine Bewertungen

- PDEng Studyguide 2019 - 2020Dokument2 SeitenPDEng Studyguide 2019 - 2020Maximiliano TaubeNoch keine Bewertungen

- MT131 Tutorial - 2 Sets Functions Sequences and Summation - 2023-2024Dokument63 SeitenMT131 Tutorial - 2 Sets Functions Sequences and Summation - 2023-2024johnnader1254Noch keine Bewertungen

- Development of A Business Website For Antonio Manuel Catering Services Final - ManuscriptDokument152 SeitenDevelopment of A Business Website For Antonio Manuel Catering Services Final - ManuscriptLesterSanchezCuevaNoch keine Bewertungen

- 100 Leads in 90 DaysDokument5 Seiten100 Leads in 90 DaysAjay GomesNoch keine Bewertungen

- GunsDokument4 SeitenGunsFaizanNoch keine Bewertungen

- XMLServices5.0 CapabilityAndQuoteServiceDokument78 SeitenXMLServices5.0 CapabilityAndQuoteServicewilson ndongoNoch keine Bewertungen

- Full Catalog 2023 - Email VerDokument80 SeitenFull Catalog 2023 - Email VeradamNoch keine Bewertungen

- Understanding Security Capability of Information System1Dokument6 SeitenUnderstanding Security Capability of Information System1upadhyay kulbhushanNoch keine Bewertungen

- Rs 485 SpecDokument3 SeitenRs 485 SpecJuan Dela CruzNoch keine Bewertungen

- Plant Enginerring ManagementDokument4 SeitenPlant Enginerring ManagementTHEOPHILUS ATO FLETCHERNoch keine Bewertungen

- Marcelo - STS 11 - Activity 1Dokument10 SeitenMarcelo - STS 11 - Activity 1MARCELO, FRANCIS MICHAEL S.Noch keine Bewertungen

- Living in The It Era Prelim Quiz 1Dokument6 SeitenLiving in The It Era Prelim Quiz 1Hazel Mae MalaguenoNoch keine Bewertungen

- Kendaraan OperasionalDokument8 SeitenKendaraan OperasionalNove KiboNoch keine Bewertungen

- ANSYS, Inc. Licensing GuideDokument124 SeitenANSYS, Inc. Licensing GuideMa HdiNoch keine Bewertungen

- Skillup: Learn Now. Transform Tomorrow. Grow ForeverDokument14 SeitenSkillup: Learn Now. Transform Tomorrow. Grow ForeverMahesh KumarNoch keine Bewertungen

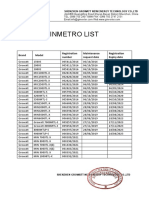

- 5 - Certificado InmetroDokument5 Seiten5 - Certificado InmetroDanilo MarinhoNoch keine Bewertungen

- Isopropil MiristatDokument1 SeiteIsopropil MiristatnofaNoch keine Bewertungen

- Calculation For Steam and Hot Water Consumption For: Sun Rise CharmingDokument4 SeitenCalculation For Steam and Hot Water Consumption For: Sun Rise CharmingYasser FathiNoch keine Bewertungen

- 22B Office Hour: Oracle Fusion Cloud Risk ManagementDokument38 Seiten22B Office Hour: Oracle Fusion Cloud Risk Managementmeera2k10Noch keine Bewertungen