Beruflich Dokumente

Kultur Dokumente

MSTwall PDF

Hochgeladen von

dinesh panchalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MSTwall PDF

Hochgeladen von

dinesh panchalCopyright:

Verfügbare Formate

WALLCHART PDF

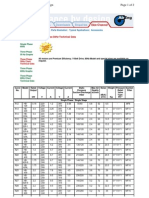

METRIC SEAMLESS TUBe

3/1/01

5:02 AM

Page 1

Metric Seamless Tube Stock Sizes & Specifications

Tube Tube Tube St. 37.4 Static Dynamic Static

Outside Wall Inside St. 37.4 Zinc Plated Pressure Pressure Burst 1.4571 Pressure Burst

Diameter Thickness Diameter Phosphated & Yellow Rating Rating Pressure Weight Stainless Rating Pressure Weight

(mm) (mm) (mm) & Oiled Chromate (Bar) (Bar) (Bar) (kg/m) Steel (Bar) (Bar) (kg/m)

4 0.5 3 R04X0.5 R04X0.5VZ 313 274 1160 0.047 – – – –

4 0.75 2.5 – R04X0.75VZ 409 393 1820 0.063 – – – –

4 1 2 R04X1 R04X1VZ 522 502 2850 0.074 R04X171 600 3850 0.075

5 1 3 – R05X1VZ 432 416 2120 0.099 – – – –

6 0.75 4.5 – R06X0.75VZ 333 289 1230 0.103 – – – –

6 1 4 R06X1 R06X1VZ 389 374 1680 0.123 R06X171 426 2340 0.125

6 1.5 3 R06X1.5 R06X1.5VZ 549 528 3050 0.166 R06X1.571 600 3250 0.169

6 2 2 – R06X2VZ 692 665 – 0.197 – – – –

6 2.25 1.5 – R06X2.25VZ 757 728 – 0.208 – – – –

8 1 6 R08X1 R08X1VZ 333 289 1190 0.222 R08X171 368 1660 0.175

Seamless Carbon Steel Tube 8 1.5 5 R08X1.5 R08X1.5VZ 431 414 1860 0.240 R08X1.571 472 2800 0.244

8 2 4 R08X2 R08X2VZ 549 528 3020 0.296 – – – –

Material: St. 37.4 fine-grain quality per DIN 1630

Tensile Strength: 340 N/mm 2 (49,000 lb/in 2) minimum 8 2.5 3 – R08X2.5VZ 658 632 – 0.339 – – – –

Yield Strength: 235 N/mm 2 (34,000 lb/in 2) minimum 10 1 8 R10X1 R10X1VZ 282 249 870 0.222 R010X171 294 1290 0.225

% Elongation: 25% minimum 10 1.5 7 R10X1.5 R10X1.5VZ 373 358 1380 0.314 R10X1.571 389 1930 0.319

Condition: Seamless, cold drawn, annealed (NBK) per DIN 2391C Part 2 10 2 6 R10X2 R10X2VZ 478 460 2100 0.395 R10X271 498 3100 0.401

Surface Finish: Tubes with inside diameter of 1.5 to 5 mm –

10 2.5 5 – R10X2.5VZ 576 553 3180 0.462 – – – –

outside and inside oiled

Tubes with 6 mm and greater inside diameter – outside 10 3 4 – R10X3VZ 666 641 – 0.518 – – – –

and inside phosphate and oiled 12 1 10 R12X1 R12X1VZ 235 210 760 0.271 R12X171 245 1220 0.275

Example of Part Number: R25X2 where R indicates tube, 25 = outside 12 1.5 9 R12X1.5 R12X1.5VZ 353 305 1150 0.388 R12X1.571 368 1580 0.394

diameter (mm), and 2 = wall thickness (mm)

12 2 8 R12X2 R12X2VZ 409 393 1580 0.493 R12X271 426 2380 0.501

12 2.5 7 – R12X2.5VZ 495 476 2600 0.586 – – – –

12 3 6 – R12X3VZ 576 553 3200 0.666 – – – –

12 3.5 5 – R12X3.5VZ 651 627 – 0.734 – – – –

14 1.5 11 – R14X1.5VZ 302 265 940 0.462 R14X1.571 315 1550 0.469

14 2 10 R14X2 R14X2VZ 403 343 1340 0.592 R14X271 420 2180 0.601

14 2.5 9 – R14X2.5VZ 434 417 1760 0.709 R14X2.571 452 2800 0.720

14 3 8 – R14X3VZ 507 487 2400 0.814 – – – –

15 1 13 R15X1 R15X1VZ 188 171 590 0.345 R15X171 196 860 0.351

15 1.5 12 R15X1.5 R15X1.5VZ 282 249 980 0.499 R15X1.571 294 1140 0.507

15 2 11 R15X2 R15X2VZ 376 323 1250 0.641 R15X271 392 1750 0.651

16 1.5 13 R16X1.5 R16X1.5VZ 264 234 820 0.536 R16X1.571 276 750 0.545

16 2 12 R16X2 R16X2VZ 353 305 1170 0.691 R16X271 368 1800 0.701

16 2.5 11 R16X2.5 R16X2.5VZ 386 372 1470 0.832 R16X2.571 403 2120 0.845

16 3 10 R16X3 R16X3VZ 452 435 1920 0.962 R16X371 472 2800 0.977

18 1 16 – R18X1VZ 157 143 510 0.419 – – – –

18 1.5 15 R18X1.5 R18X1.5VZ 235 210 780 0.610 R18X1.571 245 1050 0.620

18 2 14 R18X2 R18X2VZ 313 274 1040 0.789 R18X271 327 1520 0.801

Seamless Carbon Steel Tube with Zinc Plating 18 2.5 13 R18X2.5 R18X2.5VZ 392 335 1320 0.956 – – – –

Material: St. 37.4 fine-grain quality per DIN 1630

18 3 12 – R18X3VZ 409 393 1830 1.111 – – – –

Tensile Strength: 340 N/mm 2 (49,000 lb/in 2) minimum

20 1.5 17 – R20X1.5VZ 212 191 570 0.684 – – – –

Yield Strength: 235 N/mm 2 (34,000 lb/in 2) minimum

% Elongation: 25% minimum 20 2 16 R20X2 R20X2VZ 282 249 920 0.888 R20X271 294 1250 0.901

Condition: Seamless, cold drawn, annealed (NBK) per DIN 2391C Part 2 20 2.5 15 R20X2.5 R20X2.5VZ 353 305 1220 1.079 R20X2.571 368 1550 1.095

Surface Finish: Outside surface zinc plated (8-12 µm) and yellow 20 3 14 R20X3 R20X3VZ 373 358 1450 1.258 R20X371 389 1960 1.277

chromate – inside surface oiled

20 3.5 13 R20X3.5 R20X3.5VZ 426 410 1720 1.424 – – – –

Example of Part Number: R25X2VZ where R indicates tube, 25 =

outside diameter (mm), 2 = wall thickness (mm), and VZ indicates zinc 20 4 12 – R20X4VZ 478 460 2080 1.578 – – – –

with yellow chromate 22 1.5 19 R22X1.5 R22X1.5VZ 192 174 590 0.758 R22X1.571 200 720 0.770

22 2 18 R22X2 R22X2VZ 256 228 850 0.986 R22X271 267 1020 1.002

22 2.5 17 R22X2.5 R22X2.5VZ 320 280 1040 1.202 – – – –

22 3 16 – R22X3VZ 385 329 – 1.406 – – – –

25 2 21 R25X2 R25X2VZ 226 202 670 1.134 – – – –

25 2.5 20 R25X2.5 R25X2.5VZ 282 249 920 1.387 R25X2.571 294 1190 1.408

25 3 19 R25X3 R25X3VZ 338 294 1050 1.628 R25X371 353 1520 1.653

25 4 17 R25X4 R25X4VZ 394 379 1520 2.072 – – – –

25 4.5 16 R25X4.5 R25X4.5VZ 437 420 1780 2.275 – – – –

28 1.5 25 R28X1.5 R28X1.5VZ 151 139 450 0.980 R28X1.571 158 620 0.995

28 2 24 R28X2 R28X2VZ 201 182 620 1.282 R28X271 210 880 1.302

28 2.5 23 R28X2.5 R28X2.5VZ 252 224 770 1.572 – – – –

28 3 22 R28X3 R28X3VZ 302 265 920 1.850 – – – –

30 2 26 – R30X2VZ 188 171 620 1.381 – – – –

30 2.5 25 R30X2.5 R30X2.5VZ 235 210 770 1.695 R30X2.571 245 890 1.722

30 3 24 R30X3 R30X3VZ 282 249 920 1.998 R30X371 294 1140 2.028

30 4 22 R30X4 R30X4VZ 376 323 1250 2.565 R30X471 392 1650 2.605

Seamless Stainless Steel Tube 30 5 20 R30X5 R30X5VZ 409 393 1580 3.083 – – – –

35 2 31 R35X2 R35X2VZ 161 147 470 1.628 R35X271 168 670 1.653

Material: 1.4571 (X6CrNiMoTi17122)

35 2.5 30 R35X2.5 R35X2.5VZ 201 182 620 2.004 – – – –

Tensile Strength: 500 N/mm 2 (72,500 lb/in 2) minimum

Yield Strength: 245 N/mm 2 (35,500 lb/in 2) minimum 35 3 29 R35X3 R35X3VZ 242 216 720 2.367 – – – –

% Elongation: 35% minimum 35 4 27 – R35X4VZ 322 281 960 3.058 – – – –

Condition: Seamless, cold drawn, free of scale, heat-treated in 38 2.5 33 – R38X2.5VZ 186 168 550 2.189 – – – –

accordance with DIN 17458 Table 6

38 3 32 R38X3 R38X3VZ 223 200 660 2.589 – – – –

Example of Part Number: R25X271 where R indicates tube, 25 =

outside diameter (mm), 2 = wall thickness (mm), and 71 indicates 38 4 30 R38X4 R38X4VZ 297 261 970 3.354 R38X471 309 1240 3.405

1.4571 stainless steel 38 5 28 R38X5 R38X5VZ 371 319 1350 4.069 – – – –

38 6 26 – R38X6VZ 390 375 – 4.735 – – – –

38 7 24 – R38X7VZ 446 429 – 5.352 – – – –

42 2 38 R42X2 R42X2VZ 134 124 390 1.973 R42X271 140 520 2.003

42 3 36 R42X3 R42X3VZ 201 182 580 2.885 R42X371 210 860 2.930

42 4 34 R42X4 R42X4VZ 269 238 850 3.749 – – – –

Parker Hannifin Corporation 50 6 38 R50X6 – 338 290 – 6.511 – – – –

Tube Fittings Division 65 8 49 R65X8 – 347 300 – 11.246 – – – –

3885 Gateway Blvd. • Columbus, Ohio 43228

Telephone: (614) 279-7070 • Fax: (614) 279-7685 Static pressures are calculated in accordance with DIN 2413 Part 1. Part numbers shown are standard from stock. Other sizes are

www.parker.com/tfd available upon request. See Catalog 4300 for a complete listing

Dynamic pressure ratings are calculated in accordance with

of available sizes.

DIN 2413 Part 3.

The Fitting Authority

Specific design factors may be determined by using the burst Conversion Factors:

Bulletin WC-4300-MST © Parker Hannifin Corporation pressures shown in the above table. Bar X 14.5 = psi kg/m X 0.672 = lb/ft N/mm 2 X 145 = lb/in 2

Das könnte Ihnen auch gefallen

- Trubka Ocel ST 37 4 Bezesva Cerna Uk Katalogovy ListDokument2 SeitenTrubka Ocel ST 37 4 Bezesva Cerna Uk Katalogovy ListVratislav Němec ml.Noch keine Bewertungen

- Datasheet DIN - 200809 1Dokument4 SeitenDatasheet DIN - 200809 1Ramiro FelicianoNoch keine Bewertungen

- Pre D Des PoutresDokument20 SeitenPre D Des PoutresHamza TalibNoch keine Bewertungen

- Curvas y PartesDokument434 SeitenCurvas y PartesPAHOLA ANDREA ARDILA PUERTONoch keine Bewertungen

- Curvas y Partes PDFDokument429 SeitenCurvas y Partes PDFdfvdfvNoch keine Bewertungen

- Stainless Steel Compositions ChartDokument1 SeiteStainless Steel Compositions ChartsivaNoch keine Bewertungen

- Crelec Technical DataDokument2 SeitenCrelec Technical DataLai Kok ChauNoch keine Bewertungen

- Steet Light Tata BP SolarDokument5 SeitenSteet Light Tata BP SolarMOHD RASHIDNoch keine Bewertungen

- Sunflex Sae 100R7 Thermoplastic Hose BS4983: 1973 DIN 24951 PT 2 ISO3945Dokument1 SeiteSunflex Sae 100R7 Thermoplastic Hose BS4983: 1973 DIN 24951 PT 2 ISO3945Nova VanoNoch keine Bewertungen

- Dsa 790017Dokument1 SeiteDsa 790017Charbel TadrosNoch keine Bewertungen

- Dimension Table For R (Oval & Octagonal) Type Ring Joint GasketsDokument3 SeitenDimension Table For R (Oval & Octagonal) Type Ring Joint Gasketssascoc vannesNoch keine Bewertungen

- NR CRT.: TP /TPDokument5 SeitenNR CRT.: TP /TPLUCIAN BUZOIANUNoch keine Bewertungen

- Seals, Bearings, Linings Brochure PDFDokument24 SeitenSeals, Bearings, Linings Brochure PDFDejan Simonovic PrivatnoNoch keine Bewertungen

- Emisario Calc.1 CorrDokument7 SeitenEmisario Calc.1 CorrVictor CaritaNoch keine Bewertungen

- G 303Dokument1 SeiteG 303anilerNoch keine Bewertungen

- Propiedades Mecanicas Del B7Dokument1 SeitePropiedades Mecanicas Del B7alejandrorhino2 rhinoNoch keine Bewertungen

- PTI - Sheave SPADokument5 SeitenPTI - Sheave SPAvilash kumar sNoch keine Bewertungen

- Katalog Fitting WinnerDokument24 SeitenKatalog Fitting WinnerDavidNoch keine Bewertungen

- Panel Type Flow Meter / LZM-4T 6T 8T: LZM-4T 6T 8T LZM-4T 6T 8TDokument1 SeitePanel Type Flow Meter / LZM-4T 6T 8T: LZM-4T 6T 8T LZM-4T 6T 8THieu Nguyen ThaiNoch keine Bewertungen

- PKZM4 58Dokument1 SeitePKZM4 58samirNoch keine Bewertungen

- Moment Distribution MethodDokument101 SeitenMoment Distribution MethodLourdesNoch keine Bewertungen

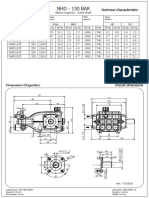

- NHD 150bar SeriesDokument4 SeitenNHD 150bar Seriesnoha azamaliNoch keine Bewertungen

- DSAH0011986Dokument12 SeitenDSAH0011986Mahdi AlizadehNoch keine Bewertungen

- Roller Chain ComparisonDokument1 SeiteRoller Chain ComparisonRicardo Wan AgueroNoch keine Bewertungen

- Heavy Hex Nuts ASTM A194 - A194MDokument1 SeiteHeavy Hex Nuts ASTM A194 - A194Mcanizales70Noch keine Bewertungen

- Steel PropertyDokument6 SeitenSteel PropertykrishbistNoch keine Bewertungen

- 格特威英文样本2018 PDFDokument56 Seiten格特威英文样本2018 PDFBinxiang XuNoch keine Bewertungen

- Eaton Transmission Specifications Catalog en UsDokument23 SeitenEaton Transmission Specifications Catalog en UsservitronicjleNoch keine Bewertungen

- Duct Calculation Fan BlowerDokument2 SeitenDuct Calculation Fan Blowerabdul0rohiminNoch keine Bewertungen

- ARaymondTinnerman 2016 Catalog 34Dokument2 SeitenARaymondTinnerman 2016 Catalog 34Gustavo HofstatterNoch keine Bewertungen

- Eaton 5 MarchasDokument2 SeitenEaton 5 MarchasPedro MelloNoch keine Bewertungen

- Line 6 Pod x3 Live Service Manual 3 PDF FreeDokument218 SeitenLine 6 Pod x3 Live Service Manual 3 PDF FreeJorge Alexis Aragon ArceNoch keine Bewertungen

- 01 Beton I Armatura - KarakteristikeDokument4 Seiten01 Beton I Armatura - KarakteristikeBojan PetronijevicNoch keine Bewertungen

- Electrical data for SQR 05.2 – SQR 14.2 Part-turn actuatorsDokument2 SeitenElectrical data for SQR 05.2 – SQR 14.2 Part-turn actuatorsGalih TrisnanugrahaNoch keine Bewertungen

- BQ PlateDokument2 SeitenBQ PlateAvishay TufikianNoch keine Bewertungen

- Sss Sttttaaaaiiiinnnnlllleeeessssssss Sssstttteeeeeeeellllssss Typical Composition % Uns WNR Ss / C CR Ni Mo NB CuDokument4 SeitenSss Sttttaaaaiiiinnnnlllleeeessssssss Sssstttteeeeeeeellllssss Typical Composition % Uns WNR Ss / C CR Ni Mo NB CuAdriano Dorneles de OliveiraNoch keine Bewertungen

- Assembly List - BoltsDokument14 SeitenAssembly List - BoltsAlex MacoveiNoch keine Bewertungen

- Material Required August 13Dokument14 SeitenMaterial Required August 13Arun DubeyNoch keine Bewertungen

- Research Paper MDMDokument100 SeitenResearch Paper MDMLourdesNoch keine Bewertungen

- MDM Frame 1-6 Frame A-FDokument202 SeitenMDM Frame 1-6 Frame A-FLourdesNoch keine Bewertungen

- Frame A moment distribution method analysisDokument100 SeitenFrame A moment distribution method analysisLourdesNoch keine Bewertungen

- TIP MDM ExampleDokument100 SeitenTIP MDM ExampleLourdesNoch keine Bewertungen

- MDM (5-Storey Condo)Dokument100 SeitenMDM (5-Storey Condo)LourdesNoch keine Bewertungen

- MDM Example ComputationDokument100 SeitenMDM Example ComputationLourdesNoch keine Bewertungen

- 2600 BomDokument2 Seiten2600 BomskyddNoch keine Bewertungen

- Service SpecificationsDokument93 SeitenService SpecificationsAbbode Horani100% (2)

- Spray Metal Polished Rod With Wrench Flats: Product DescriptionDokument3 SeitenSpray Metal Polished Rod With Wrench Flats: Product DescriptionJAVIER EDUARDO MANTILLA BUITRAGONoch keine Bewertungen

- App Man Section6 Rev1 PDFDokument41 SeitenApp Man Section6 Rev1 PDFSiding BarroNoch keine Bewertungen

- DIN 8557 steel grades and mechanical propertiesDokument1 SeiteDIN 8557 steel grades and mechanical propertiesbehzad mohammadiNoch keine Bewertungen

- Surface Roughness-Conersion Chart TableDokument2 SeitenSurface Roughness-Conersion Chart TableAnonymous w1yuNZTqONNoch keine Bewertungen

- LS Sintered Metal Spur GearsDokument2 SeitenLS Sintered Metal Spur Gearsdindo_waeNoch keine Bewertungen

- Final Liqeuv2Dokument20 SeitenFinal Liqeuv2YawgmothNoch keine Bewertungen

- Characterised control valve dimensions and specificationsDokument12 SeitenCharacterised control valve dimensions and specificationskautukNoch keine Bewertungen

- Line 6 Tone Port KB37 Service Manual PDFDokument216 SeitenLine 6 Tone Port KB37 Service Manual PDFDanilo VianaNoch keine Bewertungen

- Selection of MaterialsDokument1 SeiteSelection of MaterialsNur Sonia AbdNoch keine Bewertungen

- Casting AlloysDokument2 SeitenCasting Alloysgalvaosilva100% (1)

- Lever Style Plungers Locking Non Locking Stainless SteelDokument3 SeitenLever Style Plungers Locking Non Locking Stainless SteelPedro CaraveoNoch keine Bewertungen

- JFETSDokument1 SeiteJFETSscribddderNoch keine Bewertungen

- Sample Analysis Results for Au, Ag, Cu, Fe, Pb, Zn, Cr, and WDokument1 SeiteSample Analysis Results for Au, Ag, Cu, Fe, Pb, Zn, Cr, and WPaul BurnettNoch keine Bewertungen

- Steels For Quenching and TemperingDokument39 SeitenSteels For Quenching and Temperingjmwalker90Noch keine Bewertungen

- EESL Recruitment Advertisement of Middle and Junior Level Positions PDFDokument15 SeitenEESL Recruitment Advertisement of Middle and Junior Level Positions PDFfake fNoch keine Bewertungen

- Volume-2. Design and Manufacturing of Hydraulic CylindersDokument53 SeitenVolume-2. Design and Manufacturing of Hydraulic CylindersQ.S. Khan96% (48)

- High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingDokument3 SeitenHigh-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingBernathTurnipNoch keine Bewertungen

- HNBR207 TypicalPropsDokument2 SeitenHNBR207 TypicalPropsdinesh panchalNoch keine Bewertungen

- ASTM DL Content 2016 PDFDokument53 SeitenASTM DL Content 2016 PDFdinesh panchalNoch keine Bewertungen

- HNBR207 TypicalPropsDokument2 SeitenHNBR207 TypicalPropsdinesh panchalNoch keine Bewertungen

- Rotary O-Ring Seal GlandsDokument5 SeitenRotary O-Ring Seal Glandsdinesh panchalNoch keine Bewertungen

- HWB User Manual V 1Dokument44 SeitenHWB User Manual V 1Ayan MajiNoch keine Bewertungen

- SFN ProfileDokument4 SeitenSFN Profiledinesh panchalNoch keine Bewertungen

- Ped-Guidelines en PDFDokument261 SeitenPed-Guidelines en PDFAnte NinićNoch keine Bewertungen

- PRPQ 410 GK SeriesDokument36 SeitenPRPQ 410 GK SeriesJaime Albarrán FaríasNoch keine Bewertungen

- Centrifugal Fans Using Vibration Analysis To Detect ProblemsDokument3 SeitenCentrifugal Fans Using Vibration Analysis To Detect ProblemsGivon Da Anneista100% (1)

- ASTM DL Content 2016 PDFDokument53 SeitenASTM DL Content 2016 PDFdinesh panchalNoch keine Bewertungen

- Aula 1. - VASOS PDFDokument23 SeitenAula 1. - VASOS PDFrafaelcardosoengNoch keine Bewertungen

- Al Handbook SealsDokument17 SeitenAl Handbook SealshnafadyNoch keine Bewertungen

- 1 AdvertisementDokument1 Seite1 Advertisementdinesh panchalNoch keine Bewertungen

- Centrifugal Fans Using Vibration Analysis To Detect ProblemsDokument3 SeitenCentrifugal Fans Using Vibration Analysis To Detect ProblemsGivon Da Anneista100% (1)

- Hydraulic Hoses StandardsDokument4 SeitenHydraulic Hoses Standardssaliyarumesh2292Noch keine Bewertungen

- 700 Steel InclusionRating ASTM-E45Dokument1 Seite700 Steel InclusionRating ASTM-E45ksathisNoch keine Bewertungen

- HWB User Manual V 1Dokument44 SeitenHWB User Manual V 1Ayan MajiNoch keine Bewertungen

- Hydraulic Hoses StandardsDokument4 SeitenHydraulic Hoses Standardssaliyarumesh2292Noch keine Bewertungen

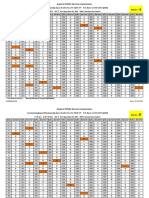

- Fak 49 201819Dokument4 SeitenFak 49 201819dinesh panchalNoch keine Bewertungen

- Sae J518 1993 PDFDokument14 SeitenSae J518 1993 PDFdinesh panchal67% (3)

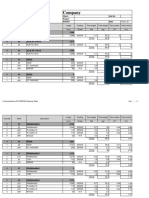

- 1560755641d.m. (Technical Services) - G&L (E-2) PDFDokument6 Seiten1560755641d.m. (Technical Services) - G&L (E-2) PDFdinesh panchalNoch keine Bewertungen

- 1834846479reminder Adm Dept PDFDokument1 Seite1834846479reminder Adm Dept PDFdinesh panchalNoch keine Bewertungen

- 1560755641d.m. (Technical Services) - G&L (E-2) PDFDokument6 Seiten1560755641d.m. (Technical Services) - G&L (E-2) PDFdinesh panchalNoch keine Bewertungen

- 09 Piston Seal For HydraulicDokument4 Seiten09 Piston Seal For Hydraulicdinesh panchalNoch keine Bewertungen

- Standard Pipe NipplesDokument1 SeiteStandard Pipe NippleschadNoch keine Bewertungen

- Soni Clinic & Pathology Center Chanda: Address:-Front of TVS AgencyDokument1 SeiteSoni Clinic & Pathology Center Chanda: Address:-Front of TVS AgencyVishalNoch keine Bewertungen

- Interest RatesDokument207 SeitenInterest RatesBenjamin RogersNoch keine Bewertungen

- As en 540-2002 Clinical Investigation of Medical Devices For Human SubjectsDokument8 SeitenAs en 540-2002 Clinical Investigation of Medical Devices For Human SubjectsSAI Global - APACNoch keine Bewertungen

- HZB-15S Service ManualDokument20 SeitenHZB-15S Service ManualJason Cravy100% (1)

- Mitsubishi v500 VFD IB NA 0600065-F FR-V500-NA Instruction Manual-DetailedDokument221 SeitenMitsubishi v500 VFD IB NA 0600065-F FR-V500-NA Instruction Manual-DetailedMROstop.comNoch keine Bewertungen

- Dimensions-Mm (Inch) : Valve Regulated Lead Acid Battery (VRLA)Dokument2 SeitenDimensions-Mm (Inch) : Valve Regulated Lead Acid Battery (VRLA)orunmila123Noch keine Bewertungen

- ECOSIADokument8 SeitenECOSIAaliosk8799Noch keine Bewertungen

- Gimnazjum Exam Practice GuideDokument74 SeitenGimnazjum Exam Practice GuideVaserd MoasleNoch keine Bewertungen

- Chapter 3 NotesDokument10 SeitenChapter 3 Notesmjamie12345Noch keine Bewertungen

- Smartphone Technician Cum App Tester: Trade PracticalDokument218 SeitenSmartphone Technician Cum App Tester: Trade PracticalF ZaidiNoch keine Bewertungen

- Blaylock Face Masks Pose Serious Risks To The HealthyDokument8 SeitenBlaylock Face Masks Pose Serious Risks To The HealthyDonnaveo ShermanNoch keine Bewertungen

- One Page AdventuresDokument24 SeitenOne Page AdventuresPotato Knishes100% (1)

- Colours of the RainbowDokument16 SeitenColours of the RainbowMd A RAZZAKNoch keine Bewertungen

- Cyril Cromier, Frost & SullivanDokument24 SeitenCyril Cromier, Frost & SullivanGaurav SahuNoch keine Bewertungen

- LLL'DSWD: Administrative Order No. Series 2017Dokument18 SeitenLLL'DSWD: Administrative Order No. Series 2017SGTNoch keine Bewertungen

- Computed Tomography (CT) - BodyDokument7 SeitenComputed Tomography (CT) - Bodyfery oktoraNoch keine Bewertungen

- Section III - Topic 3Dokument7 SeitenSection III - Topic 3KARINE HOVSEPYANNoch keine Bewertungen

- Save and share GZCL training spreadsheets onlineDokument263 SeitenSave and share GZCL training spreadsheets onlinejohn wick100% (1)

- Assignment of PsychologyDokument28 SeitenAssignment of PsychologyMuhammad Hamza AshfaqNoch keine Bewertungen

- Plant and Animal Cells Crossword Puzzle: FreebieDokument5 SeitenPlant and Animal Cells Crossword Puzzle: FreebieAref DahabrahNoch keine Bewertungen

- Rorschach y SuicidioDokument17 SeitenRorschach y SuicidioLaura SierraNoch keine Bewertungen

- Maxicare Individual and Family ProgramDokument43 SeitenMaxicare Individual and Family Programbzkid82Noch keine Bewertungen

- Breading Guide To All FoodDokument1 SeiteBreading Guide To All FoodInno EspinaNoch keine Bewertungen

- Common Safety Method GuidanceDokument66 SeitenCommon Safety Method GuidanceDiego UngerNoch keine Bewertungen

- Technical Bulletins Miglow Underwater12Dokument1 SeiteTechnical Bulletins Miglow Underwater12Arnaud PoliNoch keine Bewertungen

- Chemistry Tshirt ProjectDokument7 SeitenChemistry Tshirt Projectapi-524483093Noch keine Bewertungen

- Atlas Copco Generators: 15-360 kVA 15-300 KWDokument10 SeitenAtlas Copco Generators: 15-360 kVA 15-300 KWAyoub SolhiNoch keine Bewertungen

- McDonlads Vs Burger KingDokument6 SeitenMcDonlads Vs Burger KingSamuel Tyre Jr.Noch keine Bewertungen

- Cobb 500 PDFDokument14 SeitenCobb 500 PDFNeil Ryan100% (1)

- Installation TubeeeDokument7 SeitenInstallation TubeeeDini NovitrianingsihNoch keine Bewertungen