Beruflich Dokumente

Kultur Dokumente

MC 100 Cargador de Explosivos

Hochgeladen von

Wiwa Hernandez DonosoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MC 100 Cargador de Explosivos

Hochgeladen von

Wiwa Hernandez DonosoCopyright:

Verfügbare Formate

As versatile as it is reliable INDUSTRIAL FABRICATION INC.

PERSONNEL LOADERS

CARRIERS

SCISSOR BACK

LIFTS HOES

CRANES CABLE

REELERS

FORKLIFTS ANFO

LOADERS

AERIAL LUBE

BOOMS VEHICLES

Introducing the new E-Series from Industrial Fabrication.

Manufactured by Industrial Fabrication Inc.

2280 Long Lake Road, Sudbury ON Raising the bar even higher for safety and reliability.

telephone 705.523.1621 facsimile 705.523.0565

Please refer to the MINECAT MC100E Configuration Guide for complete specifications and options. www.ificanada.com

Introducing the new and improved Minecat MC100E. Industrial Fabrication has

been setting the standard for mine utility vehicles since we introduced our first Safety-related Proven Long-life and reliable

Minecat MC100. From the beginning, we have engineered utility vehicles for

the toughest mining environments in the world. We have closely monitored the improvements history industry-standard components

hundreds of Minecats working in the field, some of which have logged over 10,000

hours of operating time. We’ve combined our experience, expertise and dedication • Improved line of sight for greater visibility and • Successful safety record

to continuous improvement in the introduction of our latest E-series. The result… safer materials handling • Units operating in the field

the new E-series Minecat with improved safety, ergonomics and a revolutionary • Improved operator ergonomics with over 10,000 operating hours The powerful turbo-charged, 4-cylinder

engine gives you the reliability you need

• Reduced noise levels with the latest • Tripled the average expected life

modular design. while meeting or exceeding underground

Tier 3 engines of tractor type utility vehicle emissions standards. This engine is both

• Every configuration has undergone • Unsurpassed record for reliability MSHA and CANMET approved.

stability testing and availability The clutchless—fully synchronized 4x4

gearbox— transmission system allows

for increased ease of operation and safety

in ramped environments.

Because you’ve got

no time for downtime! New modular frame design

• Greatly reduces cost of commissioning the • The biggest component occupies less of a

machine underground footprint than a 4 x 8 sheet of plywood,

• Eliminates the need to cut the machine making it a simple chore to move with the

apart and re-weld together underground smallest cages

• Allows for easy change of attachments,

making this a true multi-purpose machine

The heavy-duty rear axle with 20,000 lb The ergonomically positioned operator’s The flip-open hood allows for quick and

dynamic load capacity uses fully enclosed compartment with easy to read gauges, easy access to the engine for performing

wet disks and industry standard SAHR- and mine-rated, fire-resistant wiring makes maintenance.

type braking systems. the MC100E safe, reliable, and easy to drive.

The front axle has 13,860 lb dynamic load

capacity and also uses fully enclosed wet disks

and industry standard SAHR-type braking

systems, guaranteeing improved safety.

Introducing the new and improved Minecat MC100E. Industrial Fabrication has

been setting the standard for mine utility vehicles since we introduced our first Safety-related Proven Long-life and reliable

Minecat MC100. From the beginning, we have engineered utility vehicles for

the toughest mining environments in the world. We have closely monitored the improvements history industry-standard components

hundreds of Minecats working in the field, some of which have logged over 10,000

hours of operating time. We’ve combined our experience, expertise and dedication • Improved line of sight for greater visibility and • Successful safety record

to continuous improvement in the introduction of our latest E-series. The result… safer materials handling • Units operating in the field

the new E-series Minecat with improved safety, ergonomics and a revolutionary • Improved operator ergonomics with over 10,000 operating hours The powerful turbo-charged, 4-cylinder

engine gives you the reliability you need

• Reduced noise levels with the latest • Tripled the average expected life

modular design. while meeting or exceeding underground

Tier 3 engines of tractor type utility vehicle emissions standards. This engine is both

• Every configuration has undergone • Unsurpassed record for reliability MSHA and CANMET approved.

stability testing and availability The clutchless—fully synchronized 4x4

gearbox— transmission system allows

for increased ease of operation and safety

in ramped environments.

Because you’ve got

no time for downtime! New modular frame design

• Greatly reduces cost of commissioning the • The biggest component occupies less of a

machine underground footprint than a 4 x 8 sheet of plywood,

• Eliminates the need to cut the machine making it a simple chore to move with the

apart and re-weld together underground smallest cages

• Allows for easy change of attachments,

making this a true multi-purpose machine

The heavy-duty rear axle with 20,000 lb The ergonomically positioned operator’s The flip-open hood allows for quick and

dynamic load capacity uses fully enclosed compartment with easy to read gauges, easy access to the engine for performing

wet disks and industry standard SAHR- and mine-rated, fire-resistant wiring makes maintenance.

type braking systems. the MC100E safe, reliable, and easy to drive.

The front axle has 13,860 lb dynamic load

capacity and also uses fully enclosed wet disks

and industry standard SAHR-type braking

systems, guaranteeing improved safety.

Introducing the new and improved Minecat MC100E. Industrial Fabrication has

been setting the standard for mine utility vehicles since we introduced our first Safety-related Proven Long-life and reliable

Minecat MC100. From the beginning, we have engineered utility vehicles for

the toughest mining environments in the world. We have closely monitored the improvements history industry-standard components

hundreds of Minecats working in the field, some of which have logged over 10,000

hours of operating time. We’ve combined our experience, expertise and dedication • Improved line of sight for greater visibility and • Successful safety record

to continuous improvement in the introduction of our latest E-series. The result… safer materials handling • Units operating in the field

the new E-series Minecat with improved safety, ergonomics and a revolutionary • Improved operator ergonomics with over 10,000 operating hours The powerful turbo-charged, 4-cylinder

engine gives you the reliability you need

• Reduced noise levels with the latest • Tripled the average expected life

modular design. while meeting or exceeding underground

Tier 3 engines of tractor type utility vehicle emissions standards. This engine is both

• Every configuration has undergone • Unsurpassed record for reliability MSHA and CANMET approved.

stability testing and availability The clutchless—fully synchronized 4x4

gearbox— transmission system allows

for increased ease of operation and safety

in ramped environments.

Because you’ve got

no time for downtime! New modular frame design

• Greatly reduces cost of commissioning the • The biggest component occupies less of a

machine underground footprint than a 4 x 8 sheet of plywood,

• Eliminates the need to cut the machine making it a simple chore to move with the

apart and re-weld together underground smallest cages

• Allows for easy change of attachments,

making this a true multi-purpose machine

The heavy-duty rear axle with 20,000 lb The ergonomically positioned operator’s The flip-open hood allows for quick and

dynamic load capacity uses fully enclosed compartment with easy to read gauges, easy access to the engine for performing

wet disks and industry standard SAHR- and mine-rated, fire-resistant wiring makes maintenance.

type braking systems. the MC100E safe, reliable, and easy to drive.

The front axle has 13,860 lb dynamic load

capacity and also uses fully enclosed wet disks

and industry standard SAHR-type braking

systems, guaranteeing improved safety.

As versatile as it is reliable INDUSTRIAL FABRICATION INC.

PERSONNEL LOADERS

CARRIERS

SCISSOR BACK

LIFTS HOES

CRANES CABLE

REELERS

FORKLIFTS ANFO

LOADERS

AERIAL LUBE

BOOMS VEHICLES

Introducing the new E-Series from Industrial Fabrication.

Manufactured by Industrial Fabrication Inc.

2280 Long Lake Road, Sudbury ON Raising the bar even higher for safety and reliability.

telephone 705.523.1621 facsimile 705.523.0565

Please refer to the MINECAT MC100E Configuration Guide for complete specifications and options. www.ificanada.com

As versatile as it is reliable INDUSTRIAL FABRICATION INC.

PERSONNEL LOADERS

CARRIERS

SCISSOR BACK

LIFTS HOES

CRANES CABLE

REELERS

FORKLIFTS ANFO

LOADERS

AERIAL LUBE

BOOMS VEHICLES

Introducing the new E-Series from Industrial Fabrication.

Manufactured by Industrial Fabrication Inc.

2280 Long Lake Road, Sudbury ON Raising the bar even higher for safety and reliability.

telephone 705.523.1621 facsimile 705.523.0565

Please refer to the MINECAT MC100E Configuration Guide for complete specifications and options. www.ificanada.com

MINECAT 100

TM

MINE UTILITY VEHICLE

GENERAL SPECIFICATIONS HYDRAULIC SYSTEM

Seating Capacity(Including Operator) 3-10 (Depending on Model) Type Variable Piston Pump Load Sense

Inner Turning Radius 10’ 10” (Depending on Model) Pump Rating 2350 psi

Outer Turning Radius 20’ – 24’ 6” (Depending on Model) Max hydraulic pressure 3000 psi

Gross Weight 10,500 lbs - 20,500 lbs (Depending on Model) Min pilot pressure 260+/- 30 psi

Cargo Capacity 500 lbs - 6,500 lbs (Depending on Model) Hydraulic Tank Capacity 77 Liters

GENERAL DIMENSIONS FRONT AXLE

Overall height 73” – 94” (Depending on Model) Model Carraro 26.19M

Overall width 80 1/2" - 88 1/2” Steering Integral steering cylinder

Overall length 152” - 225” (Depending on Model) Capacity 14,142 lbs. dynamic load rating

TRANSMISSION REAR AXLE

Make Turner 4x4 Model New Holland D45

Type 4 x 4 fully synchronized transmission Capacity 20,400 lbs. dynamic load rating

with power forward reversing shuttle

FUEL SYSTEM TIRES

Fuel Tank Capacity 77 Liters Tires, Front 14 x 17.5, 14 ply heavy duty front tires

Lift Pump Bosch fuel injection system Tires, Rear 19.5L x 24, 12 ply Heavy duty rear tires

BRAKES ELECTRICAL

Brakes, service Fully enclosed wet disc service brakes in Voltage 12V

both axles. Alternator 100 amp alternator

Brakes, emergency/park Fully enclosed, spring applied, hydraulic Other features NEMA 12 enclosures

release (SAHR) wet disk brakes within Complete mine grade wiring package

both axles. Bostrig cables throughout

STANDARD EQUIPMENT OPTIONAL EQUIPMENT

Ammeter Fuel Gauge Aerial Booms with Man-Up Baskets Enclosed Cabs

Hour meter Engine Temp. Warning ANFO Tanks Forklift masts

Engine Oil Pressure Warning Exhaust Scrubber Auto-greasers Front End Loader Arms

Back-up Alarm Emergency Stop Button Backhoes ROPS / FOPS Canopies

Horn Neutral Safety Switch Battery Boosters Scissor Lifts

Reverse Lockout Hydraulic Throttle Cranes Shotcreters

ENGINE TRAVEL SPEED FULLY LOADED (2500 LBS) TYPICAL PC CONFIGURATION

Make Iveco 1st gear 4 km/h (2.4 mph) on flat ground,

Model N45 4 km/h (2.4 mph) up ramp (20% grade)

Type Turbocharged Diesel 2nd gear 7 km/h (4.2 mph) on flat ground,

Tier II, Platform Tier III 7 km/h (4.2 mph) up ramp (20% grade)

CANMET Certification # 1179 3rd gear 17 km/h (10.2 mph) on flat ground,

MSHA Certification # 07-ENA060003 13 km/h (8 mph) up ramp (20% grade)

Rated 99 HP @ 2300 RPM 4th gear (locked out)

Maximum Torque 293.5 ft-lb @ 1400 RPM

No. of cylinders 4

Displacement 274 cu.in Note: Travel Speeds will vary depending on gross vehicle weight

2280 Long Lake Road, Sudbury Ont. Canada, P3E 5H4

Tel. (705) 523-1621 Fax. (705) 523-0565

www.ificanada.com

Das könnte Ihnen auch gefallen

- Planificación Minera: Introduction and Planning ProcessDokument35 SeitenPlanificación Minera: Introduction and Planning ProcessGustavo Salazar Fernandez100% (1)

- KL 900 Details SpecsDokument4 SeitenKL 900 Details SpecsbenNoch keine Bewertungen

- Ranking of Geometry/Grade Distribution For Diferent Mining MethodDokument8 SeitenRanking of Geometry/Grade Distribution For Diferent Mining MethodVictor QuispeNoch keine Bewertungen

- How To Build A Gridded Seam ModelDokument86 SeitenHow To Build A Gridded Seam ModelBill WatersonNoch keine Bewertungen

- Block CavingDokument19 SeitenBlock CavingmanikantaNoch keine Bewertungen

- PIO Antamina PDFDokument7 SeitenPIO Antamina PDFJC AlemanNoch keine Bewertungen

- 1 Modifying Factors E TulcanazaDokument21 Seiten1 Modifying Factors E TulcanazaRafael MatosNoch keine Bewertungen

- Pre Conditioning Cadia East A Catalan G DunstanDokument15 SeitenPre Conditioning Cadia East A Catalan G DunstanMatías Ignacio Fuentes Bustamante100% (1)

- Underground Extraction of Contiguous Coal SeamDokument12 SeitenUnderground Extraction of Contiguous Coal SeamRakesh RoushanNoch keine Bewertungen

- Simba 1250 PDFDokument4 SeitenSimba 1250 PDFBender Doblador Rodriguez0% (1)

- Sandvik Boxhole Borer MD 320 Trackless: in ActionDokument2 SeitenSandvik Boxhole Borer MD 320 Trackless: in ActionnambiiasNoch keine Bewertungen

- 129 Sub Level Caving For ChromiteDokument4 Seiten129 Sub Level Caving For ChromiteKenny CasillaNoch keine Bewertungen

- Preconditioning Implementation On Rock Bulks in Codelco Chile and Its ResultsDokument16 SeitenPreconditioning Implementation On Rock Bulks in Codelco Chile and Its ResultsFernando RicardoNoch keine Bewertungen

- PR Ms Model LinkDokument13 SeitenPR Ms Model LinkRicardo Contreras BNoch keine Bewertungen

- Ridgeway DeepsDokument15 SeitenRidgeway Deepsalvaroaac4Noch keine Bewertungen

- Codelco - El Teniente Final Paper DeepMining07 PreconditioningDokument10 SeitenCodelco - El Teniente Final Paper DeepMining07 PreconditioningFernando RicardoNoch keine Bewertungen

- Vulcan Gantt Scheduler TutorialDokument44 SeitenVulcan Gantt Scheduler TutorialDhayann C. Muñoz100% (2)

- Maptek Vulcan Block Advanced Reserves Advanced Reserves EditorDokument1 SeiteMaptek Vulcan Block Advanced Reserves Advanced Reserves EditorAmasso Nib Nedal0% (1)

- Orepro 3D: Blast Movement Modelling and Grade Control OptimiserDokument2 SeitenOrepro 3D: Blast Movement Modelling and Grade Control OptimiserTchouleko judicael100% (1)

- Issue110 Evolution MiningTrucksDokument4 SeitenIssue110 Evolution MiningTrucksluisparedesNoch keine Bewertungen

- 07.week 5 6 - Theoritical Model of Variograms PDFDokument38 Seiten07.week 5 6 - Theoritical Model of Variograms PDFaldo surya pratama100% (1)

- Department of Mining Engineering: Indian Institute of Technology (Indian School of Mines) DhanbadDokument25 SeitenDepartment of Mining Engineering: Indian Institute of Technology (Indian School of Mines) DhanbadAditya HimanshuNoch keine Bewertungen

- The Pseudoflow Algorithm A New Algorithm For The Maximum Flow ProblemDokument18 SeitenThe Pseudoflow Algorithm A New Algorithm For The Maximum Flow ProblemUlises ArayaNoch keine Bewertungen

- Practical Implementation of VOD at The Henderson Mine: R. Dave Brokering, D.M. Loring, C.J. RutterDokument8 SeitenPractical Implementation of VOD at The Henderson Mine: R. Dave Brokering, D.M. Loring, C.J. RutterCARLOS OSIEL SEBASTIÁN VALDÉSNoch keine Bewertungen

- Saw Et Al - AusIMM UOC 2017Dokument16 SeitenSaw Et Al - AusIMM UOC 2017sawhlaayeNoch keine Bewertungen

- A Multiple Blasthole Fragmentation Model - Its Concept Formulation CapabilityDokument10 SeitenA Multiple Blasthole Fragmentation Model - Its Concept Formulation Capabilityalvaroaac4Noch keine Bewertungen

- Weight Study Report LCI 25-30 Juni 2012Dokument33 SeitenWeight Study Report LCI 25-30 Juni 2012Mukti AliNoch keine Bewertungen

- Highwall MiningDokument10 SeitenHighwall MininghendrawanNoch keine Bewertungen

- Data Book 2013Dokument53 SeitenData Book 2013jorgegachaNoch keine Bewertungen

- MME 2010 Contents and Introduction PDFDokument13 SeitenMME 2010 Contents and Introduction PDFAmaraaZoyaNoch keine Bewertungen

- Full Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineDokument10 SeitenFull Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineandresmaureiravNoch keine Bewertungen

- Introduction To FPCDokument25 SeitenIntroduction To FPCBenito Lionel ZoboNoch keine Bewertungen

- Northparkes E26 Lift 2 Block Cave - A Case StudyDokument10 SeitenNorthparkes E26 Lift 2 Block Cave - A Case StudyEduardo MenaNoch keine Bewertungen

- D55SP - D75KS Blasthole DrillDokument4 SeitenD55SP - D75KS Blasthole DrillIrvan Aryo Prakoso0% (1)

- HXGN MIN Product NamesDokument1 SeiteHXGN MIN Product NamesRK LexNoch keine Bewertungen

- Full Text 01Dokument140 SeitenFull Text 01Lucas Martin AbascalNoch keine Bewertungen

- 077 Mining Challenge at El SoldadoDokument6 Seiten077 Mining Challenge at El SoldadoKenny CasillaNoch keine Bewertungen

- Pitram OptimumDokument2 SeitenPitram OptimumJean-Paul MwambaNoch keine Bewertungen

- Austmine METS National Survey PDFDokument14 SeitenAustmine METS National Survey PDFvictor carvalloNoch keine Bewertungen

- XPAC Open Pit MetalsDokument6 SeitenXPAC Open Pit MetalsSamuel LuisNoch keine Bewertungen

- Comparison of Mine Ventilation Simulation SoftwareDokument5 SeitenComparison of Mine Ventilation Simulation Softwarealexander ayalaNoch keine Bewertungen

- BenchFill VillaescusaDokument10 SeitenBenchFill VillaescusaFredd_AlvaroNoch keine Bewertungen

- Production Summary - Full SimulationDokument20 SeitenProduction Summary - Full SimulationJorli Reyes SanchezNoch keine Bewertungen

- Código JORCDokument44 SeitenCódigo JORCPatricio LeddyNoch keine Bewertungen

- DSI Underground Systems Cable Bolts USDokument14 SeitenDSI Underground Systems Cable Bolts USDonald Culqui ValleNoch keine Bewertungen

- RocData Tutorial 03 Triaxial Lab DataDokument3 SeitenRocData Tutorial 03 Triaxial Lab DataDanang RahadianNoch keine Bewertungen

- Example 5 - Analysis of Direct Shear Lab Data: Mohr-Coulomb Power CurveDokument5 SeitenExample 5 - Analysis of Direct Shear Lab Data: Mohr-Coulomb Power CurvedianamorabonillaNoch keine Bewertungen

- Datamine PDFDokument2 SeitenDatamine PDFLukiesse Ntima AlexandreNoch keine Bewertungen

- KAESER MOBILAIR General CatalogueDokument7 SeitenKAESER MOBILAIR General CatalogueVietnam UMacNoch keine Bewertungen

- GH 05 New Hoists Generation 2018Dokument12 SeitenGH 05 New Hoists Generation 2018Wanto SitinjakNoch keine Bewertungen

- Joy Underground Feeder Breakers Brochure PDFDokument5 SeitenJoy Underground Feeder Breakers Brochure PDFSabahNoch keine Bewertungen

- ZRT850 Catalogue 18.08Dokument8 SeitenZRT850 Catalogue 18.08Владимир СкорняковNoch keine Bewertungen

- MT2010 Battery 2018-03Dokument8 SeitenMT2010 Battery 2018-03Yosmar TorrealbaNoch keine Bewertungen

- BOBCAT S450 EN - S450-S510-S530-S550-S590-S630-S650 - Brochure - MEA - CIS - B4501691 - 11-2020 - LowResDokument11 SeitenBOBCAT S450 EN - S450-S510-S530-S550-S590-S630-S650 - Brochure - MEA - CIS - B4501691 - 11-2020 - LowResbesosdejudasNoch keine Bewertungen

- 14 OSA Product-Catalog LRDokument2 Seiten14 OSA Product-Catalog LRJet OrtegaNoch keine Bewertungen

- Zoomlion RT 60Dokument8 SeitenZoomlion RT 60dody probo100% (1)

- RENK Double Marine Gear Units enDokument7 SeitenRENK Double Marine Gear Units enABHISHEK KUMARNoch keine Bewertungen

- Electric Mining Shovel - DC Drive Product OverviewDokument5 SeitenElectric Mining Shovel - DC Drive Product OverviewLeandro Jaimes AlvaradoNoch keine Bewertungen

- The All New Arocs 6x4 and 8x4 Tipper RangeDokument5 SeitenThe All New Arocs 6x4 and 8x4 Tipper Rangemikelyon06Noch keine Bewertungen

- 9852 1872 01c Driving E2, L1, L2 and MDokument2 Seiten9852 1872 01c Driving E2, L1, L2 and MWiwa Hernandez DonosoNoch keine Bewertungen

- 1B-3 Short Instruction On Driving Meyco VersaDokument2 Seiten1B-3 Short Instruction On Driving Meyco VersaWiwa Hernandez DonosoNoch keine Bewertungen

- 9852 2379 01a DPF Regeneration During Shipping PDFDokument2 Seiten9852 2379 01a DPF Regeneration During Shipping PDFWiwa Hernandez DonosoNoch keine Bewertungen

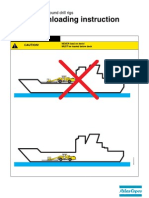

- 9852 1868 01 Loading-Unloading InstructionDokument2 Seiten9852 1868 01 Loading-Unloading InstructioncankurtaranNoch keine Bewertungen

- V80516 Ansul Fire Supp Owners ManualDokument12 SeitenV80516 Ansul Fire Supp Owners ManualPaulPaucarCamposNoch keine Bewertungen

- Operating Instructions RRC, Sender Spectrum3 enDokument26 SeitenOperating Instructions RRC, Sender Spectrum3 enWiwa Hernandez Donoso100% (1)

- 2C-5 Part List Hose ReelDokument1 Seite2C-5 Part List Hose ReelWiwa Hernandez DonosoNoch keine Bewertungen

- Panolin HLP UNI 32 enDokument6 SeitenPanolin HLP UNI 32 enWiwa Hernandez DonosoNoch keine Bewertungen

- ME Bolter F PDFDokument2 SeitenME Bolter F PDFWiwa Hernandez DonosoNoch keine Bewertungen

- MacLean Engineering Utility Vehicle OverviewDokument2 SeitenMacLean Engineering Utility Vehicle OverviewWiwa Hernandez DonosoNoch keine Bewertungen

- Corporate Presentation - Overview of Mining DivisionDokument27 SeitenCorporate Presentation - Overview of Mining DivisionWiwa Hernandez DonosoNoch keine Bewertungen

- Condition Report Handing-Over Protocol: Atlas Copco Meyco AGDokument7 SeitenCondition Report Handing-Over Protocol: Atlas Copco Meyco AGWiwa Hernandez DonosoNoch keine Bewertungen

- Ac-3 Anfo Charger PDFDokument2 SeitenAc-3 Anfo Charger PDFWiwa Hernandez Donoso100% (1)

- AC3 Specification SheetDokument4 SeitenAC3 Specification SheetWiwa Hernandez DonosoNoch keine Bewertungen

- 8999 1782 00 List of PartsDokument98 Seiten8999 1782 00 List of PartsWiwa Hernandez DonosoNoch keine Bewertungen

- Abreviaturas Hose MarkingsDokument4 SeitenAbreviaturas Hose MarkingsJose Luis ValdiviaNoch keine Bewertungen

- 1 Flota Resemin y CertificadosDokument2 Seiten1 Flota Resemin y CertificadosWiwa Hernandez DonosoNoch keine Bewertungen

- Ac-3 Anfo Charger EspDokument4 SeitenAc-3 Anfo Charger EspWiwa Hernandez DonosoNoch keine Bewertungen

- AC2 Specification SheetDokument4 SeitenAC2 Specification SheetWiwa Hernandez DonosoNoch keine Bewertungen

- 8999 1779 00 List of PartsDokument104 Seiten8999 1779 00 List of PartsWiwa Hernandez Donoso100% (1)

- 9852 2379 01a DPF Regeneration During Shipping PDFDokument2 Seiten9852 2379 01a DPF Regeneration During Shipping PDFWiwa Hernandez DonosoNoch keine Bewertungen

- 9852 3353 01b Settings COP 2238HD+ - VerF PDFDokument1 Seite9852 3353 01b Settings COP 2238HD+ - VerF PDFWiwa Hernandez DonosoNoch keine Bewertungen

- 9852 2484 01b Re-Connect Fire Fighting Equipment Instruction All M, L, E1-2 PDFDokument2 Seiten9852 2484 01b Re-Connect Fire Fighting Equipment Instruction All M, L, E1-2 PDFWiwa Hernandez DonosoNoch keine Bewertungen

- 9852 1872 01c Driving E2, L1, L2 and MDokument2 Seiten9852 1872 01c Driving E2, L1, L2 and MWiwa Hernandez DonosoNoch keine Bewertungen

- 9852 1854 01 Positioning BUT 32 and BUT 35 With RCS PDFDokument2 Seiten9852 1854 01 Positioning BUT 32 and BUT 35 With RCS PDFWiwa Hernandez DonosoNoch keine Bewertungen

- 9852 1937 01a Transport E2, L1, L2 and M Med Lastsäkring PDFDokument2 Seiten9852 1937 01a Transport E2, L1, L2 and M Med Lastsäkring PDFWiwa Hernandez DonosoNoch keine Bewertungen

- 9852 1868 01 Loading-Unloading InstructionDokument2 Seiten9852 1868 01 Loading-Unloading InstructioncankurtaranNoch keine Bewertungen

- Abreviaturas Hose MarkingsDokument4 SeitenAbreviaturas Hose MarkingsJose Luis ValdiviaNoch keine Bewertungen

- 9852 3353 01b Settings COP 2238HD+ - VerFDokument1 Seite9852 3353 01b Settings COP 2238HD+ - VerFWiwa Hernandez DonosoNoch keine Bewertungen

- Ford Everest 4pager Brochure MAY2017Dokument2 SeitenFord Everest 4pager Brochure MAY2017Rein GallardoNoch keine Bewertungen

- M30/40/50 - 2 H/L M30/40/50 - 4 H/L: Manitou North America, IncDokument368 SeitenM30/40/50 - 2 H/L M30/40/50 - 4 H/L: Manitou North America, IncRazvan MitruNoch keine Bewertungen

- Glossary NewDokument150 SeitenGlossary NewAna RistovskaNoch keine Bewertungen

- VW Amarok Model MY19Dokument25 SeitenVW Amarok Model MY19Jon joNoch keine Bewertungen

- Hilux BrochureDokument25 SeitenHilux BrochureDaniel100% (1)

- Classic Commercial Vehicles: Deliver Goods All Over The WorldDokument17 SeitenClassic Commercial Vehicles: Deliver Goods All Over The Worldtrasnochador77Noch keine Bewertungen

- 2017 Ford F 150 Owners Manual Version 2 Om en US en CA 12 2016Dokument593 Seiten2017 Ford F 150 Owners Manual Version 2 Om en US en CA 12 2016Simon Lee100% (2)

- PL2 - Basic Chassis - Slide - H - Eng2Dokument175 SeitenPL2 - Basic Chassis - Slide - H - Eng2Lloyd CompuestoNoch keine Bewertungen

- Man TGLDokument21 SeitenMan TGLViorel RoNoch keine Bewertungen

- 2014 Isuzu D-Max 3Dokument2 Seiten2014 Isuzu D-Max 3sofianina05Noch keine Bewertungen

- 1974 08 VIN DecoderDokument294 Seiten1974 08 VIN Decoder650L100% (1)

- 110707Dokument39 Seiten110707pac100% (8)

- Manuel Dentretien ABS Camion EC 60 BENDIXDokument44 SeitenManuel Dentretien ABS Camion EC 60 BENDIXUlises FloresNoch keine Bewertungen

- VOLVO G726B MOTOR GRADER Service Repair Manual PDFDokument17 SeitenVOLVO G726B MOTOR GRADER Service Repair Manual PDFsekfsekmddde50% (2)

- Pe 001Dokument216 SeitenPe 001erivan bernardoNoch keine Bewertungen

- Z-45/25 Z-45/25J IC Power: Serial Number RangeDokument198 SeitenZ-45/25 Z-45/25J IC Power: Serial Number RangeLeonardo MartinsNoch keine Bewertungen

- 04-2 N Series Manual Transmission Schematics 112010Dokument2 Seiten04-2 N Series Manual Transmission Schematics 112010Mauricio GonzalezNoch keine Bewertungen

- Catalogue Pieces WG 2001Dokument386 SeitenCatalogue Pieces WG 2001grenovsuperNoch keine Bewertungen

- Hyundai Santa Fe 2007Dokument17 SeitenHyundai Santa Fe 2007putocalvoNoch keine Bewertungen

- Torque SpecsDokument21 SeitenTorque SpecssaturnayalaNoch keine Bewertungen

- Kamaz CatalogueDokument44 SeitenKamaz CatalogueGPS MPWTNoch keine Bewertungen

- Service Manual PDFDokument3.356 SeitenService Manual PDFBernardo KumabeNoch keine Bewertungen

- Stallion 4x4 TruckDokument2 SeitenStallion 4x4 TruckUttkarsh DwivediNoch keine Bewertungen

- Manual John Deere Gator XUV 850DDokument2 SeitenManual John Deere Gator XUV 850Djoel blancoNoch keine Bewertungen

- Pre 2016 FortunerDokument1 SeitePre 2016 FortunerTagulKanotsNoch keine Bewertungen

- Part Time - T/C: Section 3DDokument74 SeitenPart Time - T/C: Section 3DMiguel RuizNoch keine Bewertungen

- DownloaderDokument6 SeitenDownloaderalex100% (1)

- TOYOTA U150, U151 01-ON, U250 05-ON: 5 SPEED FWD & AWD (Electronic Control)Dokument5 SeitenTOYOTA U150, U151 01-ON, U250 05-ON: 5 SPEED FWD & AWD (Electronic Control)Krzysztof KjbNoch keine Bewertungen

- SKODA KODIAQ Interactive Brochure 01FEB20 PDFDokument41 SeitenSKODA KODIAQ Interactive Brochure 01FEB20 PDFtroxonNoch keine Bewertungen

- 325ix - E30 Zone WikiDokument6 Seiten325ix - E30 Zone WikiFlaviu CosminNoch keine Bewertungen