Beruflich Dokumente

Kultur Dokumente

Especificacion Alineamiento MP Cus

Hochgeladen von

Elver AmesquitaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Especificacion Alineamiento MP Cus

Hochgeladen von

Elver AmesquitaCopyright:

Verfügbare Formate

SHAFT ALIGNMENT SPECIFICATION

CUSTOMER : BP EXPLORATION

PLANT LOCATION : CUSIANA/CUPIAGUA - COLOMBIA

PLANT : REINJECTION - MP

VERSION 01/2005 ASE/ROGE

Nuovo Pignone FIRENZE

COMMESSA – JOB.

2841707-09-12

SHAFT ALIGNMENT SPECIFICATION N° SOS 8229005 /3

LINGUA - LANGUAGE TAVOLA - SHEET

0 EMESSO - ISSUED MIL 11/06/09 A 1/2

SOSTITUISCE IL - REPLACES

PREP’D CHK’D APPR’D DATE

REV. DESCRIZIONE - DESCRIPTION 2002 Nuovo Pignone S.p.A., all rights reserved

PREP CONT APPR. DATA SOSTITUITO DA – REPLACED BY

PDF created with pdfFactory trial version www.pdffactory.com

1. SCOPE

This specification supplies the data necessary to perform the site shaft alignment and misalignment maps. AXIAL ALIGNMENT MEASUREMENT

Axial alignment (angular alignment) of the shafts, is measured by means of two dial indicators set at zero when they

2. ALIGNMENT CONSIDERATION are positioned at 12 and 6 o'clock.

Alignment must be accomplished prior to initial starting after the equipment has been installed on its permanent site,

and whenever any change has been made in the relative position of the driving to driven equipment. Improper Rotate both shafts and record measurements at every 90° intervals, as shown on fig. 2.

alignment may cause vibration and, at worst, premature bearing failure. Always check alignment after replacement of Assuming that both indicators are attached to the shaft P, the indicator button will track on shaft Q, the results are:

the driving or driven equipment. Alignment must be checked before and after suction and discharge pipes are -on vertical plane (av), axial misalignment is expressed as:

assembled to the compressor. av = (d – g) / 2

Cold alignment compensates for the thermal growth of operating equipment by correctly offsetting the driving and

driven equipment. The offset allows the equipment to grow into alignment at normal operating conditions. (+ or - signs should be considered)

Ideal full load (hot) alignment occurs when all drive train member centerlines exactly coincide. It is intended to position - on horizontal plane (ao), axial misalignment is expressed as:

the cold centerline of each drive train component such that at full load temperature, each member of the drive train will ao = ((c – e) – (f – h)) / 2

move to the ideal position.

(+ or - signs should be considered)

3. ALIGNMENT MEASUREMENT

RADIAL ALIGNMENT MEASUREMENT

Fig. 2

Zero the radial dial with reference to vertical, as shown on the figure 1.

Rotate both shafts in the direction expected for operation and record measurements at every at 90° intervals. A Q

Dial indicator reads minus when the plunger moves outward and plus when the plunger moves inward.

Vertical misalignment (rv) is expressed as:

P

rv = b / 2

Dia. B

where "b" is the reading of the dial indicator a 180°

Apart from slight errors, the algebraic sum of 90° (w) and 270° (z) readings coincides with the 180° reading

b=w+z

whereas their algebraic semi-difference indicates horizontal radial misalignment (ro):

Dial A Dial B

ro = (w – z) / 2

it’s imperative to take into account the plus and minus signs of w and z 0 g

Fig.1

0

rv c e h f

z w

d 0

b

Nuovo Pignone FIRENZE

COMMESSA – JOB.

2841707-09-12

SHAFT ALIGNMENT SPECIFICATION N° SOS 8229005 /3

LINGUA - LANGUAGE TAVOLA - SHEET

0 EMESSO - ISSUED A 2/3

SOSTITUISCE IL - REPLACES

REV. DESCRIZIONE - DESCRIPTION 2002 Nuovo Pignone S.p.A., all rights reserved

SOSTITUITO DA – REPLACED BY

PDF created with pdfFactory trial version www.pdffactory.com

Nuovo Pignone FIRENZE

COMMESSA – JOB.

2841707-09-12

SHAFT ALIGNMENT SPECIFICATION N° SOS 8229005 /3

LINGUA - LANGUAGE TAVOLA - SHEET

0 EMESSO - ISSUED A 3/4

SOSTITUISCE IL - REPLACES

REV. DESCRIZIONE - DESCRIPTION 2002 Nuovo Pignone S.p.A., all rights reserved

SOSTITUITO DA – REPLACED BY

PDF created with pdfFactory trial version www.pdffactory.com

Nuovo Pignone FIRENZE

COMMESSA – JOB.

2841707-09-12

SHAFT ALIGNMENT SPECIFICATION N° SOS 8229005 /3

LINGUA - LANGUAGE TAVOLA - SHEET

0 EMESSO - ISSUED A 4/5

SOSTITUISCE IL - REPLACES

REV. DESCRIZIONE - DESCRIPTION 2002 Nuovo Pignone S.p.A., all rights reserved

SOSTITUITO DA – REPLACED BY

PDF created with pdfFactory trial version www.pdffactory.com

Nuovo Pignone FIRENZE

COMMESSA – JOB.

2841707-09-12

SHAFT ALIGNMENT SPECIFICATION N° SOS 8229005 /3

LINGUA - LANGUAGE TAVOLA - SHEET

0 EMESSO - ISSUED A 5/5

SOSTITUISCE IL - REPLACES

REV. DESCRIZIONE - DESCRIPTION 2002 Nuovo Pignone S.p.A., all rights reserved

SOSTITUITO DA – REPLACED BY

PDF created with pdfFactory trial version www.pdffactory.com

Das könnte Ihnen auch gefallen

- Engineering Change Order: IntentDokument1 SeiteEngineering Change Order: IntentYanethNoch keine Bewertungen

- Anritsu Site Master S331B10580-00028F Maintenance ManualDokument16 SeitenAnritsu Site Master S331B10580-00028F Maintenance ManualThe VaultNoch keine Bewertungen

- 09E-09-00-A3-SHEET-07 -Dokument1 Seite09E-09-00-A3-SHEET-07 -eeonNoch keine Bewertungen

- Document Review Cover Sheet: EL - Merk Project Company Job No.: SC 4012100 Petrofac Job No.: JI-195Dokument9 SeitenDocument Review Cover Sheet: EL - Merk Project Company Job No.: SC 4012100 Petrofac Job No.: JI-195Marwa Koubaies100% (1)

- Detail 02 Thrust BlockDokument1 SeiteDetail 02 Thrust Blockengr_haseeb07100% (1)

- 883 Chemical Mariner Magnetic Compass Adj CertDokument1 Seite883 Chemical Mariner Magnetic Compass Adj CertGutta RavindraNoch keine Bewertungen

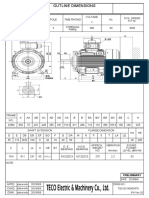

- P/N 25G130R040 P/N 25G130R050 P/N 25G130R060 P/N 25G130R070 P/N 25G130R080 P/N 25G130R090 P/N 25G130R100Dokument17 SeitenP/N 25G130R040 P/N 25G130R050 P/N 25G130R060 P/N 25G130R070 P/N 25G130R080 P/N 25G130R090 P/N 25G130R100carmenNoch keine Bewertungen

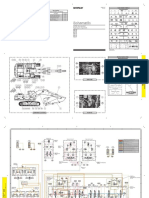

- Lines GP - Boom Float: 330D Excavator Hydraulic System - AttachmentDokument2 SeitenLines GP - Boom Float: 330D Excavator Hydraulic System - AttachmentKJDNKJZEFNoch keine Bewertungen

- Engineering Change Order: IntentDokument3 SeitenEngineering Change Order: IntentYanethNoch keine Bewertungen

- 12-00007WD_D_Garmin G950 System InterfaceDokument12 Seiten12-00007WD_D_Garmin G950 System InterfaceDeleh GonzalezNoch keine Bewertungen

- Power Supply Board (Tantalum Less) : Solidworks Drawing: All Changes Must Be Done in Solidworks DatabaseDokument2 SeitenPower Supply Board (Tantalum Less) : Solidworks Drawing: All Changes Must Be Done in Solidworks DatabasezizouhicheNoch keine Bewertungen

- ECO Corrects Starter Pressure RatingDokument2 SeitenECO Corrects Starter Pressure RatingYanethNoch keine Bewertungen

- RN Mto001 001Dokument1 SeiteRN Mto001 001work.engeslamNoch keine Bewertungen

- R.C.Details of Pile: Section A-ADokument1 SeiteR.C.Details of Pile: Section A-ALALIT SINGHNoch keine Bewertungen

- Ad 036785 001Dokument1 SeiteAd 036785 001hai sunNoch keine Bewertungen

- 324D and 326D Excavator Hydraulic System: Pump GP - Piston (Main)Dokument2 Seiten324D and 326D Excavator Hydraulic System: Pump GP - Piston (Main)heberNoch keine Bewertungen

- 324DL Hyd SCHDokument2 Seiten324DL Hyd SCHEmmanuel solomonNoch keine Bewertungen

- Esquema Hidraulico - Controller 324dDokument2 SeitenEsquema Hidraulico - Controller 324dOswaldo AndradeNoch keine Bewertungen

- Field Instrument ListDokument15 SeitenField Instrument Listmohamedsaib438Noch keine Bewertungen

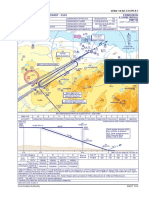

- Decl/Arp Popayan Tres Charlie (Ppn3C) - Ankas Tres Alfa (Anka3A), Dakop Tres Bravo (Dako3B), 6° W/18Dokument1 SeiteDecl/Arp Popayan Tres Charlie (Ppn3C) - Ankas Tres Alfa (Anka3A), Dakop Tres Bravo (Dako3B), 6° W/18Julio RiquelmeNoch keine Bewertungen

- 2019/9/9 Sales-Indo Sales-Indo Sales-Indo PN Ver:02: PreliminaryDokument4 Seiten2019/9/9 Sales-Indo Sales-Indo Sales-Indo PN Ver:02: PreliminaryCV buanaindahNoch keine Bewertungen

- A/V & Navigation (5) SD969-5Dokument1 SeiteA/V & Navigation (5) SD969-5Dhashana MoorthyNoch keine Bewertungen

- PHOTO FACT Folder: MODELS 571, 6O6, 611, 612, 619, 62O, 624, 627Dokument26 SeitenPHOTO FACT Folder: MODELS 571, 6O6, 611, 612, 619, 62O, 624, 627dds94Noch keine Bewertungen

- 120 H Diagrama Hidraulico PDFDokument2 Seiten120 H Diagrama Hidraulico PDFVita Ly100% (1)

- KGSB 170074 Af 06 - A0 PDFDokument1 SeiteKGSB 170074 Af 06 - A0 PDFLallamaNoch keine Bewertungen

- Lube Tech Series MasterDokument20 SeitenLube Tech Series MasterSalvador MartinezNoch keine Bewertungen

- 325D Excavator Hydraulic System: Fluid Power SymbolsDokument2 Seiten325D Excavator Hydraulic System: Fluid Power SymbolsDennis Olaya100% (3)

- Wibj ChartDokument1 SeiteWibj ChartPABLO ELNINONoch keine Bewertungen

- AL-1 (FAA) ABILENE, TEXAS Approach ChartDokument1 SeiteAL-1 (FAA) ABILENE, TEXAS Approach Charttayo_bNoch keine Bewertungen

- Apm 190Dokument142 SeitenApm 190Vincent GrondinNoch keine Bewertungen

- D6R Series II Track-Type Tractor Hydraulic System: Component LocationsDokument2 SeitenD6R Series II Track-Type Tractor Hydraulic System: Component Locationsmirbek mairykovNoch keine Bewertungen

- EG AD 2 EGPH 8-1 en 2014-03-06Dokument1 SeiteEG AD 2 EGPH 8-1 en 2014-03-06Ahz RolNoch keine Bewertungen

- 12-00010WD_D_TCAS I (Garmin GTS 855)Dokument4 Seiten12-00010WD_D_TCAS I (Garmin GTS 855)Deleh GonzalezNoch keine Bewertungen

- 320D & 320D L Excavator Hydraulic System Schematic PDFDokument2 Seiten320D & 320D L Excavator Hydraulic System Schematic PDFchanlin100% (5)

- 30600-G-G0002 4 Instr ListDokument58 Seiten30600-G-G0002 4 Instr Listmohamed abourayaNoch keine Bewertungen

- Diagrama Eletectrico MF4EDokument9 SeitenDiagrama Eletectrico MF4Edaniela lopezNoch keine Bewertungen

- COLUMBUS, OHIO AIRPORT CHARTDokument1 SeiteCOLUMBUS, OHIO AIRPORT CHARTFelipe GarciaNoch keine Bewertungen

- USAGI E 2 DepDokument2 SeitenUSAGI E 2 DeptakakihamasakiNoch keine Bewertungen

- QCOC 2762M88P01 Rev A, Int0Dokument1 SeiteQCOC 2762M88P01 Rev A, Int0nidhal kotorsiNoch keine Bewertungen

- Wiring Diagram Index: W WasDokument1 SeiteWiring Diagram Index: W WasCésar Arturo Pajuelo EspinozaNoch keine Bewertungen

- Plano Advance PDFDokument10 SeitenPlano Advance PDFjonatancgNoch keine Bewertungen

- 08000R33 PDFDokument1 Seite08000R33 PDFJoseph ArmstrongNoch keine Bewertungen

- C22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFDokument3 SeitenC22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFsartajNoch keine Bewertungen

- Earth resistance measurement report for rail depot construction projectDokument1 SeiteEarth resistance measurement report for rail depot construction projectsidharthNoch keine Bewertungen

- 330D and 336D Excavator Hydraulic System - Attachment: Machine Component LocationsDokument2 Seiten330D and 336D Excavator Hydraulic System - Attachment: Machine Component LocationsJoel RodríguezNoch keine Bewertungen

- Detail - Frame: Standard SymbolsDokument1 SeiteDetail - Frame: Standard SymbolsLallamaNoch keine Bewertungen

- Pioneer Xr-A550md SMDokument115 SeitenPioneer Xr-A550md SMDONNYNoch keine Bewertungen

- Bloemfontein Aerodrome Chart Provides Overview of Runways and TaxiwaysDokument1 SeiteBloemfontein Aerodrome Chart Provides Overview of Runways and Taxiwayss ramanNoch keine Bewertungen

- Reference List of Drawings: SwitchboardsDokument96 SeitenReference List of Drawings: SwitchboardsDINESH CHATAPNoch keine Bewertungen

- ES 3.06 15M 4.06 10M/15M BOP: User ManualDokument68 SeitenES 3.06 15M 4.06 10M/15M BOP: User Manualshahrol effendy rodziNoch keine Bewertungen

- Liferaft SR8Dokument130 SeitenLiferaft SR8ranggaNoch keine Bewertungen

- Aerodrome Chart Ad Elev 540 Lightning Ridge, NSW (Ylrd) : S29 27 24 E147 59 04 Pal+AfruDokument4 SeitenAerodrome Chart Ad Elev 540 Lightning Ridge, NSW (Ylrd) : S29 27 24 E147 59 04 Pal+AfrutadilakshmikiranNoch keine Bewertungen

- Service Bulletin: Remote Monitoring & Mees Group Energy Solution Department Engine & Energy DivisionDokument1 SeiteService Bulletin: Remote Monitoring & Mees Group Energy Solution Department Engine & Energy DivisionFalgon IslamNoch keine Bewertungen

- 2 X 660MW NCC POWER PROJECT VALVE SCHEDULEDokument53 Seiten2 X 660MW NCC POWER PROJECT VALVE SCHEDULEkkumar_717405Noch keine Bewertungen

- Umpco: CAGE CODE No. 18076 Part NumberDokument4 SeitenUmpco: CAGE CODE No. 18076 Part NumberFredNoch keine Bewertungen

- Srs z1Dokument8 SeitenSrs z1TrentungcaysoBombodealopNoch keine Bewertungen

- Crown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportDokument1 SeiteCrown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportYasar AliNoch keine Bewertungen

- SOGNDAL RNAV STAR CHARTDokument12 SeitenSOGNDAL RNAV STAR CHARTAurelien FLUTEAUXNoch keine Bewertungen

- 20kg-P&id (Sheet 2 of 3)Dokument1 Seite20kg-P&id (Sheet 2 of 3)naurizsultanov.fxNoch keine Bewertungen

- MS5002C BreakdownDokument245 SeitenMS5002C BreakdownElver Amesquita100% (2)

- MH-WH Instruction ManualDokument107 SeitenMH-WH Instruction Manualsercopetrol67% (6)

- Vciom 06208 enDokument18 SeitenVciom 06208 enElver AmesquitaNoch keine Bewertungen

- Cpi1000 Manl PDFDokument15 SeitenCpi1000 Manl PDFElver AmesquitaNoch keine Bewertungen

- Product Catalog: Circuit Protection ProductsDokument164 SeitenProduct Catalog: Circuit Protection Productsionn comNoch keine Bewertungen

- Circle: Basic Geometry With Circles 1Dokument67 SeitenCircle: Basic Geometry With Circles 1Avishkar JaiswalNoch keine Bewertungen

- Power and control cables for extreme applicationsDokument2 SeitenPower and control cables for extreme applicationsRachid SmailiNoch keine Bewertungen

- GSCC006 Rev3Dokument25 SeitenGSCC006 Rev3Palade CristiNoch keine Bewertungen

- 03-Lecture-Semiconductor DevicesDokument7 Seiten03-Lecture-Semiconductor DevicesAdnan Hyder SoomroNoch keine Bewertungen

- C5210HP Technical DataDokument9 SeitenC5210HP Technical Data顏健軒Noch keine Bewertungen

- 80 % Silver-20 % Graphite Sliding Contact Material: Standard Specification ForDokument2 Seiten80 % Silver-20 % Graphite Sliding Contact Material: Standard Specification ForROHITNoch keine Bewertungen

- User Manual: - Installation - OperationDokument76 SeitenUser Manual: - Installation - OperationKasun WeerasingheNoch keine Bewertungen

- Biomechanics of Hip Joint: A Review: Bhaskar Kumar MadetiDokument19 SeitenBiomechanics of Hip Joint: A Review: Bhaskar Kumar MadetiIrik PalaciosNoch keine Bewertungen

- Physics Assignment For Grade 9Dokument2 SeitenPhysics Assignment For Grade 9micahxNoch keine Bewertungen

- Structural Assessment of Corroded Reinforced Concrete Beams Modeling GuidelinesDokument11 SeitenStructural Assessment of Corroded Reinforced Concrete Beams Modeling GuidelinesnagarajuNoch keine Bewertungen

- Solar Swimming Pool HeatingDokument9 SeitenSolar Swimming Pool HeatingAtmesh PoudyalNoch keine Bewertungen

- Megger WEBinarDokument49 SeitenMegger WEBinarAnonymous V6y1QL6hn100% (1)

- Data Sheet Baterias 65AHDokument2 SeitenData Sheet Baterias 65AHWilson DominguezNoch keine Bewertungen

- Mobile Crane Operation & SafetyDokument55 SeitenMobile Crane Operation & SafetyBhavya ShuklaNoch keine Bewertungen

- 986K Wheel Loader Electrical System (Cab) 486-0964 Chassis and Engine (486-0965)Dokument6 Seiten986K Wheel Loader Electrical System (Cab) 486-0964 Chassis and Engine (486-0965)abduallah muhammadNoch keine Bewertungen

- HSSRPTR +1 Physics Notes KamilDokument104 SeitenHSSRPTR +1 Physics Notes KamilAswithNoch keine Bewertungen

- TL105 Test Lamp Manual For Optical Flame DetectorsDokument1 SeiteTL105 Test Lamp Manual For Optical Flame DetectorsArnulfo SanchezNoch keine Bewertungen

- Physics Revision Notes For Class 11Dokument13 SeitenPhysics Revision Notes For Class 11Gurunikesh S0% (1)

- Gold WikiDokument5 SeitenGold WikigergerwgNoch keine Bewertungen

- Chemistry Lab ManualDokument51 SeitenChemistry Lab Manualangel zoeNoch keine Bewertungen

- Analysis of The Flow Dynamics Characteristics of An Axial Piston Pump Based On The Computational Fluid Dynamics MethodDokument11 SeitenAnalysis of The Flow Dynamics Characteristics of An Axial Piston Pump Based On The Computational Fluid Dynamics MethodJose VeliNoch keine Bewertungen

- Assignment 1 Fluid Mechanics 1Dokument3 SeitenAssignment 1 Fluid Mechanics 1Right LuckNoch keine Bewertungen

- Angle Relationships in TrigonometryDokument10 SeitenAngle Relationships in Trigonometrydahlai dahlia oktaviani gintingNoch keine Bewertungen

- Carbon Black Production, Properties and Uses Production, Properties and UsesDokument308 SeitenCarbon Black Production, Properties and Uses Production, Properties and UsesJapan Polymers Analytical and Research LabNoch keine Bewertungen

- Grade 9 Quarter 4 DLL Science 9Dokument53 SeitenGrade 9 Quarter 4 DLL Science 9Willy TimbalNoch keine Bewertungen

- Introductory Hand Book For 1600HP AC-AC Demu For Loco Pilots - FINALDokument68 SeitenIntroductory Hand Book For 1600HP AC-AC Demu For Loco Pilots - FINALDinesh MehtaNoch keine Bewertungen

- ANSI C18.1M, Part 1-2001: For Portable Primary Cells and Batteries With Aqueous Electrolyte - General and SpecificationsDokument64 SeitenANSI C18.1M, Part 1-2001: For Portable Primary Cells and Batteries With Aqueous Electrolyte - General and SpecificationsSeenivasagam SeenuNoch keine Bewertungen

- Chem 213 Module 5A-Aqueous Soln and Chemical EquilibriaDokument7 SeitenChem 213 Module 5A-Aqueous Soln and Chemical EquilibriaNatalie GaidNoch keine Bewertungen

- PLT Test (Astm d1196)Dokument113 SeitenPLT Test (Astm d1196)Rango SantosoNoch keine Bewertungen