Beruflich Dokumente

Kultur Dokumente

ML 30, MLO 30 (1417G-English) PDF

Hochgeladen von

EESL AACOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ML 30, MLO 30 (1417G-English) PDF

Hochgeladen von

EESL AACCopyright:

Verfügbare Formate

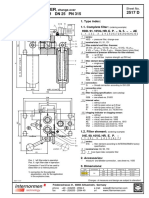

PRESSURE FILTER Sheet No.

Series ML 30, MLO 30 DN 6 PN 160 1417 G

1. Type index:

1.1. Complete filter: (ordering example)

ML. 30. 10VG. HR. E. P. -. G. 1. -. AE

1 2 3 4 5 6 7 8 9 10 11

1 series:

ML = in-line filter-medium pressure range

with indicator

MLO = in-line filter-medium pressure range

without indicator

2 nominal size: 30

3 filter-material and filter-fineness:

80 G = 80 m, 40 G = 40 m, 25 G = 25 m

stainless steel wire mesh

25 VG= 20 m(c), 16 VG= 15 m(c), 10 VG= 10 m(c),

6 VG = 7 m(c), 3 VG = 5 m(c) Interpor fleece (glass fibre)

4 resistance of pressure difference for filter element:

30 = p 30 bar

HR = p 160 bar (rupture strenght p 250 bar)

5 filter element design:

E = single-end open

6 sealing material:

P = Nitrile (NBR)

V = Viton (FPM)

7 filter element specification: (see catalog)

- = standard

VA = stainless steel

IS06 = see sheet-no. 31601

8 connection:

G = thread connection according to ISO 228

9 connection size:

1 = G¼

10 filter housing specification: (see catalog)

- = standard

IS06 = see sheet-no. 31605

11 clogging indicator or clogging sensor:

series MLO:

- = without

series ML:

AOR = visual, see sheet-no. 1606

AOC = visual, see sheet-no. 1606

AE = visual-electrical, see sheet-no. 1615

VS1 = electronical, see sheet-no. 1617

VS2 = electronical, see sheet-no. 1618

1.2. Filter element: (ordering example)

01E. 30. 10VG. HR. E. P. -

1 2 3 4 5 6 7

1 series:

01E. = filter element according to company standard

2 nominal size: 30

3 - 7 see type index-complete filter

weight without indicator: approx. 1,1 kg

weight with indicator : approx. 1,3 kg

EDV 08/12 Changes of measures and design are subject to alteration!

Friedensstrasse 41, 68804 Altlussheim, Germany

phone +49 - (0)6205 - 2094-0 e-mail info-internormen@eaton.com

fax +49 - (0)6205 - 2094-40 url www.eaton.com/filtration

2. Spare parts:

item qty. designation dimensions article-no.

1 1 filter element 01E.30

2 1 O-ring 11 x 3 312603 (NBR) 312727 (FPM)

3 1 O-ring 32 x 2,5 306843 (NBR) 308268 (FPM)

4 1 support ring 37 x 2,1 x 1 305466

5 1 clogging indicator, visual AOR or AOC see sheet-no. 1606

6 1 clogging indicator, visual-electrical AE see sheet-no. 1615

7 1 clogging sensor, electronical VS1 see sheet-no. 1617

8 1 clogging sensor, electronical VS2 see sheet-no. 1618

9 1 O-ring 15 x 1,5 315357 (NBR) 315427 (FPM)

10 1 O-ring 22 x 2 304708 (NBR) 304721 (FPM)

11 1 O-ring 14 x 2 304342 (NBR) 304722 (FPM)

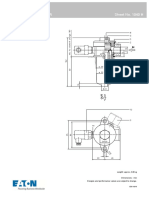

3. Description:

Pressure filter of the series ML 30 and MLO 30 are suitable for a working pressure up to 160 bar.

The pressure peaks are absorbed by a sufficient margin of safety. The filter is in-line mounted.

The filter element consists of star-shaped, pleated filter material which is supported on the inside by a perforated core tube and is

bonded to the end caps with a high-quality adhesive. The flow direction is from outside to inside.

Filter elements are available down to 4 m(c).

Internormen Product Line filter elements are known as elements with a high intrinsic stability and an excellent filtration capability, a

high dirt-retaining capacity and a long service life.

Internormen Product Line filter are suitable for all petroleum based fluids, HW-emulsions, most synthetic hydraulic fluids and

lubrication oils.

Internormen Product Line filter elements are available up to a pressure difference resistance of p 160 bar and a rupture strength of p

250 bar.

4. Technical data:

temperature range: -10°C to + 80°C (for a short time + 100°C)

operating medium: mineral oil, other media on request

max. operating pressure: 160 bar

test pressure: 229 bar

connection system: thread connection according to ISO 228

housing material: Al; C-steel

sealing material: Nitrile (NBR) or Viton (FPM), other materials on request

installation position: vertical

volume tank: 0,1 l

Classified under the Pressure Equipment Directive 97/23/EC for mineral oil (fluid group 2), Article 3, Para. 3.

Classified under ATEX Directive 94/9/EC according to specific application (see questionnaire sheet-no. 34279-4).

5. Symbols:

without with electrical with visual-electrical with visual-electrical with visual with electronical with electronical

indicator indicator indicator indicator indicator clogging sensor clogging sensor

AE 30 and AE 40 AE 50 and AE 62 AE 70 and AE 80 AOR/AOC VS1 VS2

6. Pressure drop flow curves: Precise flow rates see ‘Interactive Product Specifier’, respectively p-curves - depending

on filter fineness and viscosity.

7. Test methods: Filter elements are tested according to the following ISO standards:

ISO 2941 Verification of collapse/burst resistance

ISO 2942 Verification of fabrication integrity

ISO 2943 Verification of material compatibility with fluids

ISO 3723 Method for end load test

ISO 3724 Verification of flow fatigue characteristics

ISO 3968 Evaluation of pressure drop versus flow characteristics

ISO 16889 Multi-pass method for evaluating filtration performance

E 1417 G

Das könnte Ihnen auch gefallen

- Filter Unit, Series UM 80 58 PSIDokument2 SeitenFilter Unit, Series UM 80 58 PSIAzmi AhmadNoch keine Bewertungen

- Filter Unit, Series UM 125 58 PSIDokument2 SeitenFilter Unit, Series UM 125 58 PSIhadNoch keine Bewertungen

- Fisa Tehnica Filtru Internormen Hdd61-151Dokument2 SeitenFisa Tehnica Filtru Internormen Hdd61-151RizzoRo1Noch keine Bewertungen

- Fisa Tehnica Filtru Internormen hdd61-151 PDFDokument2 SeitenFisa Tehnica Filtru Internormen hdd61-151 PDFRizzoRo1Noch keine Bewertungen

- PCT 1107278Dokument2 SeitenPCT 1107278Ajaya RimalNoch keine Bewertungen

- Filter Unit, Series UM 40 PN4: MobileDokument2 SeitenFilter Unit, Series UM 40 PN4: MobileAmar KevricNoch keine Bewertungen

- PCT 3557915Dokument4 SeitenPCT 3557915earquaz23Noch keine Bewertungen

- Pressure Filter, Series DA 2215: Nps 4" Class 150 PsiDokument2 SeitenPressure Filter, Series DA 2215: Nps 4" Class 150 PsiRidha AbbassiNoch keine Bewertungen

- Series TSW 210-310: SUCTION FILTER, Horizontal Tank Mounted Sheet No. 1905 JDokument4 SeitenSeries TSW 210-310: SUCTION FILTER, Horizontal Tank Mounted Sheet No. 1905 Jsanjay0910Noch keine Bewertungen

- (NBR)Dokument4 Seiten(NBR)Youghorta TIRNoch keine Bewertungen

- Edu251 401Dokument2 SeitenEdu251 401ckmuneesNoch keine Bewertungen

- Series DA 103 NPS 1" CLASS 150-300 PSI: PRESSURE FILTER, Change Over Sheet No. 2213ADokument43 SeitenSeries DA 103 NPS 1" CLASS 150-300 PSI: PRESSURE FILTER, Change Over Sheet No. 2213Avictor abrajanNoch keine Bewertungen

- 06-2 Data Sheet Oil FilterDokument2 Seiten06-2 Data Sheet Oil FilterAnonymous 9WNqHZNoch keine Bewertungen

- Series TNRS 101 DN25 PN10: RETURN LINE FILTER, With Suction Connection Sheet No. 1070 LDokument4 SeitenSeries TNRS 101 DN25 PN10: RETURN LINE FILTER, With Suction Connection Sheet No. 1070 LRaid BekaltiNoch keine Bewertungen

- Линейные фильтры 40..160 LEDokument6 SeitenЛинейные фильтры 40..160 LEDelio Rafael Sánchez FernandezNoch keine Bewertungen

- 9900 Series DatasheetDokument3 Seiten9900 Series DatasheetHans HongNoch keine Bewertungen

- Duplex Filter PDFDokument4 SeitenDuplex Filter PDFmd abNoch keine Bewertungen

- Series TEF 41 DN15 PN10: Return Line Filter Sheet No. 1040 HDokument4 SeitenSeries TEF 41 DN15 PN10: Return Line Filter Sheet No. 1040 Hnemi90Noch keine Bewertungen

- Spin OnDokument2 SeitenSpin OntarobaclashNoch keine Bewertungen

- Internormen Eaton 2Dokument8 SeitenInternormen Eaton 2augusto cesarNoch keine Bewertungen

- RF Return Line FilterDokument8 SeitenRF Return Line Filterboobalan_shriNoch keine Bewertungen

- Pressure Transmitter Specification Sheet: GeneralDokument2 SeitenPressure Transmitter Specification Sheet: GeneralCesar Santiago Marquez YanezNoch keine Bewertungen

- Filtro Hidráulico Pi3000 MahleDokument7 SeitenFiltro Hidráulico Pi3000 MahleHIDRAFLUIDNoch keine Bewertungen

- Low / Medium Pressure Duplex Filter Type: 40/160-LD/LDN: Filters - AccumulatorsDokument8 SeitenLow / Medium Pressure Duplex Filter Type: 40/160-LD/LDN: Filters - AccumulatorsPietro ChiocchiNoch keine Bewertungen

- LF 251-1100 - D300483Dokument2 SeitenLF 251-1100 - D300483Anshuman AgrawalNoch keine Bewertungen

- Filtro HydacDokument2 SeitenFiltro HydacWendel AndradeNoch keine Bewertungen

- Medium Pressure Filter: 1. FeaturesDokument8 SeitenMedium Pressure Filter: 1. Featuresdhanunjay vadlapudiNoch keine Bewertungen

- Filtro Hidráulico Pi260 MahleDokument6 SeitenFiltro Hidráulico Pi260 MahleHIDRAFLUIDNoch keine Bewertungen

- ME (Parker DF60 Duplex Filter F160 - 40 I - v1)Dokument7 SeitenME (Parker DF60 Duplex Filter F160 - 40 I - v1)TuyenNoch keine Bewertungen

- HK OIM Fil 314 Rev10.15Dokument12 SeitenHK OIM Fil 314 Rev10.15Ingeniería AplicacionesNoch keine Bewertungen

- Hydac Return Line Filter RFDDokument4 SeitenHydac Return Line Filter RFDCarlos Andrés CuelloNoch keine Bewertungen

- ReF - Cruzada StauffDokument64 SeitenReF - Cruzada StauffFrederico MaiaNoch keine Bewertungen

- Eaton Hydraulic Lubrication Oil Filters Technical Data Catalog PDFDokument405 SeitenEaton Hydraulic Lubrication Oil Filters Technical Data Catalog PDFMahesh DegaonkarNoch keine Bewertungen

- Eaton Hydraulic Lubrication Oil Filters Technical Data Catalog PDFDokument405 SeitenEaton Hydraulic Lubrication Oil Filters Technical Data Catalog PDFjithanNoch keine Bewertungen

- Data Sheet For Gas FilterDokument1 SeiteData Sheet For Gas FilterKhánh TrầnNoch keine Bewertungen

- Dripk 1608: Applications SpecificationsDokument2 SeitenDripk 1608: Applications SpecificationsDiego GómezNoch keine Bewertungen

- Offline Filter Pressure Olfp 1 / 3 / 6: Description Technical DetailsDokument4 SeitenOffline Filter Pressure Olfp 1 / 3 / 6: Description Technical DetailsAnwar DeenNoch keine Bewertungen

- Eaton Filter Elements Overview Brochure US LowResDokument8 SeitenEaton Filter Elements Overview Brochure US LowResAzmi AhmadNoch keine Bewertungen

- Pressure Filter For Sandwich Stacking DFZ: Up To 80 L/min, Up To 315 BarDokument4 SeitenPressure Filter For Sandwich Stacking DFZ: Up To 80 L/min, Up To 315 BarbetancralNoch keine Bewertungen

- Re 51400Dokument14 SeitenRe 51400Jamin Smtpng0% (1)

- KS 159590 Concatenate 54261142Dokument42 SeitenKS 159590 Concatenate 54261142Raddy SantosoNoch keine Bewertungen

- Filtro Hidráulico Pi2300 MahleDokument5 SeitenFiltro Hidráulico Pi2300 MahleHIDRAFLUIDNoch keine Bewertungen

- Inline Filter DFN/LFN/LFNF To DIN 24550: Up To 400 L/min, Up To 400 BarDokument4 SeitenInline Filter DFN/LFN/LFNF To DIN 24550: Up To 400 L/min, Up To 400 BarAmitNoch keine Bewertungen

- Filtro Hidráulico Pi150 MahleDokument6 SeitenFiltro Hidráulico Pi150 MahleHIDRAFLUIDNoch keine Bewertungen

- Cooling Air Blower DatasheetDokument1 SeiteCooling Air Blower Datasheetcv.ekaputra 04Noch keine Bewertungen

- Tank Top Return-Line Filter: 1. FeaturesDokument8 SeitenTank Top Return-Line Filter: 1. FeaturesLuisFranciscoMarinMedranoNoch keine Bewertungen

- Re26411 2010-08Dokument24 SeitenRe26411 2010-08wag008Noch keine Bewertungen

- 1145 Series: Medium Pressure FiltersDokument8 Seiten1145 Series: Medium Pressure FiltersRangga NugrahaNoch keine Bewertungen

- Solenoid Controlled Relief ValvesDokument10 SeitenSolenoid Controlled Relief ValvesRenjithSivaNoch keine Bewertungen

- Dripk 5010: Applications SpecificationsDokument2 SeitenDripk 5010: Applications SpecificationsDiego GómezNoch keine Bewertungen

- Solenoid Operated Valves Pilot Operated Poppet Type 2-Way Normally Closed Common Cavity, Size 12Dokument4 SeitenSolenoid Operated Valves Pilot Operated Poppet Type 2-Way Normally Closed Common Cavity, Size 12AndryNoch keine Bewertungen

- Solenoid Operated Valves Pilot Operated Poppet Type 2-Way Normally Closed Common Cavity, Size 12Dokument4 SeitenSolenoid Operated Valves Pilot Operated Poppet Type 2-Way Normally Closed Common Cavity, Size 12AndryNoch keine Bewertungen

- Intro PF en V4Dokument6 SeitenIntro PF en V4plasticos_jfm6580Noch keine Bewertungen

- Duplex-40 - 160-LD - Nov'11Dokument6 SeitenDuplex-40 - 160-LD - Nov'11Sagar NaduvinamaniNoch keine Bewertungen

- Tank Top Return Line Filter Pi 5000 Nominal Size 160 1000 According To Din 24550Dokument8 SeitenTank Top Return Line Filter Pi 5000 Nominal Size 160 1000 According To Din 24550Mauricio Ariel H. OrellanaNoch keine Bewertungen

- Pressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10Dokument2 SeitenPressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10tecnicomanelNoch keine Bewertungen

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Dokument8 SeitenUsing The ASME VIII-1 Nozzle F Factor (UG-37)Liu YangtzeNoch keine Bewertungen

- Duplex Filter: 1. FeaturesDokument6 SeitenDuplex Filter: 1. Featuresmostafa aliNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- 2 HP SpecificationDokument1 Seite2 HP SpecificationEESL AACNoch keine Bewertungen

- NTPC Limited: Signature Not VerifiedDokument3 SeitenNTPC Limited: Signature Not VerifiedEESL AACNoch keine Bewertungen

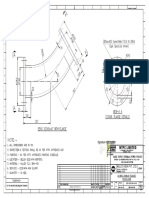

- Drawing 90 Degree 4 InchDokument2 SeitenDrawing 90 Degree 4 InchEESL AACNoch keine Bewertungen

- Ci Bend 90 Degx50nbDokument1 SeiteCi Bend 90 Degx50nbEESL AACNoch keine Bewertungen

- GA of Brakes 9571-155-PVM-B-201-01 PDFDokument5 SeitenGA of Brakes 9571-155-PVM-B-201-01 PDFEESL AACNoch keine Bewertungen

- Ik Fenner Belt2Dokument7 SeitenIk Fenner Belt2EESL AACNoch keine Bewertungen

- O & M Manual For Boiler Circulation Pump (BCP)Dokument247 SeitenO & M Manual For Boiler Circulation Pump (BCP)EESL AAC75% (4)

- Masoneilan 51 52 53 Cylinder ActuatorDokument24 SeitenMasoneilan 51 52 53 Cylinder ActuatorEESL AACNoch keine Bewertungen

- Data Sheet-Coarse Ash PumpDokument6 SeitenData Sheet-Coarse Ash PumpEESL AACNoch keine Bewertungen

- BSI-British Standard ValvesDokument3 SeitenBSI-British Standard ValvesVincent RajNoch keine Bewertungen

- Design, Development, and Analysis of A Densely Packed 500x Concentrating Photovoltaic Cell Assembly On Insulated Metal SubstrateDokument14 SeitenDesign, Development, and Analysis of A Densely Packed 500x Concentrating Photovoltaic Cell Assembly On Insulated Metal SubstrateEESL AACNoch keine Bewertungen

- AAA Catalogue - 17-18 PDFDokument56 SeitenAAA Catalogue - 17-18 PDFEESL AACNoch keine Bewertungen

- AAA Catalogue - 17-18 PDFDokument56 SeitenAAA Catalogue - 17-18 PDFEESL AACNoch keine Bewertungen

- DDTW Properties For High Strength Line Pipe SteelsDokument5 SeitenDDTW Properties For High Strength Line Pipe SteelsWagner Duarte FloresNoch keine Bewertungen

- DMRC DBR Viaduct-Ph. III Latest-9-2Dokument29 SeitenDMRC DBR Viaduct-Ph. III Latest-9-2Tarun Kant GoyalNoch keine Bewertungen

- O&m BW211 BW212Dokument124 SeitenO&m BW211 BW212Ricardo Portal70% (10)

- Asme B31.8-2007Dokument6 SeitenAsme B31.8-2007SUHANI CHANDELNoch keine Bewertungen

- Comparision of Fabrication TolerancesDokument4 SeitenComparision of Fabrication TolerancesSatish Keskar100% (1)

- 26 Type Brake EquipmentsDokument8 Seiten26 Type Brake EquipmentsRafael SchelbauerNoch keine Bewertungen

- 2007 Ford Fusion Owners ManualDokument280 Seiten2007 Ford Fusion Owners Manualmetroroad100% (1)

- Split Type AcuDokument40 SeitenSplit Type AcuKristine Ann ReclosadoNoch keine Bewertungen

- ThermodynamicsDokument7 SeitenThermodynamicsRaj BoligorNoch keine Bewertungen

- Power ScrewDokument37 SeitenPower ScrewShikhar Saurav100% (1)

- Ash HandlingDokument3 SeitenAsh HandlingAi VietNoch keine Bewertungen

- SID97-2B: Service Information DirectiveDokument26 SeitenSID97-2B: Service Information Directivefranco lopezNoch keine Bewertungen

- FRR 500 - 500S Igm0087 - 6-CylDokument4 SeitenFRR 500 - 500S Igm0087 - 6-CylMarvin White0% (1)

- Seismic Evaluation of Vertically Irregular Building Frames With Stiffness, Strength, Combined-Stiffness-And-Strength and Mass IrregularitiesDokument22 SeitenSeismic Evaluation of Vertically Irregular Building Frames With Stiffness, Strength, Combined-Stiffness-And-Strength and Mass Irregularitiesjorge david zumaran riveraNoch keine Bewertungen

- Piston Rings GuideDokument5 SeitenPiston Rings GuideAshok BishtNoch keine Bewertungen

- MFC 18M 2001Dokument18 SeitenMFC 18M 2001Joel CieltoNoch keine Bewertungen

- Review On Comparative Analysis of PSC Box Girder Bridge and PSC Precast I Girder Bridge StructureDokument11 SeitenReview On Comparative Analysis of PSC Box Girder Bridge and PSC Precast I Girder Bridge StructureIJRASETPublicationsNoch keine Bewertungen

- Selectrode: Non-Machinable Cast IronDokument2 SeitenSelectrode: Non-Machinable Cast IronAlvaro Fernando Reyes CastañedaNoch keine Bewertungen

- (Logistics Team) PDO Oilfield Transport & Interior Based Vehicle SpecificationsDokument22 Seiten(Logistics Team) PDO Oilfield Transport & Interior Based Vehicle SpecificationsVenkatesha HebbarNoch keine Bewertungen

- Dimensions of Spades and Ring Spacers ASME B16.48Dokument11 SeitenDimensions of Spades and Ring Spacers ASME B16.48Angs TazNoch keine Bewertungen

- Globalpmc - Doc - Rev 4Dokument51 SeitenGlobalpmc - Doc - Rev 4Salman HussainNoch keine Bewertungen

- Delta Sw4: Controlled Compression of Seat SealDokument2 SeitenDelta Sw4: Controlled Compression of Seat SealjhongonzalezgonzalezNoch keine Bewertungen

- MCL 311 Lab 4 PDFDokument29 SeitenMCL 311 Lab 4 PDFAditya SheoranNoch keine Bewertungen

- UNIT I Gas Power Cycles FinalDokument75 SeitenUNIT I Gas Power Cycles FinalMAYUR BHOSALENoch keine Bewertungen

- v1903 2203tvengineDokument46 Seitenv1903 2203tvenginehuo sun100% (1)

- Gearbox Failure of Large Gas Turbine Generator Case StudyDokument2 SeitenGearbox Failure of Large Gas Turbine Generator Case StudyJesusNoch keine Bewertungen

- Cummins QSK 23 Fuel Shutoff ValveDokument8 SeitenCummins QSK 23 Fuel Shutoff ValvePedro Schembri100% (1)

- Theoretical Model of Buoyancy-Induced Heat Transfer in Closed Compressor RotorsDokument7 SeitenTheoretical Model of Buoyancy-Induced Heat Transfer in Closed Compressor RotorsmhjianNoch keine Bewertungen

- PW130 7Dokument24 SeitenPW130 7Csongor Molnár100% (1)

- Fabrication Erection and Installation Procedure For PipingDokument36 SeitenFabrication Erection and Installation Procedure For Pipinggst ajah100% (2)