Beruflich Dokumente

Kultur Dokumente

Seminar Special Casting

Hochgeladen von

Ajith Sreenath0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

120 Ansichten16 SeitenAll metals may be cast in sand moulds and there is no limitation about the size of the casting which can be made. Sand casting is single purpose moulds as they are destroyed after the casting has been removed from the moulding box. The use of a permanent mould casting would do a considerable saving in labor cost of mould making.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAll metals may be cast in sand moulds and there is no limitation about the size of the casting which can be made. Sand casting is single purpose moulds as they are destroyed after the casting has been removed from the moulding box. The use of a permanent mould casting would do a considerable saving in labor cost of mould making.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

120 Ansichten16 SeitenSeminar Special Casting

Hochgeladen von

Ajith SreenathAll metals may be cast in sand moulds and there is no limitation about the size of the casting which can be made. Sand casting is single purpose moulds as they are destroyed after the casting has been removed from the moulding box. The use of a permanent mould casting would do a considerable saving in labor cost of mould making.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 16

A

SEMINAR

ON

SPECIAL

CASTING

S

Shell molding

and investment

casting

K N KRISHNAN

NAMBEESAN

ROLL NO: 7

MTECH ,SOE CUSAT

INTRODUCTION

All metals may be cast in sand moulds and

there is no limitation about the size of the

casting which can be made.

Sand casting is having wide applications

(because of low cost)\ however, sand moulds

are single purpose moulds as they are

completely destroyed after the casting has

been removed from the moulding box.

The use of a permanent mould casting would

do a considerable saving in labor cost of

mould making.

Special casting methods are not commonly

employed because of their high initial cost

however special casting methods have

following advantages over conventional sand

casting.

• High production rates.

• Lower production cost.

• Better surface finish.

• Denser and fine grain structure.

• Greater dimensional accuracy.

• More ductile.

• Good quality (less defects).

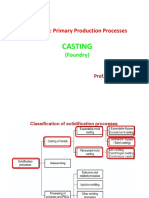

Classification of special casting

Metal Mould Casting-

(a) Gravity die or permanent mould casting.

(b) Die casting: Hot chamber process, cold

chamber process. (c), Slush casting. ,.

(d) Pressed or corthias casting.

2. Non-Metallic, Mould- Casting

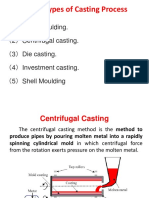

(a) Centrifugal casting

• True centrifugal casting.

• Semi centrifugal casting.

• Centrifuge casting.

(b) Carbon dioxide moulding

(c) Investment mould casting or lost wax

process or precision casting

(d) Shell moulding

(e) Plaster moulding.

3 Continuous Casting

(a) Reciprocating moulds

(b) Stationary moulds

(c) Direct sheet casting.

INVESTMENT CASTING OR LOST WAX

PROCESS OR PRECISION CASTING

This process uses wax pattern which is

subsequently melted from the mould, leaving

a cavity having all the details of the original

pattern (required casting).

1. Pattern wax is injected into metal die to

form a dispensable pattern.

2. Gating Patterns are gated to a sprue to

form a tree or cluster, and base of the

pattern material is attached to the tree.

3. (a) Solid Pattern : A metal flask is put over

the cluster of pattern and sealed to a base

plate to form a container. A hard setting

moulding material is then poured into the

flask, completing the pattern cluster

completely.

(b) Shell Pattern: The ceramic shell is formed

by dipped the clustered patterns in ceramic

slurry and then sprinkling them with a

refractory grain. This procedure is repeated

until the required thickness of the shell is

achieved.

4. Pattern Removal : The flask and shells are

then placed in ovens to bake at a moderate

temperature in order to slowly melt the

embedded patterns. The cavity left in the

mould will receive the poured molten metal.

5. Casting : The flask or shell is inverted and

the metal is poured into the hot mould.

Investment Casting Process.

Procedure

1. Producing a die for making wax pattern

• Dies may be made either by machining

cavities in two or more matching blocks of

steels

or by casting a low melting point alloy around

a (metal) master pattern.

• Dies halves are then sent for necessary

machining and drilling the gate through

which

wax is to be injected for preparing

expendable patterns (wax, plastic, tin, frozen

mercury

in merest process but wax is more commonly

used).

2. Making wax patterns

• The die halves are closed and properly

clamped.

• Molten wax is then forced into die, under

pressure, by means of a wax injection

machine. • Allow cooling and

solidification.

• The die is then opened and the pattern is

removed.

• A lubricant is then sprayed on to the die

surfaces and the same is closed for

casting the next wax pattern (therefore

one wax pattern is used for one piece

only).

3. Assembling the wax patterns

Assemble a number of small wax patterns to

a common wax gating system so that they

can be placed together in one mould (to

increase the. production).

4. Precoating the pattern assembly

• The wax pattern assembly is dipped into a

slurry of a refractory coating material.

A typical slurry consists of 325-mesh silica

flour suspended in a ethyl silicate solution.

• Wax pattern assembly is next, sprinkled

with 40 to 50 AFS (American Foundry

Society) silica sand and is permitted to

dry.

Investing the, wax pattern assembly for

the production of moulds

• This is done by inverting the wax assembly

on the bottom board, surrounding it with a

Paper lined steel flask and pouring the

investment moulding mixture around the

pattern.

The mould material settles by gravity and

completely surround,/the pattern as the work

table is vibrated.

• The moulds are then allowed to dry in air

for 2 to 3 hours.

Removal of wax pattern

• The wax pattern can be removed from

the mould by two methods

• Place the mould in a furnace in an

inverted position i.e. the sprue

downwards. The wax is melted out due to

heat and collected for reuse."

• In other method, mould is placed in-a

bath of trichloromethylene vapours which

also enable the recovery of wax for reuse.

Pouring and casting

• The mould is again heated at the rate of

40 00 to 70 °C per hour from about 150

°C to 1000 °C for ferrous alloys and 650

°C aluminum alloys.

• Preheating is done

— To remove the wax if any.

— It helps the metal to flout easily and fill up

properly.

— It causes expansion of the mould.

After preheating, the metal is poured into the

investment mould under simple gravitational

force or under the force of applied air

pressure or by centrifugal force.

Cleaning, finishing and inspection

• Each casting is separated from the

assembly and the gates, runner etc. are

removed. • Finishing and inspection of

casting is done.

Advantages of Investment Casting

• High dimensional accuracy of the order of

± 0.08 mm can be attained. ^ A very

smooth surface without parting line.

• Machining can be eliminated.

• Very thin sections can be cast easily (0.76

mm).

• Complex contours and intricate shapes

can be easily cast.

• Die castings can be replaced when short

runs are involved.

• Castings are sound and have large grains

as the rate of cooling is slow. • Complex

shapes are possible because pattern is

withdrawn by melting it.

Disadvantages of Investment Casting

• The process is suitable for small size

parts.

• This is a more expensive process.

• Process is relatively slow.

• Pattern is expendable, one wax pattern is

required to make one investment casting.

• The use of cores make the process more

difficult.

Application of Investment Casting

• Parts for sewing machines, locks, rifles,

burner nozzles, milling cutters and of

tools, jewellery and art casting.

• in dentistry and surgical implants:

• Parts of gas turbines.

• Corrosion resistant and wear resistant

alloy parts used in diesel engines, picture

and chemical industry equipments.

SHELL MOULDING .

Introduction

It is a process in which, the sand mixed with

a thermosetting resin is allowed to contact

with a heated metallic pattern plate, so that

a thin and strong shell of mould around the

pattern. Then the shell is removed from the

pattern and the cope and removed together

and kept in a flask with the necessary back

up material. After that metal is poured into

this mould.

Procedure

A metal pattern, heated to about 175°C

to 350°C, is clamped over a box .Molding

sand mixed with thermosetting resin such

* as phenol formaldehyde, urea formal

polyesters., is partially filled .

The box and pattern are inverted for a

short time. The mixture when comes with

hot pattern, it causes an initial set and

builds up a coherent sand shell pattern.

The thickness of this shell is about 6 mm

to -18 mm and,. is depends on pattern

temperature and the sand mixture. This

takes 5 to 20 seconds only.

• The box and pattern are brought in its

original position. The shell of resin

bonded sand is retained on the pattern

surface, while the unaffected sand falls

into box. The shell, still on the pattern is

cured by heating it in an oven from 250°C

to 350°C for 1 to 3 minutes.

• The assembly is removed from the oven

and the shell is stripped from the pattern

by ejector pins. In order to obtain clean

stripping, a silicon parting agent may be

sprayed on the pattern.

• The shell halves are assembled with

clamps and supported in a flask with

backing material. The shell mould is now

ready for pouring.

Advantages of Shell Moulding

Suitable for thin sections.

Surface finish obtained is excellent.

Good dimensional accuracy (Tolerance =

0.002 to 0.003 mm per mm). Less floor

space.

It can be easily machined and machining

and cleaning cost is negligible.

The total sand used is only 5 to 10% that

of green sand mould. The moulds can be

stored until required.

Less skilled labor is required.

Cooling rate of cast metal is slow so

larger gain size.

Disadvantages of Shell Moulding

Initial cost of pattern and sand is high.

Special equipments are to be used.

Reuse of sand is difficult.

Maximum size of casting is limited.

Minimum thickness of the section that

can be cast is 4 mm.

Certain casting shapes are unsuitable

when proper parting and gating are not

available.

Applications of Shell Moulding

o It is well suited to ferrous and non ferrous

alloys castings in the range of 0.1 to 10

kg.

o Alloys that can be cast by shell moulding

are aluminum alloys, copper alloys, cast

irons, stainless steels etc.

o Components cast by shell moulding are

small pipes, cam shafts, bushings

Reference

• Manufacturing process – S K Garg

• Manufacturing Engg Technology –

Serope Kalpakjian & Steven R Schimid

• http://www.deangroup-int.co.uk/

Das könnte Ihnen auch gefallen

- 7 - Special Casting ProcessesDokument21 Seiten7 - Special Casting ProcessesSaniyahNoch keine Bewertungen

- Module 3 - Casting Processes OverviewDokument18 SeitenModule 3 - Casting Processes OverviewGoutham ReddyNoch keine Bewertungen

- You CanDokument70 SeitenYou Canananda narayananNoch keine Bewertungen

- Special CastingDokument24 SeitenSpecial CastingManohara ErlaNoch keine Bewertungen

- Investment Casting ProcessesDokument10 SeitenInvestment Casting ProcessesPragyan Kumar PradhanNoch keine Bewertungen

- Advannced Manufacturing Process. Module 1Dokument61 SeitenAdvannced Manufacturing Process. Module 1Thomas TharakanNoch keine Bewertungen

- Casting Procedure StepsDokument185 SeitenCasting Procedure StepsPraffulla Mynampati100% (1)

- Casting Design and Process OptimizationDokument20 SeitenCasting Design and Process OptimizationCHANDRAJEET AMARNoch keine Bewertungen

- Special Casting ProcessDokument9 SeitenSpecial Casting ProcessChaitanya SadhanNoch keine Bewertungen

- DM-1 CO-1 Special Castings MaterialDokument9 SeitenDM-1 CO-1 Special Castings MaterialSree vishnu Sai chandan guntupalliNoch keine Bewertungen

- Molding by Shell, Die & Investment Casting: 08120033 08120009 08120021 Metallurgy 6 SemesterDokument26 SeitenMolding by Shell, Die & Investment Casting: 08120033 08120009 08120021 Metallurgy 6 SemesterSANTOSH KUMARNoch keine Bewertungen

- BMP Report G6Dokument3 SeitenBMP Report G6Damage SinghNoch keine Bewertungen

- Dr. Chaitanya Sharma Phd. Iit RoorkeeDokument40 SeitenDr. Chaitanya Sharma Phd. Iit RoorkeeTrung Quoc LeNoch keine Bewertungen

- Moulding ProcessesDokument10 SeitenMoulding ProcessesChinmay Das67% (3)

- Unit - I-Manu Tech-IDokument38 SeitenUnit - I-Manu Tech-IMareeswaran Maruthamuthu MNoch keine Bewertungen

- Cast Automobile PartsDokument52 SeitenCast Automobile PartsnunuNoch keine Bewertungen

- Metallic Materials Casting and Sintering ProcessesDokument23 SeitenMetallic Materials Casting and Sintering ProcessesgayeNoch keine Bewertungen

- Suresh 2261Dokument9 SeitenSuresh 226109m008_159913639Noch keine Bewertungen

- Expendable Moulding ProcessDokument52 SeitenExpendable Moulding ProcessSmart AkkiNoch keine Bewertungen

- Dr. Ahmed Khalifa Ahmed - Khalifa@mhiet - Edu.egDokument46 SeitenDr. Ahmed Khalifa Ahmed - Khalifa@mhiet - Edu.egØŠMÄÑ MØHÂMĒDNoch keine Bewertungen

- FOUNDRY WORKSHOP ASSESSMENT PROJECTDokument27 SeitenFOUNDRY WORKSHOP ASSESSMENT PROJECTSahil YadavNoch keine Bewertungen

- Chapter Four 4.special Casting Processes: Introduction Contents To Be IncludedDokument76 SeitenChapter Four 4.special Casting Processes: Introduction Contents To Be IncludedberhaneNoch keine Bewertungen

- Chapter 4Dokument16 SeitenChapter 4Anteneh AssefaNoch keine Bewertungen

- Casting Procedures and Casting DefectsDokument70 SeitenCasting Procedures and Casting DefectsRohan Grover100% (1)

- Special CastingDokument46 SeitenSpecial CastingJith Viswa100% (1)

- 4.0 Metal Casting ProcessDokument48 Seiten4.0 Metal Casting ProcessSyed MoizNoch keine Bewertungen

- Cast 2Dokument77 SeitenCast 2yash guptaNoch keine Bewertungen

- Sp. Casting ProcessesDokument71 SeitenSp. Casting Processesakshatkumargarg 2K20PE09Noch keine Bewertungen

- CASTING DEFECTS AND PROCEDURESDokument53 SeitenCASTING DEFECTS AND PROCEDURESዘረአዳም ዘመንቆረርNoch keine Bewertungen

- Metal Casting 1Dokument44 SeitenMetal Casting 1PIYUSH SHARMANoch keine Bewertungen

- 2,. CastingDokument37 Seiten2,. Castingmohit s sNoch keine Bewertungen

- 9 19 01 2023Dokument21 Seiten9 19 01 2023keshavkoolwalNoch keine Bewertungen

- MOdule II 2 PageDokument2 SeitenMOdule II 2 PageVyshakh SunilNoch keine Bewertungen

- MP1 M2 Short NotesDokument16 SeitenMP1 M2 Short NotesRadhika GandhiNoch keine Bewertungen

- Casting ProcessesDokument40 SeitenCasting ProcessesreynierNoch keine Bewertungen

- PSP CastingDokument7 SeitenPSP CastingalexisNoch keine Bewertungen

- Primary and Secondary Manufacturing ProcessesDokument53 SeitenPrimary and Secondary Manufacturing ProcessesSenthilKumar SubramanianNoch keine Bewertungen

- Investment CastingDokument14 SeitenInvestment CastingAkshaj NevgiNoch keine Bewertungen

- Manufacturing Process 1 (Casting Processes (B.eng) - 10092014Dokument129 SeitenManufacturing Process 1 (Casting Processes (B.eng) - 10092014bananaNoch keine Bewertungen

- Metal Casting Process Types & Design GuidelinesDokument71 SeitenMetal Casting Process Types & Design GuidelinesVijay Pawar100% (2)

- Ae15301-Aircraft Materials and Manufacturing Technology PDFDokument115 SeitenAe15301-Aircraft Materials and Manufacturing Technology PDFDurai Raj Kumar100% (1)

- Ae15301 AMMTDokument98 SeitenAe15301 AMMTDurai Raj KumarNoch keine Bewertungen

- 4castingprocesses 120526012606 Phpapp01Dokument28 Seiten4castingprocesses 120526012606 Phpapp01Chennai TuitionsNoch keine Bewertungen

- Foundry Hand ToolsDokument83 SeitenFoundry Hand ToolsKiran MunavalliNoch keine Bewertungen

- Chapter 2 Metal Casting ProcessesDokument59 SeitenChapter 2 Metal Casting Processesdagimawgchew777Noch keine Bewertungen

- BCM Unit 5Dokument113 SeitenBCM Unit 5Keerthi k.cNoch keine Bewertungen

- Imp CastingDokument42 SeitenImp CastingMRINAL MAGARNoch keine Bewertungen

- Foundary or CastingDokument88 SeitenFoundary or CastingThulasi RamNoch keine Bewertungen

- Manufacturing TechnologyDokument21 SeitenManufacturing TechnologyRoshanGeorgeNoch keine Bewertungen

- Casting ProcessesDokument42 SeitenCasting ProcessesVijay PawarNoch keine Bewertungen

- Introduction To Microcasting Techniques For MicroManufacturingDokument41 SeitenIntroduction To Microcasting Techniques For MicroManufacturingKanti Solanki100% (1)

- Metal Casting Processes & Its Advances - An Overview: - Dr.S.P.Kumaresh Babu Professor Dept. of MME N.I.T. TrichyDokument58 SeitenMetal Casting Processes & Its Advances - An Overview: - Dr.S.P.Kumaresh Babu Professor Dept. of MME N.I.T. TrichyAditya UNoch keine Bewertungen

- Mft-I Two & 13 Marks QuestionDokument16 SeitenMft-I Two & 13 Marks QuestionrahulNoch keine Bewertungen

- Different Casting Methods ExplainedDokument14 SeitenDifferent Casting Methods ExplainedRamoji Aditya Chary100% (1)

- Casting Process IIDokument35 SeitenCasting Process IIChirag TaterNoch keine Bewertungen

- Learn Critical Aspects of Pattern and Mould Making in FoundryVon EverandLearn Critical Aspects of Pattern and Mould Making in FoundryNoch keine Bewertungen

- Magical Metal Clay: Amazingly Simple No-Kiln Techniques For Making Beautiful AccessoriesVon EverandMagical Metal Clay: Amazingly Simple No-Kiln Techniques For Making Beautiful AccessoriesBewertung: 4 von 5 Sternen4/5 (4)

- Bolt Root and Tensile Stress AreasDokument1 SeiteBolt Root and Tensile Stress Areasnirga100% (5)

- Ersatzteilliste - WA80 3-8 2010 GB1Dokument116 SeitenErsatzteilliste - WA80 3-8 2010 GB1jchernandezNoch keine Bewertungen

- Tool Based Micro MachiningDokument8 SeitenTool Based Micro MachiningAnmol SatsangiNoch keine Bewertungen

- TOMMY Hex Nuts - Página - 1Dokument1 SeiteTOMMY Hex Nuts - Página - 1Miguel AngelNoch keine Bewertungen

- Line Boring ToolsDokument8 SeitenLine Boring ToolsMalik Uddin ZahirNoch keine Bewertungen

- 52crmov4 PDFDokument3 Seiten52crmov4 PDFMartin HristovNoch keine Bewertungen

- Declaration of Performance for Self-tapping Screws, Bolts, Dowels and More (40Dokument5 SeitenDeclaration of Performance for Self-tapping Screws, Bolts, Dowels and More (40Andrei GheorghicaNoch keine Bewertungen

- Nuts & Bolts CEB SpecDokument12 SeitenNuts & Bolts CEB SpecHemantha BalasuriyaNoch keine Bewertungen

- Weld SymbolsDokument5 SeitenWeld SymbolsArya KamiNoch keine Bewertungen

- Shoppracticeforh 00 YateDokument368 SeitenShoppracticeforh 00 YateOptimist8100% (5)

- ISO 10684 Hot Dip Galvanized Fasteners PDFDokument27 SeitenISO 10684 Hot Dip Galvanized Fasteners PDFOzan AtıcıNoch keine Bewertungen

- Angle Drill Press ViceDokument38 SeitenAngle Drill Press ViceKeith Wesley100% (1)

- Purchase Summary Aine Infra Till Nov 2022Dokument1 SeitePurchase Summary Aine Infra Till Nov 2022Rishabh Naresh JainNoch keine Bewertungen

- Outokumpu Machining Guidelines For Forta LDX2404Dokument2 SeitenOutokumpu Machining Guidelines For Forta LDX2404chavico113Noch keine Bewertungen

- Jig N Fixture AssignmentDokument3 SeitenJig N Fixture AssignmentkandeabigaelNoch keine Bewertungen

- Mead Steel Comparison GuideDokument14 SeitenMead Steel Comparison GuideM Usman RiazNoch keine Bewertungen

- Mechanical Workshop PracticesDokument5 SeitenMechanical Workshop PracticesPradeep GsNoch keine Bewertungen

- Background/ Profile of CompanyDokument8 SeitenBackground/ Profile of Companyethiopia ethiopiaNoch keine Bewertungen

- Coating Release Report (Pipe Line) : Wara Pressure Maintenance ProjectDokument60 SeitenCoating Release Report (Pipe Line) : Wara Pressure Maintenance ProjectVimin PrakashNoch keine Bewertungen

- Astm F568MDokument8 SeitenAstm F568MKAROL100% (1)

- Electro Motion Woodworking Stock List4Dokument3 SeitenElectro Motion Woodworking Stock List4Electro Motion UK (Export) LtdNoch keine Bewertungen

- Unit 4 Machine Tools Lecture 3Dokument14 SeitenUnit 4 Machine Tools Lecture 3Daizy Jariwala100% (1)

- CH 6 Machining ProcessesDokument32 SeitenCH 6 Machining ProcessesjssrikantamurthyNoch keine Bewertungen

- Factory planning optimizationDokument12 SeitenFactory planning optimizationRutanshu LawhaleNoch keine Bewertungen

- Clase 06 Tornillos de PotenciaDokument25 SeitenClase 06 Tornillos de PotenciajuancitoNoch keine Bewertungen

- PHNCDokument6 SeitenPHNCAmit MangaonkarNoch keine Bewertungen

- Group 41 Frame: Back HomeDokument7 SeitenGroup 41 Frame: Back HomeanwarNoch keine Bewertungen

- The Line Boring MachineDokument8 SeitenThe Line Boring MachineJinky L. LavegaNoch keine Bewertungen

- Machinist Calc Pro 2UG4088E-BDokument80 SeitenMachinist Calc Pro 2UG4088E-Bbuckeyemarv967100% (2)

- DIN 915 EN-1980 Hexagon Socket Set Screws With Dog PointDokument4 SeitenDIN 915 EN-1980 Hexagon Socket Set Screws With Dog Pointthachpn100% (1)