Beruflich Dokumente

Kultur Dokumente

Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3

Hochgeladen von

CITRIXOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3

Hochgeladen von

CITRIXCopyright:

Verfügbare Formate

ASME BPVC.VIII.

1-2019 UCS-56

Table UCS-56-2

Postweld Heat Treatment Requirements for Carbon and Low Alloy Steels — P-No. 3

Minimum Holding Time at Normal Temperature for Nominal Thickness

Normal Holding [See UW-40(f)]

Temperature, °F (°C), Over 2 in. to 5 in.

Material Minimum Up to 2 in. (50 mm) (50 mm to 125 mm) Over 5 in. (125 mm)

P‐No. 3 Gr. Nos. 1, 2, 3 1,100 (595) 1 hr/in. (25 mm), 2 hr plus 15 min for each 2 hr plus 15 min for

15 min minimum additional inch (25 mm) each additional inch

over 2 in. (50 mm) (25 mm) over 2 in.

(50 mm)

GENERAL NOTES:

(a) When it is impractical to postweld heat treat at the temperatures specified in this Table, it is permissible to carry out the postweld heat

treatment at lower temperatures for longer periods of time in accordance with Table UCS-56.1.

(b) Postweld heat treatment is mandatory on P‐No. 3 Gr. No. 3 material in all thicknesses.

(c) Except for the exemptions in General Note (d), postweld heat treatment is mandatory under the following conditions:

(1) on P‐No. 3 Gr. No. 1 and P‐No. 3 Gr. No. 2 over 5/8 in. (16 mm) nominal thickness. For these materials, postweld heat treatment is

mandatory on material up to and including 5/8 in. (16 mm) nominal thickness unless a welding procedure qualification described in

UCS-56(a) has been made in equal or greater thickness than the production weld.

(2) on material in all thicknesses if required by UW-2.

(d) For welding connections and attachments to pressure parts, postweld heat treatment is not mandatory under the conditions specified

below:

(1) for attaching to pressure parts that have a specified maximum carbon content of not more than 0.25% (SA material specification

carbon content, except when further limited by the purchaser to a value within the specification limits) or nonpressure parts with

groove welds not over 1/2 in. (13 mm) in size or fillet welds that have a throat thickness of 1/2 in. (13 mm) or less, provided preheat

to a minimum temperature of 200°F (95°C) is applied;

(2) for circumferential butt welds in pipe or tube where the pipe or tube have both a nominal wall thickness of 1/2 in. (13 mm) or

less and a specified maximum carbon content of not more than 0.25% (SA material specification carbon content, except when further

limited by the purchaser to a value within the specification limits);

(3) for studs welded to pressure parts that have a specified maximum carbon content of not more than 0.25% (SA material spec-

ification carbon content, except when further limited by the purchaser to a value within the specification limits), provided preheat to a

minimum temperature of 200°F (95°C) is applied;

(4) for corrosion resistant weld metal overlay cladding or for welds attaching corrosion resistant applied lining (see UCL-34) when

welded to pressure parts which have a specified maximum carbon content of not more than 0.25% (SA material specification carbon

content, except when further limited by the purchaser to a value within the specification limits), provided preheat to a minimum tem-

perature of 200°F (95°C) is maintained during application of the first layer;

(5) for tubes or pressure-retaining handhole and inspection plugs or fittings that are secured by mechanical means (tube expansion,

shoulder construction, machine threads, etc.) and seal welded, provided the seal weld has a throat thickness of 3/8 in. (10 mm) or less,

and preheat to a minimum temperature of 200°F (95°C) is applied when the thickness of either part exceeds 5/8 in. (16 mm).

173 --`,``,``,,`,`,,````,`,``,,,`-`-`,,`,,`,`,,`---

Licensee=Khalda Petroleum/5986215001, User=Amer, Mohamed

No reproduction or networking permitted without license from IHS Not for Resale, 07/02/2019 13:29:04 MDT

Das könnte Ihnen auch gefallen

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3Dokument7 SeitenTable UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3MechanicalNoch keine Bewertungen

- Table UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1Dokument4 SeitenTable UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1MechanicalNoch keine Bewertungen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Table UCS-56-4 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-Nos. 5A, 5B, and 5CDokument3 SeitenTable UCS-56-4 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-Nos. 5A, 5B, and 5CMechanicalNoch keine Bewertungen

- Table UCS-56-7 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10ADokument2 SeitenTable UCS-56-7 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10AMechanicalNoch keine Bewertungen

- Table UCS-56-7 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10ADokument4 SeitenTable UCS-56-7 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10AMechanicalNoch keine Bewertungen

- Table UCS-56-7 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10ADokument3 SeitenTable UCS-56-7 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10AMechanicalNoch keine Bewertungen

- Table UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CDokument4 SeitenTable UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CMechanicalNoch keine Bewertungen

- Table UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CDokument6 SeitenTable UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CMechanicalNoch keine Bewertungen

- Table UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CDokument3 SeitenTable UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CMechanicalNoch keine Bewertungen

- Table UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CDokument6 SeitenTable UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CMechanicalNoch keine Bewertungen

- Table UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CDokument3 SeitenTable UCS-56-9 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 10CMechanicalNoch keine Bewertungen

- Table Ucs 56 3 (P.no.4)Dokument1 SeiteTable Ucs 56 3 (P.no.4)Anonymous AyDvqgNoch keine Bewertungen

- Ucs 56Dokument1 SeiteUcs 56enemesio_85100% (1)

- Asme Viii 1 - PWHT PDFDokument1 SeiteAsme Viii 1 - PWHT PDFGANGADHAR SAHUNoch keine Bewertungen

- Table UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EDokument6 SeitenTable UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EMechanicalNoch keine Bewertungen

- Table UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EDokument5 SeitenTable UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EMechanicalNoch keine Bewertungen

- Table UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EDokument1 SeiteTable UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15ECITRIXNoch keine Bewertungen

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Dokument1 SeiteTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshNoch keine Bewertungen

- PWTH RequirementDokument2 SeitenPWTH Requirementveeru290683_20976731Noch keine Bewertungen

- Tablas de TT para Materiales P 91Dokument2 SeitenTablas de TT para Materiales P 91Manuel Alejandro González MarcanoNoch keine Bewertungen

- Ibr RegDokument6 SeitenIbr RegSitaram Jha100% (1)

- PWHT, HT, Igc, MawpDokument40 SeitenPWHT, HT, Igc, Mawpsachinshirnath100% (1)

- Sa 203Dokument4 SeitenSa 203gst ajahNoch keine Bewertungen

- Dillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedDokument4 SeitenDillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedBui Chi TamNoch keine Bewertungen

- Dillimax 690 eDokument4 SeitenDillimax 690 ePrabhakar TiwariNoch keine Bewertungen

- B31.3 2016 PDFDokument2 SeitenB31.3 2016 PDFEuclidesNoch keine Bewertungen

- Acero Dillimax 500 MLDokument4 SeitenAcero Dillimax 500 MLAlexis Guzmán MéndezNoch keine Bewertungen

- Tabla 132 TT - ASME B31.1Dokument1 SeiteTabla 132 TT - ASME B31.1Manuel Alejandro González MarcanoNoch keine Bewertungen

- Post WeldDokument4 SeitenPost WelddanemsalNoch keine Bewertungen

- Technical Notes (General Specification) FOR Air Cooled Heat ExchangersDokument55 SeitenTechnical Notes (General Specification) FOR Air Cooled Heat Exchangerscprcdocumentation01Noch keine Bewertungen

- ANSI B31.3 Tratamiento TermicoDokument6 SeitenANSI B31.3 Tratamiento Termicoenemesio_85Noch keine Bewertungen

- Asme CCase 2067-2Dokument2 SeitenAsme CCase 2067-2ADAMJSRAONoch keine Bewertungen

- Asme Sec Viii Ucs PWHTDokument35 SeitenAsme Sec Viii Ucs PWHTMahesh KumarNoch keine Bewertungen

- Pressure Vessel Plates, Alloy Steel, 9 Percent Nickel, Double-Normalized and TemperedDokument3 SeitenPressure Vessel Plates, Alloy Steel, 9 Percent Nickel, Double-Normalized and TemperedSofiaJabadanEspulgarNoch keine Bewertungen

- Spec EarthingDokument9 SeitenSpec EarthingsbpathiNoch keine Bewertungen

- Solved Pressure Vessels QuestionsDokument2 SeitenSolved Pressure Vessels QuestionsParminder SinghNoch keine Bewertungen

- IBR Amendment 2001,3Dokument6 SeitenIBR Amendment 2001,3Agniva DuttaNoch keine Bewertungen

- Technical Specification - FilterDokument15 SeitenTechnical Specification - FilterMurli RamchandranNoch keine Bewertungen

- Rigid Pipe Covering (K450) : With Extr A Rig IDDokument6 SeitenRigid Pipe Covering (K450) : With Extr A Rig IDraguhvacind4620Noch keine Bewertungen

- (0209) 031801Dokument12 Seiten(0209) 031801Sixto Gerardo Oña AnaguanoNoch keine Bewertungen

- Scope of Job:-: Attachment To PR 10-2275 Page 1 of 9 Hot Insulation Jobs in Fre Job Scope & Notes To VendorsDokument9 SeitenScope of Job:-: Attachment To PR 10-2275 Page 1 of 9 Hot Insulation Jobs in Fre Job Scope & Notes To VendorsraghbirNoch keine Bewertungen

- ASME B31.3 (2022) - PWHT RequirementDokument4 SeitenASME B31.3 (2022) - PWHT RequirementTactical Blackhawk Batam100% (1)

- SecVIII Div1 UW40Dokument2 SeitenSecVIII Div1 UW40arianaseriNoch keine Bewertungen

- Api Ast Subcommittee: Impact: Minimal 620 Appendix X-Duplex Stainless Steel Storage Tanks X.1 ScopeDokument14 SeitenApi Ast Subcommittee: Impact: Minimal 620 Appendix X-Duplex Stainless Steel Storage Tanks X.1 ScopeHAKANNoch keine Bewertungen

- Asme Sa 553 Astm A553Dokument6 SeitenAsme Sa 553 Astm A553clarence8bacligNoch keine Bewertungen

- D9 Ppag-100-Et-C-025-3 PDFDokument5 SeitenD9 Ppag-100-Et-C-025-3 PDFSantiago GarciaNoch keine Bewertungen

- HFY-PIP-SP-00008 X Specification - For - Insulation - A-CommentedDokument13 SeitenHFY-PIP-SP-00008 X Specification - For - Insulation - A-CommentedVignesh PanchabakesanNoch keine Bewertungen

- Lesson 06 UW40 UW56.1 New2Dokument30 SeitenLesson 06 UW40 UW56.1 New2Kandregula Mohan BabuNoch keine Bewertungen

- InsulationDokument63 SeitenInsulationSH1961Noch keine Bewertungen

- Asme BPVC 2017 Code Case 2702-3Dokument6 SeitenAsme BPVC 2017 Code Case 2702-3Anonymous lmCR3SkPrKNoch keine Bewertungen

- Tarecpir Project Spec Inst GuideDokument64 SeitenTarecpir Project Spec Inst GuideFaizal YaacobNoch keine Bewertungen

- Seamless and Welded Carbon and Alloy-Steel Tubes For Low-Temperature ServiceDokument6 SeitenSeamless and Welded Carbon and Alloy-Steel Tubes For Low-Temperature ServiceAna Emily PrentissNoch keine Bewertungen

- ALPEMA Normas (2000 - Rev. 1 e 2 de 2003 e 07)Dokument91 SeitenALPEMA Normas (2000 - Rev. 1 e 2 de 2003 e 07)thiagoNoch keine Bewertungen

- Flange Summary Data Sheet: Chemical RequirementsDokument1 SeiteFlange Summary Data Sheet: Chemical RequirementsMJ MagdyNoch keine Bewertungen

- Uha 32-2Dokument1 SeiteUha 32-2Lipika GayenNoch keine Bewertungen

- 10-87-02 Spec For Ceramic Fibre Blanket InsulationDokument5 Seiten10-87-02 Spec For Ceramic Fibre Blanket InsulationlightsonsNoch keine Bewertungen

- KG Brochure Globo GL3Dokument14 SeitenKG Brochure Globo GL3mmmlormamNoch keine Bewertungen

- Efficient LightingDokument1 SeiteEfficient LightingCITRIXNoch keine Bewertungen

- Efficient LightingDokument1 SeiteEfficient LightingCITRIXNoch keine Bewertungen

- Efficient LightingDokument1 SeiteEfficient LightingCITRIXNoch keine Bewertungen

- Efficient LightingDokument1 SeiteEfficient LightingCITRIXNoch keine Bewertungen

- Efficient LightingDokument1 SeiteEfficient LightingCITRIXNoch keine Bewertungen

- RereDokument1 SeiteRereCITRIXNoch keine Bewertungen

- ForewordDokument1 SeiteForewordCITRIXNoch keine Bewertungen

- Pages From ASME - BPVC - 2013-Brochure-3Dokument1 SeitePages From ASME - BPVC - 2013-Brochure-3CITRIXNoch keine Bewertungen

- Recommended Practice For Lightning Protection of Aboveground Storage Tanks For Flammable or Combustible LiquidsDokument1 SeiteRecommended Practice For Lightning Protection of Aboveground Storage Tanks For Flammable or Combustible LiquidsCITRIXNoch keine Bewertungen

- 3 Terms and DefinitionsDokument1 Seite3 Terms and DefinitionsCITRIXNoch keine Bewertungen

- Pages From ASME - BPVC - 2013-Brochure-4Dokument1 SeitePages From ASME - BPVC - 2013-Brochure-4CITRIXNoch keine Bewertungen

- Pages From ASME - BPVC - 2013-Brochure-5Dokument1 SeitePages From ASME - BPVC - 2013-Brochure-5CITRIXNoch keine Bewertungen

- DgnemDokument2 SeitenDgnememiliNoch keine Bewertungen

- Pages From ASME - BPVC - 2013-BrochureDokument1 SeitePages From ASME - BPVC - 2013-BrochureCITRIXNoch keine Bewertungen

- Pages From TAC - 7 PDFDokument1 SeitePages From TAC - 7 PDFCITRIXNoch keine Bewertungen

- Pages From TAC - 7 PDFDokument1 SeitePages From TAC - 7 PDFCITRIXNoch keine Bewertungen

- Pages From The Art of Thinking 1Dokument1 SeitePages From The Art of Thinking 1CITRIXNoch keine Bewertungen

- Pages From TAC - 7 PDFDokument1 SeitePages From TAC - 7 PDFCITRIXNoch keine Bewertungen

- Pages From The Art of Thinking Clearly-4Dokument1 SeitePages From The Art of Thinking Clearly-4CITRIXNoch keine Bewertungen

- Pages From TAC - 7 PDFDokument1 SeitePages From TAC - 7 PDFCITRIXNoch keine Bewertungen

- Pages From TAC - 11Dokument1 SeitePages From TAC - 11CITRIXNoch keine Bewertungen

- Bias Has Presented The Banks With Billions in LossesDokument1 SeiteBias Has Presented The Banks With Billions in LossesCITRIXNoch keine Bewertungen

- Pages From TAC - 4Dokument3 SeitenPages From TAC - 4CITRIXNoch keine Bewertungen

- Pages From TAC - 7 PDFDokument1 SeitePages From TAC - 7 PDFCITRIXNoch keine Bewertungen

- Pages From TAC - 6Dokument1 SeitePages From TAC - 6CITRIXNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- See Also Illusion of Control (Ch. 17) Coincidence (Ch. 24) False Causality (Ch. 37)Dokument1 SeiteSee Also Illusion of Control (Ch. 17) Coincidence (Ch. 24) False Causality (Ch. 37)CITRIXNoch keine Bewertungen

- Survivorship Bias Can Become Especially Pernicious When You Become ADokument1 SeiteSurvivorship Bias Can Become Especially Pernicious When You Become ACITRIXNoch keine Bewertungen

- See Also Illusion of Control (Ch. 17) Coincidence (Ch. 24) False Causality (Ch. 37)Dokument2 SeitenSee Also Illusion of Control (Ch. 17) Coincidence (Ch. 24) False Causality (Ch. 37)CITRIXNoch keine Bewertungen

- ArtofyDokument3 SeitenArtofyCITRIXNoch keine Bewertungen

- Atlas Stainless Steel Data SheetsDokument57 SeitenAtlas Stainless Steel Data Sheetszoksi67% (3)

- Difference Between Stainless Steel Grade SS316 & SS316LDokument1 SeiteDifference Between Stainless Steel Grade SS316 & SS316LSableen SinghNoch keine Bewertungen

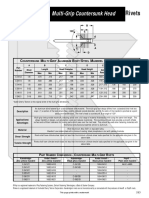

- Rivets Multi Grip CountersunkDokument1 SeiteRivets Multi Grip CountersunkIsrael OluwagbemiNoch keine Bewertungen

- Tools, and Instruments.: Contoh Flash CardDokument4 SeitenTools, and Instruments.: Contoh Flash CardBella WahonganNoch keine Bewertungen

- Squeeze Massage ToolDokument9 SeitenSqueeze Massage ToolRavi GargNoch keine Bewertungen

- Titan Guide Spec For Stucco 2012-01-12Dokument7 SeitenTitan Guide Spec For Stucco 2012-01-12Joseph ChenNoch keine Bewertungen

- Product Catalogue: Welding ConsumablesDokument44 SeitenProduct Catalogue: Welding ConsumablesSerhan AysanNoch keine Bewertungen

- Astm A153 A153m-09Dokument6 SeitenAstm A153 A153m-09TàiChínhDoanhNghiệpNoch keine Bewertungen

- GGG40 50 60Dokument10 SeitenGGG40 50 60fklicekNoch keine Bewertungen

- Yavana Soldier On Bharhut Frieze An InduDokument6 SeitenYavana Soldier On Bharhut Frieze An InduR. FortalNoch keine Bewertungen

- Main Roads Specifications and Technical Standards MRTS78 Fabrication of Structural SteelworkDokument20 SeitenMain Roads Specifications and Technical Standards MRTS78 Fabrication of Structural Steelworkmohamed salahNoch keine Bewertungen

- Aircraft Surface Protection and Paint CoatingsDokument2 SeitenAircraft Surface Protection and Paint CoatingsSarah SNoch keine Bewertungen

- Aerospace Material Specification: (R) In-Process Welding of CastingsDokument13 SeitenAerospace Material Specification: (R) In-Process Welding of CastingsRamesh R100% (1)

- Oerlikon Metco Materials GuideDokument52 SeitenOerlikon Metco Materials GuideApichitNoch keine Bewertungen

- z3T - Maraging Steel 1-2709 (EOS MS1)Dokument1 Seitez3T - Maraging Steel 1-2709 (EOS MS1)martinm3tNoch keine Bewertungen

- 11 Bolted Connections Part 2 - Sem 2 AY 2015 - 16 - IVLEDokument27 Seiten11 Bolted Connections Part 2 - Sem 2 AY 2015 - 16 - IVLESteven KuaNoch keine Bewertungen

- Steel Industry 1Dokument60 SeitenSteel Industry 1Mohammad OsamaNoch keine Bewertungen

- Arv ManholeDokument1 SeiteArv ManholeBrian BonnerNoch keine Bewertungen

- ManufacturingDokument2 SeitenManufacturingBarbieBarbieNoch keine Bewertungen

- FIRE DOORS (120 Minutes) IS 3614: A Royal Fab Group VentureDokument11 SeitenFIRE DOORS (120 Minutes) IS 3614: A Royal Fab Group VentureAlbert SekarNoch keine Bewertungen

- Tapping Feed and Speed Viking Drill and ToolDokument1 SeiteTapping Feed and Speed Viking Drill and ToolDaniele TropepeNoch keine Bewertungen

- Striking ArcDokument96 SeitenStriking ArcJohn Wilner DirectoNoch keine Bewertungen

- Inconel 625Dokument5 SeitenInconel 625koushkiNoch keine Bewertungen

- Welding of Cast IronDokument10 SeitenWelding of Cast IronKrishnendu RouthNoch keine Bewertungen

- Workshop Practice 1st YearDokument21 SeitenWorkshop Practice 1st YearVIPAN KUMARNoch keine Bewertungen

- Advantages of Open Die ForgingDokument5 SeitenAdvantages of Open Die ForgingAjith KumarNoch keine Bewertungen

- Effect of Minor and Trace Elements in Cast IronDokument2 SeitenEffect of Minor and Trace Elements in Cast IronsachinguptachdNoch keine Bewertungen

- A Tablet Inscription of Ganweriwala Is ADokument2 SeitenA Tablet Inscription of Ganweriwala Is AKrishnamurthy RangaiahNoch keine Bewertungen

- Witcher The Snail SchoolDokument4 SeitenWitcher The Snail SchoolKirillNoch keine Bewertungen

- 2016 - Steel Times International - OJ - INDUGA - DOERENTRUP - Micro - MillsDokument6 Seiten2016 - Steel Times International - OJ - INDUGA - DOERENTRUP - Micro - MillsKhaled BOUALINoch keine Bewertungen

- Waste: One Woman’s Fight Against America’s Dirty SecretVon EverandWaste: One Woman’s Fight Against America’s Dirty SecretBewertung: 5 von 5 Sternen5/5 (1)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionVon EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionBewertung: 3 von 5 Sternen3/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsVon EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNoch keine Bewertungen

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceVon EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceBewertung: 4 von 5 Sternen4/5 (19)

- Analog Design and Simulation Using OrCAD Capture and PSpiceVon EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNoch keine Bewertungen

- The Cyanide Canary: A True Story of InjusticeVon EverandThe Cyanide Canary: A True Story of InjusticeBewertung: 4 von 5 Sternen4/5 (52)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsVon EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNoch keine Bewertungen

- Laws of UX: Using Psychology to Design Better Products & ServicesVon EverandLaws of UX: Using Psychology to Design Better Products & ServicesBewertung: 5 von 5 Sternen5/5 (9)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchVon EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchBewertung: 4 von 5 Sternen4/5 (10)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsVon EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsBewertung: 4 von 5 Sternen4/5 (2)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsVon EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsBewertung: 5 von 5 Sternen5/5 (1)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableVon EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNoch keine Bewertungen

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersVon EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersBewertung: 4 von 5 Sternen4/5 (13)

- Understanding Automotive Electronics: An Engineering PerspectiveVon EverandUnderstanding Automotive Electronics: An Engineering PerspectiveBewertung: 3.5 von 5 Sternen3.5/5 (16)

- 507 Mechanical Movements: Mechanisms and DevicesVon Everand507 Mechanical Movements: Mechanisms and DevicesBewertung: 4 von 5 Sternen4/5 (28)

- Introduction to Ecology and Environmental Laws in IndiaVon EverandIntroduction to Ecology and Environmental Laws in IndiaNoch keine Bewertungen

- Practical Troubleshooting of Electrical Equipment and Control CircuitsVon EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsBewertung: 4 von 5 Sternen4/5 (5)