Beruflich Dokumente

Kultur Dokumente

On-line Partial Discharge Monitoring of MV Cable Systems with Location

Hochgeladen von

Amany HamdyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

On-line Partial Discharge Monitoring of MV Cable Systems with Location

Hochgeladen von

Amany HamdyCopyright:

Verfügbare Formate

CIRED 20th International Conference on Electricity Distribution Prague, 8-11 June 2009

Paper 0070

First Field Experience of On-line Partial Discharge Monitoring of MV Cable

Systems with location

Peter VAN DER WIELEN Fred STEENNIS

KEMA – the Netherlands KEMA – the Netherlands

peter.vanderwielen@kema.com fred.steennis@kema.com

put in operation since that time. Some of the principles,

ABSTRACT together with some results after one year of operation are

shown in this paper.

A new measuring system is presented for the on-line

monitoring and location of partial discharges (PDs) in This introduction of this paper is partly similar as in the

medium-voltage power cables. The system uses two paper presented at the CEPSI in 2008 [6]. For this CIRED

inductive sensors, each at one cable end. The measuring 2009 paper the focus is mainly on new examples of

system is called PD-OL, which stands for PD detection On- measuring results which can be find in the second half of

line with Location. A pulse injection system is used for the this paper.

time synchronization of the data intake at both cable ends

and for the on-line calibration. PD data is send via internet

to the KEMA Control Center for interpretation and final PD-OL MEASUREMENT SYSTEM SET-UP

presentation, made visible on a secured web-site for the One PD-OL system consists of two separate PD-OL

network owners. This paper discusses the basics of PD-OL measurement units, each of these to be installed at one of

and a number of measurement results. the cable circuit ends in either substation or RMU(s) (Ring

Main Units). See for an illustration Fig. 1.

INTRODUCTION

Many grid owners indicated the need for an on-line PD

measuring system, i.e. while the cable connection remains

in-service. This need has been expressed already for years,

both for hv and mv cables.

For hv cable circuits (≥ 50 kV), PD monitoring solutions

have been introduced, based on sensors per accessory. This

is unpractical for mv cable circuits (≤ 36 kV) . Therefore, in

case of mv cable connections it is much better to work with

only two sensors, one at each cable end. With two sensors

one can cover the whole cable connection indeed, simply by

measuring the difference in arrival time at both sensors. The

Fig. 1 PD-OL installation, with at each cable end a

sensitivity of such a measuring system can be compared

control unit (PD-OL - CU) for signal processing

with the well known off-line PD measuring systems for mv

and communication via internet and a

cables. Such an on-line PD measuring system works for all

sensor/injector unit (PD-OL - SIU) for the actual

types of mv cables (e.g. XLPE insulated, paper insulated)

measurement and pulse injection.

and all types of accessories installed.

Each measurement unit consists of:

So far, this approach sounds simple. However, until 2005

a) A sensor/injector unit (PD-OL - SIU). As the name

this was not really available. One of the problems that had

suggests, this unit contains both a sensor, to measure

to be solved was the synchronization of both sensors at the

pulses from the cable, and an injection device, to inject

cable ends. After a couple of years of research activities [1],

pulses into the cable. This unit can be split in two parts

[2] a prototype of a measurement system became available.

and in this way clamped around the cable or cable earth

At the CIRED 2005 conference, the basics of the PD

connection, which all can be done on-line.

measuring system called PD-OL, was fully presented for the

b) A controller unit (PD-OL - CU), which is connected to

first time [3]. PD-OL stands for Partial Discharge testing

the SIU by means of an optical fiber. The controller

On-line with Location. PD-OL is protected by a patent [5].

unit (which is in fact a small dedicated computer)

controls the measurement sequence, the data collection

Since its introduction, energy was spent in realizing

and the signal processing. It has also communication

commercial equipment, which arrived in 2007.

facilities on board (LAN, modem or mobile phone /

Approximately 120 PD-OL systems based on this have been

CIRED2009 Session 1 Paper No 0070

CIRED 20th International Conference on Electricity Distribution Prague, 8-11 June 2009

Paper 0070

GPRS card) in order to upload the resulting data via the FIELD PD RESULTS

internet to the Control Center at KEMA for further

interpretation. Furthermore, in this way, the PD-OL Since various measurement systems have been installed

units can be reached via the internet for diagnostic during the year 2007 and 2008 and lots of measurement

purposes and updates. All is performed automatically results can be presented now. To do this, various

and remotely, so once installed no physical access to presentation forms are chosen in order to show the benefits

the units is needed. of doing the PD measurements on-line.

Example Circuit A

PD-OL MEASURING SEQUENCE The first result presented here originates from a cable circuit

Power cables in an on-line situation are in many cases A. The Paper Insulated Lead Covered cable circuit length is

connected to a next cable. Therefore, PD pulses do not 143 m. For illustration, only an 8 day period is shown from

reflect at all or only to a minor degree. Furthermore, in an a much longer measuring period in Fig. 2. The PD activity

on-line situation, also PD alike pulses from adjacent is very clearly varying with time; it follows the day-night

equipment arrive at the sensors. In order to discriminate load cycles, resulting in 8 clear PD concentrations with

PDs from the cable under test from other pulses and to quiet periods in between.

locate their origin, it is necessary to apply sensors at both

sides of the cable circuit, which is the chosen solution with

PD-OL. That simple fact implies that the PD-OL - CUs

installed at both cable ends do need some trick to get in time

synchronization with each other. The patented solution [5]

is that via the PD-OL - SIUs not only PDs can be measured,

but also pulses can be injected via an inductive coil (e.g.

once every minute). This pulse injection at the master PD-

OL - SIU is the accurate starting time of measuring PDs.

The slave PD-OL - SIU at the other cable end will start

doing the same immediately after receiving this injected

pulse, which is exactly the cable propagation time later.

Since the propagation time of the cable is known, accurate

time synchronization between the two PD-OL units has

become possible. Advanced signal processing techniques Fig. 2 3D plot of measured PDs from circuit A. The top

ensure that this method achieves sufficient reliability and vertical axis on the left side is charge (pC), the

accuracy. bottom left vertical axis is the location along the

cable length (143 m) and the horizontal axis is

This sequence results in time-synchronized records of data. time, which is in total ca. 8 days.

In the control unit this data is correlated with matched filter

banks in order to judge whether the measured data contains Example Circuit B

PDs. Resulting from this signal processing are tables of In Fig. 3 results from PD-OL measurements from another

detected (PD) pulses from both cable ends. Not the circuit B (2100 m in length) with Paper Insulated Lead

complete measured waveforms, but only these (much Covered cable are shown after 4 months of measurement.

smaller) resulting tables are then communicated over the Besides the increase of activity in the other cable locations

internet to the Control Center at KEMA. In this Control and the increase in magnitude of the PDs from the 1364 m

Center the results from both cable ends are combined, which joint, a completely new PD concentration of large

leads to both the elimination of pulses from other sources magnitude and high concentration has become visible.

and the determination of the location of the PD spot. Apparently, a new weak spot, next to the 1364 m joint, has

arisen, which was not or hardly visible in the first 3 months.

There are several criteria that help to eliminate other

disturbing pulses and select whether a pulse is indeed a In Fig. 4, the 3D graph of the same measurements is shown.

valid PD pulse, being discussed in detail in [4]. Also other In this graph a clear increasing trend in PD magnitude at the

particular features of the PD-OL measuring system are 1364 m joint location is shown. The PD magnitude level as

discussed extensively in [4] like the sensors applied, the such is not dangerous yet, but if this trend of increasing PD

best sensor locations, calibration matters and noise magnitude remains, degradation is very likely to exist and

suppression. In [4] also other references are mentioned, high risk levels can be reached. It is such trends that are

discussing these items in more depth. visible now and will most probably help us a lot in the

interpretation of these PD graphs, resulting in risk levels

and remaining life estimations.

CIRED2009 Session 1 Paper No 0070

CIRED 20th International Conference on Electricity Distribution Prague, 8-11 June 2009

Paper 0070

owner was recommended to either replace the joint or do a

DC withstand test. The test was applied and the joint broke

down, proving this joint was indeed not fit for use anymore.

After this testing the cable was out of service during a few

after 4 months days, after which the new joint was PD free (as can be seen

in Fig. 6).

Fig. 3 2D graph of PDs measured in a 2.1 km long circuit

B after 4 months of measurement time.

Fig. 6 3D graph of PDs measured during 1 month on

circuit D with clear PDs from a resin joint that

failed during a withstand test.

Example Circuit E

In Fig. 7 the 3D graph shows concentrated PDs from a heat

shrink joint that failed. The joint was located at 1678 m in

an XLPE insulated cable circuit of 4258 m long. The

network owner was recommended in time to replace this

joint but unfortunely, the wrong joint (at 1801 m) was

replaced after which the PD's did not disappear of course

and a bit later the cable failed on the identified joint location

Fig. 4 3D graph of PDs measured during 4 months on

at 1678 m. Anyhow, the replacement recommendation was

circuit B. A clear increasing trend in PD activity

correct.

from the fluid-filled joint at 1364 m is visible.

Example Circuit C

In Fig. 5 the 3D graph shows also here an increasing PD

trend in a resin joint at 173 m, located in a Paper Insulated

Lead Covered cable with a circuit length of 537 m. The

network owner is now planning to replace this joint.

Fig. 7 3D graph of PDs measured during almost 1 month

on circuit E with a clear increasing trend in PD

Fig. 5 3D graph of PDs measured during 4 months on

activity from a heat shrink joint at 1678 m that

circuit C with a clear increasing trend in PD

failed.

activity from the resin joint at 173 m.

Example Circuit D

Example Circuit F

In Fig. 6 the 3D graph shows concentrated PDs from a resin

In Fig. 8 the 2D graph clearly shows concentrated PDs at

joint at about 139 m, located in a Paper Insulated Lead

three different locations in the XLPE insulated cable of

Covered cable with a circuit length of 214 m. The network

CIRED2009 Session 1 Paper No 0070

CIRED 20th International Conference on Electricity Distribution Prague, 8-11 June 2009

Paper 0070

7058 m length. The PD's were collected over a period of CONCLUSIONS

almost one month. This was a curious observation because

the PD locations were far away from joint locations. The Compared to off-line PD diagnostics, PD-OL is seen as a

network owner inspected the cable at these PD sites and step forward in diagnosing MV power cables. In summary

discovered that over large lengths, the earth wire screen of the advantages are:

the XLPE cable was burned away, due to too high fault • installation for network owners anywhere in the world

currents in the copper wire earth screen, see Fig. 9. • on-line installation, sensors without galvanic contact

• PDs seen under normal service conditions and can be

monitored continuously, making trends, variations and

short-duration PD activity visible

• all PD data is automatically uploaded via internet for

interpretation to one place in the world where expertise

is concentrated

• hourly update of PD maps and interpretation results for

all network owners via internet.

REFERENCES

[1] P.C.J.M. van der Wielen, On-line detection and

location of partial discharges in medium-voltage

Fig. 8 2D graph of PDs measured during almost 1 month power cables, Ph.D. thesis, Eindhoven University of

on circuit F with clear PDs from a heat shrink joint Technology, Eindhoven, The Netherlands, 2005.

that failed. [2] J. Veen, On-line signal analysis of partial discharges

in medium-voltage power cables, Ph.D. thesis,

Eindhoven University of Technology, Eindhoven, The

Netherlands, 2005.

[3] P.C.J.M. van der Wielen, J. Veen, P.A.A.F. Wouters

and E.F. Steennis, “On-line partial discharge detection

of MV cables with defect localisation (PDOL) based

Fig. 9 In the XLPE insulated cable of circuit F, the

on two time synchronised sensors”, The 18th Int. Conf.

copper wire earth screen was burned away due to

on Electricity Distribution (CIRED), Session 1, Paper

excessive fault currents. These spots were found

No. 456, Turin, Italy, June 6-9, 2005.

and located with the PD-OL measuring system.

[4] P. C. J. M. van der Wielen and E. F. Steennis, “On-

Example Circuit G line PD monitoring system for MV cable connections

In Fig. 10 the 3D graph shows an increasing PD trend at with weak spot location”, IEEE Power Engineering

396 m in a 666 m long Paper Insulated Lead Covered cable. Society (PES) General Meeting, Pittsburgh,

Pennsylvania, USA, July 2008.

[5] E. F. Steennis, P. A. A. F. Wouters, P. C. J. M. van

der Wielen, and J. Veen, “Method and system for

transmitting an information signal over a power

cable”, Int. Patent No. WO 2004/013642, June 2002.

[6] E.F. Steennis and P. C. J. M. van der Wielen, "New

on-line pd monitoring system with pd location for long

mv underground power cables", 17th Conference of the

Electric Power Supply Industry (CEPSI), session 5.1,

Macau, China, October 27 – 31, 2008.

MISCELLANEOUS

Fig. 10 3D graph of PDs measured during 2 weeks on

circuit G with a clear increasing trend in PD Acknowledgments

activity in the cable at 396 m.

This work was supported by KEMA Nederland B.V. and

The cable failed at this PD spot, but a couple of days after

the Dutch utilities N.V. Continuon Netbeheer (now

the PD's reached its peak, as can be seen in Fig. 10. The

Alliander), ENECO Netbeheer B.V. (now Stedin.net) and

failure cause was the root of a tree that was pressed around

Essent Netwerk B.V. (now Enexis).

the cable, meanwhile damaging it..

CIRED2009 Session 1 Paper No 0070

Das könnte Ihnen auch gefallen

- Online PD Monitoring System Detects Cable Defects Before FailureDokument4 SeitenOnline PD Monitoring System Detects Cable Defects Before Failuredes1982Noch keine Bewertungen

- Development of Smart Online Partial Discharge MoniDokument8 SeitenDevelopment of Smart Online Partial Discharge MoniJayasoruban RamakrishnanNoch keine Bewertungen

- CIRED2011_0479_finalDokument5 SeitenCIRED2011_0479_finallumoodleyNoch keine Bewertungen

- PD 6 Online PD Monitoring Power CablesDokument21 SeitenPD 6 Online PD Monitoring Power CablesAbhishek GuptaNoch keine Bewertungen

- On-line cable PD monitoring using signal processingDokument11 SeitenOn-line cable PD monitoring using signal processingNamLeNoch keine Bewertungen

- A Perspective On Online Partial Discharge Monitoring For Assessment of The Condition of Rotating Machine Stator Winding InsulationDokument6 SeitenA Perspective On Online Partial Discharge Monitoring For Assessment of The Condition of Rotating Machine Stator Winding InsulationfbogomesNoch keine Bewertungen

- Setup and Preliminary Results of A Pilot On-Line Cable PD Monitoring System On An 11 KV Switchboard Using Capacitive CouplersDokument4 SeitenSetup and Preliminary Results of A Pilot On-Line Cable PD Monitoring System On An 11 KV Switchboard Using Capacitive Couplerssnigdha_musiclover0% (1)

- 2013 03 PotM Monitoring of 420 KV XLPE Cable System in Underground Tunnel ENU PDFDokument5 Seiten2013 03 PotM Monitoring of 420 KV XLPE Cable System in Underground Tunnel ENU PDFreza515heiNoch keine Bewertungen

- HVPD - CIRED 2013 - Combined Power Quality and Condition Monitoring of Offshore NetworksDokument4 SeitenHVPD - CIRED 2013 - Combined Power Quality and Condition Monitoring of Offshore NetworksShady NasrNoch keine Bewertungen

- Modelling and Simulation of Online Partial Discharge Measurement For Medium Voltage Power CableDokument9 SeitenModelling and Simulation of Online Partial Discharge Measurement For Medium Voltage Power Cablesamart94Noch keine Bewertungen

- 220kv Cable Cross Bonding TestDokument7 Seiten220kv Cable Cross Bonding Testvivek2159Noch keine Bewertungen

- Total Accuracy of The Whole Measuring Chain - Sensor & Ied: CiredDokument4 SeitenTotal Accuracy of The Whole Measuring Chain - Sensor & Ied: Ciredintiw_23Noch keine Bewertungen

- Partial Discharge Diagnostics On Gis Using Uhf and Acoustic MethodDokument5 SeitenPartial Discharge Diagnostics On Gis Using Uhf and Acoustic MethodmersiumNoch keine Bewertungen

- Ms - PD Chek and Mpd-s2-17062013Dokument10 SeitenMs - PD Chek and Mpd-s2-17062013Mohammad Asif100% (1)

- IEEE 1434 - OffLine Vs OnLine PD in Rotating Machinery PDFDokument3 SeitenIEEE 1434 - OffLine Vs OnLine PD in Rotating Machinery PDFErick DextreNoch keine Bewertungen

- C4-201 Insulation Monitoring FinalDokument10 SeitenC4-201 Insulation Monitoring FinalMarcosGodoyPereyraNoch keine Bewertungen

- SCADA Systems Notes for Electrical Engineering StudentsDokument42 SeitenSCADA Systems Notes for Electrical Engineering StudentsMuzammil KhanNoch keine Bewertungen

- Pract Exp - PDMeas On Cable Access - IMPDokument4 SeitenPract Exp - PDMeas On Cable Access - IMPrasool waniNoch keine Bewertungen

- IEC/IEEE Precision Time Protocol for Electrical UtilitiesDokument6 SeitenIEC/IEEE Precision Time Protocol for Electrical UtilitiesHubert KirrmannNoch keine Bewertungen

- Methods For Power Quality Analysis According To EN 50160Dokument7 SeitenMethods For Power Quality Analysis According To EN 50160gerardobarriaNoch keine Bewertungen

- FIBRE OPTIC BUS DUCT MONITORING SYSTEM GEN June 2020 PDFDokument15 SeitenFIBRE OPTIC BUS DUCT MONITORING SYSTEM GEN June 2020 PDFmatthewsmlamNoch keine Bewertungen

- Best Practices For Implementing PTP in The Power Industry: Larry ThomaDokument14 SeitenBest Practices For Implementing PTP in The Power Industry: Larry Thomaiam@scribd123Noch keine Bewertungen

- Portable PD Diagnostic System for Field TestingDokument2 SeitenPortable PD Diagnostic System for Field Testingmohamed anasNoch keine Bewertungen

- Cigre 2016 - B1-205Dokument9 SeitenCigre 2016 - B1-205des1982Noch keine Bewertungen

- HVPD - CIRED 2013 - On-Line Partial Discharge Detection and Control On MV Cable Networks With Ground Fault NeutraliserDokument4 SeitenHVPD - CIRED 2013 - On-Line Partial Discharge Detection and Control On MV Cable Networks With Ground Fault NeutraliserShady NasrNoch keine Bewertungen

- Fiber-optic icing detection and dynamic rating systemDokument4 SeitenFiber-optic icing detection and dynamic rating systemtdropulicNoch keine Bewertungen

- A Basheer.Dokument11 SeitenA Basheer.A KyariNoch keine Bewertungen

- Wireless Oscilloscope Using ZigbeeDokument4 SeitenWireless Oscilloscope Using ZigbeemichaelNoch keine Bewertungen

- Basic Characteristics of Zigbee and Simpliciti Modules To Use in Measurement SystemsDokument5 SeitenBasic Characteristics of Zigbee and Simpliciti Modules To Use in Measurement SystemsSainadh AryaNoch keine Bewertungen

- OFC2017 5G JimZDokument3 SeitenOFC2017 5G JimZgreffeuille julienNoch keine Bewertungen

- CSE - 27 b1 Best Practices For Partial Discharge Monitoring of HVDC Cable Systems and Qualification TestsDokument14 SeitenCSE - 27 b1 Best Practices For Partial Discharge Monitoring of HVDC Cable Systems and Qualification TestsTXEMANoch keine Bewertungen

- Partial Discharge Detection in Medium Voltage Stators Using An AntennaDokument6 SeitenPartial Discharge Detection in Medium Voltage Stators Using An Antennadayini roslizanNoch keine Bewertungen

- Switchgear Optimization Via 61850-9-2Dokument4 SeitenSwitchgear Optimization Via 61850-9-2AdamNoch keine Bewertungen

- XLPE PD DetectionDokument4 SeitenXLPE PD DetectionClaysius DewanataNoch keine Bewertungen

- Sensors State Monitoring Based On Labview and Wireless NodesDokument5 SeitenSensors State Monitoring Based On Labview and Wireless NodesBhargav KumarNoch keine Bewertungen

- S4-05-PD Measurement On Power CablesDokument8 SeitenS4-05-PD Measurement On Power CablesRAVINDERNoch keine Bewertungen

- White Paper ESBs ADOPTION SMART NEUTRAL TREATMENTS ON ITS 20 KV SYSTEMDokument4 SeitenWhite Paper ESBs ADOPTION SMART NEUTRAL TREATMENTS ON ITS 20 KV SYSTEMkotiniNoch keine Bewertungen

- PA BAUR Combined Application of Diagnostics Tools For MV Underground Cables Full Paper enDokument6 SeitenPA BAUR Combined Application of Diagnostics Tools For MV Underground Cables Full Paper enVinciushfb2Noch keine Bewertungen

- PD Testing and Monitoring of HV XLPE Cable SystemsDokument7 SeitenPD Testing and Monitoring of HV XLPE Cable SystemsAnh Tuan NguyenNoch keine Bewertungen

- MPD 500 Brochure ENUDokument16 SeitenMPD 500 Brochure ENUShakeel AnsariNoch keine Bewertungen

- Processor in The Loop Test For Algorithms Designed To Control Power Electronics Converters Used in Grid Connected Photovoltaic SystemDokument19 SeitenProcessor in The Loop Test For Algorithms Designed To Control Power Electronics Converters Used in Grid Connected Photovoltaic SystemDjamila RekiouaNoch keine Bewertungen

- A Compact Ultra-Wideband Load-Pull Measurement SystemDokument6 SeitenA Compact Ultra-Wideband Load-Pull Measurement Systemoğuz odabaşıNoch keine Bewertungen

- Partial Discharge Measurement and Monitoring On High Voltage XLPE CablesDokument14 SeitenPartial Discharge Measurement and Monitoring On High Voltage XLPE CableskarakoukasNoch keine Bewertungen

- Wosspa 2013 Appliance Consumption Signature Database and Recognition Test ProtocolsDokument6 SeitenWosspa 2013 Appliance Consumption Signature Database and Recognition Test ProtocolsVasundhar BoddapatiNoch keine Bewertungen

- Surveillance and Protection-Based Approach For Link Failures Over Fiber-To The-Home (FTTH) With Combination of ACS and SANTADDokument17 SeitenSurveillance and Protection-Based Approach For Link Failures Over Fiber-To The-Home (FTTH) With Combination of ACS and SANTADYosia RayaNoch keine Bewertungen

- Track1 1570688080Dokument5 SeitenTrack1 1570688080satria cantaputraNoch keine Bewertungen

- Temperature Control and Monitoring System For Power Transformer Windings Using Fiber Optic SensorsDokument4 SeitenTemperature Control and Monitoring System For Power Transformer Windings Using Fiber Optic SensorsMarcel NicolaNoch keine Bewertungen

- V Cem5000 Ops A4Dokument43 SeitenV Cem5000 Ops A4Quan Nguyen Van100% (1)

- BVP Optsim1Dokument24 SeitenBVP Optsim1Ishwar SinghNoch keine Bewertungen

- Sensors 23 03405 v2Dokument21 SeitenSensors 23 03405 v2Caio FlemingNoch keine Bewertungen

- Single-Carrier Phase-Disposition PWM Implementation For Multilevel Flying Capacitor ConvertersDokument5 SeitenSingle-Carrier Phase-Disposition PWM Implementation For Multilevel Flying Capacitor ConvertersAmer Mohammad GhiasNoch keine Bewertungen

- 9AKK107992A1008 - PDCOM Data SheetDokument4 Seiten9AKK107992A1008 - PDCOM Data SheettuanvuttNoch keine Bewertungen

- Techniques For Minimizing Power Consumption in Low Data-Rate Wireless Sensor NetworksDokument5 SeitenTechniques For Minimizing Power Consumption in Low Data-Rate Wireless Sensor NetworksNikos ArvanitisNoch keine Bewertungen

- Ace IEEEDokument6 SeitenAce IEEEPavanmouliNoch keine Bewertungen

- Outer-Loop Power Control in A Live UMTS Network: Measurement, Analysis and ImprovementsDokument5 SeitenOuter-Loop Power Control in A Live UMTS Network: Measurement, Analysis and ImprovementscrscibdNoch keine Bewertungen

- Alexander Lagla Guia Practica Internet TelevisionDokument11 SeitenAlexander Lagla Guia Practica Internet TelevisionAlexander LaglaNoch keine Bewertungen

- Partial Discharge Measurement System For Routine Test ApplicationsDokument16 SeitenPartial Discharge Measurement System For Routine Test ApplicationsEyad Abu AlRoubNoch keine Bewertungen

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsVon EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNoch keine Bewertungen

- Concise Guide to OTN optical transport networksVon EverandConcise Guide to OTN optical transport networksBewertung: 4 von 5 Sternen4/5 (2)

- Four Aspects of The Quality of Life The Balance MoDokument11 SeitenFour Aspects of The Quality of Life The Balance MoAmany HamdyNoch keine Bewertungen

- IEEE Std 1268™-1997-guide-for-safety-in-the-installation-of-mobile-substation-eDokument26 SeitenIEEE Std 1268™-1997-guide-for-safety-in-the-installation-of-mobile-substation-eAmany HamdyNoch keine Bewertungen

- Hitachi_Energy_MV_Surge_Arrester_Application_GuidelinesDokument31 SeitenHitachi_Energy_MV_Surge_Arrester_Application_GuidelinesAmany HamdyNoch keine Bewertungen

- Force Calculation 28 MvaDokument12 SeitenForce Calculation 28 MvaAmany HamdyNoch keine Bewertungen

- Les Taches Actualisé 25 2 2016Dokument3 SeitenLes Taches Actualisé 25 2 2016Amany HamdyNoch keine Bewertungen

- CALCULATION 10 MVA Short Circuit PDFDokument4 SeitenCALCULATION 10 MVA Short Circuit PDFLevi Franco Carvalho100% (2)

- Induction MotorDokument59 SeitenInduction MotorAkama Kulasekara100% (3)

- Handling Objection-FinalDokument49 SeitenHandling Objection-FinalAmany HamdyNoch keine Bewertungen

- Transformer ProtectiponDokument116 SeitenTransformer ProtectiponAmany HamdyNoch keine Bewertungen

- WIE Affiity Group Petition FormDokument1 SeiteWIE Affiity Group Petition FormAmany HamdyNoch keine Bewertungen

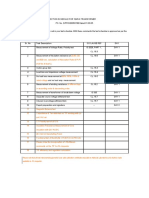

- 16MVA Transformer Inspection ScheduleDokument1 Seite16MVA Transformer Inspection ScheduleAmany HamdyNoch keine Bewertungen

- World BankDokument16 SeitenWorld BankNathaniel Felix Syailendra PrasetyoNoch keine Bewertungen

- Transformer Losses CalculationDokument4 SeitenTransformer Losses CalculationAmany HamdyNoch keine Bewertungen

- MTG Contest Proposal Power - Within - GenerationsDokument3 SeitenMTG Contest Proposal Power - Within - GenerationsAmany HamdyNoch keine Bewertungen

- Behavioral Public Administration Ad FontesDokument18 SeitenBehavioral Public Administration Ad FontesAmany HamdyNoch keine Bewertungen

- Wor - 2021 - 70 4 - Wor 70 4 Wor210476 - Wor 70 Wor210476Dokument11 SeitenWor - 2021 - 70 4 - Wor 70 4 Wor210476 - Wor 70 Wor210476Amany HamdyNoch keine Bewertungen

- Preparing Transformer SpecsDokument56 SeitenPreparing Transformer SpecsahmaborashedNoch keine Bewertungen

- Digital Government Transformation Barriers and EnablersDokument2 SeitenDigital Government Transformation Barriers and EnablersAmany HamdyNoch keine Bewertungen

- The Impact of Job Stress On Employee Productivity During Covid-19Dokument12 SeitenThe Impact of Job Stress On Employee Productivity During Covid-19Amany HamdyNoch keine Bewertungen

- The Reality of Resistance To Change Behaviour at The Department ofDokument14 SeitenThe Reality of Resistance To Change Behaviour at The Department ofAmany HamdyNoch keine Bewertungen

- Barczak Sotysik Jarosz Zakrzewska KozowskiDokument18 SeitenBarczak Sotysik Jarosz Zakrzewska KozowskiAmany HamdyNoch keine Bewertungen

- 5459 22850 1 PBDokument23 Seiten5459 22850 1 PBDARIO BIDESNoch keine Bewertungen

- The Impact of COVID-19 On The Efficiency of Packing Lines inDokument16 SeitenThe Impact of COVID-19 On The Efficiency of Packing Lines inAmany HamdyNoch keine Bewertungen

- Towards Effective Mitigation of The Digital Transformation andDokument22 SeitenTowards Effective Mitigation of The Digital Transformation andAmany HamdyNoch keine Bewertungen

- The New Era of Digital Transformation and COVID-19 Effect On TheDokument27 SeitenThe New Era of Digital Transformation and COVID-19 Effect On TheAmany HamdyNoch keine Bewertungen

- Digitization of The Economy of Ukraine StrategicDokument8 SeitenDigitization of The Economy of Ukraine StrategicAmany HamdyNoch keine Bewertungen

- IEEE C37.99-2000-Shunt Capacitor BankDokument107 SeitenIEEE C37.99-2000-Shunt Capacitor BankAmany HamdyNoch keine Bewertungen

- 1LAB000277 VOC Data Sheet enDokument2 Seiten1LAB000277 VOC Data Sheet enRafat ThongNoch keine Bewertungen

- Enhancing Performance of Mwasalat Misr Company in GreaterDokument16 SeitenEnhancing Performance of Mwasalat Misr Company in GreaterAmany HamdyNoch keine Bewertungen

- 2022 OpenNursingJournal theModerationEffectofAffectiveDokument9 Seiten2022 OpenNursingJournal theModerationEffectofAffectiveAmany HamdyNoch keine Bewertungen

- Concurrent AuditorDokument67 SeitenConcurrent AuditorAjoydeep DasNoch keine Bewertungen

- DaburDokument3 SeitenDaburchiru94Noch keine Bewertungen

- Multibody Simulation of A Freight Bogie With Friction DampersDokument10 SeitenMultibody Simulation of A Freight Bogie With Friction DampersGermán GoñiNoch keine Bewertungen

- What Is Your Road, Man?Dokument232 SeitenWhat Is Your Road, Man?Oana AndreeaNoch keine Bewertungen

- Manual PDFDokument9 SeitenManual PDFRuth ResuelloNoch keine Bewertungen

- Unit 2 - Chapter 04 - Working With FormsDokument24 SeitenUnit 2 - Chapter 04 - Working With FormsSnr Berel ShepherdNoch keine Bewertungen

- Patient Admission Note TemplateDokument4 SeitenPatient Admission Note Templatejonnyahn100% (1)

- Definition and Scope of Public FinanceDokument2 SeitenDefinition and Scope of Public FinanceArfiya MubeenNoch keine Bewertungen

- Factory Test Report For OPzS 800 EED-20041724 2VDokument3 SeitenFactory Test Report For OPzS 800 EED-20041724 2VmaherNoch keine Bewertungen

- Bareos Manual Main ReferenceDokument491 SeitenBareos Manual Main ReferenceAlejandro GonzalezNoch keine Bewertungen

- 2019 Implementasie-SamsatdiBaliDokument10 Seiten2019 Implementasie-SamsatdiBaliDiannita SusantiNoch keine Bewertungen

- CARP Law NotesDokument5 SeitenCARP Law NotesJustisia KaunlaranNoch keine Bewertungen

- Andromeda Council About The 4th DimensionDokument11 SeitenAndromeda Council About The 4th DimensionWonderlust100% (1)

- Mercury Poisoning Symptoms and TreatmentsDokument1 SeiteMercury Poisoning Symptoms and TreatmentsRakheeb BashaNoch keine Bewertungen

- Ginglen 2022 - Necrotizing Enterocolitis - StatPearlsDokument8 SeitenGinglen 2022 - Necrotizing Enterocolitis - StatPearlsBee GuyNoch keine Bewertungen

- An Introduction To Log ShootingDokument10 SeitenAn Introduction To Log ShootingSorin GociuNoch keine Bewertungen

- Sato Printer Api Reference DocumentDokument34 SeitenSato Printer Api Reference Documentsupersteel.krwNoch keine Bewertungen

- Desk PiDokument21 SeitenDesk PiThan LwinNoch keine Bewertungen

- INA128 INA129: Features DescriptionDokument20 SeitenINA128 INA129: Features DescriptionCDDSANoch keine Bewertungen

- Document 25Dokument455 SeitenDocument 25Pcnhs SalNoch keine Bewertungen

- Community HelpersDokument3 SeitenCommunity Helpersapi-252790280100% (1)

- HNM Announcement Flyer enDokument2 SeitenHNM Announcement Flyer enJali SahiminNoch keine Bewertungen

- What Is Robotic Process Automation?: ERP SystemDokument5 SeitenWhat Is Robotic Process Automation?: ERP SystemAna BoboceaNoch keine Bewertungen

- A Report On Kantajew MandirDokument21 SeitenA Report On Kantajew MandirMariam Nazia 1831388030Noch keine Bewertungen

- Inna Phos Diammonium Phosphate MSDSDokument9 SeitenInna Phos Diammonium Phosphate MSDSjosephNoch keine Bewertungen

- Greek Myth WebquestDokument9 SeitenGreek Myth Webquesthollyhock27Noch keine Bewertungen

- Pharmacology Ain Shams 123 - Compress 1Dokument552 SeitenPharmacology Ain Shams 123 - Compress 1ahmed hoty100% (1)

- Business Judgment Rule and Directors' Duty to Inform in Smith v Van GorkomDokument1 SeiteBusiness Judgment Rule and Directors' Duty to Inform in Smith v Van GorkomDorothy ParkerNoch keine Bewertungen

- Nitobond SBR (Latex)Dokument4 SeitenNitobond SBR (Latex)Samarakoon Banda100% (1)

- Ch10 Stress in Simple WordsDokument7 SeitenCh10 Stress in Simple Wordsmanaar munthirNoch keine Bewertungen