Beruflich Dokumente

Kultur Dokumente

Precision Bearing Trolley: Service Instructions and Parts List

Hochgeladen von

edark2009Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Precision Bearing Trolley: Service Instructions and Parts List

Hochgeladen von

edark2009Copyright:

Verfügbare Formate

PRECISION BEARING TROLLEY

SERVICE INSTRUCTIONS AND PARTS LIST

SECTION O/T3, P01 1/4 THRU 3 TON

CAUTION:

THE EQUIPMENT ILLUSTRATED AND DESCRIBED IN

THIS BULLETIN IS DESIGNED FOR MANUAL

OPERATION ONLY AND IS NOT TO BE POWER DRIVEN,

NOR IS IT SUITABLE FOR TRANSPORTING PERSONS!

This trolley is a relatively simple mechanism requiring

comparatively little care, maintenance, inspection and

lubrication.

The following information is provided to assist in

installing and maintaining this equipment.

INSTALLATION

Sliding the trolley over the open end of the runway

beam is the simplest way to install this unit. If an PLAIN TROLLEY GEARED TROLLEY

open beam end is not available, one side plate can be

removed and the unit can be reassembled on the ADJUSTMENT INSTRUCTIONS:

beam. Always verify the trolley is adjusted properly to Beam flange width plus 1/16” running clearance on

fit the beam. See the adjustment instructions below. each side of the flange is the correct trolley setting.

Always run the unit along the entire length of the Move the spacing washers to the inside or outside of

runway beam to verify proper operation and the plates as required.

clearances.

GENERAL MAINTENANCE

Thorough inspection is recommended at regular

intervals. The frequency of inspection must be

determined by the user, since application factors such

as duty cycle and ambient conditions will dictate the

maintenance requirements of the unit.

When inspections are made, the entire trolley should

be inspected for wear, or for damage such as may be

sustained through severe overloading or impact with

other objects. Replace all damaged parts

immediately. Check trolley motion along the runway

beam, to verify proper operation.

LUBRICATING THE TROLLEY

1/4 thru 3 ton Trolleys are built with sealed, life-time

lubricated precision ball bearings that should require WARNING:

no further lubrication. Periodic lubrication of the DO fit all open beam ends with trolley stops.

trolley drive shaft support block and the handwheel DO make sure there are no objects in the way of the

guard is recommended. A small amount of lithium

based NLGI Grade 2 grease should be applied moving load.

through the grease fittings provided. DO NOT leave a load unattended.

NEVER allow a load to swing off center.

NEVER lift an off center load.

WARNING:

DO NOT leave a load suspended for long periods of

DO NOT operate the trolley unless you are physically

time.

fit and trained to do so.

NEVER load the trolley beyond its rated capacity.

DO NOT transport loads over people.

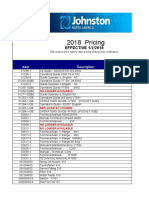

1/4 THRU 3 TON CAPACITY PT TROLLEY PARTS LIST

ITEM ITEM 1/4 AND 1/2 TON 1 TON 1-1/2 TON 2 TON 3 TON

NO DESCRIPTION PART NO QTY PART NO QTY PART NO QTY PART NO QTY PART NO

1 HAND CHAIN C33029 ?(0) C33029 ?(0) C33029 ?(0) C937 ?(0) C937

1 CONNECTING LINK C33029L 1(0) C33029L 1(0) C33029L 1(0) C937L 1(0) C937L

2 HANDWHEEL C36072P1 1(0) C36072P1 1(0) C36072P1 1(0) C9120-0075P1 1(0) C9120-0075P1

3 HANDWHEEL GUARD C37175P1 1(0) C37175P1 1(0) C37175P1 1(0) C9121-0075P1 1(0) C9121-0075P1

4 SNAP RING (EXT) 5100-87 1(0) 5100-87 1(0) 5100-87 1(0) 5100-87 1(0) 5100-87

5 KEY 13-.25-1.50 1(0) 13-.25-1.50 1(0) 13-.25-1.50 1(0) 13-.25-1.50 1(0) 13-.25-1.50

6 SUPPORT BLOCK C35494 1(0) C35494 1(0) C35494 1(0) C35494 1(0) C35494

7 LOCKWASHER 1-.31 2(0) 1-.31 2(0) 1-.31 2(0) 1-.31 2(0) 1-.31

8 CAP SCREW 14-.31-1.00 2(0) 14-.31-1.00 2(0) 14-.31-1.00 2(0) 14-.31-1.00 2(0) 14-.31-1.00

9 SET SCREW 58-.25-.87 1(0) 58-.25-.87 1(0) 58-.25-.87 1(0) 58-.25-.87 1(0) 58-.25-.87

10 GREASE FITTING 1743B 2(0) 1743B 2(0) 1743B 2(0) 1743B 2(0) 1743B

11 PLAIN SIDE PLATE C42915 1 C42917 1 C42917 1 C42919 1 C42919

12 GEARED SIDE PLATE C42915G 1 C42917G 1 C42917G 1 C42919G 1 C42919G

13 CLEVIS C42926P1 1 C42926P2 1 C42926P3 1 C42926P4 1 C42926P5

14 EQUILIZING PIN C42927P1 1 C42927P2 1 C42927P2 1 C42927P3 1 C42927P3

15 DRIVE SHAFT C154A0025 1(0) C154A0025 1(0) C154A0025 1(0) C154A0025 1(0) C154A0025

16 PLAIN WHEEL C37000-26 2(4) C37001-1 2(4) C37001-1 2(4) C37002-1 2(4) C37002-1

17 GEARED WHEEL C37000-26G 2(0) C37001-1G 2(0) C37001-1G 2(0) C37002-1G 2(0) C37002-1G

18 AXLE C9110-0025 4 C9110-0025 4 C9110-0025 4 C9110-0150 4 C9110-0150

20 NUT 98-.62-2 4 98-.62-2 4 98-.62-2 4 96-.75-2 4 96-.75-2

21 BEARING SPACER C23854 4 C23854 4 C23854 4 C23855 4 C23855

22 BEARING C9107-0050 8 C9107-0050 8 C9107-0050 8 C9107-0150 8 C9107-0150

24 LOCKWASHER 1-.62 4 1-.62 4 1-.62 4 1-.75 4 1-.75

25 WHL SPACER(THK) C9303-0025 16 C9303-0025 16 C9303-0025 16 C9303-0100 12 C9303-0100

26 WHL SPACER(THN) N.A. 0 N.A. 0 N.A. 0 C9303A0100 4 C9303A0100

28 WASHER 2-1.00 27 C99903 32 C99903 32 C99915 29 C99915

29 COTTER PIN 128-.31-1.50 2 128-.31-1.75 2 128-.31-1.75 2 128-.37-2.50 2 128-.37-2.50

30 SNAP RING (INT) 5000-137 4 5000-137 4 5000-137 4 5000-175 4 5000-175

31 SERIAL NO TAG SNT- PTG(P) 1 SNT- PTG(P) 1 SNT- PTG(P) 1 SNT- PTG(P) 1 SNT- PTG(P)

32 RIVETS 142-4-.25 2 142-4-.25 2 142-4-.25 2 142-4-.25 2 142-4-.25

NOTE: QUANTITIES SHOWN FOR GEARED UNITS. PLAIN QUANTITIES ARE SHOWN IN BRACKETS ( ).

YALE HOISTS, P.O. BOX 769, MUSKEGON, MICHIGAN 49443

PHONE: (866) 805-2962 FAX: (800) 742-9270

Das könnte Ihnen auch gefallen

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideVon EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideBewertung: 4.5 von 5 Sternen4.5/5 (8)

- 1990-1994 at Overhaul ManualDokument132 Seiten1990-1994 at Overhaul ManualmikeautotransNoch keine Bewertungen

- Army TM 9 2320 361 20 Force To 36a12 1b 1094 2Dokument1.209 SeitenArmy TM 9 2320 361 20 Force To 36a12 1b 1094 2wetfaceNoch keine Bewertungen

- SST PureDokument16 SeitenSST PureQasim KhanNoch keine Bewertungen

- Manual Oficina c4.2 c6.4 CaterpillaDokument177 SeitenManual Oficina c4.2 c6.4 CaterpillaIvo Silva88% (52)

- DOZERDokument182 SeitenDOZERBradley Gandy82% (11)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesVon EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesBewertung: 5 von 5 Sternen5/5 (1)

- A 240Dokument89 SeitenA 240Mario Diaz Lopez100% (1)

- Dodge Getrag 238 Service ManualDokument72 SeitenDodge Getrag 238 Service Manuallilfroger100% (13)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- 1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3Dokument200 Seiten1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3CandieApple100% (1)

- Roughneck RoughneckdetailsDokument28 SeitenRoughneck Roughneckdetailsrohit.g85100% (1)

- Worldiptv - Me8080 Hits 293Dokument202 SeitenWorldiptv - Me8080 Hits 293Ello84Noch keine Bewertungen

- 110 Semiconductor Projects for the Home ConstructorVon Everand110 Semiconductor Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- Clutch: SectionDokument22 SeitenClutch: SectionMatea Virgil SorinNoch keine Bewertungen

- 31TH 2001Dokument47 Seiten31TH 2001Michael FodorNoch keine Bewertungen

- What Parts Do Airlines BuyDokument376 SeitenWhat Parts Do Airlines BuyBuy Aircraft Parts67% (6)

- WP 1047 ADokument14 SeitenWP 1047 AaugustinhodjNoch keine Bewertungen

- TM 9-2350-230-12 - Armored Reconnaissance/Airborne Assault Vehicle M551 SheridanDokument783 SeitenTM 9-2350-230-12 - Armored Reconnaissance/Airborne Assault Vehicle M551 SheridanDenis75% (4)

- Ve Pump Denso Repair ManualDokument32 SeitenVe Pump Denso Repair ManualHenry Hla Khine98% (40)

- TM 9-2320-272-10 Truck, 5-Ton, 6X6, M939 SeriesDokument486 SeitenTM 9-2320-272-10 Truck, 5-Ton, 6X6, M939 SeriesJeffry Fontaine100% (1)

- 722 6Dokument4 Seiten722 6mcgyver972100% (4)

- Cat 994FDokument32 SeitenCat 994FspelzerNoch keine Bewertungen

- 336DL - Torque Culata 1Dokument4 Seiten336DL - Torque Culata 1Vargas Ortiz Jean DiomenesNoch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- GMK 6220Dokument14 SeitenGMK 6220cornel_lupu100% (1)

- CY 6102BG - 36 型柴油机备件目录: Model Cy6102Bg-36 Diesel Engine Spare Parts CatalogueDokument72 SeitenCY 6102BG - 36 型柴油机备件目录: Model Cy6102Bg-36 Diesel Engine Spare Parts Cataloguesobirin100% (1)

- Fillable No Spiral Sheet PDFDokument2 SeitenFillable No Spiral Sheet PDFLpsf PertyNoch keine Bewertungen

- Machinery Application 1A 1999Dokument178 SeitenMachinery Application 1A 1999elinpetNoch keine Bewertungen

- MWM 616V16Dokument107 SeitenMWM 616V16Dhudhik Arief Hadiyanto100% (2)

- 7FBR English PDFDokument16 Seiten7FBR English PDFVadivelNoch keine Bewertungen

- SEVO 1230 Technical Data Sheets - All PDFDokument18 SeitenSEVO 1230 Technical Data Sheets - All PDFYeni Paola SierraNoch keine Bewertungen

- 09 - Yzf - R1 - en YecDokument81 Seiten09 - Yzf - R1 - en YecOscar Melgar80% (5)

- D155ax-6 Sebm038800 PDFDokument15 SeitenD155ax-6 Sebm038800 PDFM. Arpani Yoga PranataNoch keine Bewertungen

- m3m All Data NewDokument870 Seitenm3m All Data NewAnuj DulloNoch keine Bewertungen

- 700 Diagrams of Chess Tactics Training Shumilin PDFDokument117 Seiten700 Diagrams of Chess Tactics Training Shumilin PDFKenaouia Bahaa0% (1)

- JodoDokument10 SeitenJodoJanne Fredrik100% (1)

- 41 Manual Transmission TransaxleDokument85 Seiten41 Manual Transmission TransaxleTung NguyenNoch keine Bewertungen

- 2018 RETAIL Price UPDATED 1 19 18Dokument362 Seiten2018 RETAIL Price UPDATED 1 19 18tylerNoch keine Bewertungen

- Bomba de Lubricação Automatca de MarteloDokument53 SeitenBomba de Lubricação Automatca de MarteloDaniel F BarrosNoch keine Bewertungen

- Selladora de Cajas de Carton - EXC-103TBDokument26 SeitenSelladora de Cajas de Carton - EXC-103TBMarco Antonio Pereira BustosNoch keine Bewertungen

- 32 BrakeDokument63 Seiten32 BrakeTung NguyenNoch keine Bewertungen

- KIA Sorento ManualDokument1.349 SeitenKIA Sorento ManualSteven AmadorNoch keine Bewertungen

- LO 9 2320 272 12 Lube Order 1990Dokument35 SeitenLO 9 2320 272 12 Lube Order 1990DCMAT DjiboutiNoch keine Bewertungen

- Load Control Valve (Boom Cylinder) - AssembleDokument6 SeitenLoad Control Valve (Boom Cylinder) - AssemblechanlinNoch keine Bewertungen

- Link - DesarmarDokument5 SeitenLink - DesarmarCristobal Gutierrez CarrascoNoch keine Bewertungen

- 336DL - Torque Culata 1 PDFDokument4 Seiten336DL - Torque Culata 1 PDFVargas Ortiz Jean DiomenesNoch keine Bewertungen

- Service ManualDokument16 SeitenService ManualgvankelecomNoch keine Bewertungen

- Section 90: Pedal and Pedal Switch AdjustmentsDokument24 SeitenSection 90: Pedal and Pedal Switch Adjustmentsjeffrey pelletierNoch keine Bewertungen

- U322b - Gears - Transmission Main DriveDokument8 SeitenU322b - Gears - Transmission Main DrivebennieNoch keine Bewertungen

- Variable Volume Vane Pumps Silentvane SV 20 SV 25Dokument8 SeitenVariable Volume Vane Pumps Silentvane SV 20 SV 25Mohamed BelallNoch keine Bewertungen

- 21B Clutch OverhaulDokument8 Seiten21B Clutch OverhaultakedashindenNoch keine Bewertungen

- Timberbear McCulloch 6000 Illustrated Parts ListDokument10 SeitenTimberbear McCulloch 6000 Illustrated Parts ListMelanie AgnoneNoch keine Bewertungen

- XQ89-3C Operation Manual (English)Dokument36 SeitenXQ89-3C Operation Manual (English)corvin volocaruNoch keine Bewertungen

- Arme & Desarme Base de Filtros Tractor D4HDokument6 SeitenArme & Desarme Base de Filtros Tractor D4HAlex Consuegra MedinaNoch keine Bewertungen

- Engine Quick Change Assembly BulletinDokument50 SeitenEngine Quick Change Assembly BulletinreyveNoch keine Bewertungen

- 42 - ClutchDokument24 Seiten42 - ClutchArif WidayuniNoch keine Bewertungen

- Servo System 5Dokument2 SeitenServo System 5Minn Thet NaingNoch keine Bewertungen

- Automatic Transaxle (Service) (Gf4ax-El)Dokument53 SeitenAutomatic Transaxle (Service) (Gf4ax-El)МаксNoch keine Bewertungen

- TCI 220500 TRANS-SCAT: Installation Instructions For A500 (42RH/42RE) - 1989 and Up A518 (46RH/47RH) - 1989 and UpDokument8 SeitenTCI 220500 TRANS-SCAT: Installation Instructions For A500 (42RH/42RE) - 1989 and Up A518 (46RH/47RH) - 1989 and UphidraulicNoch keine Bewertungen

- Front Wheel Drive Axle For TLD 828, 929 & TXL-838 Cargo LoadersDokument30 SeitenFront Wheel Drive Axle For TLD 828, 929 & TXL-838 Cargo LoadersCarlos SolisNoch keine Bewertungen

- Motorcycle, Solo (Harley-Davidson Model WLA)Von EverandMotorcycle, Solo (Harley-Davidson Model WLA)Noch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentVon EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNoch keine Bewertungen

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationVon EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNoch keine Bewertungen

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationVon EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNoch keine Bewertungen

- 13 Rigg Hardware Non Lifting AccessoriesDokument3 Seiten13 Rigg Hardware Non Lifting Accessoriesedark2009Noch keine Bewertungen

- ACTAIR 1.5 to 800 pneumatic actuators technical selection guideDokument16 SeitenACTAIR 1.5 to 800 pneumatic actuators technical selection guideedark2009Noch keine Bewertungen

- Pipe Size - Steel PipeDokument31 SeitenPipe Size - Steel Pipeedark2009Noch keine Bewertungen

- 12 Load RestraintDokument12 Seiten12 Load Restraintedark2009Noch keine Bewertungen

- Staal 40 Akd / Akds: Technical DataDokument6 SeitenStaal 40 Akd / Akds: Technical Dataedark2009Noch keine Bewertungen

- Akd/Akds: Gate ValvesDokument6 SeitenAkd/Akds: Gate Valvesedark2009Noch keine Bewertungen

- Nobles Contact Details Across AustraliaDokument17 SeitenNobles Contact Details Across Australiaedark2009Noch keine Bewertungen

- 14 ElectronicsDokument16 Seiten14 Electronicsedark2009Noch keine Bewertungen

- 15 Height SafetyDokument19 Seiten15 Height Safetyedark2009Noch keine Bewertungen

- Body Safety Valve Spring-Loaded: Without Bursting DiscDokument4 SeitenBody Safety Valve Spring-Loaded: Without Bursting Discedark2009Noch keine Bewertungen

- Aks/Akss: Gate ValvesDokument6 SeitenAks/Akss: Gate Valvesedark2009Noch keine Bewertungen

- Danais 150 (GB.1)Dokument23 SeitenDanais 150 (GB.1)edark2009Noch keine Bewertungen

- Gate Valve Selection ChartDokument8 SeitenGate Valve Selection Chartedark2009Noch keine Bewertungen

- Akg-A/Akgs-A: Gate ValvesDokument6 SeitenAkg-A/Akgs-A: Gate Valvesedark2009Noch keine Bewertungen

- ACTAIR 1.5 to 800 pneumatic actuators technical selection guideDokument16 SeitenACTAIR 1.5 to 800 pneumatic actuators technical selection guideedark2009Noch keine Bewertungen

- DYNACTAIR 3 To 100 Selection Chart For Throttling DutiesDokument8 SeitenDYNACTAIR 3 To 100 Selection Chart For Throttling Dutiesedark2009Noch keine Bewertungen

- Acris Isoria Mammouth: Menú Selección Válvulas Menú Válvulas de MariposaDokument12 SeitenAcris Isoria Mammouth: Menú Selección Válvulas Menú Válvulas de Mariposaedark2009Noch keine Bewertungen

- ACTAIR 3 To 200 Selection ChartDokument12 SeitenACTAIR 3 To 200 Selection Chartedark2009Noch keine Bewertungen

- D39ex PX-22 Cen00321-02Dokument12 SeitenD39ex PX-22 Cen00321-02Yosytha Parissing100% (1)

- With Tier 3 Engine: 263 KW 353 HP at 1900 RPMDokument12 SeitenWith Tier 3 Engine: 263 KW 353 HP at 1900 RPMedark2009Noch keine Bewertungen

- Danais 150 ActuadoresDokument28 SeitenDanais 150 Actuadoresedark2009Noch keine Bewertungen

- Danais 150 CatálogoDokument12 SeitenDanais 150 Catálogoedark2009Noch keine Bewertungen

- Da Wa GBDokument10 SeitenDa Wa GBedark2009Noch keine Bewertungen

- D39EX-22 D39PX-22: With Hydrostatic Transmission (HST)Dokument12 SeitenD39EX-22 D39PX-22: With Hydrostatic Transmission (HST)edark2009Noch keine Bewertungen

- Tier 4 Interim Engine: Operating Weight Net Horsepower Bucket CapacityDokument16 SeitenTier 4 Interim Engine: Operating Weight Net Horsepower Bucket Capacityedark2009Noch keine Bewertungen

- Tier 4 Interim Engine: Operating Weight Net Horsepower Bucket CapacityDokument16 SeitenTier 4 Interim Engine: Operating Weight Net Horsepower Bucket Capacityedark2009Noch keine Bewertungen

- Caterpillar 5631-04Dokument28 SeitenCaterpillar 5631-04Marcelo CardozoNoch keine Bewertungen

- C 10437180Dokument4 SeitenC 10437180Nelio Lara RicaldiNoch keine Bewertungen

- Folder 924KDokument4 SeitenFolder 924KDelgado FelipeNoch keine Bewertungen

- Reading Week 23Dokument4 SeitenReading Week 23api-263759920Noch keine Bewertungen

- Easiest Method On How To Cheat FUT 20 On Xbox One, PS4 and PCDokument3 SeitenEasiest Method On How To Cheat FUT 20 On Xbox One, PS4 and PCTuran46PriceNoch keine Bewertungen

- Shimano SLX HG81 Cassette Service ManualDokument1 SeiteShimano SLX HG81 Cassette Service ManualJose Luis GutierrezNoch keine Bewertungen

- Cuphead (Don't Deal With The Devil) StoryDokument6 SeitenCuphead (Don't Deal With The Devil) StoryJOS JOSNoch keine Bewertungen

- Rules - Game of The GeneralsDokument3 SeitenRules - Game of The GeneralsRikki EnriquezNoch keine Bewertungen

- Dynamic Gait IndexDokument2 SeitenDynamic Gait Indexvision xeroxNoch keine Bewertungen

- 2022 Presidential Scholars ProgramDokument8 Seiten2022 Presidential Scholars ProgramWKYC.comNoch keine Bewertungen

- Describing Cristiano Ronaldo Kelas 7Dokument28 SeitenDescribing Cristiano Ronaldo Kelas 7apud mahpudin0% (1)

- Physics I Problems PDFDokument1 SeitePhysics I Problems PDFbosschellenNoch keine Bewertungen

- ISO Flanges & Components GuideDokument12 SeitenISO Flanges & Components GuideJyoti Shankar MishraNoch keine Bewertungen

- Jute Draw FrameDokument4 SeitenJute Draw FrameRobotrix100% (2)

- 1X2 Handicap Double Chance Draw No Bet Under/Ov Er Goal/No Goal 1st Half To Score First Goal Total GoalsDokument36 Seiten1X2 Handicap Double Chance Draw No Bet Under/Ov Er Goal/No Goal 1st Half To Score First Goal Total GoalsOkunsolawo Samuel SeyiNoch keine Bewertungen

- Rotat PDFDokument54 SeitenRotat PDFSai PragathiNoch keine Bewertungen

- Channel Lineup: 1-800-XFINITYDokument2 SeitenChannel Lineup: 1-800-XFINITYLizbeth HerreraNoch keine Bewertungen

- 316 US Colleges With Non-Binding Early Action PlansDokument10 Seiten316 US Colleges With Non-Binding Early Action PlanspalanitNoch keine Bewertungen

- Manual Power GenerationDokument1 SeiteManual Power Generationmarlon073050Noch keine Bewertungen

- TASKalfa 1800 1801 2200 2201 PL UK - Rev2 PDFDokument49 SeitenTASKalfa 1800 1801 2200 2201 PL UK - Rev2 PDFMarch Dominick CatoNoch keine Bewertungen

- CSCDokument20 SeitenCSCSheheryar KhanNoch keine Bewertungen