Beruflich Dokumente

Kultur Dokumente

Chlor Alkali PDF

Hochgeladen von

elhamOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chlor Alkali PDF

Hochgeladen von

elhamCopyright:

Verfügbare Formate

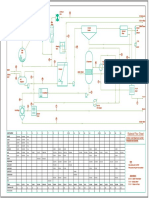

Cl2 gas

precoat Filter Aid Chlorine

Sodium Carbonate From Hypo Chlorine

Cooler

Destruction Blower Cl2

Steam LP Steam Demin Water Unit

Demin Water

Distribution

Demin Water From Hypo To Weak Brine Tank

Hydrogen

Cooler AB Chlorine Filter AB

AB

Sodium Carbonate Plant

Condensate

Return Storage

Hydrogen Vent

AB

Gas to Atm.

Chlorine Drying / Compression and Liquification aftrer

Brine

Hydrogen Hydrogen to

wet gas cooling section. ( after Blower )

Exchange Units

Compressor Lime Klin

NaoH

Brine Filter 98 % H2SO4

Coagulant Intermediate from Tank

Filter Cake To Effulent Demin Water Caustic ( 33 % )

Salt Salt Treatment Storage Tank

Demin Water

AB Cell Caustic

AB NaoH

Catholyte

Tank

Cooler

Diluted NaoH AB

Dry Chlorine Gas Dry Gas filter contatining

Glass fiber element for

C

Acid Mist seperation

Dcompression

Brine Storage

C AB C

Cl2

Brine

Saturator Saturator

Brine

Treatment AB AB Impingement or

D GH

NaoH

GH

Tank

Electrolyzers Bubble Cap Tray

E

HCL

T=20 deg C

Brine Clarified Cooling Water

GH GH

Demin Water Water

D

P = 2.5 bar

Clarifier Brine Tank Gas cooler

AB HCL From HCL Acid

Tank

Brine

Distribution

Chilled water Pre Dried

Cl2 Gas Gas re-circulation from

AB warm water

Dechlorinator

Tower compression.

Packings

LP Steam

AB AB LP Steam

NaoH

AB GH II nd Drying Column

Compressed Dry

HCL Chlorine Gas

Sludge Sludge filter Deionized Weak Brine

Filtered Dechlorinated

Carbonate Brine Storage Tank Brine Tank

Tank Brine Tank Wet Cl2 Gas

Tank

Filter Cake Condensate

Chlorate Destruction

after Blower . GH

To Effulent

Treatment

To Effulent

Treatment

AB Demin Water AB AB AB Deplted Acid P= 2000 mm Chlorine Liquifier Sniff Gas to absorption

or HCl acid synthesis

D

wc I'st Drying Column

Compressed

Cl2 Gas

AB

Sulphate

Removal

Chilling Media out

Chilling Media in

System

Effulent to

Sewar D

Liquid CL2

Storage Area

NaoH ( 33 %)

NaoH Dilution

( 50 %) NaoH NaoH

Bleaching

NaoH

Caustcizing

NaoH

Cl2 Drying

Section

H2So4 H2So4

( 98 % )

H2So4

Bleaching

Phoenix -Plant wide Gaskets Recommendation for

Chlor-alkali (Membrane cell ) Production plant.

A PS - 5001 - Panacea 6962 EPDM Gaskets G PS 5007 - 100 % Bi-axially Expanded PTFE gaskets.

B PS - 5001A - Electrolytic B3769 EPDM ( Flat & or Dual molded ) Gaskets H PS 5007 A - Uniaxially Expanded PTFE Joint Sealants.

C PS - 5002 - PTFE Noosed Special EPDM Gaskets. I PS 5005 - " Reduced Area" Special Low Torque ePTFE Gaskets.

D PS - 5006 - Pamphlet 95 Gaskets - Restructured PTFE - PTG-W , D 900 J Modified and Filled Special PTFE Gaskets. - Gylon & or Equi.

E Chlorine Membrane cell - Cathode / Anode Gaskets. K PTFE + Steel Insert Gaskets

F PS -5003/04 - Panacea PP 340 / R3400, PP -363 Gaskets.

Das könnte Ihnen auch gefallen

- NASA Facts Explorer XVI The Micrometeoroid SatelliteDokument4 SeitenNASA Facts Explorer XVI The Micrometeoroid SatelliteBob AndrepontNoch keine Bewertungen

- ANSI-ASME B16.47a (1998)Dokument90 SeitenANSI-ASME B16.47a (1998)elham100% (1)

- Consumer Surplus:: at K Chabveka Economics NotesDokument28 SeitenConsumer Surplus:: at K Chabveka Economics NotesShawn DzingayiNoch keine Bewertungen

- Pump Station System Curves Session 1Dokument29 SeitenPump Station System Curves Session 1Toan LeNoch keine Bewertungen

- The Mechanism of Gold Cyanide of Elution From Activated CarbonDokument2 SeitenThe Mechanism of Gold Cyanide of Elution From Activated CarbonwandadwilestariNoch keine Bewertungen

- Equipment Cost Index Available I Exclusively From Marshall & SwiftDokument2 SeitenEquipment Cost Index Available I Exclusively From Marshall & Swiftrubench6Noch keine Bewertungen

- NaOH UllmanDokument12 SeitenNaOH UllmanelhamNoch keine Bewertungen

- Day 4 - Iron Control PDFDokument37 SeitenDay 4 - Iron Control PDFMohanned Khairy100% (1)

- Nonferrous MetalsDokument93 SeitenNonferrous MetalsVignesh KumarNoch keine Bewertungen

- Math 11-CORE Gen Math-Q2-Week 1Dokument26 SeitenMath 11-CORE Gen Math-Q2-Week 1Christian GebañaNoch keine Bewertungen

- Copper Leaching From Chalcopyrite Concentrate in Cu (II) - Fe (III) Chloride SystemDokument6 SeitenCopper Leaching From Chalcopyrite Concentrate in Cu (II) - Fe (III) Chloride SystemSantiago NuñezNoch keine Bewertungen

- Gbhe-Peg-015 Practical Guide On The Reduction of DiscDokument87 SeitenGbhe-Peg-015 Practical Guide On The Reduction of DiscjrfmlNoch keine Bewertungen

- Midrex - Slurry TreatmentDokument2 SeitenMidrex - Slurry TreatmentMorteza RafieiNoch keine Bewertungen

- Solvent Extraction of Palladium From Chloride Media by TBPDokument6 SeitenSolvent Extraction of Palladium From Chloride Media by TBPMoreno MarcatiNoch keine Bewertungen

- SGS MIN 2001 04 Cyanide Management by SART en 11 09Dokument7 SeitenSGS MIN 2001 04 Cyanide Management by SART en 11 09Jon CastilloNoch keine Bewertungen

- Filtration Systems For Chlor-Alkali and Chlorate Plants: Edition 3, Dec 2017Dokument9 SeitenFiltration Systems For Chlor-Alkali and Chlorate Plants: Edition 3, Dec 2017elhamNoch keine Bewertungen

- Cytec Solutions 14 FinalDokument24 SeitenCytec Solutions 14 FinalAnonymous KDM8wArgNoch keine Bewertungen

- ION - CCP - LAB INSTRUCTIONS - Dr. NEUMANN - 2008 - 07 - 10 PDFDokument40 SeitenION - CCP - LAB INSTRUCTIONS - Dr. NEUMANN - 2008 - 07 - 10 PDFRahul Khandelwal100% (2)

- Material Flow SheetDokument1 SeiteMaterial Flow Sheetharsha0% (1)

- HCL ScrubberDokument2 SeitenHCL Scrubbersundhar100% (2)

- Creating Interfaces For The SAP Application Interface Framework With Service Implementation WorkbenchDokument12 SeitenCreating Interfaces For The SAP Application Interface Framework With Service Implementation WorkbenchKrishanu DuttaNoch keine Bewertungen

- Caustic Soda Industry-1Dokument3 SeitenCaustic Soda Industry-1Muhammad KhurramNoch keine Bewertungen

- Bubble Column TechnologyDokument34 SeitenBubble Column TechnologyВладимир Петров100% (1)

- Indian Oil's Petrochemical Initiatives at Paradip & Downstream OpportunitiesDokument26 SeitenIndian Oil's Petrochemical Initiatives at Paradip & Downstream Opportunitiesabhishek chowdhury100% (1)

- Chambal Fertilizers 2015 Chemical Plant Functioning Adder LedgerDokument38 SeitenChambal Fertilizers 2015 Chemical Plant Functioning Adder LedgerPallavNoch keine Bewertungen

- 2017-02-15 Brochure Ammonium Sulfate Plants SCRDokument8 Seiten2017-02-15 Brochure Ammonium Sulfate Plants SCRSya Fitri MarsellaNoch keine Bewertungen

- Current Status, Research Trends, and ChallengesDokument23 SeitenCurrent Status, Research Trends, and Challengesqgi-tanyaNoch keine Bewertungen

- Vapour Pressure DataDokument44 SeitenVapour Pressure Dataramsrivatsan50% (2)

- Caustic Soda 1Dokument21 SeitenCaustic Soda 1arpit garg100% (1)

- Random PackingDokument4 SeitenRandom PackingAadam AryanNoch keine Bewertungen

- NaOH Practicality StudyDokument51 SeitenNaOH Practicality StudyPeterWangNoch keine Bewertungen

- Production of Pearl Caustic Soda-653343 PDFDokument62 SeitenProduction of Pearl Caustic Soda-653343 PDFhardajhbfNoch keine Bewertungen

- CausticDokument40 SeitenCausticMulugeta ShiferawNoch keine Bewertungen

- Application Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFDokument8 SeitenApplication Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFAbhisek BhattacharyaNoch keine Bewertungen

- Plant Design of MIBKDokument59 SeitenPlant Design of MIBKmalini1989100% (2)

- Caustic EvaporationDokument2 SeitenCaustic EvaporationSihanu Subasingha100% (1)

- The Dry Reforming of Methane To Syngas and Subsequent Products PDFDokument107 SeitenThe Dry Reforming of Methane To Syngas and Subsequent Products PDFIntan Clarissa SophianaNoch keine Bewertungen

- SABC-1 - Circuit DesignDokument186 SeitenSABC-1 - Circuit DesignALBERTO NICHO HONDERMANNNoch keine Bewertungen

- Copper Lead Zinc OresDokument1 SeiteCopper Lead Zinc OresAnnie Black MussaNoch keine Bewertungen

- Kolwezi SX StudyDokument22 SeitenKolwezi SX StudywitkerzNoch keine Bewertungen

- NAC&SACDokument5 SeitenNAC&SACEngr. Asif malikNoch keine Bewertungen

- A Parametric Study of Froth Stability and Its EffectDokument19 SeitenA Parametric Study of Froth Stability and Its EffectJuan OlivaresNoch keine Bewertungen

- SiCl4 PreparationDokument5 SeitenSiCl4 PreparationAdam FlynnNoch keine Bewertungen

- AS Crystallization GEADokument6 SeitenAS Crystallization GEADiden DzNoch keine Bewertungen

- Modeling and Simulation of CSTR For Manufacture of Propylene GlycolDokument6 SeitenModeling and Simulation of CSTR For Manufacture of Propylene Glycolantoojacome100% (1)

- Nicholas Oligomerization PDFDokument16 SeitenNicholas Oligomerization PDFTanase DianaNoch keine Bewertungen

- Hydrocyclone BrochureDokument8 SeitenHydrocyclone BrochureMartin.c.figueroaNoch keine Bewertungen

- Descripsi Process Direct Neutralization Oe Synthetic ManufactureDokument9 SeitenDescripsi Process Direct Neutralization Oe Synthetic Manufacturerifqi fatmalaNoch keine Bewertungen

- Development of A Vanadium Redox Flow Battery For Energy Storage PDFDokument90 SeitenDevelopment of A Vanadium Redox Flow Battery For Energy Storage PDFpokygangNoch keine Bewertungen

- HSFCCDokument22 SeitenHSFCCdonald55555100% (1)

- Jacobi Tds Colorsorb Hp120a A4 Eng E0116Dokument2 SeitenJacobi Tds Colorsorb Hp120a A4 Eng E0116Alfonso García100% (1)

- 104SE-Combining New and Old Technologies - Inlet Diffuser and Random Packing Dramatically Improve Reactor PerformanceDokument10 Seiten104SE-Combining New and Old Technologies - Inlet Diffuser and Random Packing Dramatically Improve Reactor PerformanceSHINoch keine Bewertungen

- Mamufacturing of Potassium ChlorideDokument16 SeitenMamufacturing of Potassium Chloriderajesh100% (1)

- Solvay Process Obtencion Soda AshDokument6 SeitenSolvay Process Obtencion Soda AshvrosalioNoch keine Bewertungen

- Kinetic and Thermodynamic Study of Methanolysis of Poly (Ethylene Terephthalate) Waste PowderDokument6 SeitenKinetic and Thermodynamic Study of Methanolysis of Poly (Ethylene Terephthalate) Waste PowderMaria ElaineNoch keine Bewertungen

- Sodium BisulphateDokument14 SeitenSodium BisulphatemelvinkuriNoch keine Bewertungen

- Ammonium SulphateDokument32 SeitenAmmonium SulphateHariz Skeikh100% (1)

- Crystallize RsDokument12 SeitenCrystallize RsVishal SinghNoch keine Bewertungen

- Z - Chemical Process Industries - K, N IndustriesDokument68 SeitenZ - Chemical Process Industries - K, N IndustriesZVSNoch keine Bewertungen

- Technical - Data - Sheet - Catalyst - HR 538Dokument1 SeiteTechnical - Data - Sheet - Catalyst - HR 538mohsen ranjbarNoch keine Bewertungen

- Scientific Glass EquipmentDokument28 SeitenScientific Glass EquipmentJuan P RuizNoch keine Bewertungen

- Ammonium Sulfate Crystallization Fertilizer Gea - tcm11 34855 PDFDokument8 SeitenAmmonium Sulfate Crystallization Fertilizer Gea - tcm11 34855 PDFIrwan100% (1)

- Sulfuric Acid (H SO) IndustryDokument27 SeitenSulfuric Acid (H SO) IndustryAqsa chNoch keine Bewertungen

- Ammonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEODokument33 SeitenAmmonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEOAkil PrabhuNoch keine Bewertungen

- Chlorine: International Thermodynamic Tables of the Fluid StateVon EverandChlorine: International Thermodynamic Tables of the Fluid StateNoch keine Bewertungen

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsVon EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNoch keine Bewertungen

- Selected Constants: Oxidation–Reduction Potentials of Inorganic Substances in Aqueous SolutionVon EverandSelected Constants: Oxidation–Reduction Potentials of Inorganic Substances in Aqueous SolutionNoch keine Bewertungen

- CN101874949A - Back-Washing Regeneration Method of Ceramic Membrane Method Brine Refining Process Filter - Google PatentsDokument4 SeitenCN101874949A - Back-Washing Regeneration Method of Ceramic Membrane Method Brine Refining Process Filter - Google PatentselhamNoch keine Bewertungen

- Vdocuments - MX - Filter Press TechnologyDokument12 SeitenVdocuments - MX - Filter Press TechnologyelhamNoch keine Bewertungen

- 000405Dokument117 Seiten000405elhamNoch keine Bewertungen

- Ceramic Membrane Filtration System: Jiangsu Jiuwu Hi-Tech Co., LTDDokument2 SeitenCeramic Membrane Filtration System: Jiangsu Jiuwu Hi-Tech Co., LTDelhamNoch keine Bewertungen

- 000042Dokument114 Seiten000042elhamNoch keine Bewertungen

- Coulson & Richardson's Chemical EngineeringDokument1 SeiteCoulson & Richardson's Chemical EngineeringelhamNoch keine Bewertungen

- Chapter20 IonicEquilibriaIIITheSolubilityProductPrincipleDokument37 SeitenChapter20 IonicEquilibriaIIITheSolubilityProductPrincipleelhamNoch keine Bewertungen

- Coulson & Richardson's Chemical EngineeringDokument1 SeiteCoulson & Richardson's Chemical EngineeringelhamNoch keine Bewertungen

- Thesis Ebe 1978 Wiechers Hermannus Nikolaas Sybrandus PDFDokument638 SeitenThesis Ebe 1978 Wiechers Hermannus Nikolaas Sybrandus PDFelhamNoch keine Bewertungen

- Detailed Modeling of Hydrodynamics, Mass Transfer and Chemical Reactions in A Bubble Column Using A Discrete Bubble ModelDokument22 SeitenDetailed Modeling of Hydrodynamics, Mass Transfer and Chemical Reactions in A Bubble Column Using A Discrete Bubble ModelelhamNoch keine Bewertungen

- Rahim Pour 2010Dokument9 SeitenRahim Pour 2010elhamNoch keine Bewertungen

- FluidsDokument10 SeitenFluidslara alghamdiNoch keine Bewertungen

- Asset Failure Detention Codes (ICMS - PAM - ZN - SECR 312)Dokument5 SeitenAsset Failure Detention Codes (ICMS - PAM - ZN - SECR 312)mukesh lachhwani100% (1)

- Test 4: GRE Real 19Dokument6 SeitenTest 4: GRE Real 19rdrprsdm2640Noch keine Bewertungen

- Afghan SnowflakeDokument3 SeitenAfghan SnowflakekiwibeasNoch keine Bewertungen

- Proview TutorialDokument12 SeitenProview TutorialManoel NascimentoNoch keine Bewertungen

- Database Management SystemsDokument19 SeitenDatabase Management Systemsshreeya PatilNoch keine Bewertungen

- Money Calculations (F)Dokument14 SeitenMoney Calculations (F)Pavan GhelaniNoch keine Bewertungen

- Staircase Preliminary Design Based On NBC and IS CodeDokument10 SeitenStaircase Preliminary Design Based On NBC and IS CodeEducation. HubNoch keine Bewertungen

- Research Proposal TransformerDokument3 SeitenResearch Proposal Transformersohalder1026Noch keine Bewertungen

- Princom The Fundamentals of Electronics Module 2Dokument9 SeitenPrincom The Fundamentals of Electronics Module 2melwin victoriaNoch keine Bewertungen

- LISTA PRECIOS CORPORATIVOS - Garantia en Partes de Diez (10) MesesDokument10 SeitenLISTA PRECIOS CORPORATIVOS - Garantia en Partes de Diez (10) MesesJavier DavidNoch keine Bewertungen

- PU225 Series: Solenoid ValveDokument1 SeitePU225 Series: Solenoid Valveremus popescuNoch keine Bewertungen

- FMC - Novolastic Subsea Thermal Insulation - LOW RESDokument3 SeitenFMC - Novolastic Subsea Thermal Insulation - LOW RESalphading50% (2)

- Assignment 1 - Spring2006: SolutionDokument31 SeitenAssignment 1 - Spring2006: SolutionMuhammad UmairNoch keine Bewertungen

- PM BCE DCS Crash WebDokument4 SeitenPM BCE DCS Crash WebAna Paola VazquezNoch keine Bewertungen

- Unit 7 Motion Review Sheet AnswersDokument3 SeitenUnit 7 Motion Review Sheet AnswersFlorie Fe Rosario Ortega100% (1)

- LSMW To Update Customer Master Records With Standard ObjectDokument9 SeitenLSMW To Update Customer Master Records With Standard ObjectShahid_ONNoch keine Bewertungen

- Ali Math Competition 3 English Reference SolutionsDokument11 SeitenAli Math Competition 3 English Reference SolutionsJEREMIAH ITCHAGBENoch keine Bewertungen

- RF Optimization Tips - TCH Block Rate Optimization Tips in Huawei GSMDokument4 SeitenRF Optimization Tips - TCH Block Rate Optimization Tips in Huawei GSMdolisieNoch keine Bewertungen

- Surveying PDFDokument215 SeitenSurveying PDFShaira Mae Cañedo100% (1)

- Sap Basis Transaction CodesDokument2 SeitenSap Basis Transaction CodeskatrinbreaksNoch keine Bewertungen

- Chapter Test 2nd Quarter.Dokument5 SeitenChapter Test 2nd Quarter.Roziel MontalbanNoch keine Bewertungen

- BM2 24H+Installation+InstructionsDokument7 SeitenBM2 24H+Installation+InstructionsremediospereiraNoch keine Bewertungen

- August 19-23 Lesson PlanDokument1 SeiteAugust 19-23 Lesson Planapi-282162606Noch keine Bewertungen

- Differentiation11 21Dokument75 SeitenDifferentiation11 21Maryam ShahidNoch keine Bewertungen