Beruflich Dokumente

Kultur Dokumente

MAF Sensor Testing: The Tech-Assist Team

Hochgeladen von

dorckyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MAF Sensor Testing: The Tech-Assist Team

Hochgeladen von

dorckyCopyright:

Verfügbare Formate

MAF Sensor Testing

The Tech-Assist Team

It’s always a good idea to test a Mass Airflow (MAF) sensor before replacing it.

Here is a fast and accurate way to track a MAF’s performance and output to the PCM.

Connect a scan tool to see the MAF sensor Parameter Identification Data (PID) information. With the

engine at idle, the MAF’s PID value should read anywhere from 2 to 7 grams/second (g/s) at idle and rise

to between 15 to 25 g/s at 2500 rpm, depending on engine size. Most manufacturers provide

specifications for air flow at idle; some will provide specifications at several engine speeds. Those

specifications can be found in manufacturer’s PID value charts under “Scan Tool Testing and

Procedures” in ALLDATA.

A MAF sensor works dynamically, so the question becomes: Is the MAF accurate throughout the engine’s

rpm range? If it is not linear, various drivability problems can occur.

The most effective way to verify the MAF’s signal to the PCM is to graph the sensor’s output while running

the engine between 1000 and 2250 rpm.

If you do not have a graphing feature on your scan tool, no problem. You can use graph paper, which can

be purchased from any retailer that carries school or office supplies … or you can grab a few sheets from

your kids.

1. Plot the horizontal points along the bottom of the graph paper for: 1000, 1250, 1500, 1750, 2000,

2250 rpm.

2. Mark increments of grams per second (voltage or frequency) up the left side. Note: To create your

vertical scale, use the value you read at idle (g/s, voltage, or frequency) to determine the baseline

value. Then mark each line above in equal increments. In Example 1 below, we used 0.5 grams per

second increments.

3. Run the engine at each of the above-mentioned speeds and record the MAF sensor PID values on

the graph.

Interpreting the Test Results

Note: Graphs below are examples. Actual grams per second, voltage or frequency readings should come

from the MAF signal data on the scan tool at specified rpm settings.

Example 1

A good MAF senor should show a steady linear rise from

1000 to 2250.

(Sample from 2009 Ford Focus 2.0L)

Example 2

A sensor out of calibration may rise too quickly in reaction

to the rpm. This could cause an acceleration problem.

Example 3

A sensor with a dirty sensing wire or not measuring all the

air (air leak downstream) may rise too slowly.

Example 4

Another approach would be to graph both the TPS and the

MAF sensor because they should essentially produce a

plotted graph rising parallel to each other.

The graph you’ve created is also a great sales tool at the front counter. It makes explaining and verifying

the problem with your customers very easy and they’ll appreciate the fact you took to time to diagnose the

problem accurately.

Remember… If you’ve done your homework and are still not sure, then call Tech-Assist. We’re always

glad to help.

Das könnte Ihnen auch gefallen

- Vehicle Sensors WiringDokument8 SeitenVehicle Sensors WiringAudrick RussellNoch keine Bewertungen

- Automotive Electronic Diagnostics (Course 2)Von EverandAutomotive Electronic Diagnostics (Course 2)Bewertung: 4 von 5 Sternen4/5 (2)

- The Basics of Testing A Mass Air Flow (MAF) SensorDokument5 SeitenThe Basics of Testing A Mass Air Flow (MAF) SensorbroNoch keine Bewertungen

- VW Wiring DiagramDokument7 SeitenVW Wiring Diagramdorcky100% (1)

- FORScan Programming Modules Acronyms-AbbreviationsDokument4 SeitenFORScan Programming Modules Acronyms-AbbreviationsdorckyNoch keine Bewertungen

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Ob Di I Data InterpretationDokument8 SeitenOb Di I Data InterpretationMohamed WahiebNoch keine Bewertungen

- ThinkPad T440p SchematicsDokument99 SeitenThinkPad T440p Schematicsh432fh9832hf98hdsjfhNoch keine Bewertungen

- Mass Airflow MAF SensorsDokument8 SeitenMass Airflow MAF SensorsAlainbravopaezNoch keine Bewertungen

- Interpreting Generic OBDDokument6 SeitenInterpreting Generic OBDsurfsandNoch keine Bewertungen

- Obdii PDFDokument7 SeitenObdii PDFKe DFNoch keine Bewertungen

- How To Test The GM MAF SensorDokument37 SeitenHow To Test The GM MAF SensorEngine Tuning UP100% (1)

- DMAIC - GRR TemplateDokument25 SeitenDMAIC - GRR TemplateAnonymous rvXfvFNoch keine Bewertungen

- Specs Motor Grader Power TrainDokument52 SeitenSpecs Motor Grader Power Trainkaswade Brian100% (1)

- AirBag CONN PDFDokument12 SeitenAirBag CONN PDFdorckyNoch keine Bewertungen

- Calibration of Smart TransmittersDokument4 SeitenCalibration of Smart TransmittersLugabalugaNoch keine Bewertungen

- MAF Sensor TestDokument11 SeitenMAF Sensor TestagungkiworejoNoch keine Bewertungen

- How Can I Make Loop Check For Pressure Transmitter and Temperature TransmitterDokument11 SeitenHow Can I Make Loop Check For Pressure Transmitter and Temperature Transmittersushant_jhawer100% (1)

- PowerScale - Isilon - A3000 and A300-PowerScale Node Installation GuideDokument40 SeitenPowerScale - Isilon - A3000 and A300-PowerScale Node Installation Guidejega20067559Noch keine Bewertungen

- Belt Conveyors With Shaft SizingDokument5 SeitenBelt Conveyors With Shaft SizingRakhi Mor100% (2)

- Quickdev16 & Super Nintendo: David Voswinkel Matthias Nagler Matt@dforce3000.deDokument181 SeitenQuickdev16 & Super Nintendo: David Voswinkel Matthias Nagler Matt@dforce3000.deoptixxNoch keine Bewertungen

- Me7.1 - Me7.5 - Bosch SchemaDokument1 SeiteMe7.1 - Me7.5 - Bosch Schemadorcky100% (1)

- Calibration of Differential Pressure TransmitterDokument8 SeitenCalibration of Differential Pressure TransmitterLugabaluga100% (1)

- CVC Inline Filling PresentationDokument26 SeitenCVC Inline Filling PresentationFithrul Mubarok100% (1)

- WB31238 Diy-WorkbenchDokument8 SeitenWB31238 Diy-WorkbenchFrancois VaaltynNoch keine Bewertungen

- Troubleshooting Low TBF Establishment Success RatesDokument8 SeitenTroubleshooting Low TBF Establishment Success RateshoneyhhhNoch keine Bewertungen

- Pure Vent User Manual Rev 9Dokument64 SeitenPure Vent User Manual Rev 9Sandro SammoriNoch keine Bewertungen

- Maf Sensor Testing PDFDokument2 SeitenMaf Sensor Testing PDFsimon_someone217Noch keine Bewertungen

- The Mass Airflow Sensor On Your Mitsubishi VehicleDokument8 SeitenThe Mass Airflow Sensor On Your Mitsubishi VehicleAndrey AndrienkoNoch keine Bewertungen

- SenserDokument2 SeitenSenserNurul Huda SobariNoch keine Bewertungen

- Module 3-1Dokument35 SeitenModule 3-1charan cherryNoch keine Bewertungen

- Using The ODS Wizard To Animate Vibration Test ResultsDokument8 SeitenUsing The ODS Wizard To Animate Vibration Test Resultsjuancgr77Noch keine Bewertungen

- Zero OneDokument12 SeitenZero OneNestor Daniel Gonzales ArévaloNoch keine Bewertungen

- Fuzzy Logic For "Just Plain Folks "Dokument12 SeitenFuzzy Logic For "Just Plain Folks "gNoch keine Bewertungen

- Control SystemDokument10 SeitenControl Systemrajeswari_ece07Noch keine Bewertungen

- Strategies For High Quality Low Cost Optical Sensors - Automotive v7Dokument11 SeitenStrategies For High Quality Low Cost Optical Sensors - Automotive v7Poovannan PrakashNoch keine Bewertungen

- Residual Threshold PhilosophyDokument9 SeitenResidual Threshold PhilosophyTim HoltanNoch keine Bewertungen

- Ece224 MDP w2017Dokument8 SeitenEce224 MDP w2017phoebezzNoch keine Bewertungen

- Decoding Tachometer Signals Using CompactRIO and LabVIEW FPGADokument3 SeitenDecoding Tachometer Signals Using CompactRIO and LabVIEW FPGAOualid LamraouiNoch keine Bewertungen

- SK 09 DPF Emulator en SokrDokument9 SeitenSK 09 DPF Emulator en SokrizzarhmanNoch keine Bewertungen

- Assessment Sheet: Manifold Absolute Pressure (MAP) Sensor Provides Instantaneous Manifold Pressure InformationDokument6 SeitenAssessment Sheet: Manifold Absolute Pressure (MAP) Sensor Provides Instantaneous Manifold Pressure InformationShalini ShaluNoch keine Bewertungen

- LT1 PCM Scanning-R2Dokument29 SeitenLT1 PCM Scanning-R2justin stokerNoch keine Bewertungen

- LMS Test - Lab Signature-Cycle To Cycle To Averaging: ScottbeebeDokument26 SeitenLMS Test - Lab Signature-Cycle To Cycle To Averaging: ScottbeebeWe learnNoch keine Bewertungen

- Time Waveform AnalysisDokument17 SeitenTime Waveform AnalysisZaidiey HashimNoch keine Bewertungen

- Calibrate DP TXRDokument2 SeitenCalibrate DP TXRSudhanNoch keine Bewertungen

- 10step To A Perfect Digital DemodulationDokument16 Seiten10step To A Perfect Digital Demodulationbayman66Noch keine Bewertungen

- Ad7714/Ad7715 Instrumentation Converter Faqs: Calibration: How Is Self-Calibration Implemented On The Ad7714/Ad7715?Dokument4 SeitenAd7714/Ad7715 Instrumentation Converter Faqs: Calibration: How Is Self-Calibration Implemented On The Ad7714/Ad7715?mhasansharifiNoch keine Bewertungen

- Application of Flow Computers For Gas Measurement and ControlDokument6 SeitenApplication of Flow Computers For Gas Measurement and Controlvarunsingh302Noch keine Bewertungen

- FlowCAD An PSpice AutoConvergenceDokument10 SeitenFlowCAD An PSpice AutoConvergenceSirish OrugantiNoch keine Bewertungen

- Lab 14Dokument6 SeitenLab 14diegogachet1618Noch keine Bewertungen

- Flowmaster v7.0 Easy GuideDokument109 SeitenFlowmaster v7.0 Easy Guidepinenamu100% (1)

- Fuel Trim Data - A Powerful Diagnostic Tool - MOTORDokument10 SeitenFuel Trim Data - A Powerful Diagnostic Tool - MOTORVesNoch keine Bewertungen

- Automotive ElectronicsDokument9 SeitenAutomotive ElectronicsJAIRAJ MIRASHINoch keine Bewertungen

- Using A Volumetric Efficiency CalculatorDokument1 SeiteUsing A Volumetric Efficiency CalculatorWilliam KibbeNoch keine Bewertungen

- Analog To Digital ConvertDokument20 SeitenAnalog To Digital ConvertluxiaofengNoch keine Bewertungen

- ADC Guide, Part 4: Gain Error and Gain Error Drift: by Sachin Gupta and Akshay Phatak, Cypress SemiconductorDokument4 SeitenADC Guide, Part 4: Gain Error and Gain Error Drift: by Sachin Gupta and Akshay Phatak, Cypress SemiconductorPedroNoch keine Bewertungen

- Wireless Speed Control Alarm: Prepared By: Nesrudin Musa Submitted To: DR - Ing. Dereje H/mariemDokument7 SeitenWireless Speed Control Alarm: Prepared By: Nesrudin Musa Submitted To: DR - Ing. Dereje H/mariemskfslkNoch keine Bewertungen

- Report TarpDokument17 SeitenReport Tarpsimran goelNoch keine Bewertungen

- AFM To MAF ConversionDokument11 SeitenAFM To MAF ConversionRonnie Peterson100% (1)

- Differetial Pressure TransmitterDokument6 SeitenDifferetial Pressure TransmitterService MMINoch keine Bewertungen

- Chapter 1 EepwDokument11 SeitenChapter 1 EepwPandimadevi SelvakumarNoch keine Bewertungen

- ControlslabreportDokument12 SeitenControlslabreportAsha PatilNoch keine Bewertungen

- Embed SensorDokument20 SeitenEmbed SensorBelinda LeeNoch keine Bewertungen

- Beee-Unit 4Dokument115 SeitenBeee-Unit 4Sano ManjiroNoch keine Bewertungen

- Range Ability Orifice PlateDokument6 SeitenRange Ability Orifice PlateVinay ChhatrolaNoch keine Bewertungen

- Chapter No.:-01 Introuuction: Pulse-Width Modulation (PWM), Modulation (PDM)Dokument63 SeitenChapter No.:-01 Introuuction: Pulse-Width Modulation (PWM), Modulation (PDM)Pooja BanNoch keine Bewertungen

- Accuracy and RepeatablityDokument5 SeitenAccuracy and RepeatablityWalid Ben HuseinNoch keine Bewertungen

- Digital Flow Meter For GasDokument1 SeiteDigital Flow Meter For GasMASSFLOWMEASUREMENTSNoch keine Bewertungen

- General Motion Control: Siemens STEP 2000 CourseDokument25 SeitenGeneral Motion Control: Siemens STEP 2000 CoursePereira PauloNoch keine Bewertungen

- Recommended Operations: 1. Detrend ACDokument5 SeitenRecommended Operations: 1. Detrend ACPradeep TongepatilNoch keine Bewertungen

- Upgrade From V0.94 To V1.03Dokument8 SeitenUpgrade From V0.94 To V1.03Javier RojasNoch keine Bewertungen

- Getting Started:: Living Room Kitchen RefrigDokument12 SeitenGetting Started:: Living Room Kitchen RefrigdorckyNoch keine Bewertungen

- Renault Kangoo 1.5 Dci 110 Fap (K9K-804 (C8) ) : Starting/Charging ( - 12/2011)Dokument2 SeitenRenault Kangoo 1.5 Dci 110 Fap (K9K-804 (C8) ) : Starting/Charging ( - 12/2011)dorckyNoch keine Bewertungen

- CP2112 EkDokument14 SeitenCP2112 EkdorckyNoch keine Bewertungen

- Design Example ReportDokument23 SeitenDesign Example ReportdorckyNoch keine Bewertungen

- Vane Gaz Honeywell PDFDokument16 SeitenVane Gaz Honeywell PDFdorckyNoch keine Bewertungen

- SDT 2 Model Application List V 2.15.1.10 USDokument2 SeitenSDT 2 Model Application List V 2.15.1.10 USdorckyNoch keine Bewertungen

- TPC8107Dokument8 SeitenTPC8107dorckyNoch keine Bewertungen

- Certificate of Conformity: SGS Tecnos, S.ADokument1 SeiteCertificate of Conformity: SGS Tecnos, S.Afiras abou sharafNoch keine Bewertungen

- Nexan Catalouge 2023Dokument11 SeitenNexan Catalouge 2023Roshan JhaNoch keine Bewertungen

- Tower Crane CatalogDokument159 SeitenTower Crane CatalogPoorna AbeywardanaNoch keine Bewertungen

- Electronic Systems and Design - Quiz 1FDokument5 SeitenElectronic Systems and Design - Quiz 1FAshly EspaldonNoch keine Bewertungen

- ATV930 950 Installation Manual en NHA80932 03Dokument143 SeitenATV930 950 Installation Manual en NHA80932 03Anonymous Th1OVYPQYTNoch keine Bewertungen

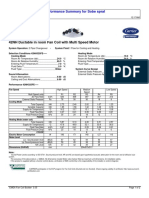

- 42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe SpratDokument2 Seiten42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe Spratvelikimag87Noch keine Bewertungen

- Cruisair 2014 PricebookDokument100 SeitenCruisair 2014 PricebooklatrancaNoch keine Bewertungen

- Tucson 2022 CatalogDokument8 SeitenTucson 2022 CatalogHyundai CambodiaNoch keine Bewertungen

- Push Button Agent Abort Switch Cut Sheet PDFDokument2 SeitenPush Button Agent Abort Switch Cut Sheet PDFAli HadiNoch keine Bewertungen

- Bettery ChargerDokument2 SeitenBettery ChargerArun GuptaNoch keine Bewertungen

- 4basics of LEDDokument3 Seiten4basics of LEDshaikh a nNoch keine Bewertungen

- MD Extru ManualDokument8 SeitenMD Extru ManualNahaadNoch keine Bewertungen

- Dmx512-A Guide (8x10) EstaDokument112 SeitenDmx512-A Guide (8x10) EstaArturo SierraNoch keine Bewertungen

- XL4015Dokument9 SeitenXL4015Jose M PeresNoch keine Bewertungen

- Electrolytic CapasitorDokument8 SeitenElectrolytic Capasitorgema ilham pangestuNoch keine Bewertungen

- Tanvo 45LDokument4 SeitenTanvo 45LTom AvidNoch keine Bewertungen

- VRV IV S Didvs2001 PDFDokument14 SeitenVRV IV S Didvs2001 PDFmas zak danielNoch keine Bewertungen

- 2d Insulation Resistance Monitor 6Dokument6 Seiten2d Insulation Resistance Monitor 6john smithNoch keine Bewertungen

- FAS Data SheetDokument2 SeitenFAS Data SheetYusNoch keine Bewertungen

- GHH Fahrzeuge MK-A20LP EN V1-16 2016-03-30 NeuDokument4 SeitenGHH Fahrzeuge MK-A20LP EN V1-16 2016-03-30 Neujyothi prakashNoch keine Bewertungen

- Dual Row Right Angle SMT Pin Header: 2037 SERIESDokument1 SeiteDual Row Right Angle SMT Pin Header: 2037 SERIESEstefaniaNoch keine Bewertungen

- Sheet 3Dokument3 SeitenSheet 3geo_bi100% (1)

- Everest U375 TEC EB3B-19G219-YAB AUS PDFDokument397 SeitenEverest U375 TEC EB3B-19G219-YAB AUS PDFIrvin James Mecos100% (1)