Beruflich Dokumente

Kultur Dokumente

Transcaer - Ammonia - Training - 2011 EmergencyResponse - IG - Rev14

Hochgeladen von

julianopetry10Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Transcaer - Ammonia - Training - 2011 EmergencyResponse - IG - Rev14

Hochgeladen von

julianopetry10Copyright:

Verfügbare Formate

Section 4: Anhydrous Ammonia Response 60 min.

Lesson Goal

After completing this lesson, the student should be familiar with response to

anhydrous ammonia events

Objectives

Upon successful completion of this section, the student should be able to:

A. Understand the potential release phases that can be encountered when

dealing with an anhydrous ammonia release

B. Understand real life cloud modeling and weather impacts on ammonia

releases and release phases

C. Employ safety measures such as assessing and protecting downwind

threats.

D. Understand terms and jargon used during an anhydrous ammonia

emergency and how they may affect communication during the event

E. Implement basic control and containment options for anhydrous

ammonia

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 1

I. ANHYDROUS AMMONIA RESPONSE

Instructor Note: The purpose of this section

is to provide students with a background in

anhydrous ammonia response options. The

information provided will discuss response

issues applicable to both Operations and

Technician Level responders.

A. OSHA Response Levels

1. First Responder Operations

a. Those responders who would

respond to a hazardous

materials release as part of

the initial response

b. Those trained to use

defensive actions to contain

the release from a safe

distance, and keep it from

spreading and prevent

exposures

2. First Responder Technician

a. Those individuals who

respond to the release for

the purpose of stopping the

release

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 2

b. They will approach the point

of release to plug, patch, or

otherwise stop the release of

a hazardous substance

3. We will discuss issues that are

applicable to both Operations and

Technician level responders

4. Note for the students the

difference between Operations and

Technician level response

approaches

5. We will discuss control and

containment options for both

levels of responders

6. Emergency Contact Numbers

B. Global Issues in Ammonia Release

1. Release Phases

a. Vapor

i. Ammonia exists

naturally as an

invisible vapor

ii. When contained in a

vessel the pressure

and temperature of the

ammonia determines

the strength of the

release

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 3

b. A dense gas phase is created

when the liquid inside a

container escapes: the

ammonia liquid is now

boiling, changing from a

liquid phase to vapor phase

to create the aerosol and

dense gas cloud

c. Aerosol

i. The liquid escapes as

an aerosol and then

mixes with the

atmosphere to create a

dense gas cloud

ii. For the most part this

could be condensation

of humidity in the air

which forms the white

cloud

iii. It then escapes to the

atmosphere as an

invisible vapor

iv. At times the escaping

aerosol can be

contained with a tarp

or other cover and the

aerosol will condense

into a liquid

d. Liquid

i. Pressure within a

vessel holds ammonia

as a liquid

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 4

ii. Liquids may exist when

large volumes of the

liquid are suddenly

released from the

vessel

iii. Once the pressure is

released the liquid will

flash off until a puddle

of liquid remains and

slowly evaporates to

the atmosphere

2. Weather Impact

a. Wind

i. The most powerful

mover of ammonia

ii. High wind will stream

out the release

iii. Moderate wind will

maximize dispersion

especially if the upper

air is warm

b. Rain/Humidity

i. Ammonia loves water

ii. Ammonia will become

a heavier than air gas

cloud when mixed with

water vapor

c. Temperature

i. Cold temps slows the

cloud dispersion

ii. Warm temps adds

energy to the ammonia

molecule thus helping

it spread more rapidly

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 5

iii. Thermodynamic Rule:

Warm always moves to

cool so ammonia

clouds will hang in

lower, cooler and more

moist areas

3. Environmental Impacts

a. Run off should be controlled

b. Keep out of drains and

waterways

4. Terminology Differences

a. Industry

b. Public Sector

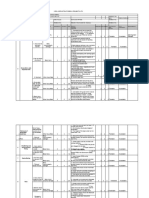

C. Release Phases

1. There are four release phases- this

picture shows three of them:

aerosol, dense gas and vapor

2. Aerosol Phase

a. Aerosol is converted to a

sub-cooled gas that

saturates the air and rides a

buoyant gas cloud

b. Distances vary depending

on:

i. Wind dispersion

ii. Weather conditions

iii. Amount of the release

iv. Distance of the aerosol

stream

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 6

c. A high pressure/high volume

release during a humid and

or cold day can develop

dense gas clouds that remain

close to the ground

3. Vapor Phase

a. Ammonia escapes the

aerosol and dense gas as the

heated air moves to warm

the releases

b. The time for vaporization is

dependent on the

temperature of the air and

humidity

c. Dry and warm days provide

the quickest dissipation of

ammonia aerosol and dense

gas to vapor

4. Liquid Phase

a. Ammonia liquid occurs when

the surrounding atmosphere

and containment area are

cooled to at least -28 F

b. Ammonia liquid is fairly

stable when left to slowly

boil off

c. If heat and water is added or

the ammonia is spread on

the ground it will produce

boiling evaporation

5. Three risk factors from leaks

a. Life: yours and the public’s

b. Environment: Downstream

pollution concerns

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 7

c. Product/Facility: Chemical

inventory and equipment

exposure and corrosion

challenges

d. Wet weather, cold weather

or a water or moisture

source can keep the cloud

close to the ground

D. Liquid Anhydrous Ammonia

Considerations

1. Low pressure liquid is relatively

safe if contained

2. After vaporizing and absorbing the

surrounding heat, the liquid settles

into a “sleeping” state

3. When the liquid is allowed to

escape and react with the heat

and moisture of the surroundings

it will vaporize and boil off again

4. Ammonia loves water and will

search it out in the environment.

Ammonia’s attraction to water is

stronger than the attraction to air.

5. One volume of water will absorb

1300 volumes of ammonia vapor.

The expansion ratio of ammonia is

840 to 1.

6. When released from containment,

ammonia boils and makes a “frying

egg” sound. Those that have

experienced this have said that it

sounded and felt like frying eggs

on their face

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 8

7. Thus the need for the proper

personal protective equipment

E. Tracking the Downwind Release

1. Chemical and physical

characteristics of an outside

release are dependent on volume

pressure

2. Higher temps bring higher and

more active pressure and vapor

movement

3. Humidity and extremely cold

temps slows vaporization

4. Ammonia is a cool gas and will

track along valleys where temps

are cooler

5. Plant life, ponds, rivers etc. will

draw the ammonia, but the wind

has the power of movement and

dilution of the ammonia vapor

6. Note the cone shaped V pattern at

the point of release

a. Note how wind conditions

affect the cloud

b. Also note how the cloud

widens as the ground cools

allowing the ammonia cloud

to dissipate

c. This is important to consider

when establishing a Hot

Zone and Protective Action

Zone

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 9

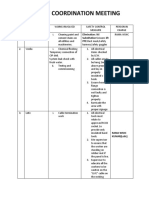

F. Weather Impacts

1. Although anhydrous ammonia’s

vapor density is lighter than air, it

can exhibit heavier than air

characteristics

a. High humidity such as foggy,

misty, rainy conditions will

keep ammonia on the

ground

b. This picture is a live

ammonia training event and

Level B is being used since

we are under controlled

circumstances

c. There was a light rain falling

and the vapor cloud hung

low to the ground

2. In good weather you will see the

vapor cloud reacting favorably by

going up and away

a. You will see a hook at the

top of the plume. This may

hook back to the ground

b. The height of the release

plume will play into how the

dense gas and vapor trail will

disperse

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 10

c. Dense gas is forming 20-30

feet in the air. Those located

in front of the release will

not be exposed as those

downwind of the release as

the dense gas cloud settles

to the ground before

dispersing into a vapor and

heading into the upper

atmosphere

d. Always be cautious about the

downwind drop of the

ammonia plume. It may be

several hundred feet

downwind in small spills or

hundreds of yards downwind

in larger spills

G. Environmental Impacts of Release

1. Use extreme caution with

unmitigated solutions of aqua or

anhydrous ammonia

2. The solution must be contained in

a safe location so that the

ammonia can evaporate

3. Aeration of the solution may allow

the pH to drop to acceptable levels

4. Don’t allow the solution to travel

into bodies of water as it is

extremely dangerous to fish and

wildlife

5. A little ammonia will drastically

affect the pH of water and any run

off should be contained to prevent

harm

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 11

H. Global Issues in Ammonia Release

1. Terminology between responder

and facility personnel could be an

issue

2. Stay away from company/industry

jargon.

3. Some industries may refer to

quantity in pounds when

responders may use gallons-

anhydrous ammonia’s liquid

density is about 5lbs per gallon

4. The key to good communication is

to have a good liaison from the

facility to communicate with

I. Response to Ammonia Releases

1. Keys are recognition and

identification, hazard and risk

assessment, choosing proper

personal protective clothing, and

developing an action plan

2. Hazards are always higher when

extreme conditions such as high

pressure, high volume, and high

density gas clouds are present

3. The Incident Commander must

assess risk and determine the

proper protective equipment for

the objective to be completed

4. Incident Action Plans and Safety

Plans are both needed and usually

required at a release

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 12

5. Understand the hazards given the

situation whether an indoor or

outdoor release

6. The glove was a Level A neoprene

glove that degraded due to the

cold temps. Responders were

working to shut off a valve in a

dense gas cloud very near the

aerosol stream

7. Use a risk/benefit analysis before

putting responders in harm’s way

a. Can you clearly see your exit

pathway?

b. Are you feeling any

discomfort from exposure

(groin, armpits, neck and

head will feel the burn and

sting of ammonia first)?

c. Calculate your risk based on

what you are able to save

J. Evacuation Recommendations

1. Follow Emergency Response Guide

Evacuation Recommendations

a. Small Spills: Initially isolate

100’ and protect downwind

0.1 mile day/night

b. Large Spills: Initially isolate

500’ and protect downwind

0.5 miles day and 1.4 miles

night

c. The most risk will be within

the downwind pattern

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 13

d. Shelter in Place works well

for the downwind exposure.

Evacuate only if it’s safe to

enter the outside

environment

2. Evacuation or Shelter in Place

Considerations

a. To evacuate: Move laterally

and upwind. Get outside the

“V” since the sideline of the

“V” is very defined with

concentrations of ammonia

b. Shelter in Place: Testing has

proved that there may be

some value in persons who

are sheltered in place turning

on a shower and putting a

wet wash cloth over their

face to protect them from

excessive amounts of

ammonia

c. In Minot, ND 9 ammonia cars

released their contents into a

dense gas cloud that floated

over the community.

d. The 911 center advised

residents to move to the

bathroom and turn on the

shower if ammonia odor

became strong in their

home. Levels of approx. 200

ppm were reported

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 14

e. The Center for Toxicology

and Environmental Health

(CTEH) tested this method of

shelter in place and found

that having the shower

running and using a wet

wash cloth were both

effective in reducing the

ammonia levels to below 50

ppm

K. Placards and Warning Signs

1. Domestic shipments within the US

can be classified as Hazard Class

2.2 non-flammable gas using the

Green non flammable placard

2. Internationally ammonia is

classified as a Hazard Class 2.3

poison gas, with a subsidiary

warning of corrosive

3. The UN Number for North America

shipments is UN1005

4. Note that there are Canadian rail

cars entering the US with a special

permit placard, which looks like

the 2.2 hazard class but is

white/black in color

5. NFPA 704 for storage facilities

a. Red diamond is for Fire

Hazard

b. Yellow diamond is for

Reactivity

c. White diamond is for Special

Hazards

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 15

d. Blue diamond is for Health

Hazards

e. The scale is from 0 to 4 with

4 being the highest hazard

f. The Special Hazards section

could have “ALK” or “COR”

for ammonia

L. Other Considerations

1. Avoid Trapping Liquids

a. Do not be valve turners

unless you know there is

pressure release protection

where the ammonia may be

trapped or contained

b. Ammonia has a high

coefficient of expansion.

c. The photo shows a kinked

line that trapped liquid

ammonia and eventually

blew out!

2. Flammability of Outdoor Releases

a. Outdoor releases do not

have a high risk of

flammability with ammonia

b. LEL/UEL is 16-25%. The

most likely flame spread will

occur while the flame is

directed to a dense gas

aerosol stream

c. The ammonia vapor will burn

much like when the smoke

from a hot campfire flash

burns above the burning

wood

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 16

3. Flammability of Indoor Releases

a. With indoor releases in a

confined area there is a

greater chance of

flammability

b. A LEL/UEL mix could form

and typically indoor releases

happen at industrial

refrigeration processes

c. Contaminants such as oil can

mix with the ammonia and

affect the “textbook”

flammability range

d. Indoor ammonia releases

can pose potential

flammability concerns

e. Ventilate and control ignition

sources prior to entry

f. This picture is an example of

a release that sparked a fire

4. Ammonia and Water

a. Ammonia loves water: One

volume of water will absorb

1300 volumes of ammonia

vapor

b. When ammonia moves to

water located in an enclosed

environment, like a tank or

vessel, that movement of

ammonia will cause a

Instructor Note: The video is in the vacuum like the one shown

Extras file on your DVD. You must in this situation. The tank

exit PowerPoint and open this integrity held up, but the

video file in an external video tank was obviously no longer

viewer. serviceable.

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 17

c. Ammonia quickly mixes with

water to form aqueous

ammonia, or ammonium

hydroxide, which is heavier

than air and has higher pH

values (up to 13.2 from

11.6)

d. When ammonia and water

mix, an exothermic reaction

occurs giving off heat. The

molecular heat of the

reaction raises the water

temperature. This can be

seen by measuring the

increase in temperature of

water used to “blow down”

or remove ammonia from a

system

e. Ammonia loves water, but if

you put water on ammonia it

will become “spitting mad.”

f. If ammonia is introduced

into water purposefully, the

reaction isn’t as bad,

especially if the amount of

water is adequate

g. The absorption of ammonia

to water is about 1 volume

of ammonia to 10 volumes of

water when the solution is

mixed completely at about

70F

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 18

h. Aqueous ammonia

vaporization is dependent

upon the temperature of the

water, the amount of wind,

and the amount of surface

area exposed. Usually, the

volume of ammonia will

reduce faster as

temperature, surface area,

and amount of warm air are

increased

i. Discuss the vapor to water

relationship: One volume of

water will absorb 1300

volumes of ammonia vapor

i. What happens to the

white cloud of aerosol

and vapor in the video

clip? The white cloud is

a result of vaporization

because of warm air

and cold air mixing in

the presence of

humidity.

ii. What happens to that

air temperature

difference when water

mixes into the vapor

cloud? It goes away.

iii. What happens to the

ammonia? It joins with

the water vapor and

lays low until vaporized

by surrounding air. Its

pH value also increases

and it can become

much more irritating to

the skin.

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 19

j. The temperature of tepid

water from a hose will be

about 55 to 65°F. What

would that do to the

ammonia temperature and

pressure within a vessel?

k. When is it a good idea to put

water on a vessel?

5. The summary message is to avoid

using water on liquid, aerosol or

dense gas ammonia releases.

6. Water is effective in reducing

downwind vapor release, but the

need for containing runoff is

critical. Do not allow ammonia

mixed with water to find its way to

a live body of water unless the pH

is below local environmental

standards (usually under 8 or 9)

7. In the bottom picture ask the class

where to use water to knock down

the cloud. Not on the leaking

container, but downwind to

protect “downwind threats” to the

right of the picture.

8. The next concern would be to dike

or contain the run off.

9. Size Up Concerns:

a. What happened – type of

release, nature of the event,

status of the release

(contained, still growing, out

of control, peaked, reducing

in impact)?

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 20

b. What are the life and

environmental threats

downwind, especially in the

protective action zone?

c. What’s happening now?

Growing, downwind threat?

Downstream threat?

d. What do you recommend

next? Personnel

accountability, environmental

damage, facility product or

equipment at risk?

e. If you don’t know, don’t go!

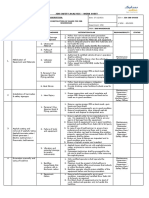

M. Control and Contain- Tarp and

Cover

1. This is a tarp and cover

control/containment method for

some ammonia release incidents

a. The release point is covered

with a tarp (basic tarp you

can buy at a local hardware

supply – polyethylene or

polypropylene)

b. The tarp covers the release

point and the escaping dense

gas cloud will condense to

liquid phase product which

will then cool the container

and release point

c. We learned that there is a

direct pressure/temperature

relationship with ammonia

and if the temperature

drops, the pressure drops

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 21

d. Your downwind concerns are

also minimized in that the

release is controlled/

contained to the local release

area

2. This is not a cure all tactic. The

ammonia is controlled or contained

at this point

3. You may then start to get liquid

ammonia pooling under and near

the tarp. Do not walk through

liquid pools

4. What is occurring under the tarp

while the dense gas flows around

the vessel?

a. The cold gas will lower the

pressure in the vessel and

the condensation of the

aerosol stream will result in

liquid ammonia saturating

the ground rather than to go

downwind to threaten life

hazard…if there is no life or

environmental hazard on the

downwind then allowing the

ammonia to escape to

atmosphere might be the

best solution

b. Notice how the dense gas

cloud stays low as the gas

begins to vaporize to

atmosphere on the

downwind side

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 22

c. On a dry day the dense gas

cloud is not as evident

although the vapor risk may

still be very high on the

downwind side

5. You can see in the picture that the

tarp has minimized the exposure

area.

a. The leak point or leaking

container will be cooled from

the ammonia – if we drop

temperature the pressure in

the container will also drop.

b. Fully contained with the first

tarp; secondary tarps may

be helpful…now we can find

the source of the release and

control the flow… shut it

down!

c. A positive pressure

ventilation fan is helpful in

directing the dense gas away

from the responders as they

place the tarp and work on

controlling the release… it’s

also a good first step to

getting fresh air to a victim

that may be collapsed in the

downwind area

6. Placing the tarp from a distance,

outside the dense gas cloud, can

be accomplished with Level A or

even Level B PPE (if the

responders stay out of the dense

gas and aerosol part of the

release)

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 23

7. A fan used to support the

responders is very valuable

8. Responders must be trained in this

procedure before attempting it

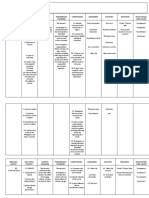

N. Large Containers and Rail Tank

Cars

1. Anhydrous ammonia tank cars

have a capacity of over 33,000

gallons; however with the required

outage, they typically contain less

than 30,000 gallons – 160,000

pounds

2. Capping kits may or may not work

on tank cars – depends if there is

enough spacing around the valve

flange

a. The middle picture shows

enough spacing

b. The bottom picture may not

have enough space around

the valve flange to cap a

leaking valve

3. Tank cars will always have:

a. 2 liquid valves which point

towards the ends of the car

b. A single vapor valve will be

perpendicular to the liquid

valves and point toward the

side of the car

c. A pressure relief valve

4. Could have other valves such as a

gauging device, thermometer well

and sample tube line

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 24

5. Cargo trailers (tractor trailer

versions) could range in size from

3.500 gallons to almost 12,000

gallons

6. Nurse tanks range in size from 500

gallons to over 1,000 gallons

O. Ammonia Response - Other Issues

1. Review the points on the slide

2. Don’t be valve turners since we do

not want to trap liquid ammonia

without being able to relieve

pressure

3. Ensure proper personal protective

pquipment is used

4. Review where and when to use

water and always contain run off

5. Evaluate tarp and cover as a

control and containment method

for incidents

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 25

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 26

EMERGENCY RESPONSE CONTACT NUMBERS

Burlington Northern Santa Fe 800-832-5452

Canadian National 800-465-9239

Canadian Pacific 800-716-9132

CSX Transportation 800-232-0144

Kansas City Southern 877-527-9464

Norfolk Southern 800-453-2530

Union Pacific 888-877-7267

CHEMTREC® 800-424-9300

CANUTEC 613-996-6666 (call collect)

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 27

LEGAL NOTICE

©The Fertilizer Institute and the American Chemistry Council, Inc. (2011)

This work is protected by copyright. The Fertilizer Institute and the American Chemistry Council, Inc.,

which are the owners of the copyright, hereby grant a nonexclusive royalty-free license to reproduce

and distribute this work, subject to the following limitations:

1. The work must be reproduced in its entirety without alteration, abridgement, revision or other

modification;

2. All copies of the work must include a cover page bearing The Fertilizer Institute and American

Chemistry Council, Inc.’s Notice of Copyright of this work; and

3. Copies of the work may not be sold or used by another party for profit or as part of a for-profit

enterprise.

The materials developed for the Anhydrous Ammonia Training Tour 2011 are intended to provide

general understanding and guidance to emergency responders in addressing anhydrous ammonia

incidents. They include information about the chemical and helpful considerations that the emergency

responder can employ when faced with such an incident. The materials are in no way intended to be

prescriptive or otherwise recommend specific procedures on how to respond. Emergency responders

are encouraged to consult with the product manufacturer, carrier and other experts when assessing and

managing any incident involving anhydrous ammonia.

TRANSCAER® Anhydrous Ammonia Course Ver. 2.0 28

Das könnte Ihnen auch gefallen

- CCPS Process Safety Beacon 2021-03Dokument1 SeiteCCPS Process Safety Beacon 2021-03KiranNoch keine Bewertungen

- Lummus Global: RA STATEMENT: Generic RA - Performing Hot WorkDokument2 SeitenLummus Global: RA STATEMENT: Generic RA - Performing Hot WorkOws AnishNoch keine Bewertungen

- Hazard Matrix of Work Activities (HIRAC)Dokument15 SeitenHazard Matrix of Work Activities (HIRAC)ROLAN RULLODA100% (1)

- Chapter 2 Hazard and Control MeasuresDokument3 SeitenChapter 2 Hazard and Control MeasuresArul PrasaadNoch keine Bewertungen

- Course of StudyDokument8 SeitenCourse of StudynorazzahNoch keine Bewertungen

- Manhole Confined SpaceDokument3 SeitenManhole Confined SpaceShah MuzzamilNoch keine Bewertungen

- In-Service Education FSMDokument4 SeitenIn-Service Education FSMapi-581342636Noch keine Bewertungen

- Mine Search and Rescue Technician: Type Type 1 Type 2Dokument6 SeitenMine Search and Rescue Technician: Type Type 1 Type 2series70med100% (1)

- JSA 004 Sand Blasting of Exposed RebarDokument1 SeiteJSA 004 Sand Blasting of Exposed RebarRyanNoch keine Bewertungen

- A Safe Simple Halogenation Experiment: Department of Chemistry, Bard College, Annandale-on-Hudson, NY 12504Dokument1 SeiteA Safe Simple Halogenation Experiment: Department of Chemistry, Bard College, Annandale-on-Hudson, NY 12504Carlos FloresNoch keine Bewertungen

- DLP Science 8 Wk3D1 2nd QTRDokument2 SeitenDLP Science 8 Wk3D1 2nd QTRLianne Marie CabanginNoch keine Bewertungen

- Mine SafetyDokument3 SeitenMine SafetyShahad BalaoroNoch keine Bewertungen

- Hira BCN 22aDokument33 SeitenHira BCN 22aDhaneswar SwainNoch keine Bewertungen

- TVL MARITIME - Safety 2 - May 2016 PDFDokument9 SeitenTVL MARITIME - Safety 2 - May 2016 PDFJunave GumapacNoch keine Bewertungen

- G9 4th QuarterDokument2 SeitenG9 4th Quarterjao orevilloNoch keine Bewertungen

- JSA. Confined Space EntryDokument3 SeitenJSA. Confined Space EntrySwaroop Cherry67% (3)

- JSA - Batching Plant OperationDokument3 SeitenJSA - Batching Plant OperationNisith SahooNoch keine Bewertungen

- Tra PPMDokument4 SeitenTra PPMkidangilarjunNoch keine Bewertungen

- Hazards ControlDokument11 SeitenHazards ControlD kuiNoch keine Bewertungen

- 4-JSA - Unloading Under Inert - F9030 B NewDokument6 Seiten4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNoch keine Bewertungen

- DLP 5 Safety Measures Owned Table Version.Dokument8 SeitenDLP 5 Safety Measures Owned Table Version.Reybeth Tahud Hamili - Matus100% (2)

- SampleAHA Control PanelDokument2 SeitenSampleAHA Control Panelanilkumaranoop74Noch keine Bewertungen

- Job Safety Analysis Light Bulb ReplacementDokument4 SeitenJob Safety Analysis Light Bulb Replacementshane.ramirez1980Noch keine Bewertungen

- Job Safety Analysis (JSA) - CONCRETE WORKS - DateDokument2 SeitenJob Safety Analysis (JSA) - CONCRETE WORKS - DatenabeelNoch keine Bewertungen

- Job Activity Hazard Effect Control Measures: Project in ChargeDokument3 SeitenJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNoch keine Bewertungen

- Grade 5 DLL SCIENCE 5 Q4 Week 4Dokument5 SeitenGrade 5 DLL SCIENCE 5 Q4 Week 4myrna.ferreria001Noch keine Bewertungen

- JOB SAFETY ANALYSIS DikonversiDokument4 SeitenJOB SAFETY ANALYSIS DikonversiAgung Tri SugihartoNoch keine Bewertungen

- HIRA of Water Proofing Work.Dokument1 SeiteHIRA of Water Proofing Work.Gyanendra SrivastavaNoch keine Bewertungen

- Weekly Coordination Meeting: Elimination: Nil Substitution:Scissors Lift PPE:Dust Mask, SafetyDokument2 SeitenWeekly Coordination Meeting: Elimination: Nil Substitution:Scissors Lift PPE:Dust Mask, SafetyRama RajanNoch keine Bewertungen

- Job Safety Analysis - Work SheetDokument4 SeitenJob Safety Analysis - Work Sheetrickie7809Noch keine Bewertungen

- MRU-QMS-HSE-Form - JSA - Geotechnical Drilling & Geotechnical Field Investigation - Rev00Dokument11 SeitenMRU-QMS-HSE-Form - JSA - Geotechnical Drilling & Geotechnical Field Investigation - Rev00AditNoch keine Bewertungen

- I1252-HSE-RAR-008 (00) Concrete Works.Dokument4 SeitenI1252-HSE-RAR-008 (00) Concrete Works.Farman ShaikhNoch keine Bewertungen

- DLP 4 Safety Measures Owned Table Version.Dokument8 SeitenDLP 4 Safety Measures Owned Table Version.Reybeth Tahud Hamili - MatusNoch keine Bewertungen

- Multiple Choice: TrueorfalseDokument4 SeitenMultiple Choice: TrueorfalseMary Francia Rico100% (1)

- HIRA - Drainage System Work-1Dokument2 SeitenHIRA - Drainage System Work-1owaissarguru.ongcsudaNoch keine Bewertungen

- Subject: Science Grade Level: Grade 9 Teacher: Janine G. Ferrer StrandsDokument3 SeitenSubject: Science Grade Level: Grade 9 Teacher: Janine G. Ferrer StrandsJanine Ginog FerrerNoch keine Bewertungen

- Job Safety Analysis WorksheetDokument7 SeitenJob Safety Analysis WorksheetMohamedSaidNoch keine Bewertungen

- Prevent, Control and Fight Fires On BoardDokument2 SeitenPrevent, Control and Fight Fires On BoardDinda OktavianaNoch keine Bewertungen

- JSA 37-Rev.01 - RADIOGRAPHY TESTDokument1 SeiteJSA 37-Rev.01 - RADIOGRAPHY TESTgolusinghdataNoch keine Bewertungen

- HEYTDokument17 SeitenHEYTMariam BakariNoch keine Bewertungen

- Risk - Batching Plant OperationsDokument6 SeitenRisk - Batching Plant Operationsmechajay2002100% (1)

- Ig2 Forms Electronic Submission v5.1 (6) (2) OldDokument9 SeitenIg2 Forms Electronic Submission v5.1 (6) (2) Oldabhilash sureshNoch keine Bewertungen

- Hazard Identification & Risk AssessmentDokument8 SeitenHazard Identification & Risk Assessmentanand.v4491Noch keine Bewertungen

- 5.1. Characterize A Typhoon. 5.2. Differentiate A Typhoon, Cyclone and Hurricane. S8Es-Iid18.5.1 S8Es-Iid18.5.2Dokument3 Seiten5.1. Characterize A Typhoon. 5.2. Differentiate A Typhoon, Cyclone and Hurricane. S8Es-Iid18.5.1 S8Es-Iid18.5.2Carla NicolasNoch keine Bewertungen

- Safe Practices August2012 Editsnov2014 FsbsDokument21 SeitenSafe Practices August2012 Editsnov2014 FsbsVahid VahidiNoch keine Bewertungen

- Ohsms Internal Auditor Course. Case Study 1Dokument2 SeitenOhsms Internal Auditor Course. Case Study 1Lakshmu NaiduNoch keine Bewertungen

- Jsa Insulation WorkDokument20 SeitenJsa Insulation WorkazerNoch keine Bewertungen

- RPT 2024 Biology KSSM t4 EnglishDokument30 SeitenRPT 2024 Biology KSSM t4 EnglishFatin NazihaNoch keine Bewertungen

- Corrosive - CleanupDokument4 SeitenCorrosive - CleanupVineet AgrawalNoch keine Bewertungen

- Inter Tank Transfers - SWPDokument5 SeitenInter Tank Transfers - SWPPriince MogomotsiNoch keine Bewertungen

- Periodical Test in Household ServicesDokument1 SeitePeriodical Test in Household Servicesjohanna100% (1)

- Tool Box Talk - Cyclone Blockage RemovalDokument3 SeitenTool Box Talk - Cyclone Blockage RemovalVisnu SankarNoch keine Bewertungen

- Emediong U. - Risk Assessment Matrix 1 WorkingDokument20 SeitenEmediong U. - Risk Assessment Matrix 1 WorkingsterlingNoch keine Bewertungen

- MSHEM-02.11-C Level 2 JSA - Veolia - RO Units Pipes Repairing and ReplacementDokument6 SeitenMSHEM-02.11-C Level 2 JSA - Veolia - RO Units Pipes Repairing and ReplacementAbdullah AbedNoch keine Bewertungen

- Specific Learning Outcome: Grade 12 - South Korea 10:00 - 11:00 (M-TH) Grade 12 - Turks & Caicos 11:00 - 12:00 (M-TH)Dokument2 SeitenSpecific Learning Outcome: Grade 12 - South Korea 10:00 - 11:00 (M-TH) Grade 12 - Turks & Caicos 11:00 - 12:00 (M-TH)Joshua ManalonNoch keine Bewertungen

- Job Safety AnalysisDokument3 SeitenJob Safety AnalysisDeshbandhu Aman PandeyNoch keine Bewertungen

- RPT Chemi 2020 2Dokument16 SeitenRPT Chemi 2020 2Thivya V NaiduNoch keine Bewertungen

- CRB Whitepaper Vapor Hydrogen Peroxide Decontamination WebDokument8 SeitenCRB Whitepaper Vapor Hydrogen Peroxide Decontamination WebVictor LeiNoch keine Bewertungen

- Caregiving Lesson PlanDokument3 SeitenCaregiving Lesson PlanDOMINIC HAWANGNoch keine Bewertungen

- Commodity Preparedness and Incident Management Reference SheetDokument17 SeitenCommodity Preparedness and Incident Management Reference Sheetjulianopetry10Noch keine Bewertungen

- Introduction To Victaulic Vortex™ Hybrid Fire Extinguishing Systems Certificate - Self-Paced PDFDokument1 SeiteIntroduction To Victaulic Vortex™ Hybrid Fire Extinguishing Systems Certificate - Self-Paced PDFjulianopetry10Noch keine Bewertungen

- Transportation Rail Incident Preparedness & ResponseDokument25 SeitenTransportation Rail Incident Preparedness & Responsejulianopetry10Noch keine Bewertungen

- TRIPR Comprehensive Instructor Lesson Plan PDFDokument320 SeitenTRIPR Comprehensive Instructor Lesson Plan PDFJuliano André PetryNoch keine Bewertungen

- Application of The Summation Methods When Classification Information Is Available For Some or All of The Ingredients of A MixtureDokument2 SeitenApplication of The Summation Methods When Classification Information Is Available For Some or All of The Ingredients of A MixtureJuliano André PetryNoch keine Bewertungen

- Leaflet CLP Labelling EIGADokument4 SeitenLeaflet CLP Labelling EIGAJuliano André PetryNoch keine Bewertungen

- Application of Data When The Available Range Data Spans More Than One Acute Toxicity Range Estimate in Table 3.1.2Dokument1 SeiteApplication of Data When The Available Range Data Spans More Than One Acute Toxicity Range Estimate in Table 3.1.2julianopetry10Noch keine Bewertungen

- Concentration of Highly Toxic Mixtures Bridging Principle Example Using Acute Toxicity DataDokument2 SeitenConcentration of Highly Toxic Mixtures Bridging Principle Example Using Acute Toxicity DataJuliano André PetryNoch keine Bewertungen

- Application of Data When The Available Range Data Spans More Than One Acute Toxicity Range Estimate in Table 3.1.2Dokument1 SeiteApplication of Data When The Available Range Data Spans More Than One Acute Toxicity Range Estimate in Table 3.1.2julianopetry10Noch keine Bewertungen

- Babok Framework Overview: BA Planning & MonitoringDokument1 SeiteBabok Framework Overview: BA Planning & MonitoringJuan100% (1)

- Public Speaking ScriptDokument2 SeitenPublic Speaking ScriptDhia MizaNoch keine Bewertungen

- MCQ Cell InjuryDokument19 SeitenMCQ Cell InjuryMoaz EbrahimNoch keine Bewertungen

- Eye Essentials Cataract Assessment Classification and ManagementDokument245 SeitenEye Essentials Cataract Assessment Classification and ManagementKyros1972Noch keine Bewertungen

- Giardiasis PDFDokument14 SeitenGiardiasis PDFSaad Motawéa0% (1)

- NFPA 220 Seminar OutlineDokument2 SeitenNFPA 220 Seminar Outlineveron_xiiiNoch keine Bewertungen

- June 2019Dokument64 SeitenJune 2019Eric SantiagoNoch keine Bewertungen

- 14DayReset Meals GeneralDokument40 Seiten14DayReset Meals GeneralRiska100% (1)

- Mpez-6 Installation Manual - Inline 201007Dokument8 SeitenMpez-6 Installation Manual - Inline 201007api-244989438Noch keine Bewertungen

- Full Download Small Animal Care and Management 4th Edition Warren Test BankDokument35 SeitenFull Download Small Animal Care and Management 4th Edition Warren Test Bankkrzyszhugvik6100% (20)

- Resume - Arun BhartiDokument3 SeitenResume - Arun BhartiArun AbNoch keine Bewertungen

- Epilepsy 2 AAN 2018Dokument12 SeitenEpilepsy 2 AAN 2018Eashaa KumarNoch keine Bewertungen

- Date SissyDokument5 SeitenDate SissyFletcher Irvine50% (2)

- Mcdes 1Dokument7 SeitenMcdes 1JerdNoch keine Bewertungen

- Fora Active Plus P 30 ManualDokument32 SeitenFora Active Plus P 30 ManualBvcNoch keine Bewertungen

- Rest Pfas Appendix g1 31097 enDokument51 SeitenRest Pfas Appendix g1 31097 endasfNoch keine Bewertungen

- De Thi Chon HSGDokument10 SeitenDe Thi Chon HSGKiều TrangNoch keine Bewertungen

- Radial Lead Varistors LA Varistor SeriesDokument13 SeitenRadial Lead Varistors LA Varistor SeriesLeman SihotangNoch keine Bewertungen

- Ems 01 Iso 14001 ManualDokument26 SeitenEms 01 Iso 14001 ManualG BelcherNoch keine Bewertungen

- Financial Markets & Institutions: Lecture Notes #3Dokument90 SeitenFinancial Markets & Institutions: Lecture Notes #3Joan MaduNoch keine Bewertungen

- Crude TBP Country United Arab Emirates Distillation: MurbanDokument2 SeitenCrude TBP Country United Arab Emirates Distillation: MurbanHaris ShahidNoch keine Bewertungen

- Ott OTT Ecolog 1000 Water Level LoggerDokument3 SeitenOtt OTT Ecolog 1000 Water Level LoggerNedimZ1Noch keine Bewertungen

- Ethical Consideration in Leadership and ManagementDokument6 SeitenEthical Consideration in Leadership and ManagementGlizzle Macaraeg67% (3)

- Cor Tzar 2018Dokument12 SeitenCor Tzar 2018alejandraNoch keine Bewertungen

- LivingScience CBSE CompanionDokument56 SeitenLivingScience CBSE Companionnjlenovo95% (19)

- Invertec 200 260 400tDokument16 SeitenInvertec 200 260 400tJxyz QwNoch keine Bewertungen

- Mental Health & TravelDokument18 SeitenMental Health & TravelReyza HasnyNoch keine Bewertungen

- Anglo American - Belt Conveyor Design CriteriaDokument19 SeitenAnglo American - Belt Conveyor Design CriteriaIgor San Martín Peñaloza0% (1)

- Allison Burke Adime 4Dokument8 SeitenAllison Burke Adime 4api-317577095Noch keine Bewertungen

- Basic Concepts and Applied Aspect of Sharir RachnaDokument122 SeitenBasic Concepts and Applied Aspect of Sharir RachnaRam Krish100% (1)

- Practical Reservoir Engineering and CharacterizationVon EverandPractical Reservoir Engineering and CharacterizationBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingVon EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNoch keine Bewertungen

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesVon EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNoch keine Bewertungen

- Gas-Liquid And Liquid-Liquid SeparatorsVon EverandGas-Liquid And Liquid-Liquid SeparatorsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsVon EverandWell Testing Project Management: Onshore and Offshore OperationsNoch keine Bewertungen

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsVon EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsBewertung: 4 von 5 Sternen4/5 (4)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideVon EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideBewertung: 2 von 5 Sternen2/5 (1)

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Heavy and Extra-heavy Oil Upgrading TechnologiesVon EverandHeavy and Extra-heavy Oil Upgrading TechnologiesBewertung: 4 von 5 Sternen4/5 (2)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesVon EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesBewertung: 5 von 5 Sternen5/5 (5)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityVon EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityBewertung: 3 von 5 Sternen3/5 (2)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsVon EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsBewertung: 4 von 5 Sternen4/5 (6)

- Asset Integrity Management for Offshore and Onshore StructuresVon EverandAsset Integrity Management for Offshore and Onshore StructuresNoch keine Bewertungen

- Advanced Production Decline Analysis and ApplicationVon EverandAdvanced Production Decline Analysis and ApplicationBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Gas and Oil Reliability Engineering: Modeling and AnalysisVon EverandGas and Oil Reliability Engineering: Modeling and AnalysisBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AVon EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANoch keine Bewertungen

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryVon EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryBewertung: 5 von 5 Sternen5/5 (3)