Beruflich Dokumente

Kultur Dokumente

V228 Brochure 7-07-Hi

Hochgeladen von

guichen wangOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

V228 Brochure 7-07-Hi

Hochgeladen von

guichen wangCopyright:

Verfügbare Formate

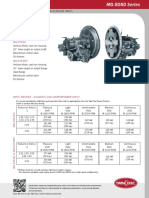

Stay the course with V228 Series engines V228 Series engine specifications GE

Electronic Fuel Injected (EFI) Marine

Item 8V228 12V228 16V228

Number of cylinders 8 12 16

Stroke cycle 4 4 4

Cylinder arrangement 45-degree V 45-degree V 45-degree V

Bore 228.6 mm (9 in.) 228.6 mm (9 in.) 228.6 mm (9 in.)

Stroke 266.7 mm (10.5 in.) 266.7 mm (10.5 in.) 266.7 mm (10.5 in.)

Compression ratio 15.7:1 15.7:1 15.7:1

Power Output at 1050 rpm

Rugged and reliable

Continuoust 1526 kw (2045 bhp) 2290 kw (3070 bhp) 3052 kw (4100 bhp)

Maximumt 1678 kw (2250 bhp) 2518 kw (3375 bhp) 3357 kw (4500 bhp)

Power Output at 1000 rpm

Continuoust 1453 kw (1948 bhp) 2180 kw (2922 bhp) 2906 kw (3896 bhp)

GE’s V228 Series engines are designed to power workboats, tugs, towboats, offshore supply vessels, Maximumt 1598 kw (2143 bhp) 2398 kw (3214 bhp) 3197 kw (4286 bhp) GE’s high-performance V228 Series diesel engines

ferries, dredges, fishing vessels and other marine transport applications. Dependable and durable, these Power Output at 900 rpm

medium-speed engines are among the best in their class for fuel efficiency and low life-cycle costs. Continuoust 1308 kw (1753 bhp) 1962 kw (2630 bhp) 2616 kw (3506 bhp)

Engines are available in 8-, 12- and 16-cylinder configurations. Maximumt 1438 kw (1929 bhp) 2158 kw (2893 bhp) 2877 kw (3857 bhp)

Engine Dimensions

A Height w/deep sump 2762 mm (109 in.) 2762 mm (109 in.) 3030 mm (119 in.)

B Height w/shallow sump 2555 mm (101 in.) 2555 mm (101 in.) 2555 mm (101 in.)

C Length 3298 mm (130 in.) 4136 mm (163 in.) 4975 mm (196 in.)

D Width 1734 mm (68 in.) 1734 mm (68 in.) 1734 mm (68 in.)

E Crank center line to marine sump 978 mm (39 in.) 968 mm (38 in.) 1246 mm (49 in.)

F Crank center line to mounting feet 480 mm (19 in.) 480 mm (19 in.) 480 mm (19 in.)

G Exhaust diameter 457 mm (18 in.) 508 mm (20 in.) 610 mm (24 in.)

The right support Dry Weight 12,478 kg (27,509 lbs) 17,778 kg (39,200 lbs) 22,132 kg (48,800 lbs)

Ratings are based on ISO3046-1

right when you need it

t

With more than 15,000 medium-speed diesel engines

in service worldwide, it’s critical we have the parts and To learn more:

service to support them. And we do―through a network

Call us 24/7 at 1-866-656-8786 or +630-893-3344

of parts distribution centers and service representatives

available 24/7 around the globe. We’re a leader in the or e-mail us at ge.marinestationary@trans.ge.com

on-time delivery of parts and services.

GE

Marine

2901 East Lake Road

Erie, Pennsylvania 16531

Learn from the diesel www.getransportation.com C D

G

engine experts

In addition to product and service support, we

provide comprehensive instruction in diesel engine B

A

maintenance. Our learning facility in Erie, Pennsylvania,

F

features classrooms, computer simulated training E

and an engine laboratory. Our instructors also provide

on-site training at customer locations around the

world. We offer custom-designed instructional courses,

computer-based learning aids, expert technical advi-

sors, training videos and train-the-trainer programs. imagination at work imagination at work

20078-D

V228 Series engines―Dependable, The easy-to-maintain engine MARPOL Annex VI NOx Emissions

The low-emissions solution gm/kWh

The modularized construction of our V228 engines Proven EFI technology, integrated with GE’s PowerStar™ 18

long-lasting marine power improves maintainability. Among the features that

make maintenance easier are large access doors on

the engine mainframe to reach bearings and other

engine control module, makes V228 engines the natural

choice for environmental compliance. Without exhaust

gas treatment, NOx emissions are below MARPOL

crankcase components. The segmented camshaft, Annex VI regulatory standards. V228 engines comply

GE has been designing and building high-performance diesel engines for more than 40 years. sectional exhaust manifold and unitized power

Today, we’re one of the leading manufacturers of medium-speed engines in the world. Our

V228 Series engines produce continuous power from 1045 kw to 3060 kw. With exceptional

assembly are features that simplify removal and

replacement of components.

with U.S. EPA Marine Tier 1 and Tier 2 standards as well.

0

*GE

0 1200

reliability and operating costs among the lowest in their class, V228 engines from GE are the

right choice for dependable, efficient power.

They work harder.

GE’s V228 engines are high-compression, four-stroke, medium-speed, turbocharged, electronically fuel injected,

class-approved engines designed and built for rigorous marine applications. Our medium-speed engines are

proven reliable, with more than 150 million hours of service. They are also among the most fuel-efficient engines

in their class.

They go longer.

With rugged construction and quality-assured parts, V228 engines are capable of operating cost-effectively for

more than 20 years. Most components can go without overhaul for up to 40,000 hours on a typical marine duty

cycle. Among medium-speed engines on the market, V228 engines offer one of the lowest life-cycle costs.

They run smarter.

A high-capacity turbocharger, electronic fuel injection and efficient combustion management come together

in V228 engines to make fuel and lube oil consumption as well as emissions among the lowest in the industry.

V228 engines comply with MARPOL Annex VI and U.S. EPA Marine Tier 1 and Tier 2 requirements.

Rigid Cast Mainframe High-Performance Turbocharger Unitized Power Assembly High-Strength Pistons Heavy-Duty Crankshaft

The V228 engine mainframes feature GE’s expertise in gas turbine technol- Four-bolt mounting makes assembly Forged steel crowns with forced oil The engine’s one-piece crankshaft is

high-strength, monobloc cast-iron ogy contributes to an industry-leading removal fast and easy. Electron-beam lubrication and cooling promote heat forged from high-quality steel, nitride-

construction. All water, fuel and design for performance in the turbo- welding of the steel liner to the forged reduction for longer life. A three- hardened for long life. Hefty journals

exhaust piping is externally mounted, charger. A high compression ratio head prevents leakage. Stainless steel ring arrangement, which distributes and crank pins minimize surface loads,

eliminating the potential for internal improves efficiency across the load valve seats, inconel exhaust, chromed pressure more evenly, and a cut-back and large radii fillet welded counter-

contamination. Large access doors range. Dual modular pulse piping intake valves and valve rotators extend design decrease lube oil consumption. weights reduce stress for longer

allow for easier maintenance, and preserves exhaust pulse energy for overhaul intervals and component life. A lightweight aluminum skirt offers crankshaft life.

generous casing and ribbed cross- maximal thermal efficiency, and the high heat resistance. The master

members dampen vibration. stainless dual exhaust pipe exhibits Electronic Fuel Injection (EFI) and articulated rod share a common Tolerant Tri-Metal Main Bearings

long component life. Our EFI systems ensure compliance journal, minimizing engine length The main bearings are oversized to

to all major regulatory standards. while maximizing bearing width. reduce pressure while providing

Precise fuel management and control exceptional oil-wedge formation for

also yields fuel savings. The reliability Segmented Camshaft low wear. A sacrificial run in overlay

and performance of electronic fuel The camshaft in a V228 engine is promotes rapid conformity at start-up.

injection technologies from GE have arranged in individual sections for A nickel barrier ensures superior heat

resistance, while a lead tin overlay

V228 components been proven with more than 150

million hours of engine service over

easy inspection and maintenance.

Forged and hardened camshaft serves as a high-tolerance contami-

nant trap for particles and degraded oil.

the past decade. lobes reduce wear. Oversized

Designed for high reliability and low life-cycle costs end bearings decrease loads for

longer camshaft life.

Das könnte Ihnen auch gefallen

- GE V228 Engines CatalogDokument1 SeiteGE V228 Engines CatalogairtupasNoch keine Bewertungen

- Powerful Delivery: 250 Series Engine Family of Stationary GensetsDokument2 SeitenPowerful Delivery: 250 Series Engine Family of Stationary Gensetsguichen wangNoch keine Bewertungen

- GE 250 Engines CatalogueDokument2 SeitenGE 250 Engines Cataloguesarvin silvarajo100% (1)

- 12 and 16v92 Ta Spec SheetDokument4 Seiten12 and 16v92 Ta Spec SheetBrandon Atz67% (3)

- 6ey22aw PDFDokument1 Seite6ey22aw PDFfajee_faridNoch keine Bewertungen

- LOCO ComparisonDokument2 SeitenLOCO ComparisonPrateekSinghBaghelNoch keine Bewertungen

- S550 SpecificationsDokument6 SeitenS550 SpecificationsMohamed ZakiNoch keine Bewertungen

- Detroit Serie 40 Especificaciones TecnicasDokument2 SeitenDetroit Serie 40 Especificaciones Tecnicas72287320Noch keine Bewertungen

- Navistar 1Dokument2 SeitenNavistar 1ValBMSNoch keine Bewertungen

- 2Uz-Fe Engine 1. General: 4runner - New Features 317Dokument5 Seiten2Uz-Fe Engine 1. General: 4runner - New Features 317goNoch keine Bewertungen

- MG-5050SC: Standard EquipmentDokument2 SeitenMG-5050SC: Standard EquipmentLin FengNoch keine Bewertungen

- Diesel Loco Parameters: Main Parameters Wdm2 Wdm3A Wdm3D Wdg3A Wdg4 Wdp4 Wds6 Demu (DPC)Dokument3 SeitenDiesel Loco Parameters: Main Parameters Wdm2 Wdm3A Wdm3D Wdg3A Wdg4 Wdp4 Wds6 Demu (DPC)mukesh lachhwaniNoch keine Bewertungen

- 6N330WDokument1 Seite6N330WJoginder SinghNoch keine Bewertungen

- C32B Tech SheetDokument2 SeitenC32B Tech SheetLeon ZwijnenburgNoch keine Bewertungen

- Unimog U 1550 L / U 1550 L/37: Technical DataDokument2 SeitenUnimog U 1550 L / U 1550 L/37: Technical DataquzwzwvfxuyoiovwncNoch keine Bewertungen

- E SD XX 0460Dokument2 SeitenE SD XX 0460Muhammad rizkiNoch keine Bewertungen

- Yanmar 6LYA-STP DatasheetDokument2 SeitenYanmar 6LYA-STP DatasheetAnton P (Ant P)Noch keine Bewertungen

- Dieselmax - 444 - I t3 Tcae 97 PDFDokument4 SeitenDieselmax - 444 - I t3 Tcae 97 PDFrenatoeliegeNoch keine Bewertungen

- 2ar FeDokument69 Seiten2ar Feroberto cruz100% (5)

- Makelsan Jenerator Mjs Series 220 Kva enDokument1 SeiteMakelsan Jenerator Mjs Series 220 Kva enСемен ГассеевNoch keine Bewertungen

- VOLVO FMX 6x4rDokument4 SeitenVOLVO FMX 6x4rDarylGonzalezNoch keine Bewertungen

- Brochure Maserati - Int Levante - 2021-2Dokument6 SeitenBrochure Maserati - Int Levante - 2021-2aleNoch keine Bewertungen

- Heat Exchanger 120-180KVA-2Dokument2 SeitenHeat Exchanger 120-180KVA-2Agi AlghifariNoch keine Bewertungen

- Row Crop Tractors: 250 To 305 HPDokument2 SeitenRow Crop Tractors: 250 To 305 HPSergey Tyasko100% (1)

- Volvo G930 Grader SpecificationsDokument6 SeitenVolvo G930 Grader SpecificationssanikkpNoch keine Bewertungen

- Diesel Engine 8V 199: For Medium Military Vehicles, 530 KW (721 MHP), 600 KW (816 MHP) at 2300 1/minDokument2 SeitenDiesel Engine 8V 199: For Medium Military Vehicles, 530 KW (721 MHP), 600 KW (816 MHP) at 2300 1/minOsorio Luis100% (3)

- Sisu 66cta 74cta 84cta PDFDokument2 SeitenSisu 66cta 74cta 84cta PDFirmaos17Noch keine Bewertungen

- MWM D234Dokument4 SeitenMWM D234Riki AkbarNoch keine Bewertungen

- Funk Drivetrain Components Selection Guide 1Dokument28 SeitenFunk Drivetrain Components Selection Guide 1Elena UriñaNoch keine Bewertungen

- 519 LeafDGLeaflet PDFDokument2 Seiten519 LeafDGLeaflet PDFeichermguptaNoch keine Bewertungen

- tAD1640/1641/1642ge-B: 16.12 Liter, In-Line 6 CylinderDokument2 SeitentAD1640/1641/1642ge-B: 16.12 Liter, In-Line 6 CylinderAdolfito PBNoch keine Bewertungen

- Terex.: QbbiinqDokument2 SeitenTerex.: QbbiinqShivam KushwahNoch keine Bewertungen

- BRANDT VMA I Series Agitators Spec Sheet EnglishDokument1 SeiteBRANDT VMA I Series Agitators Spec Sheet EnglishHV NguyenNoch keine Bewertungen

- C048036 PDFDokument5 SeitenC048036 PDFiculasiNoch keine Bewertungen

- XDiavel MY 2022 Brochure ENG PDFDokument22 SeitenXDiavel MY 2022 Brochure ENG PDFExploooringNoch keine Bewertungen

- 982 LB-FT 1332 N - MDokument5 Seiten982 LB-FT 1332 N - MEmily CamilaNoch keine Bewertungen

- Diesel Electric Locomotive: Model U15C U14C U10BDokument4 SeitenDiesel Electric Locomotive: Model U15C U14C U10BMark PascoNoch keine Bewertungen

- Portable SCR106PD-SCR126PDDokument1 SeitePortable SCR106PD-SCR126PDkwstdbjp5fNoch keine Bewertungen

- 6ey26lw PDFDokument1 Seite6ey26lw PDFAhmadFachrul03Noch keine Bewertungen

- 669 LB-FT 907 N - MDokument5 Seiten669 LB-FT 907 N - MEmily CamilaNoch keine Bewertungen

- 6ey26lw PDFDokument1 Seite6ey26lw PDFfajee_farid100% (1)

- 2uz-Fe Engine PDFDokument130 Seiten2uz-Fe Engine PDFCesar Tan Bermejo III71% (7)

- M L 1 8 0 E 2 8 R I G I D 4 X 2: Dimensions (MM)Dokument2 SeitenM L 1 8 0 E 2 8 R I G I D 4 X 2: Dimensions (MM)abd alkaderNoch keine Bewertungen

- Pro WashDokument2 SeitenPro WashabcNoch keine Bewertungen

- Transautomobile 1748 EY 452259Dokument5 SeitenTransautomobile 1748 EY 452259Jordan SonnaNoch keine Bewertungen

- S630 6987159 enUS om 02-18-2(内有油缸尺寸)Dokument15 SeitenS630 6987159 enUS om 02-18-2(内有油缸尺寸)wangNoch keine Bewertungen

- GEHL en Technical Data BL818 Backhoe Loader No Bleed 0Dokument2 SeitenGEHL en Technical Data BL818 Backhoe Loader No Bleed 0Indra RobiansyahNoch keine Bewertungen

- TR1 TR2 TR3: Specifications & Technical DataDokument2 SeitenTR1 TR2 TR3: Specifications & Technical DataDarron HernándezNoch keine Bewertungen

- JD Tractor 6seriesDokument1 SeiteJD Tractor 6seriesMuhammad DennyNoch keine Bewertungen

- Top Drive Data SheetDokument11 SeitenTop Drive Data SheetWagner Ramos100% (1)

- Mitsubishi Diesel Engine - S12R-PTAA2Dokument2 SeitenMitsubishi Diesel Engine - S12R-PTAA2Anonymous yugocxnNoch keine Bewertungen

- Gehl SL 4640 4840 5640 6640 Parts ManualDokument2 SeitenGehl SL 4640 4840 5640 6640 Parts ManualautobritaiNoch keine Bewertungen

- MFWD Tractors: 190 To 220 HPDokument2 SeitenMFWD Tractors: 190 To 220 HPSergey TyaskoNoch keine Bewertungen

- 1mz FeDokument2 Seiten1mz FePacaluNoch keine Bewertungen

- Description of Engines: CharacteristicsDokument3 SeitenDescription of Engines: Characteristics02031989Noch keine Bewertungen

- Description of Engines: CharacteristicsDokument3 SeitenDescription of Engines: Characteristics02031989Noch keine Bewertungen

- Engine 2JZ-GEDokument108 SeitenEngine 2JZ-GEroy.cheong900% (1)

- CRC Evans Standard 32 60Dokument4 SeitenCRC Evans Standard 32 60goomishNoch keine Bewertungen

- Yanmar Type 6SY-650: Rear View Right Side ViewDokument2 SeitenYanmar Type 6SY-650: Rear View Right Side ViewAlbertoNoch keine Bewertungen

- Service ExperienceDokument52 SeitenService Experienceguichen wangNoch keine Bewertungen

- 320Dokument61 Seiten320Rashid Mahmood JaatNoch keine Bewertungen

- L27/38-VBS Project Guide: Four-Stroke Propulsion Engine Compliant With IMO Tier IDokument296 SeitenL27/38-VBS Project Guide: Four-Stroke Propulsion Engine Compliant With IMO Tier Iguichen wangNoch keine Bewertungen

- Generator Set Noise Solutions:: Controlling Unwanted Noise From On-Site Power SystemsDokument6 SeitenGenerator Set Noise Solutions:: Controlling Unwanted Noise From On-Site Power Systemsguichen wangNoch keine Bewertungen

- rubber design连接尺寸Dokument3 Seitenrubber design连接尺寸guichen wangNoch keine Bewertungen

- Brush Seals: World Class Sealing TechnologyDokument12 SeitenBrush Seals: World Class Sealing Technologyguichen wangNoch keine Bewertungen

- Generator Set Noise Solutions:: Controlling Unwanted Noise From On-Site Power SystemsDokument6 SeitenGenerator Set Noise Solutions:: Controlling Unwanted Noise From On-Site Power Systemstonybutcher90Noch keine Bewertungen

- rubber design连接尺寸Dokument3 Seitenrubber design连接尺寸guichen wangNoch keine Bewertungen

- Medica PHD Thesis - 1988Dokument175 SeitenMedica PHD Thesis - 1988vmedicaNoch keine Bewertungen

- OE Brochure NPP 2 14 Lay ESDokument12 SeitenOE Brochure NPP 2 14 Lay ESguichen wangNoch keine Bewertungen

- Solution Guide: GendriveDokument43 SeitenSolution Guide: Gendriveguichen wangNoch keine Bewertungen

- Engine Ratings Guide: Exclusively For Dynamic Rotary Ups and Data Center Continuous (DCC) ApplicationsDokument4 SeitenEngine Ratings Guide: Exclusively For Dynamic Rotary Ups and Data Center Continuous (DCC) Applicationsguichen wangNoch keine Bewertungen

- Bwts Library 105 327Dokument12 SeitenBwts Library 105 327joão_scherer_1Noch keine Bewertungen

- Diesel Engine 6R 460 C: IndustrialDokument2 SeitenDiesel Engine 6R 460 C: Industrialguichen wangNoch keine Bewertungen

- Vehicle M16CR Digital 01Dokument2 SeitenVehicle M16CR Digital 01guichen wangNoch keine Bewertungen

- Vehicle M14UI Digital 01Dokument2 SeitenVehicle M14UI Digital 01Julian Alberto AlvarezNoch keine Bewertungen

- Application and Design of The Ebooster From Borgwarner: Knowledge LibraryDokument7 SeitenApplication and Design of The Ebooster From Borgwarner: Knowledge Libraryguichen wangNoch keine Bewertungen

- Regulated Two-Stage Turbocharging For Gasoline Engines: R. Sauerstein R. Dabrowski M. Becker W. BullmerDokument30 SeitenRegulated Two-Stage Turbocharging For Gasoline Engines: R. Sauerstein R. Dabrowski M. Becker W. Bullmerguichen wangNoch keine Bewertungen

- Regulated 2-Stage Turbocharging (R2S) : AcademyDokument14 SeitenRegulated 2-Stage Turbocharging (R2S) : Academyguichen wangNoch keine Bewertungen

- Powerful Turbocharging System For Passenger Car Diesel EnginesDokument10 SeitenPowerful Turbocharging System For Passenger Car Diesel Enginesguichen wangNoch keine Bewertungen

- Leave It To The Experts Who Built Your Engine!Dokument4 SeitenLeave It To The Experts Who Built Your Engine!guichen wangNoch keine Bewertungen

- Vehicle M14CR DigitalDokument2 SeitenVehicle M14CR Digitalguichen wangNoch keine Bewertungen

- Wartsila: Field Experience & Technology UpdateDokument23 SeitenWartsila: Field Experience & Technology Updateguichen wangNoch keine Bewertungen

- Brush Seals: World Class Sealing TechnologyDokument12 SeitenBrush Seals: World Class Sealing Technologyguichen wangNoch keine Bewertungen

- Application and Design of The Ebooster From Borgwarner: Knowledge LibraryDokument7 SeitenApplication and Design of The Ebooster From Borgwarner: Knowledge Libraryguichen wangNoch keine Bewertungen

- Generator Set Noise Solutions:: Controlling Unwanted Noise From On-Site Power SystemsDokument6 SeitenGenerator Set Noise Solutions:: Controlling Unwanted Noise From On-Site Power Systemstonybutcher90Noch keine Bewertungen

- MTU新轴承Dokument3 SeitenMTU新轴承guichen wangNoch keine Bewertungen

- Turbochargers in The Workshop: Technology, Variants, TroubleshootingDokument58 SeitenTurbochargers in The Workshop: Technology, Variants, Troubleshootingguichen wangNoch keine Bewertungen

- Bwts Library 105 327Dokument12 SeitenBwts Library 105 327joão_scherer_1Noch keine Bewertungen

- Regulated Two-Stage Turbocharging - 3K-Warner's New Charging System For Commercial Diesel EnginesDokument12 SeitenRegulated Two-Stage Turbocharging - 3K-Warner's New Charging System For Commercial Diesel Enginesguichen wangNoch keine Bewertungen

- Shape of Water in Rotating Bucket - Physics Stack ExchangeDokument3 SeitenShape of Water in Rotating Bucket - Physics Stack ExchangeHector TrianaNoch keine Bewertungen

- Delamination With AbaqusDokument13 SeitenDelamination With AbaqusSchmetterling TraurigNoch keine Bewertungen

- The Natureofthe ElectronDokument18 SeitenThe Natureofthe ElectronSidhant KumarNoch keine Bewertungen

- April 2024 - PSAD 2Dokument2 SeitenApril 2024 - PSAD 2rando12345Noch keine Bewertungen

- Electricity: ElectromagnetsDokument17 SeitenElectricity: ElectromagnetsAyushJaiswalNoch keine Bewertungen

- Classification of ConvertersDokument1 SeiteClassification of ConvertersJon BNoch keine Bewertungen

- Atmel 0038Dokument1 SeiteAtmel 0038namerNoch keine Bewertungen

- Behavior of Structure Under Blast LoadingDokument32 SeitenBehavior of Structure Under Blast Loadingramyashri inalaNoch keine Bewertungen

- Electroculture by Briggs, Lyman J & Others 1926Dokument38 SeitenElectroculture by Briggs, Lyman J & Others 1926Mashae McewenNoch keine Bewertungen

- Production of Hard Grade Bitumen For Using in High Modulus Asphalt ConcreteDokument18 SeitenProduction of Hard Grade Bitumen For Using in High Modulus Asphalt ConcretePanjiNoch keine Bewertungen

- Cj2m-Cpu, - md21 Cpu Units, Pulse I o Modules Datasheet en PDFDokument29 SeitenCj2m-Cpu, - md21 Cpu Units, Pulse I o Modules Datasheet en PDFKhairy YaakobNoch keine Bewertungen

- Lazauskas 2013Dokument15 SeitenLazauskas 2013Youcef FermiNoch keine Bewertungen

- Bogiflex KGD20 - For PlantDokument13 SeitenBogiflex KGD20 - For PlantAnonymous PVXBGg9TNoch keine Bewertungen

- Abnormal Labour: Perceptor: Dr. Nurul Islamy, M. Kes., Sp. OGDokument54 SeitenAbnormal Labour: Perceptor: Dr. Nurul Islamy, M. Kes., Sp. OGramadhiena destia100% (1)

- Structural Design and Optimization - Part IIDokument448 SeitenStructural Design and Optimization - Part IIFranco Bontempi100% (1)

- Zott Business ModelDokument25 SeitenZott Business ModelNico LightNoch keine Bewertungen

- 2011 Sample Final ExamDokument25 Seiten2011 Sample Final Examapi-114939020Noch keine Bewertungen

- Bedia CLS 40 45 GBDokument36 SeitenBedia CLS 40 45 GBkadir kayaNoch keine Bewertungen

- Bearing Reliability Improvement-SKFDokument55 SeitenBearing Reliability Improvement-SKFAbdulrahman AlkhowaiterNoch keine Bewertungen

- Smith Meter Microloadnet Operator Reference Manual-A Voir PDFDokument96 SeitenSmith Meter Microloadnet Operator Reference Manual-A Voir PDFmehrezNoch keine Bewertungen

- Planning TechniquesDokument85 SeitenPlanning TechniquesRush YoganathanNoch keine Bewertungen

- Isentropic ExponentDokument2 SeitenIsentropic ExponentAlf OtherspaceNoch keine Bewertungen

- NEW Handbook UG 160818 PDFDokument118 SeitenNEW Handbook UG 160818 PDFHidayah MutalibNoch keine Bewertungen

- Discovering Vanishing Objects in POSS I Red Images Using The Virtual Observatory - Beatrice - V - Stac1552Dokument12 SeitenDiscovering Vanishing Objects in POSS I Red Images Using The Virtual Observatory - Beatrice - V - Stac1552Bozidar KemicNoch keine Bewertungen

- Integrating Theory, Experiments, and FEA To Solve Challenging Nonlinear Mechanics ProblemsDokument17 SeitenIntegrating Theory, Experiments, and FEA To Solve Challenging Nonlinear Mechanics ProblemsBodieTechNoch keine Bewertungen

- MB-339A User ManualDokument196 SeitenMB-339A User Manualkepakko75% (4)

- QuesTeksFerriumC61C64andC6 PDFDokument23 SeitenQuesTeksFerriumC61C64andC6 PDFEmily MillerNoch keine Bewertungen

- Paracetamol Overdose: BW 40 KG Without Fluid RestrictionDokument2 SeitenParacetamol Overdose: BW 40 KG Without Fluid RestrictionAndy TanNoch keine Bewertungen

- Webinar HPLC PT GeneCraft LabsDokument44 SeitenWebinar HPLC PT GeneCraft LabsBayu Indra Permana100% (1)

- OSD PrintoutDokument18 SeitenOSD PrintoutDSAO AmravatiNoch keine Bewertungen