Beruflich Dokumente

Kultur Dokumente

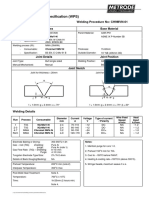

CWC-BookletF1 12

Hochgeladen von

satnamOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CWC-BookletF1 12

Hochgeladen von

satnamCopyright:

Verfügbare Formate

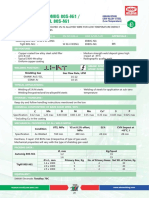

AUTOMIG 70S-A1 / GMAW/GTAW

LOW ALLOY STEEL

TIGFIL 70S-A1 (High Temperature)

A COPPER COATED LOW ALLOY WIRE

CLASSIFICATION : EN ISO 21952-A AWS A/SFA 5.28 APPROVALS:

Automig 70S-A1: G MoSi ER 70S-A1 -

Tigfil 70S-A1: W MoSi ER 70S-A1 IBR/BHEL

KEY FEATURES :

• Copper coated low alloy GMAW wire & rod • Increase strength at elevated temperature

• Typical 0.5Mo content • Weld deposit highly resistant to cold cracking

• Smooth feeding and stable arc under optimum • Shiny welds of radiographic quality

welding conditions

GMAW: DCEP

WELDING POSITION :

GTAW: DCEN

Shielding Gas Gas Flow Rate, LPM Stickout, mm

GMAW: Ar/1-5O2 15-22 10-20

GTAW: Ar 10-15 -

TYPICAL APPLICATIONS :

• Welding creep resistant 0.5% Mo steels and • Suitable for 15Mo3, 16Mo3, 14Mo6

fine grained steels with service temperatures • Welding low alloy steels such as type ASTM

up to 500°C A335 grade P1 and similar materials

• High temperature and high pressure boilers • Pipe line and crane construction as well as in

structural steel engineering

STORAGE / HANDLING :

Keep dry and follow handling instructions mentioned on the box

CHEMICAL COMPOSITION OF BARE SOLID WIRE, Wt% :

C Mn Si Mo S P Cu*

Specification 0.12 max 1.30 max 0.30-0.70 0.40-0.60 0.020 max 0.020 max 0.35 max

* Including Cu in the coating

MECHANICAL PROPERTIES OF ALL WELD METAL :

UTS, MPa YS at 0.2% offset, MPa EL%

Condition

Specification PWHT: 620°C for 1 hr 520 min 420 min 22 min

Mechanical properties will vary with the type of shielding gas used.

PACKING DATA :

Ø, mm Kg/Spool

Automig 70S-A1 1.2 15

1.6 15

Ø x L, mm Primary Box, Kg No. of Primary Boxes Net Wt. of Carton, Kg

1.6 x 1000 5 4 20

Tigfil 70S-A1

2.0 x 1000 5 4 20

2.5 x 1000 5 4 20

EQUIVALENT :

SMAW Electrode: Molyten

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

12

Das könnte Ihnen auch gefallen

- AWS D1.1 Short Code Tests #2Dokument3 SeitenAWS D1.1 Short Code Tests #2Malcolm Diamond100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Arc Gouging GuideDokument44 SeitenArc Gouging Guidedirtylsu0% (1)

- TM 9-4940-568-10 FRSDokument404 SeitenTM 9-4940-568-10 FRSAdvocate100% (3)

- P91 Profile WpsDokument6 SeitenP91 Profile WpsZead Ali Adal100% (2)

- Welding Processes ModuleDokument27 SeitenWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Introduction To Arc WeldingDokument36 SeitenIntroduction To Arc WeldingcfcshakerNoch keine Bewertungen

- Awt MCQ QuestionDokument81 SeitenAwt MCQ QuestionSHUBHAM Yadav75% (4)

- The purpose of welding procedure specification (WPS) and Procedure Qualification Record (PQRDokument68 SeitenThe purpose of welding procedure specification (WPS) and Procedure Qualification Record (PQRParvee K Nakwal100% (1)

- Handbook MetrodeDokument371 SeitenHandbook Metrodejf2587Noch keine Bewertungen

- Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDokument12 SeitenWelding of CrMo Steels For Power Generation and Petrochemical ApplicationsDries Vandezande100% (1)

- Design of Joints General LectureDokument126 SeitenDesign of Joints General LectureZarkovic011100% (2)

- Automig 70S A1 - Tigfil 70S A1Dokument1 SeiteAutomig 70S A1 - Tigfil 70S A1Vaibhavi ganganeNoch keine Bewertungen

- CWC-BookletF1 24Dokument1 SeiteCWC-BookletF1 24Jagannath SahuNoch keine Bewertungen

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDokument1 SeiteAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNoch keine Bewertungen

- Automig 80s G Tigfil 80s GDokument1 SeiteAutomig 80s G Tigfil 80s Gvijaysvm999Noch keine Bewertungen

- Automig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Dokument1 SeiteAutomig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Jagannath SahuNoch keine Bewertungen

- CWC-BookletF1 15Dokument1 SeiteCWC-BookletF1 15satnamNoch keine Bewertungen

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDokument1 SeiteAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNoch keine Bewertungen

- Automig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Dokument1 SeiteAutomig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Jagannath SahuNoch keine Bewertungen

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADokument1 SeiteAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNoch keine Bewertungen

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Dokument1 SeiteAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNoch keine Bewertungen

- CWC-BookletF1 17Dokument1 SeiteCWC-BookletF1 17satnamNoch keine Bewertungen

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Dokument1 SeiteAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNoch keine Bewertungen

- NiCu-7 solid wire for welding nickel-copper alloysDokument1 SeiteNiCu-7 solid wire for welding nickel-copper alloyssatnamNoch keine Bewertungen

- Automig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Dokument1 SeiteAutomig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Jagannath SahuNoch keine Bewertungen

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDokument1 SeiteMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNoch keine Bewertungen

- GBTDokument1 SeiteGBTRaviTeja BhamidiNoch keine Bewertungen

- Tiginox 385: Classification: en Iso 14343-ADokument1 SeiteTiginox 385: Classification: en Iso 14343-AJagannath SahuNoch keine Bewertungen

- Automig FC 71 T1Dokument1 SeiteAutomig FC 71 T1Sushil BhansaliNoch keine Bewertungen

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Dokument1 SeiteAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNoch keine Bewertungen

- Miginox 310 / Tiginox 310: Classification: en Iso 14343-ADokument1 SeiteMiginox 310 / Tiginox 310: Classification: en Iso 14343-AJagannath SahuNoch keine Bewertungen

- Miginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-ADokument1 SeiteMiginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNoch keine Bewertungen

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADokument1 SeiteTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNoch keine Bewertungen

- CWC-BookletF1 10Dokument1 SeiteCWC-BookletF1 10satnamNoch keine Bewertungen

- CWC-BookletF1 36 PDFDokument1 SeiteCWC-BookletF1 36 PDFJagannath SahuNoch keine Bewertungen

- CWC-BookletF1 29 PDFDokument1 SeiteCWC-BookletF1 29 PDFJagannath SahuNoch keine Bewertungen

- Automig 70S-61Dokument1 SeiteAutomig 70S-61tarun kaushalNoch keine Bewertungen

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Dokument1 SeiteAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNoch keine Bewertungen

- Miginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-ADokument1 SeiteMiginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNoch keine Bewertungen

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Dokument1 SeiteAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNoch keine Bewertungen

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Dokument1 SeiteTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNoch keine Bewertungen

- Miginox 307: Classification: en Iso 14343-ADokument1 SeiteMiginox 307: Classification: en Iso 14343-AJagannath SahuNoch keine Bewertungen

- Supabase X Plus 2Dokument1 SeiteSupabase X Plus 2Michael FortunaNoch keine Bewertungen

- Supabase-X-Plus AdorDokument1 SeiteSupabase-X-Plus AdorJagan TnNoch keine Bewertungen

- Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-ADokument1 SeiteMiginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNoch keine Bewertungen

- Tiginox 308H: Classification: ApprovalsDokument1 SeiteTiginox 308H: Classification: ApprovalsJagannath SahuNoch keine Bewertungen

- Miginox 347 / Tiginox 347: Classification: ApprovalsDokument1 SeiteMiginox 347 / Tiginox 347: Classification: ApprovalsJagannath SahuNoch keine Bewertungen

- Merit S-6: Lincoln Electric China Gmaw Solid WireDokument2 SeitenMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62Noch keine Bewertungen

- Ador - Auto Mig 720 E71t1Dokument1 SeiteAdor - Auto Mig 720 E71t1RaviTeja BhamidiNoch keine Bewertungen

- Electrode Booklet F Web 93Dokument1 SeiteElectrode Booklet F Web 93satnamNoch keine Bewertungen

- X Bond: Welding Electrode For Structural Welding ApplicationDokument1 SeiteX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNoch keine Bewertungen

- Automig 4043 - Tigfil 4043Dokument1 SeiteAutomig 4043 - Tigfil 4043Muhammad Whisnu NugrahaNoch keine Bewertungen

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Dokument1 SeiteTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNoch keine Bewertungen

- C-Mn Steel Solid Filler Rod for GTAW WeldingDokument1 SeiteC-Mn Steel Solid Filler Rod for GTAW WeldingsatnamNoch keine Bewertungen

- Er100s GDokument1 SeiteEr100s GAhmed Abdel NabiNoch keine Bewertungen

- 3dprint AM P22: Material TypeDokument1 Seite3dprint AM P22: Material TypeKara WhiteNoch keine Bewertungen

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDokument1 SeiteAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNoch keine Bewertungen

- Railrod: Data SheetDokument1 SeiteRailrod: Data Sheetmohamed AdelNoch keine Bewertungen

- Merit S-G: Lincoln Electric China Gmaw Solid WireDokument2 SeitenMerit S-G: Lincoln Electric China Gmaw Solid Wiredev-nullNoch keine Bewertungen

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDokument1 SeiteAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNoch keine Bewertungen

- Automig FC 71T-1Dokument1 SeiteAutomig FC 71T-1Michael FortunaNoch keine Bewertungen

- Midalloy ER80S-B6 Welding Wire Technical BulletinDokument1 SeiteMidalloy ER80S-B6 Welding Wire Technical Bulletinjoel cisnerosNoch keine Bewertungen

- Midalloy ER70S B2LDokument1 SeiteMidalloy ER70S B2LNhien ManNoch keine Bewertungen

- Midalloy ER70S B2LDokument1 SeiteMidalloy ER70S B2LNhien ManNoch keine Bewertungen

- Electrode Booklet F Web 97Dokument1 SeiteElectrode Booklet F Web 97satnamNoch keine Bewertungen

- GMAW GTAW MIGINOX 347Si STAINLESS STEELDokument1 SeiteGMAW GTAW MIGINOX 347Si STAINLESS STEELJagannath SahuNoch keine Bewertungen

- GTAW Tigfil 70S-2 Triple Deoxidized Copper Coated C-Mn Steel Filler RodDokument1 SeiteGTAW Tigfil 70S-2 Triple Deoxidized Copper Coated C-Mn Steel Filler RodSureshNoch keine Bewertungen

- Idalloy: C MN Si CR Mo V P S CuDokument1 SeiteIdalloy: C MN Si CR Mo V P S CuiocephNoch keine Bewertungen

- Merit RM-56: Lincoln Electric China Gmaw Solid WireDokument2 SeitenMerit RM-56: Lincoln Electric China Gmaw Solid WirejuanchepeinNoch keine Bewertungen

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDokument1 SeiteAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNoch keine Bewertungen

- CWC-BookletF1 59Dokument1 SeiteCWC-BookletF1 59satnamNoch keine Bewertungen

- GTAW TIGFIL CuNi solid filler rod for welding copper nickel alloysDokument1 SeiteGTAW TIGFIL CuNi solid filler rod for welding copper nickel alloyssatnamNoch keine Bewertungen

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Dokument1 SeiteAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNoch keine Bewertungen

- GMAW Solid Wire for Welding Copper AlloysDokument1 SeiteGMAW Solid Wire for Welding Copper AlloyssatnamNoch keine Bewertungen

- NiCu-7 solid wire for welding nickel-copper alloysDokument1 SeiteNiCu-7 solid wire for welding nickel-copper alloyssatnamNoch keine Bewertungen

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDokument1 SeiteAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNoch keine Bewertungen

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDokument1 SeiteAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNoch keine Bewertungen

- GMAW/GTAW Welding of Aluminium Alloys with ER1100 WireDokument1 SeiteGMAW/GTAW Welding of Aluminium Alloys with ER1100 WiresatnamNoch keine Bewertungen

- CWC-BookletF1 17Dokument1 SeiteCWC-BookletF1 17satnamNoch keine Bewertungen

- Tiginox 385: Classification: en Iso 14343-ADokument1 SeiteTiginox 385: Classification: en Iso 14343-AJagannath SahuNoch keine Bewertungen

- GMAW GTAW MIGINOX 347Si STAINLESS STEELDokument1 SeiteGMAW GTAW MIGINOX 347Si STAINLESS STEELJagannath SahuNoch keine Bewertungen

- CWC-BookletF1 38 PDFDokument1 SeiteCWC-BookletF1 38 PDFsatnamNoch keine Bewertungen

- CWC-BookletF1 36 PDFDokument1 SeiteCWC-BookletF1 36 PDFJagannath SahuNoch keine Bewertungen

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Dokument1 SeiteAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNoch keine Bewertungen

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADokument1 SeiteAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNoch keine Bewertungen

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADokument1 SeiteTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNoch keine Bewertungen

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Dokument1 SeiteTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNoch keine Bewertungen

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADokument1 SeiteTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNoch keine Bewertungen

- CWC-BookletF1 15Dokument1 SeiteCWC-BookletF1 15satnamNoch keine Bewertungen

- CWC-BookletF1 9Dokument1 SeiteCWC-BookletF1 9satnamNoch keine Bewertungen

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Dokument1 SeiteAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNoch keine Bewertungen

- CWC-BookletF1 9Dokument1 SeiteCWC-BookletF1 9satnamNoch keine Bewertungen

- CWC-BookletF1 10Dokument1 SeiteCWC-BookletF1 10satnamNoch keine Bewertungen

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADokument1 SeiteTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNoch keine Bewertungen

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Dokument1 SeiteTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNoch keine Bewertungen

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Dokument1 SeiteAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNoch keine Bewertungen

- Body RepairDokument19 SeitenBody RepairPUTRA SANINoch keine Bewertungen

- Aryigo 4 - Physics of Welding Part2 LancasterDokument20 SeitenAryigo 4 - Physics of Welding Part2 LancasterAlexsander NascimentoNoch keine Bewertungen

- Welding Electrode: The Hashimite Kingdom of JordanDokument23 SeitenWelding Electrode: The Hashimite Kingdom of JordanAhmad OmarNoch keine Bewertungen

- Tweco Spool Gun: Tweco Style Rear Connector 20% Duty Cycle - Mixed GasesDokument4 SeitenTweco Spool Gun: Tweco Style Rear Connector 20% Duty Cycle - Mixed Gasesstudent_physicianNoch keine Bewertungen

- Operating Instructions for GLC 353/503/553 MC3 MIG/MAG Welding MachinesDokument122 SeitenOperating Instructions for GLC 353/503/553 MC3 MIG/MAG Welding Machinesmatadorishe0% (1)

- Wire Feed Mig Welder: Operator's GuideDokument56 SeitenWire Feed Mig Welder: Operator's GuidepedpixNoch keine Bewertungen

- 10 Welding Processes Arc Energy & Heat InputDokument14 Seiten10 Welding Processes Arc Energy & Heat InputPraviBeetlesNoch keine Bewertungen

- PM1155 Load Cell Installation Guidelines V1.0Dokument16 SeitenPM1155 Load Cell Installation Guidelines V1.0Akrom77khasaniNoch keine Bewertungen

- MISON AR Shielding Gas135 99117Dokument4 SeitenMISON AR Shielding Gas135 99117camelod555Noch keine Bewertungen

- 5 - Section 14 - Arc Welding ConsumablesDokument11 Seiten5 - Section 14 - Arc Welding Consumablesrizkialia12Noch keine Bewertungen

- TIG MIG Welding Lab ReportDokument6 SeitenTIG MIG Welding Lab ReportSaad Saleem50% (2)

- Welding SolutionsDokument12 SeitenWelding SolutionsnyaungzinNoch keine Bewertungen

- Lesson Plans EdtpaDokument12 SeitenLesson Plans Edtpaapi-353035341Noch keine Bewertungen

- PMKVY Courses List & Registration Fees - Sarkari Yojana 2017Dokument28 SeitenPMKVY Courses List & Registration Fees - Sarkari Yojana 2017Harsh Goyal0% (1)

- BOC Welding Products & Solutions - Essential GuideDokument84 SeitenBOC Welding Products & Solutions - Essential GuidePaul CassellsNoch keine Bewertungen

- Ts 1Dokument25 SeitenTs 1NaveenNoch keine Bewertungen

- SOLDADURADokument10 SeitenSOLDADURAgNoch keine Bewertungen

- Accessories & Welding Mig Guns: CatalogDokument136 SeitenAccessories & Welding Mig Guns: CatalogMatias Roquel100% (1)