Beruflich Dokumente

Kultur Dokumente

AGP-GPS-ANOGP-Z21-0010 - C02 Advance Copy - Piping Material Specification PDF

Hochgeladen von

RubénOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AGP-GPS-ANOGP-Z21-0010 - C02 Advance Copy - Piping Material Specification PDF

Hochgeladen von

RubénCopyright:

Verfügbare Formate

ANOH Gas Processing Company Limited

PY

Security Classification: Restricted

O

AGP-GPS-ANOGP-Z21-0010

C

E

C

ANOH GAS PLANT PROJECT

(AGPP)

N

VA

PIPING MATERIAL SPECIFICATION

AD

2_

SEP, 2019

O

C

Rev Date Description Issued by Checked by Approved by

EV

R

C02 29-SEP-19 Issued for Construction-

Advance Copy TSK MM BVP

C01 11-JUL-19 Issued for Construction TSK AKS BVP

A01 30-MAY-19 Issued for Approval MM AKS BVP

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 2 OF 49

ADDITIONAL APPROVAL / REVISION HISTORY TABLE

Party Name Sign Date

PY

O

C

E

Revision Philosophy

C

All documents for approval will be issued at A01 as required.

N

If the document is for information, it will also be issued as A01.

All revisions re-Issued for approval will be issued as A02, with subsequent A03, A04, etc as

VA

required.

Documents approved for Construction will be issued at C01, C02, and C03 respectively.

Documents or drawings revised as “As built” will be issued as Z01, Z02 Z03 etc.

AD

Previous revision highlighting to be removed at subsequent issues

Drawings/diagrams revised from previous approved issues are highlighted by 'clouding' the

affected areas and by the use of a triangle containing the revision status.

2_

O

Revision History

Revision No. Date of issue Reason for change

C

C01 11-JuL-19 Revised as per comments on Rev A01.

EV

C02 Advance 29-Sep-19 Revised as marked

Copy

R

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 3 OF 49

Table of Contents

1 INTRODUCTION....................................................................................................... 5

1.1 Project Background .........................................................................................................5

2 OBJECTIVE AND SCOPE ............................................................................................ 6

PY

2.1 Objective ........................................................................................................................6

2.2 Scope ..............................................................................................................................6

O

2.3 Exclusions .......................................................................................................................6

3 DEFINITIONS AND ABBREVIATIONS .......................................................................... 7

C

3.1 Definitions ......................................................................................................................7

3.2 Abbreviations .................................................................................................................7

E

4 REFERENCE DOCUMENTS, CODES, STANDARDS & REGULATIONS .............................. 10

C

4.1 Project standards and specifications ............................................................................. 10

4.2

4.3

N

Codes and Standards .................................................................................................... 10

Order of Precedence ..................................................................................................... 14

VA

5 DESIGN PRINCIPLES ............................................................................................... 14

5.1 Design Values ............................................................................................................... 14

5.2 General Requirements .................................................................................................. 14

AD

5.3 Materials ...................................................................................................................... 19

5.4 Pipes ............................................................................................................................. 19

2_

5.5 Pipe Fittings .................................................................................................................. 20

5.6 Flanges ......................................................................................................................... 21

O

5.7 Bolting .......................................................................................................................... 22

5.8 Gaskets ......................................................................................................................... 22

C

5.9 Isolation........................................................................................................................ 24

5.10 Valves ........................................................................................................................... 24

EV

5.11 Valve Data Sheet Tag: ................................................................................................... 30

5.12 Metallic Ball Valves ....................................................................................................... 31

R

5.13 Globe Valves ................................................................................................................. 31

5.14 Check Valves ................................................................................................................. 32

5.15 Gate Valves ................................................................................................................... 32

5.16 DBB Valves .................................................................................................................... 32

6 PREPARATION FOR SHIPMENT OF VALVES .............................................................. 33

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 4 OF 49

6.1 Marking ........................................................................................................................ 33

6.2 Protection ..................................................................................................................... 34

6.3 Preparation for Dispatch ............................................................................................... 34

6.4 Preservation ................................................................................................................. 34

6.5 Quality Assurance & Control ......................................................................................... 34

PY

7 IDENTIFICATION OF PIPING CLASSES: ...................................................................... 35

8 PIPING MATERIAL SPECIFICATIONS ......................................................................... 36

9 SERVICE CODES ..................................................................................................... 38

O

10 PIPING/INSTRUMENT HOOK-UP ............................................................................. 39

C

10.1 Basic Principles ............................................................................................................. 39

10.2 Connection Configuration ............................................................................................. 39

E

11 STUD BOLT – CHART .............................................................................................. 40

11.1 Stud Bolt/Nut for ASME B16.5 (RF & FF) ........................................................................ 40

C

11.2 Stud Bolt/Nut for ASME B16.5 (RTJ) .............................................................................. 41

12 N

JACKSCREW BOLT CHART ....................................................................................... 42

VA

12.1 Jack Screw Details (RF – Flanges) ................................................................................... 42

12.2 Jack Screw Details (RTJ – Flanges) ................................................................................. 43

13 DIMENSION OF LINE BLANKS.................................................................................. 45

AD

13.1 Drawing for Line Blanks................................................................................................. 45

13.2 Dimension table for Flat face ........................................................................................ 46

13.3 Dimension table for Female Ring-Joint Face .................................................................. 47

2_

14 APPENDIX I – METALLIC PIPE CLASSES..................................................................... 48

15 APPENDIX II – NON-METALLIC PIPE CLASSES ........................................................... 49

O

C

EV

R

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 5 OF 49

1 INTRODUCTION

1.1 Project Background

The Assa North - Ohaji South (ANOH) project is a Greenfield Nigerian gas development aimed at supporting

the domestic market and targeting production for Q2 2020. Assa North field is located in block OML 21 and

is operated by Shell Petroleum Development Company.

PY

The field extends into block OML 53, where it is called Ohaji South and is operated by SEPLAT Petroleum

Company. In combination, the fields are called ANOH. ANOH field is located in Imo State, close to Owerri and

O

about 70 km North-West of Port Harcourt. ANOH field will be developed by a Joint Venture (JV) consisting

of the Nigerian Government holding 55% 57.5%, SEPLAT holding 22.5% 20%, Shell holding 15%, TOTAL

C

holding 5% and AGIP holding 2.5%.The JV will be operated by Shell Petroleum Development Company (SPDC).

The midstream will be operated by Seplat Petroleum Resources Ltd on behalf of the ANOH Gas Processing

E

Company Ltd. (AGPC).

C

The Midstream will be developed and delivered into the market in two phases:

· N

Phase 1: 300mmscfd Q1 2019 subject to offtake agreements being in place.

VA

· Phase 2: 300mmscfd Future subject to offtake agreements and feed stock gas being in place from OML

53 and ANOH/Unit..

The plant will be designed for 600 mmscfd on plot suitable for 1,200 mmscfd.

AD

The ANOH Gas Processing Facilities in its entirety is defined as the integrated Gas and Gas Liquids

development of the unitized ANOH field straddling OMLs 21 and 53.

2_

The overall purpose of the ANOH Gas facilities is to receive wet gas from the ANOH field, deliver processed

gas into the OB3 pipeline and evacuate the resulting condensate to the export terminals in Brass or Bonny.

O

For further details of the project including please refer to the Project Execution Plan ref SEP-OPS-ANOH-B01-

C

00002.

EV

R

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 6 OF 49

ANOH GAS PROCESSING COMPANY LIMITED

PROJECT LOCATION

PY

O

C

E

C

N

VA

2 OBJECTIVE AND SCOPE

AD

2.1 Objective

The purpose of this specification is to define the material requirements for various piping components for

different materials to be used in “ANOH Gas Plant Project (AGPP)” project.

2_

2.2 Scope

O

This specification defines the usage and limitation of piping materials to be used in “ANOH Gas Plant Project

(AGPP)” project.

C

Terms used in this specification are defined in section 3 & 4.

EV

2.3 Exclusions

· Gas Transmission & Distribution Piping Systems (ASME B31.8)

R

· Pipeline Transportation Systems for Liquids and Slurries (ASME B31.4)

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 7 OF 49

3 DEFINITIONS AND ABBREVIATIONS

3.1 Definitions

Within this specification, the following definitions will apply.

PROJECT :ANOH Midstream Gas Processing plant(AMGPP)

PY

CONTRACTOR :Global Process systems LLC

COMPANY :ANOH Gas Processing Company

O

PURCHASER :It is defined as the entity responsible for engineering and procurement

and who executes the PURCHASE ORDER for the supply of equipment and

C

services detailed in this specification.

E

SUPPLIER (or VENDOR) : Any person, firm, partnership, company, corporation or

combination thereof with whom the CONTRACTOR has sent the

C

MATERIAL REQUISITION or placed the PURCHASE ORDER.

SUB-SUPPLIER N

: Any person, firm, partnership, company, corporation or

VA

combination thereof other than CONTRACTOR supplying to

SUPPLIER SUPPLY or parts thereof in connection with the

PURCHASE ORDER.

AD

PURCHASE ORDER : The PURCHASE ORDER together with requisition and all the

documents referred therein.

2_

SCOPE OF WORK :The goods/service and / or equipment and /or documentation to be provided

under the PURCHASE ORDER.

O

3.2 Abbreviations

C

13% Cr Alloy Steel 13% Cr

AARH Arithmetic Average Roughness Height

AED Anti-Explosive Decompression

EV

ANSI American National Standards Institute

ALT Alternative

R

API American Petroleum Institute

APP. Appendix

ASME American Society of Mechanical

ASTM Engineers

American Society for Testing Materials

BE Bevel End

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 8 OF 49

BHN Brinell Hardness Number

BLE Bevel Large End

BS British Standard

BW Butt Weld

CA Corrosion Allowance

CE Carbon Equivalent

PY

CL Class

CS Carbon Steel

DBB Double Block & Bleed

O

DP Design Pressure

C

DPI Dye Penetrant Inspection

DT Design Temperature

E

EFW Electric Fusion Weld

EN European Norms

C

ENP Electro less Nickel Plating

ERW

ESDV

Electric Resistance Weld

Emergency Shutdown Valves

N

VA

FB Full Bore

FF Flat Face

AD

FNPT/NPTF National Pipe Thread Female

FV Full Vacuum

GALV. Galvanized

2_

GR. Grade

HEX Hexagonal

O

HVOF High Velocity Oxy Flame

ID Inside Diameter

C

ISO International Organization for

LPI Standardization

Liquid Penetrate Inspection

EV

LR Long Radius

LTCS Low Temperature Carbon Steel

MDMT Minimum Design Metal Temperature

R

mm Millimeter

MPI Magnetic Particle Inspection

MSS Manufacturers Standardization Society

NA Not Applicable

NB Nominal Bore

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 9 OF 49

NB Nominal Bore

NDE/NDT Non-destructive Examination/Testing

NPS Nominal Pipe Size

NPT National Pipe Thread

NPTM Nation Pipe Thread Male

OD Outside Diameter

PY

OS & Y Outside screw & Yoke

P&ID Piping & Instrument Diagram

PE Plain End

O

PBE Plain Both End

C

PSE Plain Small End

PCTFE Poly Chloro Tri Fluro Ethylene

E

PEEK Poly Ether Ether Ketone

PTFE Poly Tetra Fluoro Ethylene

C

PWHT Post Weld Heat Treatment

RB

RF

Reduce/Regular Bore

Raised Face

N

VA

RTJ Ring Type Joint

RPTFE Reinforced Poy Tetra Fluro Ethylene

AD

SAW Submerged Arc Welded

SCH Schedule

SMYS Specified Minimum Yield Strength

2_

SS Stainless Steel

STD Standard or Standard Weight

O

SW Socket Weld

SMLS Seamless

C

TBE Threaded Both End

TCC Tungsten Carbide Coating

EV

THRD Threaded

TSE Threaded Small End

TSO Tight Shut Off

R

UTS Ultimate Tensile Strength

WN Weld Neck

XS Extra Strong

XXS Double Extra Strong

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 10 OF 49

4 REFERENCE DOCUMENTS, CODES, STANDARDS & REGULATIONS

The following sub sections provides the list of codes and standards, which relate to the piping systems. The

latest edition as of 1st Jun-2019 including addenda and supplements of the applicable piping codes and

standards are to be considered at the time of contract award as part of this specification.

4.1 Project standards and specifications

PY

Document No. Title

AGP-GPS-ANOGP-Z02-0001 Piping Design Basis

SEP-OPE-GEN-P15-00007 Painting and Coating Specification

O

AGP-GPS-ANOGP-Z16-0005 Piping Fabrication Specification

C

AGP-GPS-ANOGP-Z05-0001 Pipe Thickness Calculations

AGP-GPS-ANOGP-Z01-0002 Valve Datasheets

E

AGP-GPS-ANOGP-Z19-0403-001 Piping Design Standard

C

4.2 Codes and Standards

4.2.1 ASME (American Society of Mechanical Engineers)

N

VA

Code Title

ASME B31.3 Process Piping

AD

ASME B16.5 Pipe Flanges and Flanged Fittings

ASME B16.9 Factory-made Wrought Steel Butt-welding Fittings

ASME B16.10 Face to Face and End to End dimensions of Valves

2_

ASME B16.11 Forged steel fittings, Socket-welding and Threaded

ASME B16.20 Metallic Gaskets for Pipe Flanges ring joint, Spiral wound and Jacketed.

ASME B16.21 Non-Metallic Flat Gaskets for Pipe Flanges

O

ASME B16.25 Butt-welding Ends

C

ASME B16.34 Valves Flanged, Threaded and Welding End

ASME B16.36 Orifice Flange

EV

ASME B16.48 Steel Line Blanks

ASME B18.2.1 Square and Hex Bolts and Screws, Inch Series

ASME B18.2.2 Square and Hex Nuts, Inch Series

R

ASME B36.10M Welded and Seamless Wrought Steel Pipe

ASME B36.19M Stainless Steel Pipe

ASME B46.1 Surface Texture (Surface Roughness, Waviness and Lay)

ASME B1.1 Unified Inch Screw Threads

ASME B1.20.1 Pipe Threads, General Purpose (Inch)

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 11 OF 49

4.2.2 ASTM (American Society for Testing Materials)

Code Title

A53 / A53M Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated,

Welded and Seamless

A105 / A105M Carbon Steel Forgings for Piping Applications

A106 / A106M Seamless Carbon Steel Pipe for High-Temperature Service

PY

A123 / A123M Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and

Steel Products

A153/ A153M Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware

O

A182 / A182M Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and

Valves and Parts for High Temperature Service

C

A193 / A193M Alloy-Steel and Stainless Steel Bolting Materials for High Temperature or High

Pressure Service

E

A194 / A194M Carbon and Alloy-Steel Nuts for Bolts for High Pressure or High Temperature

Service, or Both

C

A216 / A216M Steel Castings, Carbon, Suitable for Fusion Welding, for High Temperature

A234 / A234M

Service

N

Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and

VA

High Temperature Service

A240 / A240M Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for

Pressure Vessels and for General Applications

AD

A262 Standard Practices for Detecting Susceptibility to Intergranular Attack in

Austenitic Stainless Steels

A312 / A312M Seamless, Welded and Heavily Cold Worked Austenitic Stainless Steel Pipes

2_

A320 / A320M Alloy-Steel and Stainless Steel Bolting Materials for Low-Temperature Service

A333 / A333M Seamless and Welded Steel Pipe for Low-Temperature Service and Other

O

applications with Requiring Notch Toughness Testing

A350 / A350M Standard Specification for Carbon and Low-Alloy steel Forgings, Requiring

C

Notch Toughness Testing for Piping components.

A351 / A351M Standard specification for Castings, Austenitic, for Pressure-Containing Parts.

EV

A352 / A352M Standard Specification for Steel Castings, Ferritic and Martensitic, for

Pressure-Containing Parts, Suitable for Low-Temperature Service.

A358/ A358M Standard Specification for Electirc-Fusion-Welded Austenitic Chromium

Nickel Stainless Steel pipe for High Temperature Service and General

R

Application

A370 Standard Test Methods and Definitions for Mechanical Testing of Steel

Products

A403 / A403M Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 12 OF 49

Code Title

A420 / A420M Standard Specification for Piping Fittings of Wrought Carbon steel and Alloy

Steel for Low-Temperature Service.

A488 / A488M Standard Practice for Steel Castings, Welding, Qualifications of Procedures

and Personnel

A516 / A516M Pressure Vessel Plates, Carbon Steel, for Moderate and Lower-Temperature

PY

Service.

A671 Standard Specification for Electric-Fusion-Welded Steel Pipe for Atmospheric

and Lower Temperatures

O

A700 Standard Guide for Packing, Marking and Loading methods for steel Products

for shipment.

C

A790 / A790M Standard Specification for seamless and welded Ferritic/Austenitic Stainless

steel Pipe

E

A815 / A815M Standard Specification for Wrought Ferritic, Ferritic/Austenitic, and

Martensitic Stainless Steel Piping Fittings

C

B148 Standard Specification for Aluminum-Bronze Sand Castings

G48

N

Standard Test Method for Pitting and Crevice Corrosion Resistance of

Stainless steel and Related Alloys by Use of Ferric Chloride Solution

VA

E564 Standard Test Method for Determining Volume Fraction by Systematic

Manual Point Count.

AD

4.2.3 API (American Petroleum Institute)

Code Title

API 5L Specification for Line Pipe

2_

API 594 Check Valves: Flanged, Lug, Wafer, Wafer and Butt-Welding.

API 598 Valve Inspection and Testing

O

API 600 Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas Industries

API 602 Compact Steel Gate Valves - Flanged, Threaded, Welding, and Extended-Body

C

Ends

API 607 Fire Test for Soft-Seated Quarter-Turn Valves

EV

API 608 Metal Ball valve – Flanged, Threaded and Welding Ends

API 609 Butterfly Valves: Double Flanged, Lug- and Wafer-Type

API 623 Steel globe valves – Flanged and Butt-welding Ends, Bolted Bonnets

R

API 6D Specification for Pipe line valves

API 6FA Specification Fire Test for valves

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 13 OF 49

4.2.4 BS (British Standards)

Code Title

BS 1868 Steel check valves (flanged and butt-welding ends) for the petroleum,

petrochemical and allied industries.

BS 1873 Steel globe and globe stop and check valves (flanged and butt-welding ends)

for the petroleum, petrochemical and allied industries

BS EN ISO 17292 Metal ball valves for petroleum, petrochemical and allied industries (replaces

PY

BS 5351)

BS EN ISO 15761 Steel gate, globe and check valves for sizes DN 100 and smaller, for the

petroleum and natural gas industries (replaces BS 5352)

O

EN 10204 Metallic products - Types of inspection documents

EN 12266-1 Industrial valves - Testing of valves - Part 1: Pressure tests, test procedures

C

and acceptance criteria — Mandatory requirements (replaces BS 6755-1)

EN 10497 Testing of valves -Fire type-testing requirements (replaces BS 6755-2)

E

4.2.5 MSS (Manufacturers Standardization Society)

C

Code Title

MSS-SP-6

MSS-SP-25

N

Standard Finishes for Contact Face of Pipe Flanges

Standard Marking System for Valves, Fittings, Flanges and Unions

VA

MSS-SP-43 Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion

Resistant Applications

MSS-SP-45 Bypass and Drain Connections

AD

MSS-SP-55 Quality Standard for Steel Castings for Valves, Flanges, Fittings, and Other

Piping Components

MSS-SP-72 Ball Valves with Flanged or Butt-Welding Ends for General Service

2_

MSS-SP-80 Bronze Gate, Globe, angle and Check Valves

MSS-SP-83 Steel Pipe Unions, Socket-Welding and Threaded

O

MSS-SP-95 Swage(d) Nipples and Bull Plugs

MSS-SP-97 Forged Carbon Steel Branch Outlet Fittings – Socket Welding, Threaded and

C

Butt-welding ends

4.2.6 EEMUA (Engineering Equipment & Materials Users Association)

EV

Code Title

EEMUA 182 Specification for Integral Block and Bleed Valve Manifolds for Direct

Connection to Pipework

R

4.2.7 ISO (International Standardization Organization)

Code Title

Hold Polyvinyl Chloride (PVC)

ISO 14692 Glass Reinforced Epoxy (GRE)

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 14 OF 49

4.3 Order of Precedence

In the event of any conflict or contradiction between the specifications and standards, the same shall be

brought to the attention of company. The conflict shall be resolved, unless specifically stated otherwise, in

order of precedence starting with:

1. Mandatory Nigerian Statutory and Regulatory Requirementst

PY

2. Project Philosophies.

3. Material requisitions and Job Specification

4. Company Standards and Specifications

O

5. International codes & standards

6. CONTRACTOR Standards & Specifications

C

7. Manufacturer’s proven standards wherever applicable

E

5 DESIGN PRINCIPLES

C

5.1 Design Values

N

Process and utility Piping systems and all components included in these systems shall conform to ASME B31.3

and other codes /Standards referenced in section 4.0 as applicable.

VA

5.2 General Requirements

1. All piping component wall thicknesses specified in the individual pipe classes are calculated in accordance

AD

with ASME B31.3 based on continuous long-term internal design pressure, design temperature, specified

corrosion/erosion allowance, the manufacturing tolerance and the threading allowance as applicable.

2_

All piping subject to any additional loading such as short term upset conditions, occasional loads, external

pressure, thermal loading, live loads, etc shall be individually assessed to ensure full compliance with

ASME B31.3.

O

2. All materials shall be new, unused and free from imperfections, excessive mill scales, slag intrusion,

C

laminations, pitting and excessive rust that may impair their strength, durability or appearance.

3. Pipe, valves and fittings in sizes 1 1/4”, 2 1/2”, 3 1/2”, 5”, 7”, 9” and 22” shall not be used. Where

equipment is normally provided by a Vendor with connections in any of the above sizes, connections will

EV

be made with suitable swages or reducers to pipe of approved size.

4. Galvanized, where specified in the pipe class for pipes and components shall comply with the

R

requirements of ASTM A153 and ASTM A123.

Carbon and Low alloy steel bolting material shall be hot dip galvanized in accordance with ASTM A153.

5. Deviations from the Piping Standard Sheet may occur due to non-availability or design conditions. These

deviations are permissible if they are of an equal or higher standard than the individual Piping Standard

requirements, and written approval is given by Purchaser.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 15 OF 49

6. All piping materials except for gaskets shall be supplied with material certificates conforming to

European Standard EN 10204, Type 3.1, or Purchaser approved Inspection Certificate. Gaskets shall be

supplied with material certificates conforming to European Standard EN 10204, Type 2.2 and 2.1

respectively.

7. Threaded Component

Wherever NPT threaded connections are specified for instrument connections, the threads shallmeet

PY

the requirements of ASME B1.20.1 with the exception of the following. The objective of these exceptions

is to ensure the minimum engagement of 4 to 6 threads by hand pressure and an additional 0.5 to 1.5

turns by means of a wrench.

O

The L1 thread-gauging requirement as stated in sections 8.1 and 8.2 of ASME B1.20.1 shall be read as

C

follows.

· Gauging External Taper Threads with Ring Gauge (Male Threads) during hand tightening, the

male fitting shall engage in to the ring gauge by +1/4 to +1 turn more than the start of the first

E

scratch mark on the chamfer zone. The gauge is to be turned towards the body of the fitting.

C

· Gauging Internal Threads with Plug Gauge (Female Threads)

N

During hand tightening, the plug gauge shall engage in to the female fitting by +1/4 to +1 turn

below the last thread scratch mark on the chamfer zone. The gauge is to be turned towards the

VA

body of the fitting.

Threading allowance recommended as per ASME B1.20.1, B31.3 sections and 314 is

3/4” NPS 0.0571”

AD

1” to 1 ½” NPS 0.0696”

8. Cast iron, ductile or malleable iron, aluminum, plastic or copper-bearing alloys shall not be used in

hydrocarbon service.

2_

9. Piping design pressure is based on flange maximum-allowable working pressure, unless otherwise noted

in the Piping class Specification sheets

O

10. Asbestos gaskets shall not be used.

11. Machined or threaded surfaces shall be preserved by coating with rust inhibitor Shell ENSIS or equivalent.

C

12. All pipe & fittings shall be compliant with individual Pipe classes.

13. Butt weld end preparation shall be in accordance with Fig 2(a) or 3(a) of ASME B16.25 for normal piping

EV

application.

14. Tolerance: -

EFW pipes, seamless pipes and fittings shall be in accordance with corresponding code and standard.

R

Manufacturer shall supply pipes or fittings with manufacturing tolerance in accordance with respective

ASME codes and standard. Manufacturer shall demonstrate that at least 80% of pipe or fitting has the

required nominal or higher thickness.

15. The minimum pipe size shall be 3/4”.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 16 OF 49

16. The use of ½” pipe shall be subject to COMPANY approval and shall typically be limited to the following

applications and restrictions:

· Connecting to EXISTING or MANUFACTURER STANDARD equipment.

· 1/2” section must be kept as short as reasonably possible before swaging up to next suitable line

size, if not able to swage up immediately.

17. Instrument Tubing Classes and the specification of parts and items are not in piping scope.

PY

18. Tubing systems are typically not the responsibility of the Piping Department with including hydraulic

systems or exotic lube oil systems.

19. Reductions in line size will be made using reducers, reducing fittings or swages:

O

· Where reducing in, to or from a screwed fitting, use a swage nipple.

C

· Where reducing in a butt-welded construction use a butt weld reducer.

20. Bends shall be specified where there is like hood of erosion or erosion-corrosion or where inline

E

inspection and cleaning is required. The minimum bend radius shall be 5D (5 times the nominal pipe

diameter)

C

21. 3D bends may only be used where specified by Process and suitable for line function.

N

22. Fabricated mitre-bends shall not be permitted.

23. The smallest threaded pipe and fittings (including plugs) shall be 3/4” NPT.

VA

24. No “street elbows” or threaded bushings shall be used on piping. Hex bushings (but not flush bushings)

may only be used with tubing fittings for connections with instruments."

25. Slip-On or stub-ends lap-joint flanges shall not be permitted without written approval from COMPANY

AD

and shall not be used in the following:

· Safety Critical or Hazardous fluid piping systems

· Elevated temperature environments

2_

· Cold environments

· High pressure environments

O

· Cyclic fatigue environments

26. Where Slip-On flanges are permitted, they shall be welded on both the external and internal surfaces,

C

taking care to avoid damaging the gasket seating surface.

27. Where permitted, fabricated stub-end lap joint flanges shall be welded with full penetration welds.

EV

28. Flanges bolt holes shall be orientated to straddle the natural piping centre lines unless otherwise

specified.

29. Insert Branch Fittings and Swept Outlet Fittings shall not be used without written approval from

R

COMPANY

30. Piping will provide gasket, stud bolts c/w nuts and Insulation Washer in accordance with run-line Piping

Class.

31. All valves shall be in accordance with the requirements of Piping Class and Valve Data Sheet.

32. All flanged end valves shall have integral flanges. Welded on flanges are not acceptable.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 17 OF 49

33. All ball valves in hydrocarbon service shall be fire safe in accordance with the requirements of either API

6FA (for trunnion ball valves) or API 607 (for floating ball valves).

34. Use of butterfly valves in hazardous or safety critical service shall be subject to COMPANY review and

approval.

35. Globe type valves shall typically be used where general throttling is required.

36. Valves operated in fully open or blocked-in service shall normally be gate, ball or butterfly type valves.

PY

37. Valve casing vent & drain shall be as per applicable CODE.

38. Piping scope ends at instrument tubing connection point. All stud bolts, gaskets, insulating kit (if

applicable) and flanges shall includes in piping MTO. Piping / Instrument scope split will be reflected in

O

instrument Hook-up drawing. Piping scope excludes instrument items.

C

39. Gate, globe, angle and check valves shall be supplied with replaceable seats.

40. INSPECTION, TESTING AND REQUIREMENTS

· NON DESTRUCTIVE TESTING

E

· MINIMUM EXTENT OF NDT

C

Inspection Level in %

Material Service N ANSI Class RT MPI DPI

VA

(1,2,3,4,6) (5) (5)

150 - 300 10 10

Carbon Steel All Services

AD

600 & above 100 100

Austenitic Stainless All 150 - 300 10 10

Steel Services 600 & above 100 100

2_

Dissimilar Metal Welds All Services All Ratings 100 100

O

Notes:

1. The radiography requirements are applicable to butt welds. For branch joints, MPI or DPI shall be

C

performed at the same percentage as required for radiography for that service.

2. UT maybe applied in lieu of RT, subject to Contractor/Company approval.

EV

3. Radiography shall cover all welders involve in the job.

4. The following film qualities shall apply:

· The combination of film type and radiation source shall be capable of providing the density and

R

sensitivity requirement of governing code ASME Section V Article 2.

5. Fillet welds/ groove welds shall be subject to MPI/DPI at the same percentage as for the radiography of

butt welds.

6. For jacketed piping, if there’s any, 10% of the circumferential and 100% of the longitudinal welds shall

be examined by radiography.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 18 OF 49

41. Positive Material identification (PMI) Requirements

Positive Material identification procedure shall be issued to purchaser’s approval, below minimum

requirements shall be adhered for PMI on base materials and welds:

a. Alloy materials and welds shall be PMI examined.

b. PMI shall not be considered as a substitute for required material test reports. Material test reports

shall not be considered as acceptable PMI.

PY

c. Optical emissions technique, Portable x-ray analyzers or x-ray flourscence spectrometers may be

used for performing PMI examinations.

d. Alloying elements to be analysed for PMI shall be as per table -1, and the extent shall be as given in

O

table-2

C

Table-1

Alloy Elements

E

SS 304 / 304L (S30400 / S30403) Ni, Cr

C

SS 316 / 316L (S31600 / S31630) Ni, Cr, Mo

Duplex (S31803) Ni, Cr, Mo

N

a. A deviation of more than +/- 10% of the required percentage of alloying elements/ or absence of

VA

the alloying elements with respect to the required material specification shall be considered not

acceptable.

b. All rejected materials that are identified shall be quarantined until an investigation is carried out.

AD

c. All materials shall comply with the requirements of the applicable material specification and

relevant package specification. Materials shall be verified to ensure the correct major alloying

elements and the correct percentages of each element where applicable.

2_

Table-2

O

S.No. Item / Part Extent Extent

C

Pressure retaining parts –

1 One spot per heat

EV

Plates, Pipes, fittings & flanges

a. One spot in every 5meters in long seams and

2 circular seams per WPS/PQR.

Pressure retaining welds:

b. Minimum 5% of welds from each WPS

R

employed.

10% of each lot with minimum of two

3 Bolting

(Lot- per size and alloy material)

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 19 OF 49

5.3 Materials

1. Materials shall conform to impact test requirements specified in ASME B31.3 & respective material

specification, for the combination of minimum design metal temperature (MDMT) and reference

thicknesses specified.

2. Impact testing shall be carried out for piping based on thickness & design min temperature indicated in

pipe class. Test temperature shall not be warmer than the design temperature. Impact test requirement

PY

shall be as per B31.3 & shall be conducted in accordance with ASTM E23, A 370 & B31.3. Impact test

result shall be reported on Material Test Certificates by manufacturer or a separate report issued by an

independent test laboratory.

O

3. Impact testing on carbon steels, wherever required shall be in accordance with ASME B31.3 Para 323.3

C

(Table 323.2.2) and API standards as applicable.

4. Low Temperature Carbon Steel Pipe Impact testing shall be carried out as per ASTM A370 at -50°F.

Impact values shall meet the requirements specified in ASME B31.3.

E

5. All stainless steel welded pipes and fittings shall be solution annealed. Wherever weld metal deposits

C

are impact tested at minimum temperature listed in material specification and in accordance with ASME

B31.3.

N

6. Pipes supplied as API 5L X60 shall be Normalized, impact test qualified in accordance with ASME B31.3.

VA

5.4 Pipes

1. General :

AD

All pipes shall be specified with the nominal size and schedule number as per ASME B36.10/36.19 unless

specified otherwise on the individual Piping Standard Sheet. The pipe wall thickness may be supplied

thicker than specified only after written approval has been given by Purchaser. Corrosion allowance is

2_

as per the relevant Piping Standard Sheet.

2. Pipes shall be supplied with beveled end unless noted otherwise. Beveling shall be in accordance with

O

ASME B16.25. Where plain end pipes are specified, as for small bore pipes for socket welded piping, the

pipes shall be supplied with plain ends.

C

3. Pipe shall preferably be supplied in single and double random lengths. Each length of pipe shall be

subject to a hydrostatic test in accordance with the relevant code. Single random lengths will be

EV

accepted where specified in the Job Specification or for small diameter pipes or where double random

lengths are unavailable.

4. Pipes shall be shipped with end protectors to protect beveled ends. Also, pipes shall be supplied

R

preserved and protected as per the requirements of ASTM A700.

5. Low temperature Carbon Steel Pipe/Carbon steel Pipe/Galvanized Carbon Steel

Carbon steel pipe shall have a maximum carbon content of 0.23% by ladle analysis or 0.25% by product

analysis. Maximum carbon equivalent (CE) shall be 0.43 % by ladle analysis or 0.45% by product analysis

according to the formula:

CE = C + (Mn/6) + (Cr + Mo + V)/5 + (Ni + Cu)/15

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 20 OF 49

6. Austenitic Stainless Steel Pipe

Pipe materials shall be SS316L in accordance with ASTM A312 TP 316/316L

(UNS S31600/S31603) & Dual Certified.

All pipes shall be supplied in the de-scaled, pickled, passivated and solution heat treated condition.

Repair by welding is not permitted.

Material shall be capable of successfully passing an intergranular corrosion test in accordance with ASTM

PY

A262 Practice E and the same shall be reported.

Dual graded SS pipe is required to have higher strength of regular grade with resistance to sensitization

of ‘L” grade.

O

Welded pipe shall be marked in accordance with supplementary requirement S5.

C

Pipe with wall thickness up to 5.5mm inclusive may be furnished seamless or automatic welded unless

specified otherwise in the P.O. or material requisition, pipe with wall thickness over 5.5mm shall be

furnished seamless

E

7. Underground metallic piping shall be protected against soil corrosion by external coating & cathodic

C

protection according to Specification for painting (SEP-OPE-GEN-P15-00007)

8. All carbon steel pipe size are seamless up to 14” and above 14” shall be welded.

N

9. Welded pipes shall be with 100% radiography tested.

VA

10. Pipe class with 6mm corrosion allowance threaded nipples shall not be used.

11. If specified as “Impact Test” in the Description, it shall be Charpy V-Notch impact tested in accordance

with para 323.3 of ASME B31.3.

AD

5.5 Pipe Fittings

1. Fittings manufactured from pipe shall comply with requirements specified for pipe. CS fitting shall be

2_

seamless unless otherwise specified.

2. For SS fitting made from pipes the material requirements specified for pipes shall be complied. However,

O

SS fittings shall be finished in the solution heat treated condition.

3. Dimensions of metallic butt weld fittings shall be in accordance with ASME B16.9, with socket weld and

C

threaded fittings to ASME B16.11. All 90° butt weld elbows shall be long radius (1.5D) unless specified

otherwise.

EV

4. All O’lets / Nipoflanges shall meet the requirements of MSS SP 97. Design of all O’lets shall conform to

ASME B31.3.

5. Tees shall not be fabricated (stub-in) type.

R

6. Butt-weld fitting ends shall match the wall thickness/schedule of the attached pipe and be in compliance

with ASME B16.9

7. The thickness of reducing fittings shall match with the relevant pipe wall thickness.

8. Repair by welding of wrought fittings shall not be allowed.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 21 OF 49

9. Fittings shall be marked and shipped in crates, grouped according to pressure/class rating where

possible.

10. PWHT requirement shall be followed as per ASME B31.3 Table 331.1.1 & 333.1.3

11. CS fitting in NPS up to 14” shall be seamless 16” and above can be welded.

12. If specified as “Impact Test” in the Description, it shall be Charpy V-Notch impact tested in accordance

with para 323.3 of ASME B31.3 and respective material specification.

PY

13. Austenitic stainless steel fittings in nominal sizes up to for NPS 1 ½” inclusive shall be seamless. Large

sizes (8” & above) may be furnished either seamless or welded.

O

5.6 Flanges

C

1. Weld-neck flanges and socket-weld flanges shall be provided with bore to match the attached pipe.

2. All flanges in butt weld (BW) piping shall be weld-neck (WN) unless specific requirements dictate

otherwise.

E

3. Flange dimensions shall be in accordance with ASME B16.5 for NPS 24” and below, and with ASME

C

B16.47 Series A for NPS 26” to NPS 60”.Non-metallic flanges shall generally meet the bolting dimensions

of the above standards and be suitably face finished to mate with ASME B16.5 flanges. However, the

N

flange thickness & hub dimensions of the non-metallic flanges may vary depending on the material used

VA

4. Repair by welding is not permitted.

5. Flanges shall be packed and shipped in such a way as to prevent damage of machined parts. All machined

or threaded parts shall be protected in accordance with ASTM A700. Suitable protection shield or cover

AD

shall be provided on the gasket contact surface. Galvanized flanges shall be packed in accordance with

ASTM A53.

6. Carbon steel forgings shall be supplied with a maximum carbon content of 0.23% by ladle analysis or

2_

0.25% by product analysis and CE of 0.43% by ladle analysis or 0.45% by product analysis according to

the formula:

O

CE = C + (Mn/6) + (Cr + Mo + V)/5 + (Ni + Cu)/15

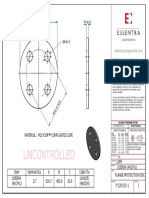

7. Dimension of figure-8 blanks, paddle spacer and blanks shall be manufactured in accordance with Clause

C

13 Figure-8 Blanks, paddle spacer and blanks in the specification.

8. Orifice flange dimensions shall be in accordance with ASME B16.36. Orifice flanges shall be supplied by

EV

vendor in pairs complete with jackscrews, bolts & gaskets with orifice plates.

9. All flange faces other than for non-metallic and Cu-Ni materials shall meet the following minimum

criteria:

R

· Roughness for RF = 125 to 250 µin Ra;

Roughness for FF flange= 250 to 500µin Ra;

Roughness of Groove for RTJ Flange = 63 µin Ra

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 22 OF 49

· Concentrated Serrated or spiral serrated for Flat Face, Smooth finish for Raised face, very smooth

groove for RTJ Flanges. These contact faces shall undergo finishing machining in accordance with

the standard MSS SP 6.

· Non-Metallic, Copper and Cu-Ni shall be stock finish.

5.7 Bolting

PY

1. Stud bolts shall be threaded full length and dimensionally in accordance with ASME B18.2.1 with two

nuts to ASME B18.2.2.

2. Reduced shank stud bolts shall not be used.

O

3. Stud bolts and nuts shall be hot-dip spun galvanized in accordance with ASTM A153.

C

4. Bolting shall be UNC threaded for diameters up to and including 1” and UN8 for bolt diameters above 1”

in accordance with ASME B1.1.

5. All stud bolts shall be Class 2A fit and nuts shall be Class 2B fit. In order to account for the additional

E

thickness provided on the studs due to galvanizing, the dimensional tolerances on mating threads shall

C

be achieved either by undercutting the male thread or over cutting the female thread.

6. Nuts for stud bolts shall be Hexagon Heavy Series to ASME B18.2.2 and oversized to accommodate the

stud bolt coating system as appropriate.

N

VA

7. Hydraulic bolt tensioning shall be used on all bolts greater than 1-1/2” diameter and length of these bolts

are to be increased by a minimum of one nut thickness to allow the use of bolt tensioning equipment.

8. The length of stud-bolts shall be in accordance with ASME B16.5 unless stated otherwise.

AD

9. Procedures for surface pre-treatment, hot-dip galvanizing, thickness measurement, storage and

packaging prior to shipment shall be submitted with the bid for review.

10. Bolting and nuts shall be supplied with nuts threaded on and packed for shipment to prevent damage to

2_

the coatings

11. Jackscrew shall be provided for all rating orifices flanges, all rating spectacle blind flanges for sizes above

O

2”, and all sizes for RTJ flanges (900# rating and above).The flanges for spectacle blind assemblies shall

be provided with jackscrews as per clause 12 (Jackscrew bolt chart). Jackscrew end shall be rounded.

C

Head of jackscrew & bolt shall be heavy hexagonal type.

EV

5.8 Gaskets

1. Asbestos is not permitted to be used for any gasket.

2. Non-metallic gaskets shall conform to ASME B16.21. Full face gaskets shall be used with flat-face flanges.

R

3. Spiral wound gaskets shall be used for all metallic RF joints. Spiral Wound gaskets shall be as per

following.

· 0.175” nominal thickness.

· Windings as per Piping Class Specification Sheets.

· Flexite super filler or equal.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 23 OF 49

· Outer ring 0.125" thick,

a. CS Outer ring for CS

b. SS Outer ring for SS & LTCS

· Design to ASME B16.20.

4. Ring type joint gaskets shall be octagonal in section and shall conform to ASME B16.20.

5. Octagonal gaskets for 900# & above shall be Type-R and ring material shall be as following.

PY

· For CS/LTCS Piping, ring material shall be Soft Iron with Max BHN 90.

· For SS Piping, ring material shall be SS316 with Max BHN 135.

6. When two dissimilar piping materials are in contact (e.g. CS to SS, CU-NI to CS etc), an insulating gasket

O

or sacrificial spool piece of minimum 600mm length shall be provided.

C

7. Insulation Gasket sets

Note: - Cut insulating sleeve length ¼” shorter than dimension A. The type & material shall be submitted

E

to COMPANY for approval prior to use. Bolt torque value shall be given by manufacturer and the same

shall be applied at site using a wrench.

C

· The bore of insulating gasket should be equal to the pipe bore. This will prevent any service

N

material from accumulating in the annular space between the bore of the gasket and the bore

of the pipe thus preventing formation of electrical bridge.

VA

· Insulating gasket sets shown on the P&ID’s, shall be as per detail below

AD

2_

O

C

8. Galvanic corrosion shall be prevented. Galvanic isolation sets shall be in accordance with the project

EV

piping material specifications.

· General criteria for prevention of galvanic corrosion in piping are as below.

· Piping to Piping dissimilar – Use Insulating gasket

R

· Piping to Equipment dissimilar – Use Insulating gasket

· Piping to Instrument connections(PI & TI) dissimilar – No insulating gasket

· Equipment to instrument dissimilar – No insulating gasket (Instruments are free standing and do

not have electrical continuity).

· AG / UG connection - Use Insulating gasket

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 24 OF 49

5.9 Isolation

1. Isolation joints or sacrificial spools shall be installed when shown on the P&ID’s as Special Piping Items

(SP).

5.10 Valves

1. Pressure/temperature ratings and valve design shall meet ASME B16.34 requirements. Flange pressure

PY

rating shall be in accordance with ASME B16.5.

2. The minimum wall thickness of valves shall be as per the manufacturing standard of valve, but shall not

be less than table 3 of ASME B16.34.

O

If the data sheets specify corrosion allowance, the wall thickness of valve body and other pressure

C

containing parts shall include corrosion allowance in addition to the minimum wall thickness required as

per ASME B16.34.

3. Valve selection shall be in accordance with the relevant Piping Class Specification Sheets and the

E

associated Valve data sheet TAG.

C

4. Valves sized 2” and over which are described as Outside Screw and Yoke (OS&Y) with rising stem and

N

non-rising hand wheel shall be provided with stem protectors and visual position indicators.

5. Valves shall be supplied with gear operators as indicated in the Piping Material Specification. Valves

VA

heavier than 500lb (225kg) shall be provided with lifting points. The design of such lifting points shall be

approved by the Purchaser.

6. Valves shall be bi-directional unless valve construction specifically renders this requirement impractical

AD

– eg. globe, check and needle valves. For uni-directional valves, an indicator showing flow direction shall

be engraved or cast/forged into the valve body.

7. Gearbox operators shall be sized to provide an output torque of at least 150% of the maximum required

2_

valve operating torque. Gearbox ratios shall be 60:1 maximum for valves 8” and smaller and 120:1

maximum for valves 10” and larger. Maximum operating force required to operate the valve shall be

O

with in 70lbf (30kgf), else gear operators shall be permitted. Where indicated in the Piping Material

Specification, gear operators are to be supplied and shall be the manufacturer's standard heavy duty

C

models selected to provide the valve torque requirements. Gearboxes shall be fitted with position

indicators, have self-locking mechanisms, and be fully sealed and protected to suit a very corrosive

EV

marine environment. Gear Units shall be fully protected from a coastal marine atmosphere whilst

permitting lubrication and maintenance. Bevel type gearing shall be supplied unless specified otherwise

on the Valve Data Sheets. As a general guide the following valves shall be gear operated:

R

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 25 OF 49

CLASS BALL GATE GLOBE BUTTERFLY

150 6” & above 14” & above 10” & above 8” & above

300 6” & above 12” & above 8” & above 8” & above

600 6” & above 8” & above 8” & above -

900 4” & above 6” & above 6” & above -

PY

1500 3” & above 4” & above 4” & above -

2500 3” & above 3” & above 3” & above -

8. The number of hand wheel turns required to operate a valve from fully open to fully close should be

O

minimised and shall not exceed the 100 turns.

C

9. Bonnet gaskets may be to the manufacturer’s standard, provided that the standard is equal to, or better

than, that of associated flange gaskets.

E

10. Valve position indicators shall be designed so as to prevent incorrect orientation on valve assembly.

11. Quarter turn valve handles shall be lever lock type if specified in the purchase requisition or data sheet.

C

Each lever operated valve shall be provided with Lever.

N

12. The materials for soft seals shall be selected to coincide with the temperature limit and shall be suitable

for the pressure rating and service intended.

VA

13. Elastomeric material used for O-rings in ASME class 600 and higher shall be AED (anti explosive

decompression type)

14. Bonnet gaskets may be to the manufacturer’s standard, provided that the standard is equal to, or better

AD

than, that of associated flange gaskets.

15. Valve bolting shall comply with the following:

2_

Valve Base Material Non-Sour Services Remarks

ASTM A193 GR B7 With hot-dip galvanized to

Carbon Steel

O

ASTM A194 GR 2H ASTM A153

ASTM A320 GR L7 With hot-dip galvanized to

C

Low Temp. Carbon Steel

ASTM A194 GR 4 ASTM A153

ASTM A193 B8M Cl. 2

EV

Stainless Steel

ASTM A194 8M

16. Alternate coating on bolting is subject to purchaser approval.

R

· Bolting specified above is for external bolting only. Internal bolting requirements are subject to

intended fluid service requirements.

17. Vendor shall confirm that valves intended for low temperature are suitable for temperature specified in

pipe class. Impact test is mandatory for all materials used in low temp service.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 26 OF 49

18. Valves shall be tested as per API 598, test pressures shall be as per ASME B16.34. Hydrostatic seat test

for bi-directional valves shall be carried out in both directions.

19. Hydrostatic test fluid shall have a chloride content of less than 200 ppm for carbon steel valves and less

than 30 ppm for stainless steel valves.

20. Valve ends and stuffing box shall be covered with close fitting protectors (eg plastic caps) to protect the

machined parts and prevent ingress of dirt and moisture.

PY

21. All valves shall be marked in accordance with MSS SP-25.

22. Material certificate per EN 10204 Type 3.1 shall be provided for all the pressure containing parts of the

valves.

O

23. All valves shall be shipped in the closed position except ball valves, which shall be shipped in the open

C

position.

24. Carbon steel valves, and austenitic stainless steel shall be sandblasted and coated in accordance with

(Doc. No. SEP-OPE-GEN-P15-00007) Painting and Coating Specification. Alternatively, valves shall be

E

supplied with the manufacturer’s standard finish, only if agreed in writing by the Purchaser.

C

25. Materials of valve trim components (ball, gate, stem, etc) shall be suitable for the working fluid and valve

duty. The Vendor may offer a superior alternative to those specified on the Valve Material Specification

N

in each individual pipe class having regard for service conditions and the required operating

VA

characteristics. Materials shall be selected such that galling does not occur and galvanic corrosion

between dissimilar metals is avoided.

26. Valves with body cavities are to be provided with a body cavity relief facility to relieve high pressure that

AD

may exist due to temperature changes in fluids trapped in the cavity. A pressure relief hole in ball is not

allowed for floating ball or on trunnion mounted valves.

Special Features for LPG Services:-

2_

Floating Ball Valves

· The floating ball designed ball valves shall have a pressure relief hole or an appropriate

O

cavity relief system. The hole shall be drilled inside the seat facing inner area of the

closure member

C

· When a pressure relief hole is selected, the diameter of the hole shall be minimum

3mm, unless 3mm hole is not applicable due to valve size.

EV

Trunnion Mounted Ball Valves

· The trunnion mounted designed ball valves shall have the pressure balance hole at the top of

R

the ball, where combined with the seat, or an appropriate cavity relief system

· When a pressure balance hole is selected, Ball valve which cannot be equipped with pressure

balance hole at the top of the ball shall have pressure relief hole as per

requirements of floating ball valves.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 27 OF 49

27. NDT of valves shall be carried out as specified below.

Valve castings shall be subject to inspection in accordance with the following requirements

RATING SIZES INSPECTION REQUIREMENTS

Class 150 All )

Class 300 12”NB & below ) To MSS-SP-55

PY

Class 600 6”NB & below )

RATING SIZES INSPECTION REQUIREMENTS

Class 300 14”NB & above ) To MSS-SP-55 and 10%

O

Class 600 8”NB & above ) radiography selected at

C

Class 900 3”NB to 10”NB ) random to ASME B 16.34

Class 1500* 2”NB & below ) Appendix-I **

Class 2500 2”NB & below)

E

C

RATING SIZES INSPECTION REQUIREMENTS

Class 900

Class 1500

12”NB & above )

3”NB & above)

N To MSS-SP-55 and 100%

radiography to

VA

Class 2500 3”NB & above ) ASME B 16.34 Appendix-I

*Note: This includes valves 2”NB and below which are for class 900 valves.

AD

**Note: Random selection shall be per heat/quantity to be agreed between Contractor and Supplier.

For all valve forging & welds magnetic particle/Dye penetrates examination shall be carried out.

28. All valves face to face dimension (long pattern) are in accordance with ASME B16.10, unless otherwise

2_

stated. Supplier shall advise face to face or end to end dimension in their quotation.

29. Flanged valves shall not be used in place of socket weld or screwed valves in order to permit insertion of

O

blank for isolation. Instead, a pipe nipple and flange shall be installed on the end of the socket weld or

threaded valve that requires the flanged connection.

C

30. Flanged valve shall not be used in place of socket weld or screwed valves whenever mounted directly to

vessels or other equipment that has been furnished with flanged connection.

EV

31. Locking devices shall be supplied as per manufacturers standard. Valves shall be provided with position

indicator. Showing open position in the direction of flow and close position in perpendicular direction of

flow. The shut and open terms shall be indicated at visible location.

R

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 28 OF 49

32. The following describes all valve materials and codes that govern their design, fabrication and testing:

Rating:

· Class 800 as defined by API 602

· Class 150, 300, 600, 900, 1500, and 2500 as defined by ASME B16.34.

Ends:

· Threaded ends as defined by ASME B1.20.1 and ASME B16.11

PY

· Socket weld ends as defined by ASME B16.11

· Flanged ends as defined by ASME B16.5 and ASME B16.47

Design and Test:

O

· Steel gate valves as per API 600, API 602

C

· Steel ball valves as per ASME B16.34, API 598, API 6D, BS EN ISO 17292, API 608

· Steel globe valves as per ASME B16.34 API 598, BS 1873, BS 5352, API 623

E

· Steel check valves as per ASME B16.34, API 598, BS1868, BS EN ISO 15761, API 594

· Steel DBB valves as per API 6D

C

Note: The ‘optional’ tests in API 598 are not mandatory to be applied.

N

All valves with non-metallic seat and seals in hydrocarbon service shall be fire safe type.Fire safe

certificates duly recognized by a third party inspection agency shall be furnished by vendor.

VA

Fire safe test shall be as per API 607/BS 6755 part II/ API 6FA.Leakage rates better than API/BS standards

shall also be accepted.

33. Table for Extended Stem Length for Ball Valves: -

AD

· Extended stem assembly, when specified, shall have the stem within a tube & shall be proven

vendor’s standard design.

·

2_

Design shall enable necessary stem seal adjustment to be carried out at the top of the stem

extension without removing insulation.

· Any requirement for such valves will be indicated in requisition. Extended stem length shall be

O

as per the below table.

C

Insulation Extended Stem

Valve (NB)

Thickness in (mm) Length (mm)

EV

3/4” – 2” 40 100

3” – 16” 50 150

18” – 24” 75 150

R

· For flanged valves, the extended stem length is measured from the top of an end flange.

For screwed or socket weld valves, it is measured from the top of the valve body.

· For personnel protection insulation extended stem is not applicable.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 29 OF 49

34. Table for Floating / Trunnion Mounted for Ball Valves:-

Valve Valve End Floating Ball Trunnion Mounted

Rating Connection Type (NB) Type (NB)

800# SW / SW X NPTF / NPTF 3/4” – 1 1/2” N/A

PY

150# FLANGED 2” – 6” 8” – 24”

300# FLANGED 2” – 6” 8” – 24”

600# FLANGED 2” – 3” 4” – 24”

O

900# FLANGED N/A 2” – 24”

C

1500# FLANGED 3/4” – 1 1/2” 2” – 12”

2500# FLANGED N/A 2” – 12”

E

C

35. All soft-seated valves with butt weld or socket weld end shall have pup pieces/transition pieces welded

N

at both ends. Pup pieces/transition pieces lengths shall be as indicated below unless specified in the

Purchase descriptions. Shell pressure test and 100% radiographic examination shall be performed with

VA

pup pieces/transition pieces welded.

· 3/4” - 1 ½” - 100MM

· 2” – 6” - 150MM

AD

· 8” and above - 200MM

36. THE CAVITY VENT SIDE (HIGHER PRESSURE SIDE) SHALL BE CLEARLY MARKED AS “PS” ON THE VALVE

BODY FOR EASY INSTALLATION FOR LPG SERVICE VALVES.

2_

O

C

EV

R

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 30 OF 49

5.11 Valve Data Sheet Tag:

First two Fifth & Seventh

Third digit Fourth digit Optional

letters Sixth digits digits

Valve Special

Valve Type - Material - Rating End -

specialty characters

PY

0 - Carbon 0-Raised M- Metal

BA - Ball Valve 1- Reduced 01-150#

steel Face Flange Seated

O

2- Full bore /

CH- Check 1-Ring joint E- Extended

1- LTCS Standard 03- 300#

C

Valve flanged Stem

bore

P1-SCH

E

GA - Gate 2- Stainless

3- Wafer 06- 600# 2-Butt weld XS/80 Pup

Valve Steel

Piece

C

GL-Globe 3- Duplex 3-NPTF P2-SCH 160

valve Stainless Steel

4-Wafer lug

N 08- 800#

screwed Pup Piece

VA

DB- Double

4-Socket P3-SCH 40

Block and 4- Al Bronze 5-Piston Lift 09- 900#

weld Pup Piece

Bleed Valve

AD

NE- Needle 6-Swing P4-SCH 40S

5- Bronze 15- 1500# 5-SW x NPTF

Valve check Pup Piece

6- Carbon

2_

6- Flat faced P5-SCH 80S

Steel High 7- Modular 25- 2500#

flanged Pup Piece

Strength

O

8-Plug type 6- CS with

7-Clamped

disc 6mm CA

C

9- Wedge C – Cavity

8-RF x NPTF

type vent/relief

EV

9-RTJ x NPTF

R

Example: CS Ball Valve, Full Bore, Metal Seats data sheet will be tagged as BA-02-010-M

This tagging shall be applied only for procurement purpose. How ever all valves shall be identified by unique

tag no. as per project tag numbering philosophy (Doc. No. AGP-GPS-ANOGP-G05-0010). This tag shall

physically appear on each valves as well as identified in P&IDs. This marking is in addition to the marking as

given in secion 6.1 of this specification.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 31 OF 49

5.12 Metallic Ball Valves

1. Vents or drains are not required for floating ball valves.

2. For trunnion mounted ball valves, vent and drain connection shall be provided as per API 6D. Seats of

trunnion mounted valves shall be spring energized.

3. Ball valves shall be reduced bore unless specifically stated otherwise except 1-1/2” & below ball valves.

With valve bodies of either one piece or split body construction. The Full bore valve shall be designated

PY

with “FB” on the P&ID’s when required.

4. Ball valve shall be antistatic design to ensure electrical continuity. Stem shall be anti-blow out proof

design.

O

5. Ball valves shall be fitted with anti blow-out proof stems and have the body split outside the plane of the

C

stem protrusion. Trunnion mounted balls shall have body cavity relief. Stem seal covers shall be bolted.

Valve stems shall be designed so that the stem “weak point” is outside of the valve body.

6. All valves shall be provided with a Lock Open / Lock Close facility.

E

7. Ball and seat contact for the metal seated valves are to be coated with High velocity oxy flame (HVOF).

C

Tungsten carbide coating application procedure for HVOF coating shall be submitted to purchaser for

approval.

N

8. Metal seated Ball valve shall be tested as per API 6D or API 6A as applicable. Leakage rate shall not be

VA

more than Rate “B” as per API 6D/ISO 5208.

9. Socket welded ball valves shall be of 2 piece/3 piece construction. Threaded body inserts are not

acceptable. Vendor shall clearly indicate the methodology of welding so as not to damage soft seats

AD

during welding with piping.

10. Steel ball valves shall be as per ASME B16.34, API 598,API 6D, ISO 17292, API 608

11. The Vendor shall select materials to minimize the effect of galling by providing differential hardness

2_

between mating surfaces .Where ENP is required on stems, ENP application procedure shall be

submitted to the purchaser for approval.

O

12. All soft seats/seals valves shall be certified “fire-safe” in accordance with API 607, API 6FA or BS6755 Part

2. Test certification shall be provided by the valve manufacturer to verify the valve performance.

C

13. All ball valve body patterns shall be long pattern to ASME B16.10 & shall be quarter turn design.

5.13 Globe Valves

EV

1. Valve dimensions shall meet the requirements of ASME B16.10. Valve ends shall be in accordance with

the piping Material Specification.

2. The minimum requirement for valve trim for carbon steel valve bodies is 13% chrome. When 13% Cr trim

R

is specified, stellite No.6 seats are an acceptable alternative.

3. Unless specified otherwise, straight plug designs only are acceptable.

4. Globe valve shall not be specified in size over 12” for ANSI 150# - 600# piping classes without approval

by purchaser.

5. Steel globe valves shall be as per ASME B16.34 API 598, BS 1873, BS 5352, API 623

6. All valves shall be capable of being locked.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 32 OF 49

5.14 Check Valves

1. Flow direction of the valve shall be clearly marked on the valve body.

2. Swing Check valves, wherever specified shall meet requirements of API 6D. For swing check valves, the

disk shall be secured in the closed or open position to prevent damage during transport and handling.

Valves shall be regular pattern unless specified otherwise. The area of the flow passage shall be at least

equal to the seat port area. Valves shall also have a travel stop to limit disc swing in the open position

PY

3. Wherever Non Slam type check valves are specified, the Vendor shall prove the non-slam capability of

the valve by necessary calculations and valve characteristic plots.

4. Check Valves 1½” and below shall be Piston check valves unless noted otherwise on Valve Material

O

Specification.

C

5. In general check valves 2” and above shall be swing type. These shall be suitable for horizontal or vertical

up-flow installation.

6. Steel check valves as per ASME B16.34, API 598, BS1868, BS EN ISO 15761, API 594

E

7. The Swing check and Lift Check valves shall have bolted cover for inline maintenance.

C

5.15 Gate Valves

N

1. Gate valves 1-1/2” and smaller shall be of forged body construction and meet API STD 602 requirements

VA

and above 2” shall be API STD 600.

2. Gate Valves shall be solid wedge types with solid disc or flexible wedge disc. Split wedge gates are not

permitted.

AD

3. The Valves shall be of Outside and Yoke type with bolted bonnet for inline maintenance.

4. For Gate valve sizes 3” and smaller, where operating torque is not a concern, solid wedge discs shall be

used.

2_

5. For gate valve sizes 4” and larger, higher operating torques and possibilities of sticking of gate due to

differential temperatures shall be considered. Accordingly, flexible wedge ‘H’ type discs shall be used.

O

6. Where corrosion or erosion of seat material is possible due to entrapped fluid between the ‘H’ type disc

and the seat, simple flexible wedge discs shall be used.

C

7. Wedge shall be made from one solid piece of material (mono-block construction).

8. All valves shall be capable of being locked.

EV

5.16 DBB Valves

1. The double block and bleed valve shall be of integral design as single piece with two ball valves (full bore)

R

for isolation & one needle valve for bleed.

2. All integral double block & bleed valves shall be in accordance with EEMUA publication number 182.

However, the ball valves shall be designed and supplied in accordance with API 6D/ ISO 14313 and needle

valve shall be designed and supplied in accordance with BS EN ISO 15761 (supersedes BS 5352) as

applicable

3. Stem shall be anti-blow out proof design and one piece solid construction.

GPS DOC NO. D1034-01-EL-GD-0010

Document No. AGP-GPS-ANOGP-Z21-0010 REV. C02

Document Title PIPING MATERIAL SPECIFICATION PAGE 33 OF 49

4. DBB valves shall be provided with adequate pads and holes for enabling locking at both the open and

closed positions.

5. DBB valves shall meet the as per BS EN ISO 15848 Part -2 with leakage class ‘B’

6. Handles / wrenches for primary and secondary isolation valve shall be in line with the pipe centerline

when valves are open.

7. The design, size, bore and material of construction shall be as specified in the Individual pipe class.

PY

8. DBB valve shall be supplied with inside dimeter of Full and Reduce bore as per specified in pipe class.

9. Pressure temperature rating of all double block & bleed valves shall be in accordance with the

appropriate class for the body material in accordance with ASME B16.5 / ASME B16.34.

O

10. Double Block and Bleed valves shall be designed to seal in both directions, i.e. bidirectional, against all

C

pressures upto the maximum service pressure rating for the class unless specified otherwise.

11. CS/LTCS Forgings shall be in ‘Normalized’ or ‘Normalized and Tempered’ or ‘Quenched and Tempered’

condition as per respective material standard.

E

C