Beruflich Dokumente

Kultur Dokumente

5-01-2019 Physical Design

Hochgeladen von

RamakrishnaRao SoogooriOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

5-01-2019 Physical Design

Hochgeladen von

RamakrishnaRao SoogooriCopyright:

Verfügbare Formate

5-01-2019 Physical design

lef&def is common formats used by several EDA tools. Power mesh requires less

resistance & high current carrying capacity, so top metal layers are used as

these are more thick. For cell delay is higher for low voltage & Cmax. For

wire delay is higher at high temp and Rcmax corner. Power mesh act as decap.

After each stage check qor. After placement check qor for congestion & timing

analysis.

Placement & Optimization

Tasks

1. Give legal locations to all std cells

2. optimize design for best routability,timing(DRV/setup), power&area

Goals:

1. Achieve a placed design for best routability & timing clean

Steps:

1. Pre place

Before placing std cells

1. Add End cap cells(At the start & end of the rows to avoid well proximity

effects*)

2. Tap cells are placed at regular intervals based on well tap placing info

given by foundry depends on latchup phenomena, so that power IRdrop

requirement is achived. To avoid latchup back2back paracitic BJT leads to

power ground shorting tapcells/guard rings are used.

3. IO port buffers (signals are buffered at IO ports for strengthening)

4. Spare cells(used for ECOs / post tape out ECO) without spare cells, all

base layers/metal layers are to be changed for ECO implimentination, if spare

cells were present only metal layers can be redone. If mask changes are less

will cause less cost

5. placement guidance(placement bounds sync cells are placed

closely(soft/hard/exclusive bound no other cells can sit in the defined

boundary)/blockages/keepouts)

2. placement: Standard cells are placed

A. Coarse placement(timing/congestion driven)

B. Leagal placement (right location & orientation)

3.Trial/global route

4.Optimisation:Congestion/timing ICC UserGuide refer 2 placement chapter

4. post placement: Tie cell addition/scan chain reordering. Tie cell contains

Low pass filter which filters power ground high frequency noise/fluctuations

during circuit operation. Scan chain reordering is done to reduce scan wire

length optimisation&congestion.

5.QOR checked for routabilty(congestion),timing(DRV max tran/max cap,setup

violations),power,area

Congestion is the measure of routability. Tool reports metrics as OVERCON,

WIRELENGTH & congestion map

Reasons of congestion: Higher global placement density, higher local placement

density, higher pin density

Impact of congestion: Routability (DRC,shorts,timing detouring,cross talk)

Horizantal & vertical overcon numbers

1000 Gcells 500 -> -2 track deficiency

0.5(H) & 0.2(V) cong = Number of routs%number of tracks preferred value is

less than 1

1. Global congestion: Congestion is every where in the design

2. Local congestion: Congestion present in local area.

To analyze/mitigate congestion: Congestion maps open placement density map &

pin density map.

Methods to resolve congestion: Tool switches (high congestion effort, magnet

placement(closer placement), bounds,placement blockage,keepout,max

utilization,re floor plan

For Global congestion try max utilization, for high pin desnity try

keepout/halo/cell padding partial blockage around high pin count cells OR keep

higher channel width between macros.

Lab

After power mesh is performed

Add missing power vias

High fanout synthesis is performed on clock reset scan clk enable

Legalise placement makes all cells sit on site rows

GRC global route congestion should be less than 0.5

Das könnte Ihnen auch gefallen

- SynthesisDokument18 SeitenSynthesissrajeceNoch keine Bewertungen

- ALLtime SynthesisDokument18 SeitenALLtime SynthesisAgnathavasiNoch keine Bewertungen

- PNR FlowDokument23 SeitenPNR Flowsanthosh216eeeNoch keine Bewertungen

- Fiber Kinks and Breaks: Fiber Optic Testing - OTDRDokument5 SeitenFiber Kinks and Breaks: Fiber Optic Testing - OTDRPedroNoch keine Bewertungen

- Le Nguyen Thai Ha Test 19-05-2021: 1. Why CMOS Structure Always Pull-Up PMOS and Pull-Down NMOS, Not Reverse?Dokument17 SeitenLe Nguyen Thai Ha Test 19-05-2021: 1. Why CMOS Structure Always Pull-Up PMOS and Pull-Down NMOS, Not Reverse?emaNoch keine Bewertungen

- Week 5Dokument71 SeitenWeek 5apoorvaNoch keine Bewertungen

- Vlsi Mitra DefinitionsDokument5 SeitenVlsi Mitra DefinitionsVamsi Krishna100% (1)

- Questions BankDokument47 SeitenQuestions Bank1am17ec014 ashnal ahmedNoch keine Bewertungen

- 1.5b - Cliff WhiteDokument71 Seiten1.5b - Cliff WhiteHilmi SanusiNoch keine Bewertungen

- What Is Leakage Power? (Definition, How It Happend, Formula, What Factor Affect To Leakage Power)Dokument9 SeitenWhat Is Leakage Power? (Definition, How It Happend, Formula, What Factor Affect To Leakage Power)emaNoch keine Bewertungen

- A 409 GOPS W Adaptive and Resilient Domino Register File2Dokument13 SeitenA 409 GOPS W Adaptive and Resilient Domino Register File2emmasustechNoch keine Bewertungen

- 09 PlacementDokument48 Seiten09 PlacementSujit Kumar100% (1)

- VLSI Design Interview QuestionsDokument79 SeitenVLSI Design Interview QuestionsashhbamNoch keine Bewertungen

- Back-End 500 Questions Ing - Back-End Physical Design Questions-CSDN BlogDokument109 SeitenBack-End 500 Questions Ing - Back-End Physical Design Questions-CSDN BlogRA NDYNoch keine Bewertungen

- VLSI CMOS Interview Questions and AnswersDokument67 SeitenVLSI CMOS Interview Questions and AnswersrAM95% (85)

- Micrel PCB Design ConsiderationsDokument0 SeitenMicrel PCB Design Considerationstomscribd18Noch keine Bewertungen

- Physical DesignDokument71 SeitenPhysical Designmaniroop100% (3)

- MOSFET Leakage PowerDokument47 SeitenMOSFET Leakage PowerRamakrishnaRao SoogooriNoch keine Bewertungen

- Physical Design CompleteDokument303 SeitenPhysical Design CompleteReddicool89100% (47)

- Chip IO Circuit Design - Input Ouput CircuitryDokument9 SeitenChip IO Circuit Design - Input Ouput CircuitryVăn CôngNoch keine Bewertungen

- Interview QuestionsDokument11 SeitenInterview Questionsprashanth100% (1)

- Antenna Downtilt-Finalised GuidelineDokument17 SeitenAntenna Downtilt-Finalised GuidelineChee LeongNoch keine Bewertungen

- Week 11Dokument3 SeitenWeek 11apoorvaNoch keine Bewertungen

- PD Checks TechniquesDokument11 SeitenPD Checks TechniquesJayant IndLa100% (1)

- InterviewDokument24 SeitenInterviewCatherine RyanNoch keine Bewertungen

- Designing of HV Power Substation and LayoutDokument11 SeitenDesigning of HV Power Substation and LayoutSuresh UmadiNoch keine Bewertungen

- Vlsi FaqsDokument29 SeitenVlsi Faqsanon-417212100% (4)

- 11 RoutingDokument23 Seiten11 Routingketchrajath24Noch keine Bewertungen

- Tunable Ferroelectric Microwave Bandpass Filters Optimised For System-Level IntegrationDokument8 SeitenTunable Ferroelectric Microwave Bandpass Filters Optimised For System-Level IntegrationyarkinyigitNoch keine Bewertungen

- Floorplaning GuidelinesDokument23 SeitenFloorplaning GuidelinesBindu MakamNoch keine Bewertungen

- Vlsi Interview QnsDokument46 SeitenVlsi Interview QnsARNoch keine Bewertungen

- 220kV-400Kv-345KV Details of CableDokument26 Seiten220kV-400Kv-345KV Details of CableDhanaji Wakade100% (1)

- Lower-Power: LayoutDokument11 SeitenLower-Power: LayoutmturadagiNoch keine Bewertungen

- 11timing Concepts and Physical DesignDokument42 Seiten11timing Concepts and Physical DesignTeja Reddy100% (2)

- Gain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipVon EverandGain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipNoch keine Bewertungen

- Radio Control for Model Ships, Boats and AircraftVon EverandRadio Control for Model Ships, Boats and AircraftBewertung: 5 von 5 Sternen5/5 (1)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsVon EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNoch keine Bewertungen

- Signal Integrity: From High-Speed to Radiofrequency ApplicationsVon EverandSignal Integrity: From High-Speed to Radiofrequency ApplicationsNoch keine Bewertungen

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsVon EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNoch keine Bewertungen

- Connection-Oriented Networks: SONET/SDH, ATM, MPLS and Optical NetworksVon EverandConnection-Oriented Networks: SONET/SDH, ATM, MPLS and Optical NetworksNoch keine Bewertungen

- The Fast Track to Your Extra Class Ham Radio License: Covers All FCC Amateur Extra Class Exam Questions July 1, 2020 Through June 30, 2024Von EverandThe Fast Track to Your Extra Class Ham Radio License: Covers All FCC Amateur Extra Class Exam Questions July 1, 2020 Through June 30, 2024Noch keine Bewertungen

- CISA Exam - Testing Concept-Network Physical Media (Fiber Optic/ UTP/STP/Co-axial) (Domain-4)Von EverandCISA Exam - Testing Concept-Network Physical Media (Fiber Optic/ UTP/STP/Co-axial) (Domain-4)Noch keine Bewertungen

- High-Performance D/A-Converters: Application to Digital TransceiversVon EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNoch keine Bewertungen

- Indoor Radio Planning: A Practical Guide for 2G, 3G and 4GVon EverandIndoor Radio Planning: A Practical Guide for 2G, 3G and 4GBewertung: 5 von 5 Sternen5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Cross-Layer Resource Allocation in Wireless Communications: Techniques and Models from PHY and MAC Layer InteractionVon EverandCross-Layer Resource Allocation in Wireless Communications: Techniques and Models from PHY and MAC Layer InteractionNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Satellite Communications: Principles and ApplicationsVon EverandSatellite Communications: Principles and ApplicationsBewertung: 5 von 5 Sternen5/5 (2)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- Digital Signal Processing Techniques and Applications in Radar Image ProcessingVon EverandDigital Signal Processing Techniques and Applications in Radar Image ProcessingNoch keine Bewertungen

- 3G Evolution: HSPA and LTE for Mobile BroadbandVon Everand3G Evolution: HSPA and LTE for Mobile BroadbandBewertung: 2.5 von 5 Sternen2.5/5 (4)

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingVon EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Radio-Frequency Digital-to-Analog Converters: Implementation in Nanoscale CMOSVon EverandRadio-Frequency Digital-to-Analog Converters: Implementation in Nanoscale CMOSBewertung: 4 von 5 Sternen4/5 (1)

- Solution Manual for 100 Genesys Design Examples: Second EditionVon EverandSolution Manual for 100 Genesys Design Examples: Second EditionNoch keine Bewertungen

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsVon EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNoch keine Bewertungen

- RATE Quantity of MaterialsDokument104 SeitenRATE Quantity of MaterialsRamakrishnaRao SoogooriNoch keine Bewertungen

- DDR4 SdramDokument189 SeitenDDR4 SdramRamakrishnaRao SoogooriNoch keine Bewertungen

- 1'st Floor 15X4.5 112.5Dokument2 Seiten1'st Floor 15X4.5 112.5RamakrishnaRao SoogooriNoch keine Bewertungen

- Buildup PlanDokument2 SeitenBuildup PlanRamakrishnaRao SoogooriNoch keine Bewertungen

- Painting Codes Int Ext 2014Dokument1 SeitePainting Codes Int Ext 2014RamakrishnaRao SoogooriNoch keine Bewertungen

- C-17 Painting Cost Break Up1Dokument4.371 SeitenC-17 Painting Cost Break Up1RamakrishnaRao SoogooriNoch keine Bewertungen

- Clock Domain Crossing (CDC) : Erik Seligman CS 510, Lecture 17, March 2009Dokument39 SeitenClock Domain Crossing (CDC) : Erik Seligman CS 510, Lecture 17, March 2009Rohan PeterNoch keine Bewertungen

- E CheckDokument47 SeitenE CheckRamakrishnaRao SoogooriNoch keine Bewertungen

- Date Expenditure AmountDokument9 SeitenDate Expenditure AmountRamakrishnaRao SoogooriNoch keine Bewertungen

- Understanding Clock Domain Crossing IssuesDokument7 SeitenUnderstanding Clock Domain Crossing IssuesaanbalanNoch keine Bewertungen

- SpyGlass CDC MethodologyDokument36 SeitenSpyGlass CDC Methodologyajaysimha_vlsi100% (4)

- Machine Learning OverviewDokument54 SeitenMachine Learning OverviewRamakrishnaRao SoogooriNoch keine Bewertungen

- Delhi Public School, Bangalore - East: FEE STRUCTURE 2015-16Dokument1 SeiteDelhi Public School, Bangalore - East: FEE STRUCTURE 2015-16RamakrishnaRao SoogooriNoch keine Bewertungen

- Full Flow Clock Domain Crossing - From Source To Si: March 2016Dokument13 SeitenFull Flow Clock Domain Crossing - From Source To Si: March 2016RamakrishnaRao SoogooriNoch keine Bewertungen

- Quiz 1 On WednesdayDokument46 SeitenQuiz 1 On WednesdayAmitava KansabanikNoch keine Bewertungen

- SDC AnDokument5 SeitenSDC AnRoberto de MedeirosNoch keine Bewertungen

- 1 Clock Domain CrossingDokument35 Seiten1 Clock Domain CrossingRamakrishnaRao SoogooriNoch keine Bewertungen

- High-Speed Serial I/O Made Simple: A Designers' Guide, With FPGA ApplicationsDokument210 SeitenHigh-Speed Serial I/O Made Simple: A Designers' Guide, With FPGA ApplicationseliomayNoch keine Bewertungen

- Phy Interface Pci Express Sata Usb30 Architectures 3.1 PDFDokument161 SeitenPhy Interface Pci Express Sata Usb30 Architectures 3.1 PDFakssreenathNoch keine Bewertungen

- Clock DOM CrossingDokument16 SeitenClock DOM CrossinggharudaNoch keine Bewertungen

- Lec 1Dokument36 SeitenLec 1cgmpcc3Noch keine Bewertungen

- IntroDokument17 SeitenIntroRamakrishnaRao SoogooriNoch keine Bewertungen

- An Overview of Machine LearningDokument23 SeitenAn Overview of Machine LearningAmany Morsey100% (1)

- Full Flow Clock Domain Crossing - From Source To Si: March 2016Dokument13 SeitenFull Flow Clock Domain Crossing - From Source To Si: March 2016RamakrishnaRao SoogooriNoch keine Bewertungen

- Pre Req For Digital and VerilogDokument2 SeitenPre Req For Digital and VerilogRamakrishnaRao SoogooriNoch keine Bewertungen

- NNMLDokument113 SeitenNNMLshyamd4Noch keine Bewertungen

- Machine Learning TopicDokument21 SeitenMachine Learning TopicNaldoNoch keine Bewertungen

- IEEE 802.11 Overview: Mustafa Ergen UC BerkeleyDokument42 SeitenIEEE 802.11 Overview: Mustafa Ergen UC BerkeleyguptasugandhNoch keine Bewertungen

- Migrating To Onsemi Network & CliosoftDokument29 SeitenMigrating To Onsemi Network & CliosoftRamakrishnaRao SoogooriNoch keine Bewertungen

- 802 - 11 IntroDokument32 Seiten802 - 11 IntroAli KazmiNoch keine Bewertungen

- A Soc ControllerDokument11 SeitenA Soc ControllerpaggyNoch keine Bewertungen

- Prefinal Quiz 2 Network SecDokument9 SeitenPrefinal Quiz 2 Network SecMark RosellNoch keine Bewertungen

- 10 VsatDokument37 Seiten10 VsatAhmed FadulNoch keine Bewertungen

- Princomm 2Dokument23 SeitenPrincomm 2Danah Mae Garingo Narsolis100% (1)

- Mavenir Data Sheet VEPC 073117Dokument7 SeitenMavenir Data Sheet VEPC 073117garzulo100% (1)

- Consilium - VDR F1Dokument6 SeitenConsilium - VDR F1anusprasadNoch keine Bewertungen

- Tl072 Low Noise Dual J-Fet OpampsDokument9 SeitenTl072 Low Noise Dual J-Fet OpampssfvNoch keine Bewertungen

- TELIN Product Catalog Network Protection 1Dokument4 SeitenTELIN Product Catalog Network Protection 1Joni GarciaNoch keine Bewertungen

- Press Ss SssssssssDokument36 SeitenPress Ss SssssssssinsharaajNoch keine Bewertungen

- CCNPTraining KitDokument872 SeitenCCNPTraining KitFaizan UddinNoch keine Bewertungen

- Comandos IdirectDokument7 SeitenComandos IdirectOscar MachadoNoch keine Bewertungen

- SHARE VISIBILITY ACTUAL (COPPEL) SanandresDokument26 SeitenSHARE VISIBILITY ACTUAL (COPPEL) SanandresRubenNoch keine Bewertungen

- 8088 Single Board ComputerDokument4 Seiten8088 Single Board ComputerPritapiranti SolusiNoch keine Bewertungen

- Mla-M Mla-M: Magnetic Loop Antenna - MultibandDokument12 SeitenMla-M Mla-M: Magnetic Loop Antenna - MultibandCristobalNoch keine Bewertungen

- Blue Toot 1Dokument25 SeitenBlue Toot 1shanin2006Noch keine Bewertungen

- Final - BcsiDokument3 SeitenFinal - Bcsiphython 1109Noch keine Bewertungen

- MiCOM P12x - P121 - 2Dokument2 SeitenMiCOM P12x - P121 - 2AkashManusmareNoch keine Bewertungen

- CTS DebugDokument3 SeitenCTS DebugRAZNoch keine Bewertungen

- Color TV Service Manual: MODEL: CE-29C82IDokument31 SeitenColor TV Service Manual: MODEL: CE-29C82ISilomo-saka MambaNoch keine Bewertungen

- ISL6455 RenesasDokument13 SeitenISL6455 RenesasArief MandolloNoch keine Bewertungen

- Installation Manual FK-502: I. Accessory Parts II. Installation ProceduresDokument6 SeitenInstallation Manual FK-502: I. Accessory Parts II. Installation ProcedureshashemNoch keine Bewertungen

- Caracol TelevisiónDokument5 SeitenCaracol TelevisiónLarios WilsonNoch keine Bewertungen

- 05 - LTE Physical Channels and ProceduresDokument73 Seiten05 - LTE Physical Channels and ProceduressaeedfsaeedNoch keine Bewertungen

- Communication Option Manual - Kawasaki Robot Controller F SeriesDokument88 SeitenCommunication Option Manual - Kawasaki Robot Controller F SeriescromerobarrenoNoch keine Bewertungen

- Building Blocks of A CPUDokument11 SeitenBuilding Blocks of A CPURajNoch keine Bewertungen

- COC LEVEL 4 ExamDokument11 SeitenCOC LEVEL 4 Examdave takele100% (1)

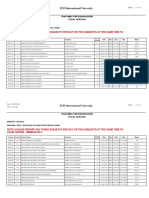

- Item Analysis With: Most Learned and Least LearnedDokument9 SeitenItem Analysis With: Most Learned and Least LearnedBern Mariveles-JavanaNoch keine Bewertungen

- CAN FD White PaperDokument10 SeitenCAN FD White PapershaludheenanNoch keine Bewertungen

- Aprisa FE Datasheet ETSI EnglishDokument2 SeitenAprisa FE Datasheet ETSI EnglishfonpereiraNoch keine Bewertungen

- M.E. App Ele R21 SyllabusDokument62 SeitenM.E. App Ele R21 SyllabusValar MathyNoch keine Bewertungen