Beruflich Dokumente

Kultur Dokumente

IRJET-Replacement of Natural Sand in Con PDF

Hochgeladen von

Rana Talal RaziOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

IRJET-Replacement of Natural Sand in Con PDF

Hochgeladen von

Rana Talal RaziCopyright:

Verfügbare Formate

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 02 Issue: 01 | Apr-2015 www.irjet.net p-ISSN: 2395-0072

Replacement of Natural Sand in Concrete by Polyethylene Bottles

1Sahil Verma, 2Sahil Arora

1 Assistant Professor, Civil Engineering, KCET, Punjab, India

2 Assistant Professor, Civil Engineering, CU, Punjab, India

…………………………..…………………………………………….………………….***………………………………………………………………….………………………..

Abstract- Presently a lot of attention has been taken on waste Consumption, the amount of waste is going to grow by leaps

plastic materials which are generated in huge amount in all and bounds. At present, the total recycling capacity in India

over the world. The main problem is disposal of waste plastic is around 145,000 TPA, out of which Reliance Industries Ltd.

material. In this research paper a little try is to use the waste has a capacity of 42,000 TPA and Kanpur-based Ganesh

plastic crushed bottles of appropriate size in concrete with Polytex Ltd (GPL) has a capacity of around 39,600 TPA and

partial replacement of fine aggregates and it has the potential rest is with other small local players As such quantity of

of disposing off large quantities of the catastrophic waste in a waste need to have large area of landfill to dump it, its use in

beneficial way. The environmental effects can be substantially concrete mix will prove a better option for land fill that,

reduced by proper encapsulation of these waste plastic being non-degradable, remain for long years and cause

bottles. The study also gives the comparison of compressive problem before us. Concrete is the most widely used

strength of normal conventional concrete with the concrete construction material in the world due to its high

made from the partial substitution of aggregates with compressive strength, long service life, and low cost.

Polyethylene Terephthalate bottles. Nowadays, unfortunately, the recycling rate of PET bottles is

much less than the sales of virgin PET production for

Key words: PET, Load, Strength, Concrete, Coarse Aggregates, common uses. This gap is dramatically increasing, pushing

Fine Aggregates towards finding a solution of this problem and a higher

recycle of PET. Particular interest is stirring, at present, the

1. INTRODUCTION

use of fibers obtained from waste PET bottles. A possible

Plastic is one of the materials showing immense potential in

application is to utilize waste PET fibers as replacement of

our daily lives as it posses low density, high strength, user

fine aggregates in concrete. In this research experiment has

friendly designs, fabrication capabilities, long life, light

been performed by taking the specified mix ratio 1:1.5:3

weight and low cost characteristics are the factors behind

(M25), as per IS code 456.

such extraordinary growth. Although, plastics have been

used in very large and useful applications, it bestows to an 2. OBJECTIVES-

ever increasing amount in the solid waste stream. In the 2.1. To study the properties of PET.

plastics waste, polyethylene forms the largest fraction, 2.2 To study the effect of PET over the compressive strength

which is followed by Polyethylene terephthalate (PET) that of concrete

represents one of the most common plastics in solid urban 2.3 To compare the strength of PET mix concrete with

waste. In field of concrete technology India as well as other conventional mix concrete.

nation now is seeking for alternative for conventional

aggregate that may be recognized as use plastic waste, for it 3. LITRETURE REVIEW

might be realized as PET phase capacities. As per the

estimates, India produces 500,000 tons of pet waste every According to Chan et.al. (1999), the major degradation of the

year and due to increasing use of pet bottles in daily mechanical strength of concrete occurs at the stage between

950 and 1200° C, concrete becomes a consolidated

© 2015, IRJET.NET- All Rights Reserved Page 120

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 02 Issue: 01 | Apr-2015 www.irjet.net p-ISSN: 2395-0072

material and so experimented for three types of plastic Vytlacilova worked for same and found similar result that

waste aggregates, including coarse and fine particles, and reinforced concrete with the use of plastic waste give

studied two replacement ratios (7.5% and 15%), reach out reliable result.

with results that fire behavior of concrete is strongly Pelisser.et.al. (2012) experimented on use of PET fiber in

influenced by its water content and its evaporation results in concrete and had got that, at 28 days, the concrete flexural

an increase of its volume which, due to being confined to toughness and impact resistance increased with the

concrete pores, causes internal pressures that can lead to presence of PET fibers, except for the 0.05 % volume sample

cracking and to spelling of the surface layer of concrete. and no significant effect of the fiber addition on the

compressive strength and modulus of elasticity were

Bakri et al., in 2007, worked on the effects of HDPE plastic observed.And also show that an increase in porosity has

waste aggregate on the properties of concrete, and carried occurred at 365 days for the fiber reinforced concrete, as

out tests on Compressive Strength, Flexural Strength, Water determined by MIP (mercury intrusion porositimetry).

absorption, Analysis DSC and Slump test and found that the

compressive strength was measured after 28 days of curing K.Ramadevi and Ms. R. Manju (2012), also worked on fibre

and it was found that the PC is suitable for nonstructural concrete and result got revealed an increase in compression

usage. As for cost analysis, the results showed that the and tensile strength.

Polymer Concrete was more cost effective than conventional

concrete. Chowdhury.et.al (2013), have observed PET fiber reinforced

concrete offers less compression strength and flexural

Naik et al., (1996) researched on use of post-consumer rigidity than conventional concrete but it offers high

waste plastics in cement-based composites, and carried out ductility thereby increasing deforming capability of the

chemical treatments, Compressive Strength tests, Splitting concrete.

Tensile Strength tests and came with the result that, on

application of plastic High Density Polyethene. Lopez.et.al.(2013), found, on use of Recycled PET fibers, a

good performance of the PET fibers, especially in the case of

Pai and Chandra (2013), carried out tests on Compressive continuous fibers, which were able to greatly increase the

Strength and Ultrasonic Pulse Velocity (UPV Test) and concrete properties.

observed that with the use of fiber fire resistance property

of concrete can increased significantly.Nibudey.et.al. (2013), Lopez1 et al.(2014), researched on “Influence of continuous

performed several design concrete mixes with different plastic fibers reinforcement arrangement in concrete

percentages (0 % to 3 %) of waste plastic fibers and strengthened” and found a better performance of the

observed the improvement in mechanical properties of continuous PET fiber reinforcement than that of the short,

concrete (HDPE) in Concrete mix, it enhanced the discontinuous one; the continuous PET samples presented a

compressive strength and tensile strength too.Oliveira. Et al., great increase in the concrete properties in 150% of the

in 2011, carried out research on Physical and mechanical maximum load in bending.

behavior of recycled PET fiber reinforced mortar following

Irwan.et.al. (2014), worked on “A comparative study on

the experiments found that, by adding fraction of PET bottle

compressive and tensile strength of recycled ring waste pet

in dry mix mortar about 0.5%, 1.0% and 1.5%, it

bottle (RPET) fiber” and found ultimate tensile strength of

significantly improved the flexural strength of mortars with

RPET concretes were greater as compared to normal

a major improvement in mortar toughness. The maximum

concrete.

volume of PET fiber for a desired workability was 1.5%. In

the same year, Jose and Balasubramanian (2014), investigated the effect of

waste polyethene as concrete mix design component and

compared the compressive strength with conventional

concrete mix cube.

© 2015, IRJET.NET- All Rights Reserved Page 121

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 02 Issue: 01 | Apr-2015 www.irjet.net p-ISSN: 2395-0072

4. Materials and Methodology 4.3 PET Fiber:

4.1 Cement: The polyethylene (PET) bottle which can easily be obtained

The cement used for this experiment is OPC (43Grade) from the environment with almost no cost is chopped and

Conforming to IS 8112-1982 and has the following added into ordinary concrete to examine the strength

properties which have been experimentally determined at behavior of various specimens. Thermal insulation

the time of use: enhancement in concretes by adding waste PET and rubber

Type and grade Ordinary Portland pieces can also be studied. Also the plastic waste is found to

cement G-43 have no water absorption (based on literature) and hence

corrosion control analysis can be done. The products which

Specific gravity 3.15 are aimed in this project really have a commercial value

since there is a need for alternate materials for construction

Bulk density 1450 kg/m3

owing to the rapid depletion of the natural resources. The

properties of PET are as follows:

Initial Setting time 30 min

Sr.No. Coefficient of 0.2 -0.4

Final Setting time 600 min

friction

1 Hardness – Rockwell M94-101

Soundness Expansion 5mm

2 Poisson’s ratio 0.37-0.44

Table 1: Properties of cement used.

3 Tensile modulus 2-4 GPa

4.2 Aggregates:

The size of the aggregate, particle shape, color, surface 4 Tensile Strength 80

texture, density (heavyweight or lightweight), impurities, all

of which have an influence on the durability of concrete, 5 Density ( g.cm3) 1.3-1.4 g.cm3

should conform to IS: 383–1970. The size of coarse 6 Water absorption <0.7 %

aggregates used are 20mm and that of fine aggregates are of equilibrium

ZONE-II as given

Aggregates Fine coarse

7 Water absorption 0.1 %

aggregates aggregates

over 24 hours

Type River sand Crushed

(Zone II) granite Table 2: Properties of PET

Maximum nominal — 20mm 4.4 Methodology “

size

Mixing of concrete: Mixing of the actual quantities of the

Specific gravity 2.60 2.65 ingredients of concrete is done in a concrete mixer for 3

minutes Preparation of cubes: Cubes were prepared

Bulk density (kg/m3) 1700 1800 conforming to IS 456-2000. For most of the work cubical

size of 15cmX15cmX15cm is used.

Fineness modulus 2.3 6.0

Curing: cubes were stored in moisture for 24 hours and

Free surface moisture 2.0 1.0 period were marked the removed from the moulds and kept

(%) submerged in fresh water until test is performed.

© 2015, IRJET.NET- All Rights Reserved Page 122

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 02 Issue: 01 | Apr-2015 www.irjet.net p-ISSN: 2395-0072

Testing: Test cubes were taken under compressive testing fiber and it gives peak value at 2% of PET. Thereafter, it start

machine and load applied gradually at rate of 1.4 to 2.1 decreasing and minimum is at 6%.

MPa/min till specimen fails. Load at the failure divided by

area of specimen gives the compressive strength of concrete. 6.1 CONCLUSION

5. Experimental Results: According to the discussion of results the following

conclusions are derived by this study:

Going through the experiments with actual M25

(conventional concrete), Concrete with various proportions • Upto 2% replacement of fine aggregates with waste

PET fiber, there is increase in compressive strength

of PET in place of aggregate, the following result are

of concrete.

obtained that enlisted below in tables:

• Concrete mixed with waste PET fiber is eco-friendly,

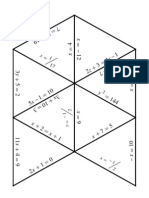

7 DAYS non-hazardous as it easily get dispersed in concrete

29 mix

14 DAYS

COMPRESSIVE STRENGTH N/mm^2

27 28 DAYS • Hence concrete with waste PET fiber can be used as

an effective plastic waste management practice in

25 future.

23 References

21 1. A. Mohd Mustafa Al Bakri, G. Che Mohd Ruzaidi,

M.N. Norazian, H. Kamarudin and S. Mohammad

19 Tarmizi (2007) “Effects of hdpe plastic waste

aggregate on the properties of concrete”.

17

2. Chan, Y., N., Peng, G., F., Anson, M., 1999. Residual

strength and pore structure of high-strength

15 concrete and normal strength concrete after

0% 2%

%AGE OF4% 6%

PET FIBRE 8% exposure to high temperatures. Cement and

Concrete Composites 21 (1), 23-27

Figure1. Average compressive strength with various 3. Fernando Pelisser, Oscar Rubem Klegues Montedo,

%age of PET fiber at different curing periods Philippe Jean Paul Gleize and Humberto Ramos

Roman (2012) Mechanical Properties of Recycled

From Figure-3 the comparison of compressive strength of PET Fibers in Concrete. Materials Research.:5(4):

conventional concrete and concrete with PET fiber, it is very 679-686.

clear that PET fiber concrete gives better results than

4. F.J. Baldenebro-Lopeza, J.H. Castorena-Gonzalezb,

conventional concrete. It is also visible that with the

J.I. Velazquez-Dimas, J.E. Ledezma-Sillasa, R.

replacement of fine aggregates with waste PET fiber, there is Martinez-Sancheza and J.M. Herrera-

increase in compressive strength upto 2% replacement, at Ramireza,(2013) Mechanical properties

which there is 12% increase in compressive strength. For enhancement of a concrete reinforced with

percentage replacement more than 2% there is decrease in recycled PET fibers: PROFAPI 2012/4

compressive strength.

5. F.J. Baldenebro-Lopez, J.H. Castorena-Gonzalez, J.I.

6. Discussion Velazquez-Dimas, J.E. Ledezma-Sillas, C.D. Gómez-

Esparza, R. Martinez-Sanchez and J.M. Herrera-

From the above experimental results, it is clear that the Ramirez (2014) Influence of continuous plastic

fibers reinforcement arrangement in concrete

compressive strength of cube increases with increase in PET

© 2015, IRJET.NET- All Rights Reserved Page 123

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 02 Issue: 01 | Apr-2015 www.irjet.net p-ISSN: 2395-0072

strengthened: ISSN (e): 2250-3021, ISSN (p): 13. Swaptik Chowdhury, Aastha Tashkant Maniar, and

2278-8719 Om. Suganya (2013)PET Waste as Building

Solution: ISSN 2320 –4087

6. G.Manikandan, D r . M . Sivaraja and R.Krishnaraja

(2013) Flexural behavior of RCC beams reinforced 14. Siddesh pai and Kaushik Chandra. L(2013)

with PET bottle waste fibres: ISSN: 2347-1964 Analysis of polyester fibre reinforced concrete

subjected to elevated temperatures: ISSN 2249-

7. Hasan Taherkhani (2014) An Investigation on the 6866

Properties of the Concrete Containing Waste PET

Fibers: ISSN: 2251-8843 15. Shivam Nema, Kamlesh Keshre, Yash Soni and

Ashish Nim (2014) Experimental investigation on

8. J.M. Irwan , S.K. Faisal , N. Othman, Wan Ibrahim properties of concrete by replacement of fine

M.H, R.M. Asyraf, and M.M.K. Annas (2014) aggregate by grinded mixture of plastic and glass

waste: e-ISSN : 2249-8303.

9. J. Simson Jose and Mr. M. Balasubramanian (2014)

Experimental Investigation on Characteristics of 16. Tarun R. Naik, Shiw S. Singh, Calvin O. Huber and

Polythene Waste Incorporated Concrete: ISSN: Brian S. Brodersen(1994) Use of post-consumer

2231-5381 waste plastics in cement-based composites: PP.

1489-149

10. K.Ramadevi, Ms. R. Manju (2012) “Experimental

Investigation on the Properties of Concrete With

Plastic PET (Bottle) Fibers as Fine Aggregates”

ISSN 2250-2459, Volume 2, Issue 6,

11. Nibudey. R.N, Nagarnaik. P. B, Parbat.D.K and

Pande. A.M (2013) Cube and cylinder compressive

strengths of waste plastic fiber reinforced

concrete: ISSN 0976 – 4399

12. R. N. Nibudey,P.B. Nagarnaik, D.K.Parbat and

A.M.Pande (2013) Strength and fracture properties

of post consumed waste plastic fiber reinforced

concrete. IJCSEIERD: 9-16

© 2015, IRJET.NET- All Rights Reserved Page 124

Das könnte Ihnen auch gefallen

- Experimental Investigation On The Properties of Concrete With Plastic Pet Bottle Fibers As Partial Replacement of Fine AggregatesDokument7 SeitenExperimental Investigation On The Properties of Concrete With Plastic Pet Bottle Fibers As Partial Replacement of Fine AggregatesEditor IJTSRDNoch keine Bewertungen

- UTHM Concrete With Plastic FibreDokument8 SeitenUTHM Concrete With Plastic FibreLeong Shi Shen100% (1)

- Polyethylene Terephthalate (PET) WasteDokument5 SeitenPolyethylene Terephthalate (PET) WasteleniucvasileNoch keine Bewertungen

- Partial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderDokument7 SeitenPartial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderIJSTENoch keine Bewertungen

- Feasibility Study of Waste Poly Ethylene Terephthalate (PET) Particles As Aggregate PDFDokument41 SeitenFeasibility Study of Waste Poly Ethylene Terephthalate (PET) Particles As Aggregate PDFAniel Dias0% (1)

- Use of Waste Plastic in Concrete Mixture As Aggregate ReplacementDokument4 SeitenUse of Waste Plastic in Concrete Mixture As Aggregate ReplacementIJAERS JOURNALNoch keine Bewertungen

- Eco-Friendly Concrete Containing Recycled Plastic As Partial Replacement For SandDokument13 SeitenEco-Friendly Concrete Containing Recycled Plastic As Partial Replacement For SandSofii VictoriannaNoch keine Bewertungen

- Combined Effects of Sawdust and Building Rubbles As Aggregate On The ConcreteDokument12 SeitenCombined Effects of Sawdust and Building Rubbles As Aggregate On The ConcreteOudhai VONGKEONoch keine Bewertungen

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Von EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Noch keine Bewertungen

- Mohamed Elfatih - TechnicalDokument11 SeitenMohamed Elfatih - Technical6qwhnq9z4h100% (1)

- Partial Replacement of Fine Aggregates by Rubber in ConcreteDokument6 SeitenPartial Replacement of Fine Aggregates by Rubber in ConcretemuazNoch keine Bewertungen

- Coconut Husk FiberDokument12 SeitenCoconut Husk FiberArnie Romero CrispinoNoch keine Bewertungen

- Rehabilitation of Shear-Damaged Reinforced Concret PDFDokument14 SeitenRehabilitation of Shear-Damaged Reinforced Concret PDFAbdulkhaliq AbdulyimahNoch keine Bewertungen

- Enhancing the Climate Resilience of Africa's Infrastructure: The Power and Water SectorsVon EverandEnhancing the Climate Resilience of Africa's Infrastructure: The Power and Water SectorsNoch keine Bewertungen

- Literature Review and ConclusionDokument12 SeitenLiterature Review and ConclusionHaiqal RafiqNoch keine Bewertungen

- Thesis 111Dokument74 SeitenThesis 111Mubashir SheheryarNoch keine Bewertungen

- TERRAZYME Seminar With Page No ReportDokument17 SeitenTERRAZYME Seminar With Page No ReportAbhinav DhayalNoch keine Bewertungen

- Site Visit Bukit Tagar NewDokument15 SeitenSite Visit Bukit Tagar Newelffie yunus100% (2)

- Analysis of The Characteristic Behaviour of Concrete With Rice Husk Ash and Sugarcane Bagasse AshDokument6 SeitenAnalysis of The Characteristic Behaviour of Concrete With Rice Husk Ash and Sugarcane Bagasse AshEditor IJTSRDNoch keine Bewertungen

- ThesisDokument62 SeitenThesisWaquar TaiyebNoch keine Bewertungen

- Dete C - Partial Replacement of Course Aggregate With Waste GlassDokument54 SeitenDete C - Partial Replacement of Course Aggregate With Waste Glass1man1bookNoch keine Bewertungen

- Plastic Mixed Reinforced ConcreteDokument10 SeitenPlastic Mixed Reinforced ConcreteUmange RanasingheNoch keine Bewertungen

- Study On Concrete With Partial Replacement of Cement by Rice Husk AshDokument12 SeitenStudy On Concrete With Partial Replacement of Cement by Rice Husk AshDorothy Yen EscalañaNoch keine Bewertungen

- Formwork SeminarDokument19 SeitenFormwork Seminarfaisal0% (1)

- ECG524-Topic 2a-Asphaltic Concrete Pavement DesignDokument68 SeitenECG524-Topic 2a-Asphaltic Concrete Pavement DesignAdika Azwan100% (1)

- High Performance Repairing of Reinforced Concrete StructuresDokument7 SeitenHigh Performance Repairing of Reinforced Concrete StructuresCarlos CalleNoch keine Bewertungen

- Soil Design Exp Final 2019Dokument71 SeitenSoil Design Exp Final 2019John Rhey Almojallas BenedictoNoch keine Bewertungen

- A Review-Use of Recycled Aggregate in Making Concrete in India - Abstract.jaswant NITJDokument8 SeitenA Review-Use of Recycled Aggregate in Making Concrete in India - Abstract.jaswant NITJashu_gbpec2005Noch keine Bewertungen

- Soil Progress ReportDokument13 SeitenSoil Progress ReportJohn Rhey Almojallas Benedicto100% (1)

- Utilization of Recycled Crumb Rubber As Ne Aggregates in Concrete Mix DesignDokument6 SeitenUtilization of Recycled Crumb Rubber As Ne Aggregates in Concrete Mix DesignGuzalgNoch keine Bewertungen

- Experimental Investigation of The Performance of Rubberized Concrete Mixtures Without AdditivesDokument15 SeitenExperimental Investigation of The Performance of Rubberized Concrete Mixtures Without AdditivesIAEME PublicationNoch keine Bewertungen

- Concrete With Highly Active Rice Husk AshDokument4 SeitenConcrete With Highly Active Rice Husk AshEssy BasoenondoNoch keine Bewertungen

- Partial Repacement of Plastic in BitumenDokument5 SeitenPartial Repacement of Plastic in BitumenSri HariNoch keine Bewertungen

- Supplementary Cementitious Materials - LiteratureDokument68 SeitenSupplementary Cementitious Materials - LiteraturealulatekNoch keine Bewertungen

- Water Content Effect On Shear StrenghtDokument3 SeitenWater Content Effect On Shear StrenghtOlivinNoch keine Bewertungen

- An Experimental Investigation On Concrete by Using Glass As A Fine Aggregate ReplacementDokument52 SeitenAn Experimental Investigation On Concrete by Using Glass As A Fine Aggregate ReplacementUDAYA M.E.T COLLEGE100% (1)

- Bone Ash Project 1-3 On Progress QaDokument26 SeitenBone Ash Project 1-3 On Progress QaOshogbunu Onoriode ErnestNoch keine Bewertungen

- Lecture Note Course Code-Bce 303 Geotechnical Engineering-IDokument127 SeitenLecture Note Course Code-Bce 303 Geotechnical Engineering-IMahesh RamtekeNoch keine Bewertungen

- Use of Waste Material in ConcreteDokument56 SeitenUse of Waste Material in Concretemanoj588Noch keine Bewertungen

- Use of Traditional Material in Low Cost: HousingDokument70 SeitenUse of Traditional Material in Low Cost: HousingSarang WarjurkarNoch keine Bewertungen

- Interlocking Plastic Blocks (IPB)Dokument7 SeitenInterlocking Plastic Blocks (IPB)IJRASETPublicationsNoch keine Bewertungen

- E WasteDokument7 SeitenE WasteAmitSinghYadavNoch keine Bewertungen

- Waste PlasticDokument18 SeitenWaste PlasticAshwath100% (1)

- Mechanically Stabilized Earth Retaining Walls Effective: February 3, 1999 RevisedDokument8 SeitenMechanically Stabilized Earth Retaining Walls Effective: February 3, 1999 RevisedJoseph StalinNoch keine Bewertungen

- Waste Glass in Cement MortarDokument8 SeitenWaste Glass in Cement MortarHasnanurfajriahNoch keine Bewertungen

- Plastic Aggregates Use in Hallow BlocksDokument12 SeitenPlastic Aggregates Use in Hallow BlocksEdison KingNoch keine Bewertungen

- Report Inovasi (Paving Block Using Hdpe Plastic) FinalDokument15 SeitenReport Inovasi (Paving Block Using Hdpe Plastic) Finalsathwik 77Noch keine Bewertungen

- COconut Shell PaperDokument10 SeitenCOconut Shell PaperPeer MohamedNoch keine Bewertungen

- Dyuthi T1796Dokument206 SeitenDyuthi T1796Prajval EmNoch keine Bewertungen

- Papercrete: Guided by Presented byDokument34 SeitenPapercrete: Guided by Presented byRoshan Nambiar0% (1)

- CHAPTER 1 FINAL YEAR ProjectDokument5 SeitenCHAPTER 1 FINAL YEAR ProjectdejayzNoch keine Bewertungen

- Waste Glass Powder As Partial Replacement of CementDokument8 SeitenWaste Glass Powder As Partial Replacement of CementdivyaNoch keine Bewertungen

- Recycling Research On International StudentDokument11 SeitenRecycling Research On International StudentAbdelrazaq Al-JazaziNoch keine Bewertungen

- MSC Thesis Camila PDFDokument91 SeitenMSC Thesis Camila PDFMohamed ElfawalNoch keine Bewertungen

- Dr. Rizwan ThesisDokument168 SeitenDr. Rizwan ThesisSufian AhmadNoch keine Bewertungen

- Class NoteDokument67 SeitenClass NoteSujan SinghNoch keine Bewertungen

- Resilient Modulus and Dynamic Modulus of Warm Mix AsphaltDokument8 SeitenResilient Modulus and Dynamic Modulus of Warm Mix AsphaltJorge LuisNoch keine Bewertungen

- Recycled Plastic Used in Concrete Paver Block PDFDokument3 SeitenRecycled Plastic Used in Concrete Paver Block PDFRusel ZahrawNoch keine Bewertungen

- 08 - Chapter 2 (Literature Review)Dokument26 Seiten08 - Chapter 2 (Literature Review)Nancy PrevinNoch keine Bewertungen

- Effect of Using Ground Waste Tire Rubber As Fine Aggregate On The Behaviour of Concrete MixesDokument9 SeitenEffect of Using Ground Waste Tire Rubber As Fine Aggregate On The Behaviour of Concrete MixesMaridil IsidroNoch keine Bewertungen

- Railway Engineering & Runway EngineeringDokument42 SeitenRailway Engineering & Runway EngineeringRana Talal RaziNoch keine Bewertungen

- ISO 9000 - What Is ISO 9000 - A Standards Series - ASQDokument5 SeitenISO 9000 - What Is ISO 9000 - A Standards Series - ASQRana Talal RaziNoch keine Bewertungen

- Chapter 01Dokument35 SeitenChapter 01Rana Talal RaziNoch keine Bewertungen

- Soil Mechanics-II: Stress DistributionDokument18 SeitenSoil Mechanics-II: Stress DistributionRana Talal RaziNoch keine Bewertungen

- Rain Gauge: Non-Recording TypeDokument3 SeitenRain Gauge: Non-Recording TypeRana Talal RaziNoch keine Bewertungen

- Broad Crested Weir and FlumeDokument12 SeitenBroad Crested Weir and FlumeRana Talal RaziNoch keine Bewertungen

- Problem WastewaterDokument6 SeitenProblem WastewaterRana Talal RaziNoch keine Bewertungen

- Title Page For Lab ManualDokument9 SeitenTitle Page For Lab ManualRana Talal RaziNoch keine Bewertungen

- Testing Facilities: Plain & Reinforced Concrete Laboratory Department of Civil Engineering UET, LHRDokument1 SeiteTesting Facilities: Plain & Reinforced Concrete Laboratory Department of Civil Engineering UET, LHRRana Talal RaziNoch keine Bewertungen

- Lec#2, Rail Gauges PDFDokument43 SeitenLec#2, Rail Gauges PDFRana Talal RaziNoch keine Bewertungen

- Supervisor's DeclarationDokument24 SeitenSupervisor's DeclarationRana Talal RaziNoch keine Bewertungen

- Department of Civil Engineering: Plain and Reinforced Concrete Ii (Ce-411) (Seventh Semester, CR 3+1)Dokument8 SeitenDepartment of Civil Engineering: Plain and Reinforced Concrete Ii (Ce-411) (Seventh Semester, CR 3+1)Rana Talal RaziNoch keine Bewertungen

- Ministry of Finance - Government of Pakistan - 3Dokument20 SeitenMinistry of Finance - Government of Pakistan - 3muhammad nazirNoch keine Bewertungen

- ACI Method of Mix DesignDokument18 SeitenACI Method of Mix DesignRana Talal RaziNoch keine Bewertungen

- P S and L Wave FinalDokument10 SeitenP S and L Wave FinalRana Talal RaziNoch keine Bewertungen

- Lec - 1-Week (1) (Introduction To Environmental Engineering) PDFDokument22 SeitenLec - 1-Week (1) (Introduction To Environmental Engineering) PDFKhanNoch keine Bewertungen

- Equivalent Static Load MethodDokument37 SeitenEquivalent Static Load MethodRana Talal RaziNoch keine Bewertungen

- Shake Table Test For The Collapse Investigation ofDokument17 SeitenShake Table Test For The Collapse Investigation ofRana Talal RaziNoch keine Bewertungen

- Effect of Recycled Plastic in Mortar and ConcreteDokument12 SeitenEffect of Recycled Plastic in Mortar and ConcreteRana Talal RaziNoch keine Bewertungen

- Formula Sheet, Structural Engineering: Variable Tendon Eccentricity Constant Tendon EccentricityDokument1 SeiteFormula Sheet, Structural Engineering: Variable Tendon Eccentricity Constant Tendon EccentricityRana Talal RaziNoch keine Bewertungen

- Use of Recycled Plastics in Concrete: A Critical Review: Waste Management March 2016Dokument25 SeitenUse of Recycled Plastics in Concrete: A Critical Review: Waste Management March 2016Rana Talal RaziNoch keine Bewertungen

- Obe Section Attendance - Report Student Registered SubjectDokument2 SeitenObe Section Attendance - Report Student Registered SubjectZishan AhmadNoch keine Bewertungen

- Construction and Building Materials: Nabajyoti Saikia, Jorge de BritoDokument17 SeitenConstruction and Building Materials: Nabajyoti Saikia, Jorge de BritoRana Talal RaziNoch keine Bewertungen

- Use of Plastic Aggregates in Concrete: A5088119119/2019©BEIESP A5088Dokument7 SeitenUse of Plastic Aggregates in Concrete: A5088119119/2019©BEIESP A5088Rana Talal RaziNoch keine Bewertungen

- IRJET-Replacement of Natural Sand in Con PDFDokument5 SeitenIRJET-Replacement of Natural Sand in Con PDFRana Talal RaziNoch keine Bewertungen

- Effect of Recycled Plastic in Mortar and ConcreteDokument12 SeitenEffect of Recycled Plastic in Mortar and ConcreteRana Talal RaziNoch keine Bewertungen

- Performance of Structural Concrete With Recycled Plastic WasteDokument7 SeitenPerformance of Structural Concrete With Recycled Plastic WasteAstrit KiranaNoch keine Bewertungen

- Re-Use of Hospital Plastic Waste in Asphalt Mixes As Partial Replacement of Coarse AggregateDokument7 SeitenRe-Use of Hospital Plastic Waste in Asphalt Mixes As Partial Replacement of Coarse AggregateSanjay R NairNoch keine Bewertungen

- Irjet V6i4297 PDFDokument7 SeitenIrjet V6i4297 PDFRana Talal RaziNoch keine Bewertungen

- Irjet V6i4297 PDFDokument7 SeitenIrjet V6i4297 PDFRana Talal RaziNoch keine Bewertungen

- Focus On Teaching - Jim KnightDokument213 SeitenFocus On Teaching - Jim KnightFernando TeixeiraNoch keine Bewertungen

- Union Metal SemiconductorDokument4 SeitenUnion Metal SemiconductorskinhugoNoch keine Bewertungen

- CHAPTER 2 - ALGEBRA (Latest)Dokument41 SeitenCHAPTER 2 - ALGEBRA (Latest)FirdausNoch keine Bewertungen

- Pile Capacity - An Overview - ScienceDirect TopicsDokument15 SeitenPile Capacity - An Overview - ScienceDirect TopicssurNoch keine Bewertungen

- Blockchain Disruption in The Forex Trading MarketDokument64 SeitenBlockchain Disruption in The Forex Trading MarketVijayKhareNoch keine Bewertungen

- Canadian-Solar Datasheet Inverter 3ph 75-100KDokument2 SeitenCanadian-Solar Datasheet Inverter 3ph 75-100KItaloNoch keine Bewertungen

- Strategic Cost AnalysisDokument24 SeitenStrategic Cost AnalysisBusiness Expert Press100% (10)

- Fiitjee All India Test Series: Concept Recapitulation Test - Iv JEE (Advanced) - 2019Dokument13 SeitenFiitjee All India Test Series: Concept Recapitulation Test - Iv JEE (Advanced) - 2019Raj KumarNoch keine Bewertungen

- Algebra1 Review PuzzleDokument3 SeitenAlgebra1 Review PuzzleNicholas Yates100% (1)

- FINAL ReportDokument48 SeitenFINAL ReportMythri RangaswamyNoch keine Bewertungen

- AIMMS Modeling Guide - Linear Programming TricksDokument16 SeitenAIMMS Modeling Guide - Linear Programming TricksgjorhugullNoch keine Bewertungen

- Inglês - Degrees of ComparisonDokument4 SeitenInglês - Degrees of ComparisonVersehgi IINoch keine Bewertungen

- NC Error PropagationDokument12 SeitenNC Error PropagationSalman KhanNoch keine Bewertungen

- Vocology For The Singing Voice PDFDokument120 SeitenVocology For The Singing Voice PDFNathalia Parra Garza100% (2)

- Himachal Pradesh Staff Selection Commission Hamirpur - 177001Dokument2 SeitenHimachal Pradesh Staff Selection Commission Hamirpur - 177001Verma JagdeepNoch keine Bewertungen

- Fire Alarm SymbolsDokument6 SeitenFire Alarm Symbolscarlos vasquezNoch keine Bewertungen

- Grade 8 - EnglishDokument2 SeitenGrade 8 - EnglishTCHR KIMNoch keine Bewertungen

- One Plan Student 1Dokument7 SeitenOne Plan Student 1api-465826207Noch keine Bewertungen

- COCCIMORPHDokument13 SeitenCOCCIMORPHmiminNoch keine Bewertungen

- The Research Problem: The Key Steps in Choosing A TopicDokument5 SeitenThe Research Problem: The Key Steps in Choosing A TopicJoachim San JuanNoch keine Bewertungen

- Module 3: Literature Review and CitationDokument3 SeitenModule 3: Literature Review and CitationLysss EpssssNoch keine Bewertungen

- Steam TableDokument3 SeitenSteam TableMUHAMAD SAUKINoch keine Bewertungen

- How The Audiences Feel Closer and Connected To Their Culture With StorytellingDokument7 SeitenHow The Audiences Feel Closer and Connected To Their Culture With Storytellingmarcelo quezadaNoch keine Bewertungen

- Results 2020: Climate Change Performance IndexDokument32 SeitenResults 2020: Climate Change Performance IndexTonyNoch keine Bewertungen

- INT PL 2020 Web 01-20 PDFDokument320 SeitenINT PL 2020 Web 01-20 PDFAndriana Vilijencova100% (1)

- SFN ProfileDokument4 SeitenSFN Profiledinesh panchalNoch keine Bewertungen

- Mecanica MD - AZG-UDokument29 SeitenMecanica MD - AZG-UStefanoViganóNoch keine Bewertungen

- Advanced Laser Al170: Instruction ManualDokument35 SeitenAdvanced Laser Al170: Instruction ManualJuan Camilo100% (1)

- PP in Ii 001Dokument15 SeitenPP in Ii 001Dav EipNoch keine Bewertungen

- PTN Guide Compilation by EmeraldchowDokument24 SeitenPTN Guide Compilation by EmeraldchowMirzaNoch keine Bewertungen