Beruflich Dokumente

Kultur Dokumente

Fundamentals of Lubrication: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved

Hochgeladen von

Jahmia CoralieOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fundamentals of Lubrication: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved

Hochgeladen von

Jahmia CoralieCopyright:

Verfügbare Formate

Performance you can rely on.

Fundamentals of lubrication

InfineumInsight.com/Learn

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Introduction to Tribology

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Outline

At the end of this presentation you will be able to:

– State what the word Tribology means

– List the main regimes of lubrication and state the

conditions under which each tends to occur

– Understand our approach to lubricant performance

testing

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Tribology history

Tribology is study of friction, wear and lubrication between

surfaces sliding against each other

Source: WSJ

While direct application of tribology by Ancient Egyptians is well documented,

Leonardo Da Vinci was the first to enunciate the laws of friction

The word ‘Tribology’ came later and was first coined by David Tabor and Peter

Jost in 1964

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Tribology solving real world problems

Tribology is about understanding, analysing, predicting and controlling

interactions between moving surfaces

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Why does tribology matter?

Energy

Safety

Environment Reliability

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Multi-disciplinary aspect of tribology

o Rheology Fluids

o Fluids dynamic mechanics

o Stress o Metallurgy

Solid Material o Coatings

o Deformation

mechanics

Tribology science

o Motion o Crystallography

o Fluids structure interactions

Physical-

o Surface chemistry

chemistry

o Thermochemistry

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Stribeck curve and lubrication regimes

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Stribeck curve

Stribeck curve is used to represent friction response of a tribological

contact across different lubrication regimes

h/σ<<1 h/σ≈1 1<h/σ<3 h/σ>>3 Boundary lubrication

Mixed lubrication

Coefficient of friction (µ)

Minimum film thickness (h)

Elastrohydrodynamic

Hydrodynamic

σ = composite

surface roughness

Viscosity x speed

Log

Load

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Hydrodynamic lubrication (HD)

The contact is designed such that their relative motion drags (or entrains)

lubricant in between them, forcing the lubricant to high pressures of up to

200 MPa (30,000 psi), large enough to support external loads.

Lube oil

supply (2÷6 bar)

Bearing Bearing load

Pressurised film

creating a 'lift' of

the top surface

Lubrication

gap

Oil Flow

Journal

Moving Surface

Oil film thickness typically 1 to 100μm Hydrodynamic

Minimum oil oil film pressure

film thickness profile

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Hydrodynamic lubrication - examples

Plain journal bearings

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Elastohydrodynamic lubrication (EHL)

When all the loading is concentrated over a small contact area.

• High localised stresses cause elastic deformation of the surfaces

• An exponential rise in viscosity of the lubricant as it is squeezed

through the contact

• Thin fluid film is formed due to surface deformation and viscosity

increase

Oil film thickness typically 0.1 to 1μm

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

EHL - examples

Toyota 1HZ timing gear

Valve train – cam and lifter experience EHL at cam nose

Example of a component experiencing

elastohydrodynamic lubrication

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Mixed lubrication

Enough film to separate

most of the rubbing surfaces

Some contact between the

asperities + reacted film

Oil film thickness typically 1 to 100 nm (roughness dependent)

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Boundary lubrication

Insufficient film to

separate the surfaces

Tribo-reacted film on the

contacting asperities

Oil film thickness typically 20 to 100 nm (roughness dependent)

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Mixed and boundary lubrication examples

Top Dead Center (TDC) Piston rings experience all lubrication

regimes as piston slides from TDC to BDC

Mixed/boundary to EHL

Bottom Dead Center (BDC)

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Applied tribology and key properties

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Functional Requirements of Lubricants

• Keep surfaces separate under all loads, temperatures

and speeds, thus minimising friction and wear.

• Act as a cooling fluid removing the heat produced by

friction or from external sources

• Remain adequately stable in order to guarantee

constant behavior over the forecasted useful life

• Protect surfaces from the attack of aggressive

products formed during operation

• Fulfil detersive and dispersive functions in order to

remove residue and debris that may form during

operation

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Parameters to consider in tribology

• Material

– Roughness

– Metallurgy

– Hardness

• Fluid properties

– Viscosity

– Newtonian vs. Non-Newtonian

– Pressure viscosity coefficient

• Contact conditions

– Pressure

– Temperature

– Rubbing part entrainment speed

• Surface active additives

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Material properties - examples

Roughness

Real example

of top ring

roughness

discrepancy

Metallurgy Hardness

Chilled

cast iron

Grey cast iron

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Fluids Properties - Viscosity

• Dynamic viscosity: resistance to shearing flow 𝑁

𝜏 𝑆ℎ𝑒𝑎𝑟 𝑠𝑡𝑟𝑒𝑠𝑠 (𝑚2 )

𝜂= 𝛾 𝑆ℎ𝑒𝑎𝑟 𝑟𝑎𝑡𝑒 (𝑠 −1 )

[Pa.s]

• Kinematic viscosity: flow response to gravity

𝜂 𝐷𝑦𝑛𝑎𝑚𝑖𝑐 𝑣𝑖𝑠𝑐𝑜𝑠𝑖𝑡𝑦

𝜗= 𝜌 𝑑𝑒𝑛𝑠𝑖𝑡𝑦

[𝑚2 /𝑠]

• Viscosity Index: VI is an empirical parameter that compares kinematic

viscosity of a given oil to the viscosities of two reference oils that have

appreciable difference in sensitivity of viscosity to temperature.

Kinematic Viscosity, mm2/s

300

250

VI ~ 65

200

150

100

50 VI > 250

0 110

30 40 50 60 70 80 90 100

Temperature, C

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Fluids Properties – High pressure

• Viscosity pressure relationship: lubricant viscosity increases with

pressure and this effect is generally greater than the effect of temperature.

– Barus equation is most commonly used to show the relationship:

𝜂𝑝 = 𝜂0 𝑒 𝛼𝑝

𝜂𝑝 viscosity at pressure ‘p’ [Pa.s]

𝜂0 viscosity at atmospheric pressure [Pa.s]

𝛼 is the pressure viscosity coefficient [m2/N]

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Physical Properties of Lubricants

• Viscosity-shear rate relationship: Almost all lubricants behave as non-

Newtonian under high shear rates (~106 s-1 and above), i.e., shear stress

and shear rate are not directly proportional

– Pseudoplastic behavior: during the shearing process the randomly oriented

long molecules tend to align resulting in reduction in apparent viscosity. This is

also referred to as shear thinning.

– Thixotropic behavior: is associated with a loss of consistency of the fluid as the

duration of shear increases. This is also known as shear duration thinning.

Pseudoplastic behavior Thixotropic behavior

Viscosity

Shear rate

Newtonian

Shear rate Shear stress

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Tribology and Infineum

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Why study friction and wear in an engine?

• Combustion engine contains many moving metal parts

• Movement between parts can lead to surfaces wearing

away

• Affect durability

• Certain engines are more prone to wear

• As such these troublesome engines tend to be used for

the qualification of a formulated oil

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Tribology of an internal combustion engine

Camshaft

Valves Tappet

Piston

Conrod

Crankshaft Big end bearing

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Levels of tribo-testing

• Level A. Vehicle on- and/or off-road tests

• Level B. Full-size dynamometer test stand (entire vehicle)

• Level C. Full-scale engine tests (engine test cells)

• Level D. Sub-assembly tests (full-scale mating parts)

• Level E. Coupon tests (sub-scale tests, part sections or simple

coupons)

• The complexity and the cost of testing goes up as the testing moves

from Level E to Level A

• Control of operating variables and fundamental learnings increase

as the testing moves from Level A to Level E

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Factors determining design of a tribo-test

Designing a tribo-test a correlate performance of materials (metals

and/or lubricants) across various levels of testing requires

consideration of several factors

Mechanical factors Material factors

surface geometry, design, composition, processing,

relative motion, contact stress, surface treatments

vibrations

Chemical factors

Thermal factors lubricant chemistry, tribo-

heat generation and chemistry, oxidation, corrosion

dissipation rate

Lubrication factors

Third bodies lubrication regime, fluid flow,

wear debris, contaminants film thickness

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Bench test rigs (Level E)

Examples of Level E tribo-testing

SRV-5 reciprocating test rig Block-on-ring test rig

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Sub-system testing (Level D)

Examples of sub-assembly test rigs

Valve-train test rigs developed by Infineum used for formulation

development and fundamental understanding

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Engine testing (Level C)

Examples of engine test installation used for evaluation and

validation of lubricant performance

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Vehicle testing (Level B)

Examples of vehicle testing on a dynamometer to evaluate lubricant performance in

real driving condition in a very control and repeatable environment

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Vehicle testing (Level A)

Examples of field testing to validate lubricant performance in a very

variable but representative of the end-user utilisation environment

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Surface examination tools

25x to

5x to 100x 1000x

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Surface examination tools: Optical interferometer

• Zemetrics Ze-scope

• 5x to 50x objective

• Max field of view 3.35mm x 2.58mm

• 1nm vertical resolution

• HD imaging camera

• Fully motorised

• Greater vertical resolution

Example – HD resolution measurement of a liner

honing marks (HDD engine)

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Surface examination tools: Scanning electron

microscope

Range of magnification: 10x – 1000,000x

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Summary

This presentation should have helped you to understand

more about:

– What Tribology is and how we use it in developing

new lubricants

– The main lubrication regimes and conditions under

which they occur

– Different levels of tribo-testing

– Understand our approach to lubricant performance

testing and surface analysis techniques

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Performance you can rely on.

Permission is given for storage of one copy in electronic means for reference purposes. Further reproduction of any

material is prohibited without prior written consent of Infineum International Limited.

The information contained in this document is based upon data believed to be reliable at the time of going to press and

relates only to the matters specifically mentioned in this document. Although Infineum has used reasonable skill and

care in the preparation of this information, in the absence of any overriding obligations arising under a specific contract,

no representation, warranty (express or implied), or guarantee is made as to the suitability, accuracy, reliability or

completeness of the information; nothing in this document shall reduce the user’s responsibility to satisfy itself as to the

suitability, accuracy, reliability, and completeness of such information for its particular use; there is no warranty against

intellectual property infringement; and Infineum shall not be liable for any loss, damage or injury that may occur from

the use of this information other than death or personal injury caused by its negligence. No statement shall be

construed as an endorsement of any product or process. For greater certainty, before use of information contained in

this document, particularly if the product is used for a purpose or under conditions which are abnormal or not

reasonably foreseeable, this information must be reviewed with the supplier of such information.

Links to third party website from this document are provided solely for your convenience. Infineum does not control

and is not responsible for the content of those third party websites. If you decide to access any of those third party

websites, you do so entirely at your own risk. Please also refer to our Privacy Policy.

INFINEUM, 润英联 and the interlocking ripple device are Trade Marks of Infineum International Limited.

© Infineum International Limited 2017. All rights reserved.

© INFINEUM INTERNATIONAL LIMITED 2017. All Rights Reserved.

Das könnte Ihnen auch gefallen

- Viscosity & Viscosity Modifiers: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDokument39 SeitenViscosity & Viscosity Modifiers: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia CoralieNoch keine Bewertungen

- Fundamentals of Lubrication: © INFINEUM INTERNATIONAL LIMITED 2019. All Rights ReservedDokument32 SeitenFundamentals of Lubrication: © INFINEUM INTERNATIONAL LIMITED 2019. All Rights ReservedSiva KulanjiNoch keine Bewertungen

- Viscosity and Viscosity ModifiersDokument37 SeitenViscosity and Viscosity ModifiersmaiatostiNoch keine Bewertungen

- Fundamentals of Engine Design and Operation: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDokument62 SeitenFundamentals of Engine Design and Operation: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia Coralie100% (1)

- Field Testing: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDokument47 SeitenField Testing: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia CoralieNoch keine Bewertungen

- Lubricant BasestocksDokument37 SeitenLubricant BasestocksmaiatostiNoch keine Bewertungen

- What You Need To Know When Selecting Gear OilsDokument5 SeitenWhat You Need To Know When Selecting Gear OilsmarciofelipessantosNoch keine Bewertungen

- Engine Oil ChartDokument1 SeiteEngine Oil ChartprsovNoch keine Bewertungen

- Lubricant Base Stocks: OutlineDokument23 SeitenLubricant Base Stocks: OutlineJahmia Coralie100% (1)

- Innovations in Lube Marketing: Indian Perspective Challenges & Way AheadDokument27 SeitenInnovations in Lube Marketing: Indian Perspective Challenges & Way AheadBhagyesh DokeNoch keine Bewertungen

- 02 Additive Components Southern Asia 2019Dokument42 Seiten02 Additive Components Southern Asia 2019Jahmia Coralie100% (1)

- Calcium Sulfonate Complex GreasesDokument9 SeitenCalcium Sulfonate Complex GreasesFrancis XavierNoch keine Bewertungen

- Gear OilsDokument3 SeitenGear OilsPurchase ZenoilNoch keine Bewertungen

- Construction Lube Apps 18 Jan 16Dokument46 SeitenConstruction Lube Apps 18 Jan 16José Cesário NetoNoch keine Bewertungen

- Gear Lubrication 3Dokument9 SeitenGear Lubrication 3rashm006ranjan100% (1)

- Hitec-11410 Pds WotrDokument2 SeitenHitec-11410 Pds WotrAlex CamposNoch keine Bewertungen

- Passenger Car Engine Oil: Introduction and OutlineDokument18 SeitenPassenger Car Engine Oil: Introduction and OutlineJahmia CoralieNoch keine Bewertungen

- HiTEC-419 PDSDokument2 SeitenHiTEC-419 PDSSong Hum KangNoch keine Bewertungen

- Synthetic Gear Oil SelectionDokument9 SeitenSynthetic Gear Oil Selectionsmallik3Noch keine Bewertungen

- By: Muhammad Rafay IbadDokument18 SeitenBy: Muhammad Rafay IbadMuhammad sherazNoch keine Bewertungen

- Consistency Training: Contamination ControlDokument67 SeitenConsistency Training: Contamination ControlMaerks KevinNoch keine Bewertungen

- Ipac 2310K PDS 16RT0R4T1TT9D PDFDokument1 SeiteIpac 2310K PDS 16RT0R4T1TT9D PDFJorge ZegarraNoch keine Bewertungen

- Mobil Serv Lubricants Analysis Guide 2 PDFDokument20 SeitenMobil Serv Lubricants Analysis Guide 2 PDFFajar EkoNoch keine Bewertungen

- ANALEX PQL Datasheet PDFDokument2 SeitenANALEX PQL Datasheet PDFmaye palominoNoch keine Bewertungen

- EB1605 Breather Ebook FinalDokument15 SeitenEB1605 Breather Ebook FinalArun PrakashNoch keine Bewertungen

- PETROLENE Product CatalogueDokument45 SeitenPETROLENE Product CatalogueOscar Vargas GuerreroNoch keine Bewertungen

- 06 Passenger Car Engine Oil 1600615748970Dokument32 Seiten06 Passenger Car Engine Oil 1600615748970maiatostiNoch keine Bewertungen

- Understanding Elevated Copper Levels in Used Oil SamplesDokument3 SeitenUnderstanding Elevated Copper Levels in Used Oil SamplesYuszra SabillaNoch keine Bewertungen

- Splash Lubrication PDFDokument32 SeitenSplash Lubrication PDFRajender KumarNoch keine Bewertungen

- JAMA Engine: Mco WGDokument45 SeitenJAMA Engine: Mco WGida fariyanti100% (1)

- Lubricants and LubricationDokument5 SeitenLubricants and LubricationsafowanNoch keine Bewertungen

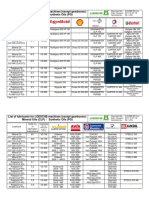

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Dokument8 SeitenList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaNoch keine Bewertungen

- Gearbox LubricationDokument5 SeitenGearbox LubricationTaranpreet Singh100% (1)

- Afton Industrial Overview Booklet 2019Dokument11 SeitenAfton Industrial Overview Booklet 2019Clairin LohNoch keine Bewertungen

- Lubricants FinalDokument18 SeitenLubricants FinalRonak GandhiNoch keine Bewertungen

- Shell Turbo T46 PDFDokument2 SeitenShell Turbo T46 PDFdionisio emilio reyes jimenezNoch keine Bewertungen

- SAE J300 Viscosity Grades Below 20 Grade-SAE Power Trains Fuels and Lubricants-2010Dokument11 SeitenSAE J300 Viscosity Grades Below 20 Grade-SAE Power Trains Fuels and Lubricants-2010Irfan ShaikhNoch keine Bewertungen

- Lubrizol360 Webinar PPT Template - v2 - Evaluation of Performance Properties of Slideway Lubricants - Z124Dokument58 SeitenLubrizol360 Webinar PPT Template - v2 - Evaluation of Performance Properties of Slideway Lubricants - Z124tiến thử huỳnhNoch keine Bewertungen

- Sabroe-Oil-Recommendation en 2012-11Dokument56 SeitenSabroe-Oil-Recommendation en 2012-11john smithNoch keine Bewertungen

- Gulf Lubricants Brief ProfileDokument10 SeitenGulf Lubricants Brief Profileatripathi2009100% (1)

- Industrial Lubricants - Viscosities Equivalent ISO-VG GradeDokument3 SeitenIndustrial Lubricants - Viscosities Equivalent ISO-VG GradeArifinNoch keine Bewertungen

- 3 - Syntetic Pocket GuideDokument9 Seiten3 - Syntetic Pocket GuideRay Cepeda MenaNoch keine Bewertungen

- 4 Additive Components NaDokument26 Seiten4 Additive Components NaJahmia Coralie100% (2)

- 100 Ways To Improve Lubrication ProgramDokument21 Seiten100 Ways To Improve Lubrication ProgramTalha NizamiNoch keine Bewertungen

- Loesche List of Lubricants 03 2015 - enDokument6 SeitenLoesche List of Lubricants 03 2015 - enphucdc095041Noch keine Bewertungen

- Tests For The Analysis of Used Lubricating GreaseDokument36 SeitenTests For The Analysis of Used Lubricating Greasegilar herliana putraNoch keine Bewertungen

- Copia de Petrobras Marine Lubricating Oils Equivalent ListDokument5 SeitenCopia de Petrobras Marine Lubricating Oils Equivalent Listeddy1588Noch keine Bewertungen

- Lubricant Condition Monitoring: Why The Lubricants MonitoringDokument14 SeitenLubricant Condition Monitoring: Why The Lubricants Monitoringrbdubey2020Noch keine Bewertungen

- Lubrizol 1038 - Auto Gear Oil - TdsDokument3 SeitenLubrizol 1038 - Auto Gear Oil - TdsPranit More Arabian Petroleum LimitedNoch keine Bewertungen

- Aceites Lubricantes para Motores Diesel Sep-2015Dokument28 SeitenAceites Lubricantes para Motores Diesel Sep-2015Carlos Andres BonillaNoch keine Bewertungen

- Lube Analyst Next Generation: Limit Guide ParametersDokument4 SeitenLube Analyst Next Generation: Limit Guide ParametersfrancisNoch keine Bewertungen

- Base Stocks 基础油Dokument18 SeitenBase Stocks 基础油Yesica RozoNoch keine Bewertungen

- Lubricantes LSCDokument22 SeitenLubricantes LSCAndres PozoNoch keine Bewertungen

- Clean Oil GuideDokument28 SeitenClean Oil GuideAlex VulpeNoch keine Bewertungen

- OEM Engine Oil Lubricant Specifications: White PaperDokument4 SeitenOEM Engine Oil Lubricant Specifications: White Papermohamed100% (1)

- Classification of Engine Oil ViscosityDokument1 SeiteClassification of Engine Oil ViscosityRio aji RiyantoNoch keine Bewertungen

- LZ 7077 Pds PDFDokument4 SeitenLZ 7077 Pds PDFNadia SalemNoch keine Bewertungen

- Technology Forum - Indoneusa - Gas Engines (Oct.2014) V2Dokument42 SeitenTechnology Forum - Indoneusa - Gas Engines (Oct.2014) V2Frana HadiNoch keine Bewertungen

- Hydraulic Fluid Shear Stability: Technical TopicDokument2 SeitenHydraulic Fluid Shear Stability: Technical TopicJahmia CoralieNoch keine Bewertungen

- Singapore Refinery To Expand Group II ProductionDokument1 SeiteSingapore Refinery To Expand Group II ProductionJahmia CoralieNoch keine Bewertungen

- Safety in Lubrication: Technical TopicDokument2 SeitenSafety in Lubrication: Technical TopicJahmia CoralieNoch keine Bewertungen

- SC RefrigerationDokument2 SeitenSC RefrigerationLuu ChayleNoch keine Bewertungen

- Reliable global supply of Group I & II base stocksDokument1 SeiteReliable global supply of Group I & II base stocksJahmia CoralieNoch keine Bewertungen

- Managing Base Stock Expansions: ExxonMobil's ApproachDokument1 SeiteManaging Base Stock Expansions: ExxonMobil's ApproachJahmia CoralieNoch keine Bewertungen

- EXXON Oil AnalysisDokument2 SeitenEXXON Oil AnalysisCorina StanculescuNoch keine Bewertungen

- Basestocks Interactive MapDokument1 SeiteBasestocks Interactive MapJahmia CoralieNoch keine Bewertungen

- EXXON Oil AnalysisDokument2 SeitenEXXON Oil AnalysisCorina StanculescuNoch keine Bewertungen

- Technical Topic - Fire Resistant Fluids in Power GenerationDokument2 SeitenTechnical Topic - Fire Resistant Fluids in Power GenerationJahmia CoralieNoch keine Bewertungen

- Determining Relubrication Intervals For Rolling Element BearingsDokument2 SeitenDetermining Relubrication Intervals For Rolling Element BearingsJahmia CoralieNoch keine Bewertungen

- EHC 45 65 Sell Sheet 034 NewDokument2 SeitenEHC 45 65 Sell Sheet 034 NewJahmia CoralieNoch keine Bewertungen

- Three Tips To Control Leakage: Exxonmobil Technical Help DeskDokument1 SeiteThree Tips To Control Leakage: Exxonmobil Technical Help DeskJahmia CoralieNoch keine Bewertungen

- Mobilgrind Series: Honing and Grinding Fluids For Precision MachiningDokument2 SeitenMobilgrind Series: Honing and Grinding Fluids For Precision MachiningJahmia CoralieNoch keine Bewertungen

- 1 © 2018 Infineum International Limited. All Rights ReservedDokument8 Seiten1 © 2018 Infineum International Limited. All Rights ReservedJahmia CoralieNoch keine Bewertungen

- power transmissions 动力传动Dokument13 Seitenpower transmissions 动力传动Jahmia CoralieNoch keine Bewertungen

- In Large Engines, We Cover Stationary Gas Engines and The Railroad SectorDokument13 SeitenIn Large Engines, We Cover Stationary Gas Engines and The Railroad SectorJahmia CoralieNoch keine Bewertungen

- Store Lubricant Oil Drums IndoorsDokument1 SeiteStore Lubricant Oil Drums IndoorsJahmia CoralieNoch keine Bewertungen

- Small Engines: Global Motorcycle Trends E-Mobility Trends Emissions Legislation Upgrades Motorcycle MarketDokument8 SeitenSmall Engines: Global Motorcycle Trends E-Mobility Trends Emissions Legislation Upgrades Motorcycle MarketJahmia CoralieNoch keine Bewertungen

- Stuttgart Trends China Market UpdateDokument9 SeitenStuttgart Trends China Market UpdateJahmia CoralieNoch keine Bewertungen

- Understanding Lubricant Requirements of Hybrid-Electric Vehicles - Dean B. Clarke (Infineum) PDFDokument22 SeitenUnderstanding Lubricant Requirements of Hybrid-Electric Vehicles - Dean B. Clarke (Infineum) PDFJahmia CoralieNoch keine Bewertungen

- Stuttgart Trends China Market UpdateDokument9 SeitenStuttgart Trends China Market UpdateJahmia CoralieNoch keine Bewertungen

- Trends PTF ModuleDokument19 SeitenTrends PTF ModuleJahmia CoralieNoch keine Bewertungen

- In Passenger Vehicles, We Explore Trends in Light Duty Vehicles and Power TrainsDokument29 SeitenIn Passenger Vehicles, We Explore Trends in Light Duty Vehicles and Power TrainsJahmia CoralieNoch keine Bewertungen

- 5 Engine Oil Specifications NaDokument27 Seiten5 Engine Oil Specifications NaOscar CampoNoch keine Bewertungen

- Trends PVL Modujle June 18Dokument29 SeitenTrends PVL Modujle June 18Jahmia CoralieNoch keine Bewertungen

- Worldwide Winter Diesel Fuel Quality Survey 2014: Performance You Can Rely OnDokument18 SeitenWorldwide Winter Diesel Fuel Quality Survey 2014: Performance You Can Rely OnJahmia CoralieNoch keine Bewertungen

- Passenger Car Engine Oil: Introduction and OutlineDokument18 SeitenPassenger Car Engine Oil: Introduction and OutlineJahmia CoralieNoch keine Bewertungen

- Lubricant Base Stocks: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDokument48 SeitenLubricant Base Stocks: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia CoralieNoch keine Bewertungen

- Modeling of Dynamically Loaded Hydrodynamic Bearings at Low Sommerfeld NumbersDokument219 SeitenModeling of Dynamically Loaded Hydrodynamic Bearings at Low Sommerfeld NumbersMircea BolovedeaNoch keine Bewertungen

- Bearings and BushingsDokument11 SeitenBearings and Bushingssaritha0003Noch keine Bewertungen

- Hydrodynamic Bearing PDFDokument4 SeitenHydrodynamic Bearing PDFAndrey ZagorulkoNoch keine Bewertungen

- Surface Lubrication 2Dokument42 SeitenSurface Lubrication 2chawboc huabNoch keine Bewertungen

- Lubrication Regimes: Dr. Dmitri KopeliovichDokument7 SeitenLubrication Regimes: Dr. Dmitri Kopeliovichramesh t100% (1)

- Design and Optimization of Gas Foil Journal Bearing: Mechanical Engineering DeptDokument24 SeitenDesign and Optimization of Gas Foil Journal Bearing: Mechanical Engineering DeptakshayNoch keine Bewertungen

- CatalogueDokument12 SeitenCataloguehamidNoch keine Bewertungen

- Tribology The Science of Combatting WearDokument33 SeitenTribology The Science of Combatting Wearahmed titoNoch keine Bewertungen

- Practical Task 2 BearingDokument2 SeitenPractical Task 2 Bearingshirleyna saraNoch keine Bewertungen

- NotesOnFluidFilmJournalBearing OverviewDokument72 SeitenNotesOnFluidFilmJournalBearing OverviewAsemota OghoghoNoch keine Bewertungen

- Cost-Efficient: DesigningDokument275 SeitenCost-Efficient: DesigningPedro MogollonNoch keine Bewertungen

- Propellers and Shafting: G RedpathDokument26 SeitenPropellers and Shafting: G RedpathIsrael Romani CaceresNoch keine Bewertungen

- Fundamentals of Engineering Tribology With Applications - Harish Hirani PDFDokument455 SeitenFundamentals of Engineering Tribology With Applications - Harish Hirani PDFSahitya Yadav100% (2)

- Tribology in Industry: J.R. Patel, G.M. DeheriDokument14 SeitenTribology in Industry: J.R. Patel, G.M. DeherishekhawatmahaveerNoch keine Bewertungen

- Gas BearingsDokument23 SeitenGas BearingsAlex CooperNoch keine Bewertungen

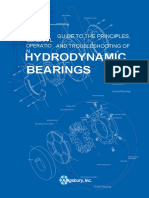

- The Principles, Operation and Troubleshooting-DikonversiDokument37 SeitenThe Principles, Operation and Troubleshooting-DikonversiHendra wahyudiNoch keine Bewertungen

- GGB DU BearingsDokument52 SeitenGGB DU BearingsMSc Kostic MilosNoch keine Bewertungen

- Design of Machine Members Short Questions 1. Desgin of BearingsDokument3 SeitenDesign of Machine Members Short Questions 1. Desgin of BearingsAraveetiCSReddyNoch keine Bewertungen

- Te 2019 DTSDokument6 SeitenTe 2019 DTSVishalNoch keine Bewertungen

- Hydrostatic & Hydrodynamic Bearing: Name:Kalani Mitesh H. Machine Tool EnggDokument12 SeitenHydrostatic & Hydrodynamic Bearing: Name:Kalani Mitesh H. Machine Tool EnggMitesh KalaniNoch keine Bewertungen

- Design of Machine Elements Study MaterialDokument190 SeitenDesign of Machine Elements Study MaterialR Raj Singh SinghNoch keine Bewertungen

- Lubricant SlidesDokument34 SeitenLubricant SlidesDinesh Kumar GattuNoch keine Bewertungen

- Module 4 Part 1Dokument72 SeitenModule 4 Part 1Vighnesh SNoch keine Bewertungen

- A Bi - Directional Gas Thrust BearingDokument9 SeitenA Bi - Directional Gas Thrust Bearingshahir93Noch keine Bewertungen

- Slide Bearings - Johnson MetallDokument5 SeitenSlide Bearings - Johnson Metallpablo.perez.fuentes5840Noch keine Bewertungen

- Fundamentals of Rotating EquipmentDokument61 SeitenFundamentals of Rotating EquipmentFery HartantoNoch keine Bewertungen

- Chapter 04 SealDokument25 SeitenChapter 04 Sealdewidar1234100% (1)

- Bearing Failure AnalysisDokument26 SeitenBearing Failure AnalysisengrsurifNoch keine Bewertungen

- Engineering Chemistry Unit 3 Lubricants Notes PDFDokument11 SeitenEngineering Chemistry Unit 3 Lubricants Notes PDFbhanu100% (1)

- Unit I DTS - Journal BearingDokument19 SeitenUnit I DTS - Journal BearingsathiaNoch keine Bewertungen