Beruflich Dokumente

Kultur Dokumente

Internal Thread Measurement

Hochgeladen von

Ahmed Al-SahafiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Internal Thread Measurement

Hochgeladen von

Ahmed Al-SahafiCopyright:

Verfügbare Formate

Engineering Research Center for

Reconfigurable Manufacturing Systems

Internal Thread Measurement

Dr. Reuven Katz, Dr. Hongwei

g Zhang

g and Dr. En Hong

g

Mar. 16, 2009

The University of Michigan, College of Engineering

Project Overview

Goals:

• Develop methodologies for the inspection of geometrical features of

internal threads in machined automotive parts.

Deliverables and benefits

• The two methods to be presented enable in-process internal thread

q alit verification

quality erification using

sing optical sensors.

sensors

• The approaches allow to extract thread pitch, major and minor diameter,

flank angle and even the starting point of the thread with respect to a

reference location on the perimeter.

perimeter

Main tasks

• Laser scan measurement using Optimet sensor

• Optical inspection using a CCD camera with sightpipe

• R&R test to be done partially

NSF Engineering Research Center for Reconfigurable Manufacturing Systems 2

University of Michigan College of Engineering

Methodology using a laser sensor and set-up

Principle

Internal Thread

Z axis

Rotary

Rotary

Probe

Motion Mirror

OpticalS

ensor X axis

Z

Y Motorized

Rotary Stage

Motion Stages periscope

X Y axis

Rotary Motion Stages

Motion

Method:

Periscope

Measuring internal threads using a Laser Range Finder (Optimet Sensor)

Sensor

integrated with a motorized periscope designed at ERC.

45˚ Mirror inside

Stepper Motor

NSF Engineering Research Center for Reconfigurable Manufacturing Systems 3

University of Michigan College of Engineering

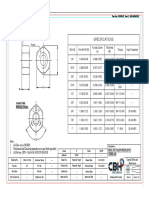

Measurements results of M12X1.25 internal thread

STANDARD: ANSI/ASME B1.13M-1983 (R1995)

M12 X 1.25 Unit: mm

Minor Diameter --D1 Pitch Diameter --D2 Major Diameter --D

Min

Min. Max

Max. Min

Min. Max

Max. Tol

Tol. Min

Min. Max

Max.

10.647 10.912 11.188 11.368 0.18 12 12.360

Measured Parameters

0˚ 180˚ 90˚ 270˚ Average

Major Dia.

Minor Dia.

Pitch (mm) 1.248 1.251 1.252 1.246 1.249

Height (mm) 0.639 0.696 0.539 0.615 0.622

Major Dia. (mm) 12.014 12.127 12.071

Minor Dia

Dia. (mm) 10 667

10.667 10 871

10.871 10 769

10.769 Δ Pitch

Conclusion 1:

Compared to the standard data, all the parameters we get are

within acceptable limits for the designated thread type. axial cross section

NSF Engineering Research Center for Reconfigurable Manufacturing Systems 4

University of Michigan College of Engineering

Measurements results of starting location of a thread

Method:

• Measuring the axial distance between the edge of the threaded

bore and the center point of the bottom of the first thread tooth.

• Four measurements were taken at four different angles. The area

of thread started is determined by comparing these four values.

90˚ Δ=2.288

• Theoretically, the largest and smallest must be neighbors and the Area of

starting

t ti point

i t off the

th thread

th d iis llocated

t dbbetween

t th

them. Thread Started

II I

180˚ Δ=1.942 0˚ Δ=2.531

Conclusion 2:

III IV

* The starting point of the thread is located in quadrant IV.

* The helix is clockwise. 270˚ Δ=1.384

radial cross section

NSF Engineering Research Center for Reconfigurable Manufacturing Systems 5

University of Michigan College of Engineering

Methodology and setup based on a CCD and a Sight-pipe

360 degree view from

the sight pipe Selected annular zone Reconstruct final

image

Lens & Illumination

Sight Pipe

Define the annular Zone of Extract and unwrap the Stitching Line strip CCD

each Frame annular Zone of each

Frame

360-degree-view Line Scan Flow

Tilt Stages

Motion stages

LED

Illumination Internal Thread Measurement System

Conical Lens

Optical principle of the sight-Pipe

The integrated sensor

NSF Engineering Research Center for Reconfigurable Manufacturing Systems 6

University of Michigan College of Engineering

Measurements results

1. A smoothing filter followed by Prewitt filter is used to bring out edges.

2. LabVIEW Shape detection is used to extract average angle of threads.

3. A series of line profiles are generated perpendicular to the thread

lines and peaks are detected.

NSF Engineering Research Center for Reconfigurable Manufacturing Systems 7

University of Michigan College of Engineering

Discussion on Method 2 (3D Digitalization)

NSF Engineering Research Center for Reconfigurable Manufacturing Systems 8

University of Michigan College of Engineering

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Aircraft HardwareDokument103 SeitenAircraft HardwareJuly Tade100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Manual Do Sax Yamaha PDFDokument144 SeitenManual Do Sax Yamaha PDFIlmar Ferreira100% (4)

- Asme B1.3-2007 (2017)Dokument24 SeitenAsme B1.3-2007 (2017)jamie courney100% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Astm F 1145Dokument12 SeitenAstm F 1145Amine Hamdi100% (1)

- M271 Bolted Connections Excel Calculations Bolt Tension: © Copy Write John Andrew P.E. 4 March 2008 Rev. 11 Feb 2012Dokument36 SeitenM271 Bolted Connections Excel Calculations Bolt Tension: © Copy Write John Andrew P.E. 4 March 2008 Rev. 11 Feb 2012John MoralesNoch keine Bewertungen

- Ibong Tiririt (MDSP 2)Dokument10 SeitenIbong Tiririt (MDSP 2)Stephanie ParkNoch keine Bewertungen

- Tapered Thread Inspection - Tubing, Casing, &: Required EquipmentDokument1 SeiteTapered Thread Inspection - Tubing, Casing, &: Required EquipmentTulio WeverNoch keine Bewertungen

- 8209-Models D, DA, DAB and DB Retainer Production Packers FoDokument12 Seiten8209-Models D, DA, DAB and DB Retainer Production Packers Fodanonnino0% (1)

- SSS CLUTCH 10T S Short Shaft Instructions 270907 PDFDokument4 SeitenSSS CLUTCH 10T S Short Shaft Instructions 270907 PDFferayiNoch keine Bewertungen

- Technical Catalog Sandwich Panels Paneltech 2020.1Dokument88 SeitenTechnical Catalog Sandwich Panels Paneltech 2020.1cheikh ahmed Mohamed NagimNoch keine Bewertungen

- Safety Breakaway CouplingsDokument16 SeitenSafety Breakaway CouplingsBerniceNoch keine Bewertungen

- Problems Sheet Machine Tools 2015 16Dokument9 SeitenProblems Sheet Machine Tools 2015 16Shafiq AhmadNoch keine Bewertungen

- VARGUS General CatalogDokument420 SeitenVARGUS General Catalogsaepudin 40Noch keine Bewertungen

- Bolt On Wear Runners and BasesDokument2 SeitenBolt On Wear Runners and Basescarlos hernandezastNoch keine Bewertungen

- Design of Machine Elements PageDokument203 SeitenDesign of Machine Elements PageKrishnan P MNoch keine Bewertungen

- Threads and Thread Cutting Operations: Arul R ApmechDokument22 SeitenThreads and Thread Cutting Operations: Arul R ApmecharulsivagiriNoch keine Bewertungen

- Das Buch Zur Uhr M5-E-Doppelseite-InternetDokument59 SeitenDas Buch Zur Uhr M5-E-Doppelseite-InternetY LoNoch keine Bewertungen

- TDS 011 Metric ProductsDokument2 SeitenTDS 011 Metric ProductsRohan KulkarniNoch keine Bewertungen

- Tabella D-1 Asme b1.1 2003Dokument7 SeitenTabella D-1 Asme b1.1 2003Ru MonNoch keine Bewertungen

- Ridgid 12RDokument1 SeiteRidgid 12RFindy SetiawanNoch keine Bewertungen

- Determining Dimensions of "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Pipe and FittingsDokument4 SeitenDetermining Dimensions of "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Pipe and FittingsVikas TiwariNoch keine Bewertungen

- 2019 Winter Model Answer PaperDokument21 Seiten2019 Winter Model Answer PaperIsmail TanteNoch keine Bewertungen

- Specifications: Hex Nuts (Inches) Unc ThreadDokument2 SeitenSpecifications: Hex Nuts (Inches) Unc ThreadqualityNoch keine Bewertungen

- T.E (2015 Pattern)Dokument256 SeitenT.E (2015 Pattern)SanketNoch keine Bewertungen

- Ms 01 180Dokument88 SeitenMs 01 180FabricioNoch keine Bewertungen

- Threading Inserts and GradesDokument3 SeitenThreading Inserts and GradeskarthikeyanNoch keine Bewertungen

- Refined Rolled Thread Bar-Rock BoltDokument10 SeitenRefined Rolled Thread Bar-Rock Boltzhongkeqin16Noch keine Bewertungen

- Chapter Two Power Screw Theory and CalculationsDokument5 SeitenChapter Two Power Screw Theory and Calculationsgeorge chirumeNoch keine Bewertungen

- Calculating Tapping Drill Sizes 2Dokument9 SeitenCalculating Tapping Drill Sizes 2Moh RhmNoch keine Bewertungen

- Technical Manual Adjustable Choke MANUAL006-1 PDFDokument51 SeitenTechnical Manual Adjustable Choke MANUAL006-1 PDFanwarhas05Noch keine Bewertungen