Beruflich Dokumente

Kultur Dokumente

Av 05

Hochgeladen von

davidbejuOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Av 05

Hochgeladen von

davidbejuCopyright:

Verfügbare Formate

790-Airvents keyline 6/19/00 1:36 PM Page AV-5

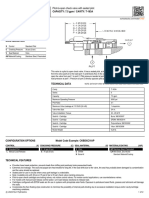

1-AVC See-Thru Air Vent

For Pressures to 150 psig (7 bar) or Specific Gravity Down to 0.80

Alternate

Inlet

Outlet

B

C

Inlet

1-AVC

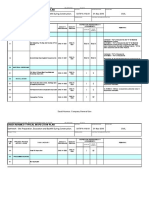

A See-Thru Body—So You’ll Know When It’s Working Efficient Operation

Now, you can literally see what you’ve been missing—the Simple ball float mechanism discharges only when air is

early warning signs of a system problem. Since you’ll know present so it doesn’t waste liquid.

the operating condition of the air vent, you won’t have to

waste time and money scheduling maintenance that isn’t Positive Seating

needed. In other words, you will be able to react to a Free-floating valve mechanism assures positive seating

condition before it becomes a problem. so it prevents liquid loss. There are no fixed pivots to wear

or create friction, and wear points are heavily reinforced

A simple ball float mechanism requiring no electricity to for long life.

operate, the new Armstrong 1-AVC discharges automatically

only when air/gas are present. That means no liquid loss as Reduced Maintenance

with manual venting. Stainless steel internals mean corrosion resistance and

reduced maintenance.

An Inside Look

See-thru body means you can observe changing conditions Corrosion Resistance

as they occur. See a problem in the making—instead of having Long-lasting polysulfone body and reinforced nylon cap

to deal with it after the fact. resist corrosion and provide long, trouble-free service life.

Compare… and Save the Difference

Seeing is really believing—especially when you compare

List of Materials the Armstrong see-thru air vent with manual venting.

Name of Part Material Measure the differences in the time and money you can

Cap Reinforced Nylon save with a more efficient, easier-to-maintain system.

Body Polysulfone* For more information or technical assistance, contact

O-Rings (Body Cap and Fitting) Nitrile Elastome Compound your local Armstrong Representative.

Float Lever and Screws Stainless Steel

Valve & Seat Stainless Steel NOTE: The Armstrong 1-AVC should not be used in an

Fitting & Pipe Plug Reinforced Nylon environment where there are high levels of ketones or

Retainer Ring Zinc Plated Steel chlorinated or aromatic hydrocarbons.

*UV sensitive.

Air Vents

Physical Data Model 1-AVC Capacity

in mm Differential Pressure

Orifice Size scfm m3/hr

Inlet Connection 1/2, 3/4 15, 20 psig bar

Outlet Connection 1/2 15 15 1.0 4.3 7.3

A Face-to-Face 3-1/2 89 30 2.0 6.5 11.0

B Height 6-3/4 171 50 3.5 9.5 16.1

C Bottom to CL 6 152 75 5.0 1/8" 13.1 22.2

Maximum Allowable Pressure 150 psig @ 150°F

100 7.0 16.9 28.7

(Vessel Design) (10 bar @ 65°C)

125 8.5 20.5 34.8

Maximum Operating Pressure 150 psi (10 bar)

150 10.5 24.3 41.3

Specific Gravity Range 1.00 to 0.80

NOTE: Discharge of air through an orifice in scfm (standard cubic feet of free air

Weight, lb (kg) 1 (.45) per minute) at a standard atmospheric pressure of 14.7 psi (1 bar) and 70°F (21°C).

All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice.

Armstrong International, Inc., 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (616) 273-1415 Fax: (616) 278-6555

AV-5 www.armstrong-intl.com

Next

Das könnte Ihnen auch gefallen

- Navistar DT466 Engine CatalogDokument36 SeitenNavistar DT466 Engine CatalogClifton Jamison88% (16)

- DIN 76-1 - (2004) - Thread Run-Outs and Thread Undercuts For ISO Metric Threads As in DIN 13-1 PDFDokument5 SeitenDIN 76-1 - (2004) - Thread Run-Outs and Thread Undercuts For ISO Metric Threads As in DIN 13-1 PDFnoraafshin100% (2)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryVon EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNoch keine Bewertungen

- FP Diesel International Navistar Engines - DigipubZDokument212 SeitenFP Diesel International Navistar Engines - DigipubZdavidbeju100% (7)

- 8HP45Dokument8 Seiten8HP45Adrian Biasussi Biasuzzi100% (7)

- 1-AVC See-Thru Air Vent: Inlet Alternate Inlet OutletDokument1 Seite1-AVC See-Thru Air Vent: Inlet Alternate Inlet Outletalexander ferraoNoch keine Bewertungen

- Pneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServiceDokument2 SeitenPneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServicedmitosNoch keine Bewertungen

- Alarm Valve DetailsDokument5 SeitenAlarm Valve DetailsRoshan JaiswalNoch keine Bewertungen

- Company Profile (ACE VALVE)Dokument20 SeitenCompany Profile (ACE VALVE)DDFSFNoch keine Bewertungen

- Deluge Valve Installation ManualDokument7 SeitenDeluge Valve Installation Manualrahull.miishraNoch keine Bewertungen

- Vickers DCV With Manual LatchDokument12 SeitenVickers DCV With Manual LatchIon Logofătu AlbertNoch keine Bewertungen

- ITAPTECH AUTOMATIC-AIR-VENT EngDokument14 SeitenITAPTECH AUTOMATIC-AIR-VENT EngCarlos EspNoch keine Bewertungen

- BHMY 2x1 Flowgrid SP FS 34016A 1120 EnglishDokument2 SeitenBHMY 2x1 Flowgrid SP FS 34016A 1120 EnglishLuis Alberto Portugal MariacalNoch keine Bewertungen

- RNP Actuator Metso NewDokument11 SeitenRNP Actuator Metso NewOGPE-AMC1Noch keine Bewertungen

- 1.butterfly ValveDokument3 Seiten1.butterfly ValveRudy Nizama RosellNoch keine Bewertungen

- WHA-1260XL Water Hammer ZurnDokument2 SeitenWHA-1260XL Water Hammer ZurnJeffry GabilanNoch keine Bewertungen

- Relief Valve 500 ES1196-1Dokument5 SeitenRelief Valve 500 ES1196-1Jhon GuerreroNoch keine Bewertungen

- HBE Anti FlashDokument3 SeitenHBE Anti Flashinsult2injuryNoch keine Bewertungen

- Related Products: Auto Drain Valve: PrecautionsDokument10 SeitenRelated Products: Auto Drain Valve: Precautionsteknik otomotifNoch keine Bewertungen

- Model 1260XL: Water Hammer ArresterDokument2 SeitenModel 1260XL: Water Hammer ArresterAbou Backar Sittique JNoch keine Bewertungen

- Air Compressor Manual PDFDokument14 SeitenAir Compressor Manual PDFLa ErNoch keine Bewertungen

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDokument2 SeitenModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNoch keine Bewertungen

- Omni Sleeve Wall Pipe Penetration Sleeve: SIGMA CorporationDokument4 SeitenOmni Sleeve Wall Pipe Penetration Sleeve: SIGMA CorporationJojolasNoch keine Bewertungen

- 07 ValvesDokument33 Seiten07 Valvesshiva_ssk17Noch keine Bewertungen

- Air Valve CombinationDokument3 SeitenAir Valve CombinationFun TonNoch keine Bewertungen

- Caleffi: Water Hammer ArresterDokument4 SeitenCaleffi: Water Hammer ArresterMohamad ItaniNoch keine Bewertungen

- Descarga 1er Paso Mercer 91-52j11t84u1Dokument16 SeitenDescarga 1er Paso Mercer 91-52j11t84u1Alberto Esau Reyes CruzNoch keine Bewertungen

- 701-10-001 2021-12-01 Avkcms en 430686Dokument2 Seiten701-10-001 2021-12-01 Avkcms en 430686bre brilianNoch keine Bewertungen

- CTLCTDokument2 SeitenCTLCTgumustuNoch keine Bewertungen

- Royal Model Flushometer: BG U XYV YJ YKDokument1 SeiteRoyal Model Flushometer: BG U XYV YJ YKMohammed BasheeruddinNoch keine Bewertungen

- AVK-S 45-00 - NRS-ANSI FL Flat FaceDokument2 SeitenAVK-S 45-00 - NRS-ANSI FL Flat FaceAhmed Said IbrahimNoch keine Bewertungen

- Electric Actuated Butterfly Valves: FeaturesDokument7 SeitenElectric Actuated Butterfly Valves: FeaturesRicardo NapitupuluNoch keine Bewertungen

- DemblaDokument12 SeitenDemblaISHAN VERMANoch keine Bewertungen

- 2way/2 - Part IIIDokument2 Seiten2way/2 - Part IIIYidel FloresNoch keine Bewertungen

- Dust Collector Main Pulse Valves: FeaturesDokument4 SeitenDust Collector Main Pulse Valves: FeaturesQuân TrịnhNoch keine Bewertungen

- Structural: Composite Pressure VesselsDokument4 SeitenStructural: Composite Pressure Vesselswacsii ccasullaNoch keine Bewertungen

- Model Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADokument2 SeitenModel Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AVignesh PandiyanNoch keine Bewertungen

- CKBDXCV ApDokument2 SeitenCKBDXCV ApŁukasz OlszewskiNoch keine Bewertungen

- Avcon Solenoid IndiaDokument2 SeitenAvcon Solenoid Indiajhon manurungNoch keine Bewertungen

- Tom Wheatley Piston Check Valves BrochureDokument8 SeitenTom Wheatley Piston Check Valves BrochureRandiRahmansyahNoch keine Bewertungen

- Parker Oil X FilterDokument4 SeitenParker Oil X FilterVijay Pawar Innovative TechnologiesNoch keine Bewertungen

- Watts Sok OnleyicilerDokument8 SeitenWatts Sok OnleyicilerErdinc KlimaNoch keine Bewertungen

- Клапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnDokument12 SeitenКлапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnAli KianersiNoch keine Bewertungen

- Solenoid Valve VSVA-B-M52-AZD-A2-1T1L: Data SheetDokument2 SeitenSolenoid Valve VSVA-B-M52-AZD-A2-1T1L: Data Sheetedinson villanueva santistebanNoch keine Bewertungen

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADokument2 SeitenModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AAnurag JainNoch keine Bewertungen

- Automatic Air Release Valve For Low PressureDokument2 SeitenAutomatic Air Release Valve For Low PressuresijilNoch keine Bewertungen

- Assembly ReportDokument2 SeitenAssembly ReportKatherine Toloza AcostaNoch keine Bewertungen

- Asco Dust Collector Main Pulse Valves DC CatalogDokument4 SeitenAsco Dust Collector Main Pulse Valves DC CatalogFelipe SalvatierraNoch keine Bewertungen

- Asco Series 290 Angle Body CatalogDokument10 SeitenAsco Series 290 Angle Body CatalogcillongNoch keine Bewertungen

- Jamesbury Ball Valves PDFDokument20 SeitenJamesbury Ball Valves PDFGabriel Andrés Barcha Angulo100% (1)

- Mercer Valve 9100 Relief Valve Flanged AEDokument16 SeitenMercer Valve 9100 Relief Valve Flanged AEChristopher Kenneth ChoaNoch keine Bewertungen

- Av11 Av13airventsDokument1 SeiteAv11 Av13airventskicsnerNoch keine Bewertungen

- Air and Water Solenoid Valves: NC NODokument4 SeitenAir and Water Solenoid Valves: NC NODevinNoch keine Bewertungen

- Valtek Maxflo: Control ValvesDokument11 SeitenValtek Maxflo: Control Valvessaroat moongwattanaNoch keine Bewertungen

- Ba BM: Backflow Preventer With Verifiable Reduced Pressure Zone With Funnel IncorporatedDokument4 SeitenBa BM: Backflow Preventer With Verifiable Reduced Pressure Zone With Funnel IncorporatedPriyanka rajpurohitNoch keine Bewertungen

- Leaftlet OneStop+ 2022Dokument3 SeitenLeaftlet OneStop+ 2022smenamorado27Noch keine Bewertungen

- Oxywise Oxygen GeneratorDokument2 SeitenOxywise Oxygen GeneratorAbrourNoch keine Bewertungen

- CH 10 Additional ProductsDokument47 SeitenCH 10 Additional Productssaddam khanNoch keine Bewertungen

- Ball Valve (Maxflow)Dokument16 SeitenBall Valve (Maxflow)vishnuNoch keine Bewertungen

- Mooney Flowgrid Valve: Technical Specifications 12/2018Dokument2 SeitenMooney Flowgrid Valve: Technical Specifications 12/2018Luis Yovany Aldana PonceNoch keine Bewertungen

- SVPL Catalogue - Compressed PDFDokument33 SeitenSVPL Catalogue - Compressed PDFSales SVPLNoch keine Bewertungen

- Butterfly Valves - CatalogDokument30 SeitenButterfly Valves - CatalogRamzi BEN AHMEDNoch keine Bewertungen

- Tomoe Valve-ManualDokument2 SeitenTomoe Valve-Manualphuc nguyenNoch keine Bewertungen

- VST - Axial Flow Catalog - 2021.R010Dokument6 SeitenVST - Axial Flow Catalog - 2021.R010Jaydeep PanchalNoch keine Bewertungen

- ANSI (See Sheets 2 & 3) CE (See Sheets 4 & 5) : TH255 Hydraulic Schematic UENR7968-02Dokument8 SeitenANSI (See Sheets 2 & 3) CE (See Sheets 4 & 5) : TH255 Hydraulic Schematic UENR7968-02davidbejuNoch keine Bewertungen

- S12 Water Flushing CircuitDokument24 SeitenS12 Water Flushing CircuitdavidbejuNoch keine Bewertungen

- 2.10.670 Brochure Doosan C185Dokument4 Seiten2.10.670 Brochure Doosan C185davidbejuNoch keine Bewertungen

- TH255 Eléctrico UENR79670001Dokument11 SeitenTH255 Eléctrico UENR79670001davidbejuNoch keine Bewertungen

- S01 Hydraulic CartridgesDokument40 SeitenS01 Hydraulic CartridgesdavidbejuNoch keine Bewertungen

- Spare Parts Manual L17D6673Dokument4 SeitenSpare Parts Manual L17D6673davidbejuNoch keine Bewertungen

- 2017 Mule Pro - DXT (Diesel) KAF1000AHF: Parts ManualDokument139 Seiten2017 Mule Pro - DXT (Diesel) KAF1000AHF: Parts Manualdavidbeju0% (1)

- CFD Analysis of Centrifugal Pump A Revie PDFDokument4 SeitenCFD Analysis of Centrifugal Pump A Revie PDFNecdet DemiralpNoch keine Bewertungen

- 4 Bomba de FrenoDokument2 Seiten4 Bomba de FrenodavidbejuNoch keine Bewertungen

- Bearing Interchange Guide 7536Dokument395 SeitenBearing Interchange Guide 7536Misho IvanovNoch keine Bewertungen

- Eaton Fuller Rtx-14715Dokument43 SeitenEaton Fuller Rtx-14715davidbeju100% (1)

- FalkDokument8 SeitenFalkjmartinezmoNoch keine Bewertungen

- Link Belt Spherical Roller BearingDokument10 SeitenLink Belt Spherical Roller BearingdavidbejuNoch keine Bewertungen

- Cat 2 Micron Pehp9522 - 01Dokument4 SeitenCat 2 Micron Pehp9522 - 01sanigzl100% (1)

- Retenedor CR p26Dokument1 SeiteRetenedor CR p26davidbejuNoch keine Bewertungen

- Offshore Access To America's Oil and Natural Gas ResourcesDokument13 SeitenOffshore Access To America's Oil and Natural Gas ResourcesEnergy Tomorrow100% (6)

- Chicago Rawhide Oil Seals R25Dokument1 SeiteChicago Rawhide Oil Seals R25davidbejuNoch keine Bewertungen

- Guia ILAC G24 - Determination of Calibration-Intervals of Measuring Instruments - 2007Dokument11 SeitenGuia ILAC G24 - Determination of Calibration-Intervals of Measuring Instruments - 2007Kelly de Souza SilvaNoch keine Bewertungen

- Computer Crime: What Is Security ?Dokument49 SeitenComputer Crime: What Is Security ?Husein KattabNoch keine Bewertungen

- Medidor AC 630 PDFDokument2 SeitenMedidor AC 630 PDFRoxi GonzalesNoch keine Bewertungen

- AbstractDokument4 SeitenAbstractVaibhav GawandeNoch keine Bewertungen

- ItishDokument140 SeitenItishGabriel Cano100% (6)

- Screw ConveyorDokument5 SeitenScrew ConveyorEDUARDO100% (3)

- Magnetic Field Sensor MB60-12GM50-E2: DimensionsDokument4 SeitenMagnetic Field Sensor MB60-12GM50-E2: DimensionsHemant RasamNoch keine Bewertungen

- Jig and FixtureDokument38 SeitenJig and FixtureNaman Dave100% (1)

- BP Cat Feb09 ContactorsContactsDokument25 SeitenBP Cat Feb09 ContactorsContactssaqibmaxNoch keine Bewertungen

- IEC 61724-1 - Monitoreo de Sistemas FotovoltaicosDokument62 SeitenIEC 61724-1 - Monitoreo de Sistemas FotovoltaicosJhonny Richard Verdugo RodríguezNoch keine Bewertungen

- Moi Truong Chromogenic Coliform AgarDokument5 SeitenMoi Truong Chromogenic Coliform AgarNgoc Tuan HaNoch keine Bewertungen

- Safety Assessment of Foreign Aircraft - NotesDokument8 SeitenSafety Assessment of Foreign Aircraft - NotesBasharat UllahNoch keine Bewertungen

- SMS Bundle OfferDokument4 SeitenSMS Bundle OfferWaseem KhanNoch keine Bewertungen

- Electrical Specifications, Division 16, SECTION 16425 SWITCHGEAR ASSEMBLIES MAIN DISTRIBUTION BOARDDokument21 SeitenElectrical Specifications, Division 16, SECTION 16425 SWITCHGEAR ASSEMBLIES MAIN DISTRIBUTION BOARDeng_asayedNoch keine Bewertungen

- Samba As A Print Server - SambaWikiDokument7 SeitenSamba As A Print Server - SambaWikibernamorilloNoch keine Bewertungen

- Fatpipe Wanoptimization BrochureDokument4 SeitenFatpipe Wanoptimization BrochureAndres ShaonNoch keine Bewertungen

- SD 9100G PDFDokument65 SeitenSD 9100G PDFkirilla2006Noch keine Bewertungen

- Ip-10 Cli Command LineDokument9 SeitenIp-10 Cli Command Linedipaksahoo4025100% (2)

- Owner'S Manual: Netcontroller Console KVM and Rackmount KVM SwitchesDokument36 SeitenOwner'S Manual: Netcontroller Console KVM and Rackmount KVM SwitchesGabriel GamezNoch keine Bewertungen

- Satip A 114 01 Earth WorkDokument11 SeitenSatip A 114 01 Earth WorkZia ur RehmanNoch keine Bewertungen

- Motor Protection and ControlDokument6 SeitenMotor Protection and Controlaanup_2011Noch keine Bewertungen

- P6Blade NIB121509 V2Dokument24 SeitenP6Blade NIB121509 V2darkmountaincloudNoch keine Bewertungen

- CV - Jean-Claude Mulobe NgoyDokument4 SeitenCV - Jean-Claude Mulobe NgoyMarclauryn AdewaleNoch keine Bewertungen

- Linked List: Singly, Doubly and CircularDokument53 SeitenLinked List: Singly, Doubly and CircularMia SamNoch keine Bewertungen

- Tolerances and Limits For Construction Drilling and Sawing: Edition E Second Edition May 2006 FinalDokument8 SeitenTolerances and Limits For Construction Drilling and Sawing: Edition E Second Edition May 2006 FinalvazrodriNoch keine Bewertungen

- Maintenance Management of Electrical Equipment Condition Monitoring Based Part 1Dokument5 SeitenMaintenance Management of Electrical Equipment Condition Monitoring Based Part 1Abdan ShidqiNoch keine Bewertungen

- Grading and ReportingDokument25 SeitenGrading and ReportingLcc-dnc BedNoch keine Bewertungen

- GS1 System of StandardsDokument32 SeitenGS1 System of StandardsJavier RomerolNoch keine Bewertungen