Beruflich Dokumente

Kultur Dokumente

Testing Parallelism of Micrometer Measuring Faces: Quick Guide To Measurement

Hochgeladen von

puneetOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Testing Parallelism of Micrometer Measuring Faces: Quick Guide To Measurement

Hochgeladen von

puneetCopyright:

Verfügbare Formate

Testing Parallelism of Micrometer Measuring Faces 4.

4. Wipe off the measuring faces of both the anvil and spindle with

lint-freepaper set the start (zero) point before measuring.

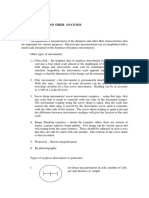

Optical parallel reading direction on the spindle side

PG

11

Optical parallel

Fringes on the spindle side

Parallelism can be estimated using an optical parallel held between the faces.

Firstly, wring the parallel to the anvil measuring face. Then close the spindle

on the parallel using normal measuring force and count the number of red

interference fringes seen on the measuring face of the spindle in white light. Each 5. Wipe away any dust, chips and other debris from the circumference and

fringe represents a half wavelength difference in height (0.32μm for red fringes). measuring face of the spindle as part of daily maintenance. In addition,

In the above figure a parallelism of approximately 1µm is obtained from 0.32µm sufficiently wipe off any stains and fingerprints on each part with dry cloth.

x 3=0.96µm. 6. Use the constant-force device correctly so that measurements are performed

with the correct measuring force.

アンビル側

Testing Flatness of Micrometer Measuring Faces 7. When attaching the micrometer onto a micrometer stand, the stand should

clamp the center of the micrometer frame. Do not clamp it too tightly.

Flatness can be estimated using an optical flat (or parallel) held against a face.

Count the number of red interference fringes seen on the measuring face

in white light. Each fringe represents a half wavelength difference in height

(0.32μm for red).

Interference fringe

reading direction

Optical flat Optical flat

Anvil Anvil

Measuring face is curved by approximately Measuring face is concave (or convex) approximately

1.3μm. (0.32μm x 4 paired red fringes.) 0.6μm deep. (0.32μm x 2 continuous fringes)

General notes on using the micrometer

1. Carefully check the type, measuring range, accuracy, and other specifications

to select the appropriate model for your application.

2. Leave the micrometer and workpiece at room temperature long enough for

their temperatures to equalize before making a measurement. 8. Be careful not to drop or bump the micrometer on anything. Do not rotate

3. Look directly at the fiducial line when taking a reading against the thimble the micrometer thimble using excessive force. If you believe a micrometer

graduations. may have been damaged due to accidental mishandling, ensure that it is

If the graduation lines are viewed from an angle, the correct alignment inspected for accuracy before further use.

position of the lines cannot be read due to parallax error. 9. After a long storage period or when there is no protective oil film visible,

lightly apply anti-corrosion oil to the micrometer by wiping with a cloth

soaked in it.

(b)

10. Notes on storage:

(a) Avoid storing the micrometer in direct sunlight.

(c) Store the micrometer in a ventilated place with low humidity.

Store the micrometer in a place with little dust.

Store the micrometer in a case or other container, which should not be kept

Thimble (a) From above the index line on the floor.

Sleeve When storing the micrometer, always leave a gap of 0.1 to 1 mm between

the measuring faces.

Do not store the micrometer in a clamped state.

(b) Looking directly at the index line

(c) From below the index line

Quick Guide to Measurement

Das könnte Ihnen auch gefallen

- A) Micro Meter Srew Gauge: Micrometer Screw Gauge, Is A Device Incorporating A Calibrated Screw Widely Used ForDokument14 SeitenA) Micro Meter Srew Gauge: Micrometer Screw Gauge, Is A Device Incorporating A Calibrated Screw Widely Used ForSapun SomarathnaNoch keine Bewertungen

- CP-004 - Calibration of External MicrometerDokument5 SeitenCP-004 - Calibration of External MicrometerSUNIL100% (1)

- Fresnel'S Biprism: Experiment 7Dokument7 SeitenFresnel'S Biprism: Experiment 7Tech TalkNoch keine Bewertungen

- Auto Collimator TestDokument5 SeitenAuto Collimator TestRaghavendra ReddyNoch keine Bewertungen

- PDF Manual190+160Dokument15 SeitenPDF Manual190+160torbenNoch keine Bewertungen

- Micrometer and Vernier Caliper Instruciion SheetDokument1 SeiteMicrometer and Vernier Caliper Instruciion Sheetketha056.302Noch keine Bewertungen

- Micrometer and Slip GaugeDokument17 SeitenMicrometer and Slip GaugeKrishh GuptaNoch keine Bewertungen

- TVET 1 (Worksheet 4)Dokument5 SeitenTVET 1 (Worksheet 4)Abrigondo, Vindel J.Noch keine Bewertungen

- Cp-005-Calibration of Internal MicrometerDokument5 SeitenCp-005-Calibration of Internal MicrometerSUNILNoch keine Bewertungen

- Murali - Metrology & Measurements Lab ManualDokument30 SeitenMurali - Metrology & Measurements Lab ManualsubhashNoch keine Bewertungen

- IAS Physics - Study Note 11 - MeasurementsDokument4 SeitenIAS Physics - Study Note 11 - Measurementsthriyampakan dhivyakrishnanNoch keine Bewertungen

- Sapun Tool Assessment Eg-3012Dokument17 SeitenSapun Tool Assessment Eg-3012Sapun SomarathnaNoch keine Bewertungen

- Micrometer Screw GaugeDokument13 SeitenMicrometer Screw GaugeLugafloNoch keine Bewertungen

- (Drawings Are in The PDF) : Worksheet No. 4A MicrometersDokument5 Seiten(Drawings Are in The PDF) : Worksheet No. 4A MicrometersNeal John VillarmenteNoch keine Bewertungen

- Instruction ReportDokument2 SeitenInstruction Reportapi-592929885Noch keine Bewertungen

- Calibration MicroscopeDokument6 SeitenCalibration MicroscopeJeAyuSPutri100% (1)

- How To Use Micrometer On Microscopes: Biology 1Dokument7 SeitenHow To Use Micrometer On Microscopes: Biology 1Rakeesh VeeraNoch keine Bewertungen

- Profile Projector 300 Small Final 2020Dokument5 SeitenProfile Projector 300 Small Final 2020Ashish VermaNoch keine Bewertungen

- A Spherometer of Precision: Home Search Collections Journals About Contact Us My IopscienceDokument10 SeitenA Spherometer of Precision: Home Search Collections Journals About Contact Us My IopscienceAyu MardianaNoch keine Bewertungen

- MicrometerDokument3 SeitenMicrometerJanno MallariNoch keine Bewertungen

- Experiment No. 3: Angle Measurement Metrology & Instrumentation (3341905)Dokument7 SeitenExperiment No. 3: Angle Measurement Metrology & Instrumentation (3341905)T.MNoch keine Bewertungen

- Micrometer Screw GaugeDokument4 SeitenMicrometer Screw GaugeElyse Kymberly TeohNoch keine Bewertungen

- Profile Projector: Dynamics of Machine LaboratoryDokument4 SeitenProfile Projector: Dynamics of Machine LaboratoryAshish VermaNoch keine Bewertungen

- Lab 9Dokument18 SeitenLab 9UsamaNoch keine Bewertungen

- Micrometer CaliperDokument35 SeitenMicrometer Caliperaeronkenneth.montanoNoch keine Bewertungen

- Outside Micro MeterDokument4 SeitenOutside Micro Meterer.jit717Noch keine Bewertungen

- MQC Apparatus & MethodsDokument18 SeitenMQC Apparatus & MethodsNayemNoch keine Bewertungen

- Autocollimator Angle Dekkor: Mechanical Measurement and Metrology Prof. Naman M. DaveDokument24 SeitenAutocollimator Angle Dekkor: Mechanical Measurement and Metrology Prof. Naman M. DaveRaghavendra KilariNoch keine Bewertungen

- Micrometer ManualDokument3 SeitenMicrometer Manualjehoshaphat71Noch keine Bewertungen

- Calibration of Microscope - 2019Dokument3 SeitenCalibration of Microscope - 2019Gabrielle Robinson100% (2)

- Micrometers - Measurement System Types and Characteristics - Measurement Fundamentals - KEYENCE AmericaDokument1 SeiteMicrometers - Measurement System Types and Characteristics - Measurement Fundamentals - KEYENCE AmericaTatsNoch keine Bewertungen

- 2119 Product FundDokument20 Seiten2119 Product FundMukesh PadwalNoch keine Bewertungen

- Pocket Gage: User's Manual No.99MAG018B Series No.7300Dokument2 SeitenPocket Gage: User's Manual No.99MAG018B Series No.7300deregilNoch keine Bewertungen

- Experiment No.02Dokument21 SeitenExperiment No.02Raval DhruvNoch keine Bewertungen

- Surface TopographyDokument25 SeitenSurface Topographytumaini matandalaNoch keine Bewertungen

- PROFILE Projector 300 SMALLDokument4 SeitenPROFILE Projector 300 SMALLAshish VermaNoch keine Bewertungen

- Calibration Ocular Micrometer 508Dokument1 SeiteCalibration Ocular Micrometer 508JERICO . TAPIA100% (1)

- Surface Roughness PDFDokument16 SeitenSurface Roughness PDFkevinNoch keine Bewertungen

- Interaction Forces During The Sliding of A Water Droplet On A Textured SurfaceDokument4 SeitenInteraction Forces During The Sliding of A Water Droplet On A Textured Surfacedemy antonyNoch keine Bewertungen

- Manual AimpointDokument2 SeitenManual AimpointMogos RobertNoch keine Bewertungen

- 5.EMM Lab ManualDokument38 Seiten5.EMM Lab ManualRakeshkumarcegNoch keine Bewertungen

- Science Lab Manual Merged 1712032675Dokument43 SeitenScience Lab Manual Merged 1712032675yuvrajchopra178Noch keine Bewertungen

- Scales, Rules, Verniers and MicrometersDokument29 SeitenScales, Rules, Verniers and MicrometersHao DinhNoch keine Bewertungen

- Results For Laser InterferometryDokument3 SeitenResults For Laser InterferometrychetsNoch keine Bewertungen

- Sensor de Campo MagneticoDokument2 SeitenSensor de Campo Magneticooasto13101Noch keine Bewertungen

- MQA Lab Manual 2018-2019Dokument27 SeitenMQA Lab Manual 2018-2019poluri manicharanNoch keine Bewertungen

- Differentiate Between Line Standard and End Standard of Measurement 1Dokument19 SeitenDifferentiate Between Line Standard and End Standard of Measurement 1ghghgNoch keine Bewertungen

- Micrometro AjusteDokument2 SeitenMicrometro Ajustealvaro5Noch keine Bewertungen

- Micro Optic TheodoliteDokument28 SeitenMicro Optic TheodoliteVishal shingadeNoch keine Bewertungen

- Michel SonDokument8 SeitenMichel Sonsaba1388Noch keine Bewertungen

- MicrometryDokument4 SeitenMicrometryMofoluwaso Adedeji OyinloyeNoch keine Bewertungen

- PAG 06.2 - Experiments With LightDokument5 SeitenPAG 06.2 - Experiments With LightjmsonlNoch keine Bewertungen

- Calibration of Microscope - 2016Dokument2 SeitenCalibration of Microscope - 2016Amanda Sturridge100% (1)

- Instrument Care TrainingDokument35 SeitenInstrument Care Trainingbalram1979754798Noch keine Bewertungen

- 2nd Educational Article - Part 3Dokument22 Seiten2nd Educational Article - Part 3Francisco AugustoNoch keine Bewertungen

- Metrology-Lab-Manual 3 Year 1semDokument41 SeitenMetrology-Lab-Manual 3 Year 1semBHARATH Chandra100% (1)

- TITLE: Study & Calibration of Outside Micrometer and Introduction To Other MicromDokument29 SeitenTITLE: Study & Calibration of Outside Micrometer and Introduction To Other MicromMANISH DASNoch keine Bewertungen

- BIOBASE Biological Microscope BX-102 Series User ManualDokument12 SeitenBIOBASE Biological Microscope BX-102 Series User ManualVictor BlancoNoch keine Bewertungen

- Moiré Fringes in Strain Analysis: The Commonwealth and International Library: Applied Mechanics DivisionVon EverandMoiré Fringes in Strain Analysis: The Commonwealth and International Library: Applied Mechanics DivisionBewertung: 4 von 5 Sternen4/5 (1)

- Section A2 PDFDokument38 SeitenSection A2 PDFpuneetNoch keine Bewertungen

- Section A2 PDFDokument38 SeitenSection A2 PDFpuneetNoch keine Bewertungen

- ME8501 Metrology and Measurements PDFDokument93 SeitenME8501 Metrology and Measurements PDFpuneetNoch keine Bewertungen

- ME8501 Metrology and Measurements PDFDokument93 SeitenME8501 Metrology and Measurements PDFpuneetNoch keine Bewertungen

- Lecture 4 Metrology F 21-8-14Dokument20 SeitenLecture 4 Metrology F 21-8-14hari0118Noch keine Bewertungen

- (Fuel Injection in SI engine-B.Patil) Lecture-11-Converted-CompressedDokument16 Seiten(Fuel Injection in SI engine-B.Patil) Lecture-11-Converted-CompressedpuneetNoch keine Bewertungen

- AETPaperIIYR2 PDFDokument81 SeitenAETPaperIIYR2 PDFAnonymous 1aCZDEbMMNoch keine Bewertungen

- Automotive Suspension SystemsDokument20 SeitenAutomotive Suspension SystemsAkhil0% (1)

- Suspension 001Dokument26 SeitenSuspension 001Vincentius NikimNoch keine Bewertungen

- Business Correspondence For English 2aDokument14 SeitenBusiness Correspondence For English 2ajera garciaNoch keine Bewertungen

- 10 5923 J Jmea 20120206 05 PDFDokument9 Seiten10 5923 J Jmea 20120206 05 PDFpuneetNoch keine Bewertungen

- Career Form 1581335282Dokument11 SeitenCareer Form 1581335282puneetNoch keine Bewertungen

- G12 Online Brochure PDFDokument36 SeitenG12 Online Brochure PDFpuneetNoch keine Bewertungen

- Notice chsl2018 11092019 PDFDokument1 SeiteNotice chsl2018 11092019 PDFSrikanthrao MadarapuNoch keine Bewertungen

- Mechanical Engineering Pre 2013Dokument16 SeitenMechanical Engineering Pre 2013meetbalakumarNoch keine Bewertungen

- Transworld EnterprisesDokument13 SeitenTransworld EnterprisespuneetNoch keine Bewertungen

- List of Recruiters For 2018 2019Dokument5 SeitenList of Recruiters For 2018 2019puneetNoch keine Bewertungen

- Diesel Engine SystemsDokument23 SeitenDiesel Engine SystemsNitin GangwarNoch keine Bewertungen

- List of Recruiters For 2018 2019 PDFDokument5 SeitenList of Recruiters For 2018 2019 PDFpuneetNoch keine Bewertungen

- Mahindra Scientific IndustriesDokument6 SeitenMahindra Scientific IndustriespuneetNoch keine Bewertungen

- Du 8th Science CutoffDokument14 SeitenDu 8th Science CutoffpuneetNoch keine Bewertungen

- IIT Bombay Placement and Internship Report 2017-18Dokument25 SeitenIIT Bombay Placement and Internship Report 2017-18Romesh RajputNoch keine Bewertungen

- JATBMSBBAFIABAHonsBusinessEconomics ResDokument863 SeitenJATBMSBBAFIABAHonsBusinessEconomics RespuneetNoch keine Bewertungen

- Me 604Dokument44 SeitenMe 604Vinay DograNoch keine Bewertungen

- Leadership in 21st CenturyDokument17 SeitenLeadership in 21st Centuryraisandeep2006100% (1)

- Explosives Sazfety Seminar 1992 AD A261116Dokument634 SeitenExplosives Sazfety Seminar 1992 AD A261116lpayne100% (1)

- Evidence - 3 - Audio - Reading - Technical - Texts - To Pronounce - VocabularyDokument7 SeitenEvidence - 3 - Audio - Reading - Technical - Texts - To Pronounce - VocabularyÅďřïàņä Łüćïą HõýöšNoch keine Bewertungen

- Psych ManualDokument340 SeitenPsych ManualMarius_20100% (1)

- Ten Strategies For The Top ManagementDokument19 SeitenTen Strategies For The Top ManagementAQuh C Jhane67% (3)

- English II Homework Module 6Dokument5 SeitenEnglish II Homework Module 6Yojana DubonNoch keine Bewertungen

- Al Maps Ulas PDFDokument3 SeitenAl Maps Ulas PDFMaycol FernandoNoch keine Bewertungen

- Entity Relationship Diagram: TBL - Students TBL - ProgramsDokument1 SeiteEntity Relationship Diagram: TBL - Students TBL - ProgramsEun Chae KimNoch keine Bewertungen

- VMD-412 9 April 2014Dokument8 SeitenVMD-412 9 April 2014ashish kumarNoch keine Bewertungen

- A Brief About Chandrayaan 1Dokument3 SeitenA Brief About Chandrayaan 1DebasisBarikNoch keine Bewertungen

- Android TV Media Player User ManualDokument17 SeitenAndroid TV Media Player User ManualAneez Ahmed NNoch keine Bewertungen

- Physics Sample Problems With SolutionsDokument10 SeitenPhysics Sample Problems With SolutionsMichaelAnthonyNoch keine Bewertungen

- Ifrs SapDokument6 SeitenIfrs Sapravikb01Noch keine Bewertungen

- HT 02 Intro Tut 07 Radiation and ConvectionDokument46 SeitenHT 02 Intro Tut 07 Radiation and ConvectionrbeckkNoch keine Bewertungen

- Ba101 Engineering Mathematics 1Dokument21 SeitenBa101 Engineering Mathematics 1nurhaiziinovasiNoch keine Bewertungen

- Lip Prints: IntroductionDokument4 SeitenLip Prints: Introductionkaran desaiNoch keine Bewertungen

- T3904-390-02 SG-Ins Exc EN PDFDokument89 SeitenT3904-390-02 SG-Ins Exc EN PDFBrunoPanutoNoch keine Bewertungen

- Work Immersion Plan For Psychology Students in PsychologyDokument2 SeitenWork Immersion Plan For Psychology Students in PsychologyJune DelaPaz Baunillo100% (1)

- Vmod Pht3d TutorialDokument32 SeitenVmod Pht3d TutorialluisgeologoNoch keine Bewertungen

- Youtube Poop: Subverting Art OnlineDokument14 SeitenYoutube Poop: Subverting Art OnlineWill KurlinkusNoch keine Bewertungen

- Welspun One Logistics Parks: Hazard Risk AssessmentDokument2 SeitenWelspun One Logistics Parks: Hazard Risk AssessmentR. Ayyanuperumal AyyanuperumalNoch keine Bewertungen

- Feedback For Question 1-MIDTERM 2 AFM 451Dokument2 SeitenFeedback For Question 1-MIDTERM 2 AFM 451jason fNoch keine Bewertungen

- c4 Index PDFDokument100 Seitenc4 Index PDFhitkajiNoch keine Bewertungen

- Forecasting The Return Volatility of The Exchange RateDokument53 SeitenForecasting The Return Volatility of The Exchange RateProdan IoanaNoch keine Bewertungen

- Taylor Linker ResumeDokument2 SeitenTaylor Linker ResumeTaylor LinkerNoch keine Bewertungen

- فص یروئت Queuining TheoryDokument47 Seitenفص یروئت Queuining Theorycampal123Noch keine Bewertungen

- Seminar WorkshopDokument3 SeitenSeminar Workshopsir_mhickoNoch keine Bewertungen

- Sustainability Indicators: Are We Measuring What We Ought To Measure?Dokument8 SeitenSustainability Indicators: Are We Measuring What We Ought To Measure?yrperdanaNoch keine Bewertungen

- Fall 2011 COP 3223 (C Programming) Syllabus: Will Provide The Specifics To His SectionDokument5 SeitenFall 2011 COP 3223 (C Programming) Syllabus: Will Provide The Specifics To His SectionSarah WilliamsNoch keine Bewertungen