Beruflich Dokumente

Kultur Dokumente

Chemical Resistance Chart

Hochgeladen von

Pinyaporn VeerapraditOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chemical Resistance Chart

Hochgeladen von

Pinyaporn VeerapraditCopyright:

Verfügbare Formate

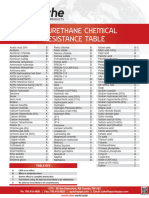

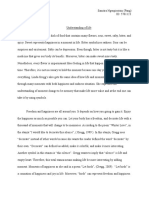

CHEMICAL RESISTANCE CHART

Plasticized PVC ( Polyvinyl Chloride)

R – recommended

L - limited recommendation

X - not recommended

68°C (155°F)

50°C (122°F)

68°C (155°F)

50°C (122°F)

50°C (122°F)

68°C (155°F)

23°C (72°F)

23°C (72°F)

23°C (72°F)

REAGENT REAGENT REAGENT

Acetaldehyde (100%) X X X Bismuth Carbonate R R R Dextrin R R R

Acetic Acid (10%) R L X Bleach (16% Chlorine) R L X Dextrose R R R

Acetic Acid (100%) X X X Boric Acid R R L Dibutyl Phthalate X X X

Acetic Anhydride X X X Brine (Salt) R R L Diethyl Ketone X X X

Acetone X X X Bromic Acid (10%) R L X Dimethylamine X X X

Allyl Alcohol X X X Bromine (Liquid) (100%) X X X Disodium Phosphate R R R

Allyl Chloride X X X Bromine (Water) R R X Distilled Water R R R

Alum R R R Butyl Alcohol (100%) X X X Ethyl Acetate X X X

Aluminum Chloride R R R Butyl Phenol X X X Ethyl Alcohol L X X

Aluminum Fluoride (20%) R R L Butyric Acid (20%) X X X Ethyl Bromide X X X

Aluminum Hydroxide R R R Calcium Bisulfate R R R Ethyl Chloride X X X

Aluminum Sulfate (50%) R R R Calcium Carbonate R R R Ethyl Ether X X X

Ammonium Carbonate R R R Calcium Chloride R R R Ethylene Glycol R L X

Ammonium Chloride R R R Calcium Hydroxide R R R Fatty Acid R L X

Ammonium Fluoride (20%) R R X Calcium Hypochlorite R L X Ferric Chloride R R L

Ammonium Hydroxide (10%) R R X Calcium Nitrate R R R Ferric Nitrate R R X

Ammonium Hydroxide (20%) R L X Calcium Sulfate R R R Ferric Sulfate R R R

Ammonium Hydroxide (30%) R X X Carbon Bisulfide X X X Ferrous Chloride R R L

Ammonium Nitrate R R R Carbon Disulfide X X X Ferrous Sulfate R R L

Ammonium Sulfate R R R Carbon Tetrachloride X X X Fertilizers R L X

Ammonium Sulfide R R R Carbonic Acid R L X Fluoboric Acid R R R

Amyl Acetate (100%) X X X Castor Oil R R X Flourine (Gas) R X X

Amyl Alcohol (100%) X X X Chloracetic Acid (100%) X X X Fluosilicic Acid R R X

Amyl Chloride (100%) X X X Chlorine Dioxide (15%) R L X Formaldehyde (37%) R L X

Aniline (100%) X X X Chlorine, Water R R R Formic Acid L L L

Antimony Trichloride R R R Chlorobenzene X X X Fruit Juices R L L

Apple Cider R L X Chloroform X X X Fruit Pulp R L L

Aqua Ammonia (10%) R R X Chlorosulfonic Acid X X X Furfural X X X

Aqua Ammonia (20%) R L X Chrome Alum R R R Gallic Acid X X X

Aqua Ammonia (30%) R X X Chrome Liquor R R L Gasoline L X X

Aqua Regia L X X Chromic Acid (10%) R R R Glucose R R R

Arsenic Acid R L X Chromic Acid (30%) R R X Glycerine R L L

Barium Carbonate R R R Chromium Tioxide R R L Grape Sugar R L L

Barium Chloride R R R Citric Acid R R L Hydrobromic Acid R R X

Barium Hydroxide R R R Copper Chloride R R R Hydrochloric Acid (10%) R R L

Barium Sulfate R R R Copper Nitrate R R R Hydrochloric Acid (20%) R R L

Barium Sulfide R L X Copper Sulfate R R R Hydrochloric Acid (38%) L X X

Battery Acid R R L Corn Syrup R R X Hydrofluoric Acid (10%) R R L

Beer R L X Cottonseed Oil R R L Hydrofluoric Acid (48%) L X X

Benzaldehyde X X X Cuprous Chloride R R R Hydrofluosilicic Acid R R X

Benzene X X X Cyclohexanol X X X Hydrogen Peroxide (3%) R R R

Benzoic Acid R L X Cyclohexanone X X X Hydrogen Peroxide (30%) R L X

(CONTINUED OVER)

50°C (122°F)

68°C (155°F)

50°C (122°F)

68°C (155°F)

50°C (122°F)

68°C (155°F)

23°C (72°F)

23°C (72°F)

23°C (72°F)

REAGENT REAGENT REAGENT

Hydrogen Sulfide R L X Plating Solutions Sodium Hyprochlorite (16%) R L X

Hydroquinone X X X Sodium Nitrate R R L

Inks L L L Sodium Sulfate R R R

Iodine X X X Sodium Sulfide (10%) R R R

Kerosene R L X Brass, Cadmium, Sodium Sulfite (10%) R R R

Kymene 557 R X X Copper, Gold, Lead, R R R Stannic Chloride R R R

Nickel, Rhodium,

Kymene 709 R X X Silver, Tin, Zinc Stannous Chloride (25%) R L X

Lactic Acid (28%) R L X Stearic Acid R L X

Lead Acetate R L X R R L Sugar Solution R R L

Chromium

Magnesium Carbonate R R L Polyvinyl Acetate R X X Sulfur Dioxide (Gas) R R X

Magnesium Chloride R R R Potassium Bicarbonate R R R Sulfuric Acid (10%) R R R

Magnesium Hydroxide R R R Potassium Bromate R R R Sulfuric Acid (35%) R R L

Magnesium Nitrate R R L Potassium Bromide R R R Sulfuric Acid (50%) R L X

Magnesium Sulfate R R L Potassium Carbonate R R R Sulfuric Acid (98%) L X X

Malic Acid R L X Potassium Chloride R R R Sulfurous Acid R L X

Mercuric Chloride R R L Potassium Chromate R R R Tannic Acid R L X

Mercurous Nitrate R R L Potassium Cyanide R R L Tanning Liquors R R X

Mercury R R R Potassium Ferricyanide R R R Tetraethyl Lead X X X

Methyl Alcohol L L X Potassium Fluoride R R R Tetrahydrofuran X X X

Methyl Ethyl Ketone X X X Potassium Hydroxide (10%) R R L Toluene X X X

Molasses R R L Potassium Hydroxide (50%) L X X Trichloroethylene X X X

Muriatic Acid R R L Potassium Nitrate R R R Triethanolamine X X X

Mustard R R L Potassium Perchlorate R R L Trisodium Phosphate R R R

Nickel Sulfate R R R Potassium Permanganate R R L Turpentine X X X

Nitric Acid (10%) R R L Potassium Sulfate R R R Urea R R X

Nitric Acid (15%) R R X Sea Water R R R Vanilla Extract X X X

Nitric Acid (25%) R L X Silver Nitrate R R R Vinegar R R L

Nitrobenzene X X X Sodium Acetate R L X Water

Oakite No. 31 R L X Sodium Bicarbonate R R R

Oleic Acid R X X Sodium Bisulfite R R L Demineralized,

Distilled, Potable, R R R

Oleum X X X Sodium Borate R R R Sea, Deionized

Oxalic Acid R R L Sodium Carbonate R R R

Perchloric Acid (10%) R R X Sodium Chlorate R R L

Perchloric Acid (70%) X X X Sodium Chloride R R L White Water R R L

Phenol Acid X X X Sodium Dichromate R R R Wine R L X

Phosphoric Acid (15%) R R R Sodium Ferrocyanide R R R Xylene X X X

Phosphoric Acid (85%) R R L Sodium Fluoride R R R Yeast R R R

Phosphorus (Yellow) R X X Sodium Hydroxide (10%) R R R Zinc Chloride R R R

Phosphorous Pentoxide R X X Sodium Hydroxide (50%) R L X Zinc Sulfate R R R

The above ratings are based on the consideration of chemical resistance only. Potable water will not attack flexible vinyls. But to store it safely

from the standpoint of toxicity, a specially formulated vinyl must be used. This would also apply to any material that is intended for human

consumption. In this latter category, the possibility of the migration of very small amounts of plasticizer having an effect on the taste of the stored

liquid should be considered.

Most of the service conditions are based on constant use at a specific temperature. In some applications, the temperature can be exceeded without

liner damage but may decrease the life expectancy. Contact KENTAIN for more information.

KENTAIN PRODUCTS LIMITED This tabulation is based on laboratory tests and records of actual service performance.

55 Howard Place It should be used as a guide only. Each application varies. Therefore no guarantee,

Kitchener, Ontario explicit or implied, is given that similar results will be obtained in your actual

N2K 2Z4 operating conditions. Whenever KENTAIN liners are to be used in a particular

Telephone (519) 576-0994 application where no previous operating experience is available, preliminary testing

Fax (519) 576-0919 should be done by the user or fabricator.

Das könnte Ihnen auch gefallen

- Basic Techniques For Transmission Electron MicroscopyVon EverandBasic Techniques For Transmission Electron MicroscopyNoch keine Bewertungen

- Chemical Resistant Industrial Grade RTV Silicone Sealants: Typical Properties of AG 300 - RTV 38Dokument2 SeitenChemical Resistant Industrial Grade RTV Silicone Sealants: Typical Properties of AG 300 - RTV 38Jagdish PatelNoch keine Bewertungen

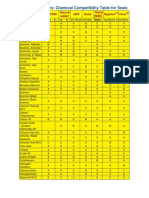

- Chemical Compatibility Table For SealsDokument3 SeitenChemical Compatibility Table For SealsThanh Tuyên VõNoch keine Bewertungen

- Polycarbonate Chemical CompatibilityDokument15 SeitenPolycarbonate Chemical CompatibilityVio AmarieiNoch keine Bewertungen

- Chemical Resistance Chart: ChemicalsDokument1 SeiteChemical Resistance Chart: ChemicalsAllahbaksh ShaikhNoch keine Bewertungen

- Copper Development Association TABLESDokument5 SeitenCopper Development Association TABLESCaleb FalcoteloNoch keine Bewertungen

- Chemical Compatibility Chart For Nylon Membrane: R N T LDokument1 SeiteChemical Compatibility Chart For Nylon Membrane: R N T LLiea Vhelievha DjuanNoch keine Bewertungen

- CHEMICAL COMPATIBILITY TABLE 2013 Graphical Review Part 3Dokument6 SeitenCHEMICAL COMPATIBILITY TABLE 2013 Graphical Review Part 3RafalNoch keine Bewertungen

- Lwtech LW-1 T LW4CR TDokument4 SeitenLwtech LW-1 T LW4CR TSony CNoch keine Bewertungen

- Chemical Resistance Guide: Resin SelectionDokument4 SeitenChemical Resistance Guide: Resin SelectionmarklaforestNoch keine Bewertungen

- Chemical Resistance GuideDokument20 SeitenChemical Resistance GuideDarien EdwardsNoch keine Bewertungen

- A Rough Guide To Chemical ResistanceDokument8 SeitenA Rough Guide To Chemical ResistancewantamanualNoch keine Bewertungen

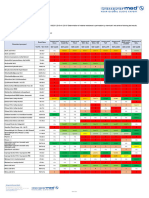

- Sempermed Chemicals ResistanceDokument2 SeitenSempermed Chemicals ResistanceSamerNoch keine Bewertungen

- Polyester Chemical Resistance TableDokument5 SeitenPolyester Chemical Resistance TableGuz UchihaNoch keine Bewertungen

- PA12 Chemical Resistance ChartsDokument3 SeitenPA12 Chemical Resistance ChartsJosé Luis Pinto VergaraNoch keine Bewertungen

- Enp Corrosion ChartDokument6 SeitenEnp Corrosion CharthycromeNoch keine Bewertungen

- Polyurea Resistance ChartDokument1 SeitePolyurea Resistance ChartTanmay GorNoch keine Bewertungen

- Chemical Compatibility Guide For Polyethylene ItemsDokument5 SeitenChemical Compatibility Guide For Polyethylene Itemsredpole12Noch keine Bewertungen

- HDPE Chemical Compatibility & Resistance Chart: Explanation of FootnotesDokument8 SeitenHDPE Chemical Compatibility & Resistance Chart: Explanation of FootnotesRozaq Alfan WNoch keine Bewertungen

- Chemical Properties A-FDokument1 SeiteChemical Properties A-FGreggC66Noch keine Bewertungen

- Trench Drain Chemical Resistance ChartDokument2 SeitenTrench Drain Chemical Resistance ChartJovenal TuplanoNoch keine Bewertungen

- The Secrets of Pyrotechnic Whistles: Joseph A. Domanico VP Publications / Webmaster Crackerjacks, IncDokument57 SeitenThe Secrets of Pyrotechnic Whistles: Joseph A. Domanico VP Publications / Webmaster Crackerjacks, Incradical63Noch keine Bewertungen

- Mapefloor I300 SLDokument13 SeitenMapefloor I300 SLSandy PinedaNoch keine Bewertungen

- HDPE Chemical Resistance ChartDokument3 SeitenHDPE Chemical Resistance ChartSarvesh Parmanand SeebundhunNoch keine Bewertungen

- Chemical Compatibility Ver 6Dokument2 SeitenChemical Compatibility Ver 6omkar123456Noch keine Bewertungen

- ChemLastChemicalCompat 01Dokument14 SeitenChemLastChemicalCompat 01andrescaligoNoch keine Bewertungen

- Acrylite Chem ResistDokument2 SeitenAcrylite Chem ResistMiguel ArriecheNoch keine Bewertungen

- FGS Line Pipe-OverviewDokument45 SeitenFGS Line Pipe-OverviewTaras ByloNoch keine Bewertungen

- Chemical Compatibility Metal CartridgesDokument1 SeiteChemical Compatibility Metal CartridgesMurli RamchandranNoch keine Bewertungen

- Chemical Compatibility of VitonDokument5 SeitenChemical Compatibility of Vitonmarisca83830Noch keine Bewertungen

- Chemical Environment Concentration % TemperatureDokument12 SeitenChemical Environment Concentration % TemperatureYousuf RagieNoch keine Bewertungen

- Chemical Resistance TableDokument1 SeiteChemical Resistance TableSteve FransiscusNoch keine Bewertungen

- Tego Amid Mio Mio Conditioner EmulsifierDokument21 SeitenTego Amid Mio Mio Conditioner EmulsifierMirtha Del ArrayánNoch keine Bewertungen

- Technical Data: Fiberglass Tubulars Selected Chemical Resistance ChartDokument2 SeitenTechnical Data: Fiberglass Tubulars Selected Chemical Resistance ChartMargarit IonelaNoch keine Bewertungen

- Corrosion Resistance of Polymer ConcreteDokument4 SeitenCorrosion Resistance of Polymer Concrete1limonataNoch keine Bewertungen

- Chemical Resistance Chart PDFDokument3 SeitenChemical Resistance Chart PDFJaya LakshmiNoch keine Bewertungen

- VITLAB Genius2 Simplex2 Recommended Application RangeDokument1 SeiteVITLAB Genius2 Simplex2 Recommended Application RangeNur RosyidahNoch keine Bewertungen

- Rubber Chemical Resistance Chart V001MAR17Dokument27 SeitenRubber Chemical Resistance Chart V001MAR17Deepak patilNoch keine Bewertungen

- Chemical Compatibility TableDokument28 SeitenChemical Compatibility TableBea LubaoNoch keine Bewertungen

- Acrylic Pmma Chemical Compatibility Chart From IsmDokument11 SeitenAcrylic Pmma Chemical Compatibility Chart From IsmDeidra CadeNoch keine Bewertungen

- Chemical Resistance ChartDokument32 SeitenChemical Resistance Chartdalton2004Noch keine Bewertungen

- Chemical Corrosion Chart 2Dokument40 SeitenChemical Corrosion Chart 2teddydeNoch keine Bewertungen

- Transducer Disinfectants and Cleaning SolutionsDokument10 SeitenTransducer Disinfectants and Cleaning SolutionsMario RamosNoch keine Bewertungen

- X R R-H2-X R - H-R R - X R 2 Allylic Halides CH2 CH - H2-X Benzylic Halides H2-XDokument2 SeitenX R R-H2-X R - H-R R - X R 2 Allylic Halides CH2 CH - H2-X Benzylic Halides H2-XAnonymousNoch keine Bewertungen

- Chemical Compatibility of PPR Niron PipingDokument9 SeitenChemical Compatibility of PPR Niron PipingaurinkokelloNoch keine Bewertungen

- Household and I&I Formul Ation GuideDokument15 SeitenHousehold and I&I Formul Ation Guidezaryab khanNoch keine Bewertungen

- Appendix 2 Chemical Compatibility of Materials With Homogeneous GRAFOIL SheetDokument11 SeitenAppendix 2 Chemical Compatibility of Materials With Homogeneous GRAFOIL SheetHolayilNoch keine Bewertungen

- Chemical Compatibility Table For SealsDokument3 SeitenChemical Compatibility Table For Sealspi31415926535Noch keine Bewertungen

- 1111cr CoatingReferencebookDokument5 Seiten1111cr CoatingReferencebookQuy RomNoch keine Bewertungen

- Chemical Resistant ChartDokument13 SeitenChemical Resistant ChartC.TNoch keine Bewertungen

- PP Chemical ResistanceDokument4 SeitenPP Chemical ResistancePoep PeopNoch keine Bewertungen

- Syringe Filters Solvent Compatibility Chart: Pure ChromatographyDokument2 SeitenSyringe Filters Solvent Compatibility Chart: Pure ChromatographyParijat DasNoch keine Bewertungen

- Hazardous - Resistance List KL10K Coil Coating v1.2Dokument6 SeitenHazardous - Resistance List KL10K Coil Coating v1.2ajajsainNoch keine Bewertungen

- Chemical Resistance - FRP PipeDokument5 SeitenChemical Resistance - FRP Pipeปัญญกฤษฎิ์ จันทรสวัสดิ์Noch keine Bewertungen

- DisolventesDokument2 SeitenDisolventesolga mariaNoch keine Bewertungen

- Chemical Compatibility Reference Chart: SteelDokument15 SeitenChemical Compatibility Reference Chart: SteelSreesanth SaruvilNoch keine Bewertungen

- Carta Resistencia de MaterialesDokument19 SeitenCarta Resistencia de Materialeslacrimosa881021Noch keine Bewertungen

- Sostanza Chemical PP PVDF Aisi 316 Epdm Viton PtfeDokument2 SeitenSostanza Chemical PP PVDF Aisi 316 Epdm Viton Ptfescribd1364scribdNoch keine Bewertungen

- Chemical Compatibility Chart Hypalon: Page 1 of 10 Kelco 15/12/2008Dokument10 SeitenChemical Compatibility Chart Hypalon: Page 1 of 10 Kelco 15/12/2008Jagdish PatelNoch keine Bewertungen

- Influence of Metal Stearates On Thermal Stability of Polyvinyl Chloride) I. Calcium StearateDokument11 SeitenInfluence of Metal Stearates On Thermal Stability of Polyvinyl Chloride) I. Calcium StearatePinyaporn VeerapraditNoch keine Bewertungen

- Comparison of PB PPR CPVC PeDokument7 SeitenComparison of PB PPR CPVC PePinyaporn VeerapraditNoch keine Bewertungen

- Baerlocher Acquires Chem..Dokument2 SeitenBaerlocher Acquires Chem..Pinyaporn VeerapraditNoch keine Bewertungen

- PVC and FireDokument9 SeitenPVC and FirePinyaporn VeerapraditNoch keine Bewertungen

- TDS Siamvic 360NADokument1 SeiteTDS Siamvic 360NAPinyaporn VeerapraditNoch keine Bewertungen

- TDS Siamvic 258RBDokument1 SeiteTDS Siamvic 258RBPinyaporn VeerapraditNoch keine Bewertungen

- The Impact Behaviour of Composite MaterialsDokument6 SeitenThe Impact Behaviour of Composite MaterialsVíctor Fer100% (1)

- PulpectomyDokument3 SeitenPulpectomyWafa Nabilah Kamal100% (1)

- Plumbing Breakup M 01Dokument29 SeitenPlumbing Breakup M 01Nicholas SmithNoch keine Bewertungen

- A V N 2 0 0 0 9 Airspace Management and Air Traffic Services Assignment 1Dokument2 SeitenA V N 2 0 0 0 9 Airspace Management and Air Traffic Services Assignment 1Tanzim Islam KhanNoch keine Bewertungen

- Muscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeDokument4 SeitenMuscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeCarlo FilipponeNoch keine Bewertungen

- Notice of Privacy Practices (Generic)Dokument3 SeitenNotice of Privacy Practices (Generic)cecilled_08Noch keine Bewertungen

- E10b MERCHANT NAVY CODE OF CONDUCTDokument1 SeiteE10b MERCHANT NAVY CODE OF CONDUCTssabih75Noch keine Bewertungen

- Safety AuditDokument9 SeitenSafety AuditRobena Nagum BagasNoch keine Bewertungen

- Handout Module6Dokument69 SeitenHandout Module6Oana MirceaNoch keine Bewertungen

- Blood DonationDokument19 SeitenBlood DonationsuruthiNoch keine Bewertungen

- SSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemDokument56 SeitenSSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemJose Ramón Orenes ClementeNoch keine Bewertungen

- Powerful Communication Tools For Successful Acupuncture PracticeDokument4 SeitenPowerful Communication Tools For Successful Acupuncture Practicebinglei chenNoch keine Bewertungen

- Family Stress TheoryDokument10 SeitenFamily Stress TheoryKarina Megasari WinahyuNoch keine Bewertungen

- Olivares VsDokument2 SeitenOlivares VsDebbie YrreverreNoch keine Bewertungen

- Constipation Treatment For Infants and ChildrenDokument2 SeitenConstipation Treatment For Infants and Childrenapi-559575515Noch keine Bewertungen

- Formulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersDokument5 SeitenFormulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersIndradewiNoch keine Bewertungen

- Tractor Price and Speci Cations: Tractors in IndiaDokument4 SeitenTractor Price and Speci Cations: Tractors in Indiatrupti kadamNoch keine Bewertungen

- Biomedical Admissions Test 4500/12: Section 2 Scientific Knowledge and ApplicationsDokument20 SeitenBiomedical Admissions Test 4500/12: Section 2 Scientific Knowledge and Applicationshirajavaid246Noch keine Bewertungen

- ClistDokument14 SeitenClistGuerraNoch keine Bewertungen

- English PoemDokument4 SeitenEnglish Poemapi-276985258Noch keine Bewertungen

- c3175492 Pavan Kumarvasudha Signed OfferletterDokument6 Seitenc3175492 Pavan Kumarvasudha Signed OfferletterPavan Kumar Vasudha100% (1)

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsDokument10 SeitenVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorNoch keine Bewertungen

- Measurement of Bioreactor K ADokument18 SeitenMeasurement of Bioreactor K AAtif MehfoozNoch keine Bewertungen

- Kingdom of AnimaliaDokument6 SeitenKingdom of AnimaliaBen ZerepNoch keine Bewertungen

- Chi - Square Test: PG Students: DR Amit Gujarathi DR Naresh GillDokument32 SeitenChi - Square Test: PG Students: DR Amit Gujarathi DR Naresh GillNaresh GillNoch keine Bewertungen

- Calao Deliquente Diadi River SystemDokument15 SeitenCalao Deliquente Diadi River SystemJason MalamugNoch keine Bewertungen

- EM2U60CLP 115-127 V 60 HZ 1Dokument4 SeitenEM2U60CLP 115-127 V 60 HZ 1armagedrumNoch keine Bewertungen

- Remote Control Unit Manual BookDokument21 SeitenRemote Control Unit Manual BookIgor Ungur100% (1)

- An Energy Saving Guide For Plastic Injection Molding MachinesDokument16 SeitenAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoNoch keine Bewertungen

- Uttarakhand District Factbook: Almora DistrictDokument33 SeitenUttarakhand District Factbook: Almora DistrictDatanet IndiaNoch keine Bewertungen