Beruflich Dokumente

Kultur Dokumente

AISC Comparison (2005 To 2010 To 2016) PDF

Hochgeladen von

Prima AdhiyasaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AISC Comparison (2005 To 2010 To 2016) PDF

Hochgeladen von

Prima AdhiyasaCopyright:

Verfügbare Formate

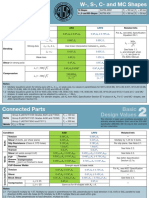

AISC Basic Design Value 1 Comparison

Based upon simplyfying assumptions and arbitary limitations. Direct use of the AISC Spesification may be less constrained and less conservative

Code Version AISC 360-05 (2005) AISC 360-10 (2010) AISC 360-16 (2016)

References References RELATED INFO

Condition ASD LRFD ASD LRFD ASD LRFD

Tension 0.6 Fy Ag ≤ 0.5 Fu Ae 0.9 Fy Ag ≤ 0.75 Fu Ae 0.6 Fy Ag ≤ 0.5 Fu Ae 0.9 Fy Ag ≤ 0.75 Fu Ae Page 26, 282 0.6 Fy Ag ≤ 0.5 Fu Ae 0.9 Fy Ag ≤ 0.75 Fu Ae Page 28, 299 For Ae, see Equation D3-1

Lb≤Lp 0.66 Fy Sx 0.99 Fy Sx 0.66 Fy Sx 0.99 Fy Sx 0.66 Fy Sx 0.99 Fy Sx See Note 1.

Strong Axis Lp<Lb≤Lr Use linear interpolation between Lp and Lr Use linear interpolation between Lp and Lr Use linear interpolation between Lp and Lr p 300ry /

LasdddddddddddFy

Bending Page 44, 302 Page 44, 323

Lb=Lr 0.42 Fy Sx 0.63 Fy Sx 0.42 Fy Sx 0.63 Fy Sx 0.42 Fy Sx 0.63 Fy Sx Lr and strengths when Lb > Lr

Weak Axis 0.9 Fy Sy 1.35 Fy Sy 0.9 Fy Sy 1.35 Fy Sy 0.9 Fy Sy 1.35 Fy Sy are given in the AISC Manual

Shear (In strong axis) 0.4 Fy Aw 0.6 Fy Aw 0.4 Fy Aw 0.6 Fy Aw Page 67, 325 0.4 Fy Aw 0.6 Fy Aw Page 70, 350

p p P P P P

Kl / r 800 / Fy 0.6 Fy Ag x 0.658 0.9 Fy Ag x 0.658 0.6 Fy Ag x 0.658 0.9 Fy Ag x 0.658 0.6 Fy Ag x 0.658 0.9 Fy Ag x 0.658

Compression Kl / r 800 / Fy 2 2 2 2

Page 31, 290 2 2

Page 33, 307 2

150,000 Ag / (Kl/r) 226,000 Ag / (Kl/r) 150,000 Ag / (Kl/r) 226,000 Ag / (Kl/r) 150,000 Ag / (Kl/r) 226,000 Ag / (Kl/r) P= Fy (Kl/r) / 286,000

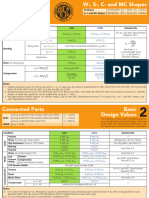

AISC Basic Design Value 2 Comparison

Based upon simplyfying assumptions and arbitary limitations. Direct use of the AISC Spesification may be less constrained and less conservative

Code Version AISC 360-05 (2005) AISC 360-10 (2010) AISC 360-16 (2016)

References References RELATED INFO

Condition ASD LRFD ASD LRFD ASD LRFD

Tension 0.6 Fy Ag ≤ 0.5 Fu Ae 0.9 Fy Ag ≤ 0.75 Fu Ae 0.6 Fy Ag ≤ 0.5 Fu Ae 0.9 Fy Ag ≤ 0.75 Fu Ae Page 26, 282 0.6 Fy Ag ≤ 0.5 Fu Ae 0.9 Fy Ag ≤ 0.75 Fu Ae Page 28, 299 For Ae, see Equation D3-1

Rectangular HSS 0.66 Fy S 0.99 Fy S 0.66 Fy S 0.99 Fy S Page 56, 312 0.66 Fy S 0.99 Fy S Page 57, 335

Bending

Round HSS, Pipe 0.78 Fy S 1.17 Fy S 0.78 Fy S 1.17 Fy S Page 57, 314 0.78 Fy S 1.17 Fy S Page 59, 336

Rectangular HSS 0.36 Fy Aw 0.54 Fy Aw 0.36 Fy Aw 0.54 Fy Aw Page 71, 329 0.36 Fy Aw 0.54 Fy Aw Page 74, 354

Shear

Round HSS, Pipe 0.18 Fy Ag 0.27 Fy Ag 0.18 Fy Ag 0.27 Fy Ag Page 72, 330 0.18 Fy Ag 0.27 Fy Ag Page 75, 355

p p p p p p

Kl / r 800 / Fy 0.6 Fy Ag x 0.658 0.9 Fy Ag x 0.658 0.6 Fy Ag x 0.658 0.9 Fy Ag x 0.658 0.6 Fy Ag x 0.658 0.9 Fy Ag x 0.658

Compression Page 31, 290 Page 33, 307

Kl / r 800 / Fy 150,000 Ag / (Kl/r)

2

226,000 Ag / (Kl/r)

2

150,000 Ag / (Kl/r)

2

226,000 Ag / (Kl/r)

2

150,000 Ag / (Kl/r)

2

226,000 Ag / (Kl/r)

2 2

P= Fy (Kl/r) / 286,000

AISC Basic Design Value 3 Comparison

Based upon simplyfying assumptions and arbitary limitations. Direct use of the AISC Spesification may be less constrained and less conservative

Code Version AISC 360-05 (2005) AISC 360-10 (2010) AISC 360-16 (2016)

References References RELATED INFO

Condition ASD LRFD ASD LRFD ASD LRFD

Tension 0.38 Fu Ab 0.56 Fu Ab 0.38 Fu Ab 0.56 Fu Ab Page 125 Page 131

Shear (N bolts, per shear plane) 0.2 Fu Ab 0.3 Fu Ab 0.23 Fu Ab 0.34 Fu Ab Page 125 Page 131 Multiply by 1.25 for X bolts

Bolts

Slip Resistance (Class A, STD holes) 0.14 Fu Ab 0.21 Fu Ab 0.12 Fu Ab 0.18 Fu Ab Page 126 0.12 Fu Ab 0.18 Fu Ab Page 134 per slip plane

Bearing 0.6 Fu lc t ≤ 1.2 Fu db t 0.9 Fu lc t ≤ 1.8 Fu db t 0.6 Fu lc t ≤ 1.2 Fu db t 0.9 Fu lc t ≤ 1.8 Fu db t Page 127 0.6 Fu lc t ≤ 1.2 Fu db t 0.9 Fu lc t ≤ 1.8 Fu db t Page 135

Shear (all welds except CJP) 0.3 FEXX Aw 0.45 FEXX Aw 0.3 FEXX Aw 0.45 FEXX Aw Page 115 0.3 FEXX Aw 0.45 FEXX Aw Page 123

Tension 0.32 FEXX Aw 0.48 FEXX Aw 0.32 FEXX Aw ≤ 0.5 Fu ABM 0.48 FEXX Aw ≤ 0.75 Fu ABM Page 114 0.32 FEXX Aw ≤ 0.5 Fu ABM 0.48 FEXX Aw ≤ 0.75 Fu ABM Page 123 See Section J2 1a.

Welds

PJP Groove

Welds Compression (joint not

0.48 FEXX Aw ≤ 0.6 Fy ABM 0.72 FEXX Aw ≤ 0.9 Fy ABM 0.48 FEXX Aw ≤ 0.6 Fy ABM 0.72 FEXX Aw ≤ 0.9 Fy ABM Page 114 0.48 FEXX Aw ≤ 0.6 Fy ABM 0.72 FEXX Aw ≤ 0.9 Fy ABM

finished to bear) Page 123 See Section J2 1a.

CJP Groove Welds Strength equal to base metal Strength equal to base metal Strength equal to base metal

Tension 0.6 Fy Ag ≤ 0.5 Fu Ae 0.9 Fy Ag ≤ 0.75 Fu Ae 0.6 Fy Ag ≤ 0.5 Fu Ae 0.9 Fy Ag ≤ 0.75 Fu Ae 0.6 Fy Ag ≤ 0.5 Fu Ae 0.9 Fy Ag ≤ 0.75 Fu Ae

Connested Parts

For Ae, see equation D3-1

Shear 0.4 Fy Ag ≤ 0.3 Fu An 0.6 Fy Ag ≤ 0.45 Fu An 0.4 Fy Ag ≤ 0.3 Fu An 0.6 Fy Ag ≤ 0.45 Fu An 0.4 Fy Ag ≤ 0.3 Fu An 0.6 Fy Ag ≤ 0.45 Fu An

Block Shear 0.3 Fu Anv + 0.5 Ubs Fu Ant 0.45 Fu Anv + 0.75 Ubs Fu Ant 0.3 Fu Anv + 0.5 Ubs Fu Ant 0.45 Fu Anv + 0.75 Ubs Fu Ant 0.3 Fu Anv + 0.5 Ubs Fu Ant 0.45 Fu Anv + 0.75 Ubs Fu Ant

Kl / r ≤ 25 0.6 Fy A 0.9 Fy A 0.6 Fy A 0.9 Fy A 0.6 Fy A 0.9 Fy A

Compression

Kl / r > 25 Same as for W-shapes with Ag = A Same as for W-shapes with Ag = A Same as for W-shapes with Ag = A

Das könnte Ihnen auch gefallen

- 68rfe IntroductionDokument71 Seiten68rfe IntroductionThePokeOne83% (6)

- Purlin & Cladding RailDokument67 SeitenPurlin & Cladding RailPrima AdhiyasaNoch keine Bewertungen

- Design of RC Corbels and NibsDokument21 SeitenDesign of RC Corbels and Nibsscg1998100% (2)

- A Strategic Management PaperDokument7 SeitenA Strategic Management PaperKarll Brendon SalubreNoch keine Bewertungen

- Basic Design ValuesDokument4 SeitenBasic Design Valuesnenpatel-1Noch keine Bewertungen

- Concrete AdmixturesDokument17 SeitenConcrete AdmixturesNaveen Veeramani100% (7)

- Design of Precast Pier Cap - 1Dokument24 SeitenDesign of Precast Pier Cap - 1Ankush SharmaNoch keine Bewertungen

- Understanding Urbanization & Urban Community DevelopmentDokument44 SeitenUnderstanding Urbanization & Urban Community DevelopmentS.Rengasamy89% (28)

- FrankensteinDokument24 SeitenFrankensteinLisa WardNoch keine Bewertungen

- Pyrolysis ProjectDokument122 SeitenPyrolysis ProjectSohel Bangi100% (1)

- Basic Design Value AISCDokument4 SeitenBasic Design Value AISCmrajansubramanian100% (2)

- ACI 314 Design Aid 11 PDFDokument29 SeitenACI 314 Design Aid 11 PDFPrima AdhiyasaNoch keine Bewertungen

- MATH 8 QUARTER 3 WEEK 1 & 2 MODULEDokument10 SeitenMATH 8 QUARTER 3 WEEK 1 & 2 MODULECandy CastroNoch keine Bewertungen

- Katalog Gunung Garuda NewDokument36 SeitenKatalog Gunung Garuda Newabduh81Noch keine Bewertungen

- 2018 Cambridge Lower Second Progression Test Science Stage 8 QP Paper 2 - tcm143-430409Dokument16 Seiten2018 Cambridge Lower Second Progression Test Science Stage 8 QP Paper 2 - tcm143-430409AnisahNoch keine Bewertungen

- Manual Card AISC Ver.16Dokument4 SeitenManual Card AISC Ver.16Phanathon OunonNoch keine Bewertungen

- LRFD 0.9F 0.75F 0.99F: LR F A LRDokument4 SeitenLRFD 0.9F 0.75F 0.99F: LR F A LREstructuras MaquinariasNoch keine Bewertungen

- Aisc Basic Design ValueDokument10 SeitenAisc Basic Design ValueTauhidul IslamNoch keine Bewertungen

- Guide to Steel Beam Design ExampleDokument66 SeitenGuide to Steel Beam Design ExampleVince GarciaNoch keine Bewertungen

- CN Rexroth变量斜轴柱塞泵A7VODokument88 SeitenCN Rexroth变量斜轴柱塞泵A7VOcunvip163.comNoch keine Bewertungen

- R3-Signal StationDokument40 SeitenR3-Signal StationRoshan KejariwalNoch keine Bewertungen

- Trans1 ParasiticDokument1 SeiteTrans1 ParasiticTran TriNoch keine Bewertungen

- Steel Member Design Report AISC-ASD89Dokument5 SeitenSteel Member Design Report AISC-ASD89Sopanat BoonkhanNoch keine Bewertungen

- Osing Kertarajasa UTS ANALISADokument11 SeitenOsing Kertarajasa UTS ANALISAOsing kertarajasaNoch keine Bewertungen

- Adobe Scan Apr 23, 2023Dokument1 SeiteAdobe Scan Apr 23, 2023sankhadeep goswamiNoch keine Bewertungen

- Denah Atap (B & P Workshop) : Penutup Atap Zincalume Spandek Penutup Atap Zincalume SpandekDokument1 SeiteDenah Atap (B & P Workshop) : Penutup Atap Zincalume Spandek Penutup Atap Zincalume Spandekwisnu koroNoch keine Bewertungen

- Wear Triaxial Rev Formula Min OK1Dokument1 SeiteWear Triaxial Rev Formula Min OK1Adrien OfthestoneNoch keine Bewertungen

- Rev 3 GBR Arsitek Aparthouse MentengDokument19 SeitenRev 3 GBR Arsitek Aparthouse MentengTri AriantoNoch keine Bewertungen

- Column Design Column-C1: M M M MDokument3 SeitenColumn Design Column-C1: M M M MMustefa Mohammed AdemNoch keine Bewertungen

- Output Shaft Lube Nozzle Bearings Bolts RCM Face-Gear PMC Face-GearsDokument9 SeitenOutput Shaft Lube Nozzle Bearings Bolts RCM Face-Gear PMC Face-GearsMichael KinneyNoch keine Bewertungen

- Chip Resistors GuideDokument6 SeitenChip Resistors Guideh_878236333Noch keine Bewertungen

- Least Angle Regression: Tim Hesterberg, Insightful CorpDokument14 SeitenLeast Angle Regression: Tim Hesterberg, Insightful Corpapi-16456140Noch keine Bewertungen

- 2 ND Order Analysis ExampleDokument76 Seiten2 ND Order Analysis ExampleChristian Pinto100% (1)

- Coulmn GoodDokument558 SeitenCoulmn GoodAbel BerhanmeskelNoch keine Bewertungen

- Rigorous Heat Exchanger: Schematic OfaDokument5 SeitenRigorous Heat Exchanger: Schematic Ofanico123456789Noch keine Bewertungen

- 89124417-Wiring Diagram FH A749973 B664026 07.2013Dokument2 Seiten89124417-Wiring Diagram FH A749973 B664026 07.2013Vass75 Vass75Noch keine Bewertungen

- 1683540171310Dokument12 Seiten1683540171310charitha85Noch keine Bewertungen

- Slab Detailing-ModelDokument1 SeiteSlab Detailing-ModelKamal RaoNoch keine Bewertungen

- Design of Lifting Lug - Part2Dokument1 SeiteDesign of Lifting Lug - Part2ArchieNoch keine Bewertungen

- Loss 6pretrs Du: WSBBLNGDokument106 SeitenLoss 6pretrs Du: WSBBLNGDasun FernandoNoch keine Bewertungen

- 301 PDFDokument14 Seiten301 PDFNader OkashaNoch keine Bewertungen

- Beautifil II Ls Bro UsDokument6 SeitenBeautifil II Ls Bro Usleejiawen97524Noch keine Bewertungen

- TBX-1-2 (FTB-2)Dokument1 SeiteTBX-1-2 (FTB-2)jomer john estoneloNoch keine Bewertungen

- OpenSees Navigator GUIDokument52 SeitenOpenSees Navigator GUIjames_frankNoch keine Bewertungen

- SamirDokument15 SeitenSamirMohamed ElshahidiNoch keine Bewertungen

- Tabla #2 Metodos: Deformaciones Angulares Y CrossDokument1 SeiteTabla #2 Metodos: Deformaciones Angulares Y CrossAngel AfaNoch keine Bewertungen

- Table: Active Degrees of Freedom: Example Y.Sdb SAP2000 v14.2.2 - License # 13 November 2023Dokument17 SeitenTable: Active Degrees of Freedom: Example Y.Sdb SAP2000 v14.2.2 - License # 13 November 2023Almansyah (Almansyah 07232111132)Noch keine Bewertungen

- Catalogo BC35Dokument16 SeitenCatalogo BC35tecnicomanelNoch keine Bewertungen

- Built Up Box PlatesDokument16 SeitenBuilt Up Box Platesvrajan1988Noch keine Bewertungen

- Hazardous Area Cable Joints (Zone 1 & 2) Power CablesDokument1 SeiteHazardous Area Cable Joints (Zone 1 & 2) Power Cablesarturo velazcoNoch keine Bewertungen

- PROBLEM 2.124: SolutionDokument14 SeitenPROBLEM 2.124: SolutionCharbel Abou KhalilNoch keine Bewertungen

- Massachusetts Institute of TechnologyDokument47 SeitenMassachusetts Institute of TechnologyAmanNoch keine Bewertungen

- Compare S355J2+N, St52-3, Fe510DDokument4 SeitenCompare S355J2+N, St52-3, Fe510DGANESHNoch keine Bewertungen

- Swing BallDokument16 SeitenSwing BallalphatoolsNoch keine Bewertungen

- Dibujo MarioDokument1 SeiteDibujo MarioUriel VillasanaNoch keine Bewertungen

- (8.1) Programa de Produccion Planta Villahermosa Semana 8 Del 19 Feb Al 25 FebDokument4 Seiten(8.1) Programa de Produccion Planta Villahermosa Semana 8 Del 19 Feb Al 25 FebOmar OlánNoch keine Bewertungen

- GR_COR_1 RHO_COR_1 Logs DataDokument1 SeiteGR_COR_1 RHO_COR_1 Logs DataMaulana FajariadiNoch keine Bewertungen

- Vishay Mono-Kap ceramic capacitors guideDokument13 SeitenVishay Mono-Kap ceramic capacitors guideishakNoch keine Bewertungen

- CN Rexroth径向柱塞马达MCR20Dokument12 SeitenCN Rexroth径向柱塞马达MCR20cunvip163.comNoch keine Bewertungen

- Table: Assembled Joint Masses: Taller 1.sdb SAP2000 v15.1.0 - License #281F7 15 Mayo 2017Dokument1 SeiteTable: Assembled Joint Masses: Taller 1.sdb SAP2000 v15.1.0 - License #281F7 15 Mayo 2017Blady CòrdovaNoch keine Bewertungen

- Manual Tool Change Electrospindles Increase Machine EfficiencyDokument5 SeitenManual Tool Change Electrospindles Increase Machine EfficiencyM. MUBASHARNoch keine Bewertungen

- Buckling MachineDesignNotesDokument6 SeitenBuckling MachineDesignNotesFurkan YildirimNoch keine Bewertungen

- Taller 1Dokument1 SeiteTaller 1Blady CòrdovaNoch keine Bewertungen

- Conversor Buck Boost V8 PDFDokument1 SeiteConversor Buck Boost V8 PDFMatheusNoch keine Bewertungen

- Efficient voltage regulator circuit designDokument1 SeiteEfficient voltage regulator circuit designMatheusNoch keine Bewertungen

- CE 411 - Lecture 5Dokument14 SeitenCE 411 - Lecture 5Israel PopeNoch keine Bewertungen

- Mie - Set 05Dokument7 SeitenMie - Set 05jrcq9022Noch keine Bewertungen

- Finite Element Beam Deflection AnalysisDokument7 SeitenFinite Element Beam Deflection Analysisjrcq9022Noch keine Bewertungen

- Form: Dl. 2.2 Scala Dynamic Cone Penetrometer TestDokument4 SeitenForm: Dl. 2.2 Scala Dynamic Cone Penetrometer TestJacky AyalNoch keine Bewertungen

- RC Pile Cap Design (ACI318) - 4-GRID-C4Dokument101 SeitenRC Pile Cap Design (ACI318) - 4-GRID-C4Prima AdhiyasaNoch keine Bewertungen

- RC Pile Cap Design (ACI318) - 4-GRID-C4Dokument101 SeitenRC Pile Cap Design (ACI318) - 4-GRID-C4Prima AdhiyasaNoch keine Bewertungen

- RC Pile Cap Design (ACI318) - 4-GRID-C4Dokument101 SeitenRC Pile Cap Design (ACI318) - 4-GRID-C4Prima AdhiyasaNoch keine Bewertungen

- RC Pile Cap Design (ACI318) - 4-GRID-C4Dokument101 SeitenRC Pile Cap Design (ACI318) - 4-GRID-C4Prima AdhiyasaNoch keine Bewertungen

- Detail Splicing IWFDokument100 SeitenDetail Splicing IWFPrima Adhiyasa0% (1)

- Irregularity of Structures 011316Dokument7 SeitenIrregularity of Structures 011316Prima AdhiyasaNoch keine Bewertungen

- Splice Beam and Column Rev-160225Dokument6 SeitenSplice Beam and Column Rev-160225Prima AdhiyasaNoch keine Bewertungen

- Fibre AlumDokument20 SeitenFibre AlumPrima AdhiyasaNoch keine Bewertungen

- Pedestal WWTPDokument5 SeitenPedestal WWTPPrima AdhiyasaNoch keine Bewertungen

- Install Melalui " Silent Installation (ENG) .CMD" (Akan Muncul Command Promt Dan Enjoy Full)Dokument1 SeiteInstall Melalui " Silent Installation (ENG) .CMD" (Akan Muncul Command Promt Dan Enjoy Full)Prima AdhiyasaNoch keine Bewertungen

- Install Melalui " Silent Installation (ENG) .CMD" (Akan Muncul Command Promt Dan Enjoy Full)Dokument1 SeiteInstall Melalui " Silent Installation (ENG) .CMD" (Akan Muncul Command Promt Dan Enjoy Full)Prima AdhiyasaNoch keine Bewertungen

- Fibre BeamDokument8 SeitenFibre BeamPrima AdhiyasaNoch keine Bewertungen

- Joint Reaction (SAP2000 Output)Dokument93 SeitenJoint Reaction (SAP2000 Output)Prima AdhiyasaNoch keine Bewertungen

- Airsoft FavoriteDokument1 SeiteAirsoft FavoritePrima AdhiyasaNoch keine Bewertungen

- AISI S100-07 Appendix 1 With CommentaryDokument32 SeitenAISI S100-07 Appendix 1 With CommentaryPrima AdhiyasaNoch keine Bewertungen

- Structure PDFDokument1 SeiteStructure PDFPrima AdhiyasaNoch keine Bewertungen

- Access Architectural Flooring ProductsDokument36 SeitenAccess Architectural Flooring ProductscysautsNoch keine Bewertungen

- 14 - Anchorage and Development LengthDokument11 Seiten14 - Anchorage and Development LengthPunya SureshNoch keine Bewertungen

- Connection DesignDokument24 SeitenConnection DesignPrima AdhiyasaNoch keine Bewertungen

- Aisc s340 Metric Properties of StructuralDokument49 SeitenAisc s340 Metric Properties of StructuraltgrimleyNoch keine Bewertungen

- Astm C 143 PDFDokument4 SeitenAstm C 143 PDFAbhijeet SahuNoch keine Bewertungen

- Structure Structure Structure Structure Structure Structure Structure Structure Structure StructureDokument1 SeiteStructure Structure Structure Structure Structure Structure Structure Structure Structure StructurePrima AdhiyasaNoch keine Bewertungen

- Handout 13 13Dokument5 SeitenHandout 13 13Prima AdhiyasaNoch keine Bewertungen

- MJ Richard ThesisDokument170 SeitenMJ Richard ThesisPrima AdhiyasaNoch keine Bewertungen

- Salt Analysis-Ferric ChlorideDokument3 SeitenSalt Analysis-Ferric ChlorideVandana0% (1)

- BCMEDokument9 SeitenBCMEVenkateshwaran VenkyNoch keine Bewertungen

- TG KPWKPDokument8 SeitenTG KPWKPDanmar CamilotNoch keine Bewertungen

- Lewis Carrol: Birth: DeathDokument21 SeitenLewis Carrol: Birth: DeathmarialuvsjeffNoch keine Bewertungen

- Citi Global College Inc 12STEM3G72Dokument9 SeitenCiti Global College Inc 12STEM3G72yanna villarealNoch keine Bewertungen

- Pure Quality Pure Natural: Calcium Carbonate Filler / MasterbatchDokument27 SeitenPure Quality Pure Natural: Calcium Carbonate Filler / MasterbatchhelenNoch keine Bewertungen

- Film set safety rules for COVIDDokument12 SeitenFilm set safety rules for COVIDTanveer HossainNoch keine Bewertungen

- Solution Proposal For SGF - BomDokument2 SeitenSolution Proposal For SGF - BomABHISHEK ADHIKARYNoch keine Bewertungen

- 74VHCU04Dokument6 Seiten74VHCU04Alexandre S. CorrêaNoch keine Bewertungen

- Provisional List of Institutes1652433727Dokument27 SeitenProvisional List of Institutes1652433727qwerty qwertyNoch keine Bewertungen

- NCERT Solutions For Class 12 Flamingo English Lost SpringDokument20 SeitenNCERT Solutions For Class 12 Flamingo English Lost SpringHarsh solutions100% (1)

- Image Formation in Plane Mirrors: Ray DiagramsDokument3 SeitenImage Formation in Plane Mirrors: Ray DiagramsSouvik BanerjeeNoch keine Bewertungen

- Bimbo Marketing ResearchDokument27 SeitenBimbo Marketing Researcheman.konsouhNoch keine Bewertungen

- Avance Collection Mixer Grinder SpecsDokument3 SeitenAvance Collection Mixer Grinder SpecsfaNoch keine Bewertungen

- Rigor Mortis and Lividity in Estimating Time of DeathDokument2 SeitenRigor Mortis and Lividity in Estimating Time of DeathfunnyrokstarNoch keine Bewertungen

- Radiant Tube BurnersDokument18 SeitenRadiant Tube BurnersRajeshNoch keine Bewertungen

- trac-nghiem-ngu-am-am-vi-hoc-tieng-anh-đã chuyển đổiDokument18 Seitentrac-nghiem-ngu-am-am-vi-hoc-tieng-anh-đã chuyển đổiNguyễn ThiênNoch keine Bewertungen

- Test 1 Grammar, Revised Ecpe HonorsDokument3 SeitenTest 1 Grammar, Revised Ecpe HonorsAnna Chronopoulou100% (1)

- Augustine and The Devil Two BodiesDokument12 SeitenAugustine and The Devil Two BodiesAlbert LanceNoch keine Bewertungen

- Main: Exploded ViewDokument30 SeitenMain: Exploded ViewamokssantiagoNoch keine Bewertungen

- KOREADokument124 SeitenKOREAchilla himmudNoch keine Bewertungen

- Range of Muscle Work.Dokument54 SeitenRange of Muscle Work.Salman KhanNoch keine Bewertungen

- Final Case Study 0506Dokument25 SeitenFinal Case Study 0506Namit Nahar67% (3)