Beruflich Dokumente

Kultur Dokumente

Boiler Anf Turbine

Hochgeladen von

Kshirod Mohan BoseOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Boiler Anf Turbine

Hochgeladen von

Kshirod Mohan BoseCopyright:

Verfügbare Formate

11/14/2019

What is Boiler?

Boiler Function, Boiler Accessories

Kshirod Mohan Bose

Executive Engineer (Mechanical)

Ghorashal 3rd Unit CCPP.

Mobile: 01711-076856

E-mail: kshirod124@yahoo.com

1 2

Phenomenon Water (Steam Generation) Pressure Temperature Relationship for Water

Sensible Latent Heat Sensible Latent Heat Sensible Temperature °C

CRITICAL POINT

Heat of fusion Heat of vaporization or condensation Heat

150oC

400 374.15°C What is Supercritical

350°

Pressure ?

Water boiling 22123 kPa

15000 kPa Critical point in water

100oC

Temperature oC

300° 10000 kPa vapour cycle is a

Steam Condensing thermodynamic state

250° 5000 kPa where there is no clear

3000 kPa distinction between

200° liquid and gaseous state

Change of State of water

Ice Melting 150° 600 kPa

Steam Water reaches to this

0oC Water

Ice Freezing 100° 100 kPa state at a critical

ICE Change of State pressure above 22.1 MPa

-17.77oC 50° and 374 oC

37 kJ 334 kJ 418 kJ 2250 kJ 97.4 kJ

Heat (kJ) per kg of Water 0° Pressure kPa

3 4

Classification of Boiler

On the basis of Use: For power

Plant On the basis of

On the basis of

furnace Position

Tube of Boiler

Stationary For Utility of Boiler

Boiler Power Plant

Water Externally

For Plant

Process

Tube Fired

Boiler

Locomotive Internally

Fire Tube

Mobile Fired

boiler

Marine

5 6

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 1

11/14/2019

On the basis of Steam On the basis of

Circulation Draught

Boiler

Natural Natural Draught

Hot Waste Gases as By- Circulation Boiler Boiler

Solid/Liquid/Gaseous Fuel product of other

Electrical Nuclear

(Conventional Boiler) Chemical Process Energy Energy

(HRSG) Forced Forced Draught

Circulation Boiler Boiler

Induced Draught

HRSG

Gas &

HRSG with

Boiler

Coal Fired Oil Fired Gas Fired Oil/Duel

without Burner/d

Boiler Boiler Boiler Fuel

Burner uct Firing

Boiler Balanced

System

Draught Boiler

7 8

• Application: hotel, heater, small industrial • Application: Auxiliary boiler, industrial process

Low Pressure

process • Fuel: Oil and Gas only

boiler

• Fuel: Oil, Gas • Steam Capacity up to 220 Ton/hr

(P<1.275 MPa)

• Steam capacity up to 5 Ton/h • Design Pressure up to 110 Bar

• Saturated temperature • Design Temperature up to 500o C

Medium Pressure

boiler (P<3.82 • Design pressure up to 2.5 Bar • Mainly shop assembly, very minimum site works

Sub Critical MPa) • Fully shop assembly

Pressure boiler

(P<16.67 MPa) High Pressure

Boiler boiler

Super Critical (P<9.8 MPa)

Pressure boiler

(P<22.13 MPa) Super High

Pressure boiler

(P<13.73 MPa)

9 10

Heat Recovery Steam Generator (HRSG)

• Application: Steam turbine drive

(turbine propulsion) in the shipboard

• Multi Fuels: Oil, Gas and Solid

• Steam Capacity up to 70 Ton/hr

• Design Pressure up to 58 Bar

• Design Temperature up to 500o C

• Limited spaces, compact arrangement

• Dynamic behavior

11 12

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 2

11/14/2019

HRSG of Ghorashal 3rd Unit

• Application: Industrial process, Steam

Bypass Stack

turbine drive (< 50 MW)

Stack

• Multi Fuels: Oil, Gas and Solid

• Steam Capacity up to 200 Ton/hr

• Design Pressure up to 120 Bar

• Design Temperature up to 500o C

• Site assembly

LP Super-heated

IP Super-heated

Steam

HP FWP IP FWP

Consideration of Industrial Boiler:

IP HP – Multi-fuel Burning capability

Steam

OTC OTC

– Waste Fuel Utilization (biomass, waste acid,

Deaerator

sludge, etc.)

HP Super-heated Steam

Triple Pressure Drum, Natural Circulation Type – Cogeneration Potential to maximize heat

from their fuel

13 14

Drum

Final Super Heater

Down comer

• Application: Electric Utility (more

Secondary Super Heater

than 50 MWe) Primary Super Heater

• Main Fuel: Coal Water Wall Re- Heater

• Steam Capacity up to 1,850

Ton/hr (600 MW) Burner Position

• Design Pressure up to 173 Bar Economizer

• Design Temperature up to 550o C Lower Header

• Site assembly

Cross Sectional View of an

Utility Boiler

15 16

To IPC From HPC

To HPC

Stack

Platen SH

Con. SH 1

Con. SH 2

RH 2

RH 1

• Application: Electric Utility

• Fuels: Pulverized Coal

• Steam Capacity up to 2,500

Econ. Ton/hr (800 MW)

Regenerative Air • Design Pressure up to 253 Bar

Radiant SH FW Heater • Design Temperature up to

565o C

• Higher efficiency (no steam

drum, no blow-down system)

FD Fan

Air

ID Fan

FUEL • Feed water quality is major

concern

Furnace Boiler of 210 MW Ghorashal Power Station • Site assembly

Sub- critical, Super High Pressure, Water Tube,

Balanced Draft with Condensing Turbine

© kshirod124@yahoo.com

17 18

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 3

11/14/2019

Features of Super Critical Boiler Efficiency and CO2 Emission

• Latent heat for evaporation is not required

• Internally Ribbed Tube construction

• Increases heat transfer rate Steam Steam CO2

Plant type Efficiency

Pressure Temperature Emissions

• Spiral tube water wall construction with power rating (%)

(kg/cm2) (C) (g/kW-hr)

• Absence of nuclear boiling

• Maintenance free boiler

Sub Critical

• Circulation is forced type 170 540 35 900

(Maximum Capacity 500 MW)

• Absence of Dozing, Condensate Polishing Unit (CPU) is applied for maintaining the

water quality

# Super Critical 247 565 40 830

• Less emission Up to Crip limit

• Higher efficiency Ultra Super Critical 250 600 42 784

• Less fuel consumption

• No Blow down (Less water consumption) Advanced Ultra Super

300 700 45 740

Critical

19 20

Circulation of Water and Steam in Boiler

Natural Circulation • Forced Circulation

Furnace

– radiation mode

STEAM (Ms)

Spaced SH

Radiant SH

Evap.

Ms Radiant (Platen) Super-heater

– luminous radiation mode

Econ.

WATER – non-luminous radiation mode

Mw

(Mw) – convection mode

COLD SIDE

Steam +

Convective (Spaced) Super-heater

DOWNTAKE or

DOWNCOMER

Water

– non-luminous radiation mode

HOT SIDE

HOT SIDE

COLD SIDE

– convection mode

Evaporator (Boiler Bank)

Furnace

– convection mode

Economizer

ORIFICE – convection mode

CIRCULATING PUMP

21 22

Water Wall Construction

Tube & Tile

Furnace and convection pass

Tangential Tube

Water Circuits, including drums and steam separators and re-heater.

Connection Piping and Headers Studded Tube

Burners

Membrane Wall Studded Tube

23 24

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 4

11/14/2019

Boiler Drum Internals Burner

Cyclone Separators

Water Level

• Fuel

• Natural Gas

• Oil

• Coal Dust

• Quantity

• Boiler Size

25 26

Boiler Auxiliaries Air Heaters

Non- pressure Boiler

Components Balance of Plant

Equipment

(Fuel & Air System)

• Fuel preparation • Fans

Equipments • Feed Pumps

• Burners • Pollution Control

• Air Heaters Equipment

• Duct works and supports. • Controls

Tubular Air Heater Re- Generative Air Heater 28

27 28

Economizer

• Used for Feed Water

Heating.

• For adding heat at higher

temperature

• Use waste Heat

• Increases Efficiency.

29 30

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 5

11/14/2019

Feed Pump

• Multi- stage

centrifugal pump

• Driven by Motor or

Turbine

• May be configured as

1 100%, 2 100%, 3

66%

31 32

COMBUSTION AIR and FLUE GAS CIRCUITS

Fan types

33 34

What turbine?

Details Discussion on Different • Turbine is an engine that converts energy of fluid into mechanical

energy

types of Turbine

35 36

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 6

11/14/2019

On the basis of Action On the Basis of Working Fluid

Turbine

Turbine

Hydro Steam Gas Turbine

Turbine Turbine (Reaction)

Impulse Reaction Pelton

Turbine

Kaplan Turbine

(Axial Flow -

Francis Turbine

(Radial Flow- Impulse

Impulse &

Reaction

Turbine Turbine (Impulse) Reaction) Reaction) Reaction

37 38

On the basis of Steam flow

Steam Turbine

Condensing Back pressure Extraction

Turbine Turbine Turbine

Condensing Back Pressure

39 40

Impulse Turbine Impulse Turbine

41 42

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 7

11/14/2019

Reaction type

43 44

45 46

Blade Arrangement

Impulse Turbine Reaction Turbine

47 48

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 8

11/14/2019

IMPULSE-REACTION TURBINE

49 50

Gas Turbine Components of Gas Turbine

Combustion Chamber

• Compressor to compress air[Iso-entropic Compression]

• Combustion Chamber to add Heat by burning the fuel [Constant

Air Exhaust Pressure Heat Addition]

Flue Gas • Turbine to convert energy for flue gas to Mechanical Energy [Iso-

~

entropic Expansion]

Generator

Compressor Turbine

51 52

Air intake system: Compressor

• Compressor sucks air • Compressor is rotary type air

through an air intake compressor which is coupled

manifold. with the turbine hence is

• The air used for GT is driven by the turbine.

filtrated.

• To control air flow Inlet guide

• The air from vanes is used, named Variable

Atmosphere through

air cleaners in which Inlet Guide Vane (VIGV) &

big & small dust Variable Guide Vanes (VGVs).

particles are removed. • The compressor has multi-

stages of blades.

53 54

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 9

11/14/2019

Combustion System: Turbine and exhaust system:

• Heavy Duty Gas turbine of common type has three to five

stages.

• Each stage blade is provided

• with air-cooling system to sustain in high temperature. The

flue gas temperature just after firing is about 900o C to

1300oC the final temperature at exhaust zone is about only

550oC to 650oC

• The flue gas after combustion passed through stages of

nozzle and Blades (Conventionally called Bucket)

• Passing through blades the flue gas goes to exhaust

diffuser at reduced pressure and temperature.

55 56

GT26 Operating Principle

From Air Intake

Combustion Chamber Turbine Blades Exhaust Diffuser

System

Compressor

Fig.-Simple Cycle Single Shaft Heavy Duty Gas Turbine

57 58

Electrical System (Simplified SLD)

230 kV Substation Hydro Energy

HCB

Gen Step-up

Transformer

YNd1, 392 MVA

ODAF

20/230 kV

Service Transformer

20/6.75/3.5 kV

GCB 30/20/15 MVA

To 6.6 KV

Excitation Transformer

Static Starting Device (SSD)

Generator,

375 MVA at

40oC

~ Static Excitation System

From 0.4 kV

59 60

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 10

11/14/2019

Types of Hydroelectric Installation Meeting Peak Demands

Head (50 m above)

• Hydroelectric plants:

Head 15 m to 50 m • Start easily and quickly and change power output rapidly

Head less than 15 m

• Complement large thermal plants (coal and nuclear), which are most efficient

in serving base power loads.

• Save millions of barrels of oil

61 62

Conventional Impoundment Dam Large Hydropower

Hoover Dam (US)

63 64

Example

Diversion (Run-of-River) Hydropower Diversion Hydropower (Tazimina, Alaska)

65 66

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 11

11/14/2019

UMM, Indonesia Experiences in Micro-hydro

Small Hydropower

Small hydropower facilities

can produce

100 – 30,000 kilowatts

(kW) of electricity.

Small hydropower facilities

may involve a small dam,

or be a diversion of the

main stream, or be a

run-of-the-river system.

67 68

Types of Hydropower Turbines Classification of Hydro Turbines

• Reaction Turbines

• Derive power from pressure drop across turbine

• Totally immersed in water

• Angular & linear motion converted to shaft power

• Propeller, Francis, and Kaplan turbines

• Impulse Turbines

• Convert kinetic energy of water jet hitting buckets

• No pressure drop across turbines

• Pelton, Turgo, and cross flow turbines

69 70

Francis Turbine Fixed-Pitch Propeller Turbine

71 72

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 12

11/14/2019

Kaplan Turbine Kaplan Turbine

73 74

Vertical Kaplan Turbine Setup Horizontal Kaplan Turbine

75 76

© Kshirod Mohan Bose, XEN, GPS +8801711076856,

78

kshirod124@yahoo.com

77 78

Kshirod Mohan Bose, XEN, G3 CCPP,

01777760056, 01711076856 13

Das könnte Ihnen auch gefallen

- Chapter-2 Steam Cycle TheoryDokument20 SeitenChapter-2 Steam Cycle TheoryPhanindra Kumar J100% (1)

- MODEL 496: Nfpa Gravimetric Coal FeederDokument2 SeitenMODEL 496: Nfpa Gravimetric Coal FeederZahoor Ahmed100% (1)

- Steam Turbine and Its Auxiliary Systems: Course PurposeDokument19 SeitenSteam Turbine and Its Auxiliary Systems: Course PurposeMuhammad luqmanNoch keine Bewertungen

- Control Engineering February 2019 PDFDokument62 SeitenControl Engineering February 2019 PDFdavev2005Noch keine Bewertungen

- TurbineDokument23 SeitenTurbineKarthikeyanNoch keine Bewertungen

- Final Project KundanDokument55 SeitenFinal Project KundanKundan Singh100% (1)

- Stackers Active in The StockyardDokument4 SeitenStackers Active in The Stockyardsalkan_rahmanovic810Noch keine Bewertungen

- QMS Paper PDFDokument13 SeitenQMS Paper PDFPrisman Cahya NugrahaNoch keine Bewertungen

- MP Lecture NotesDokument125 SeitenMP Lecture NotesTatenda SibandaNoch keine Bewertungen

- Presentation On Coal Handling Systems: Prepared By:-Arnab Chakraborty Mba-PmDokument16 SeitenPresentation On Coal Handling Systems: Prepared By:-Arnab Chakraborty Mba-PmIgnatius SamrajNoch keine Bewertungen

- Project Management in Thermal Power Plant-Ntpc'S ExperienceDokument58 SeitenProject Management in Thermal Power Plant-Ntpc'S ExperienceEzhil Vendhan PalanisamyNoch keine Bewertungen

- 1c Low Mass Flux Once Through Boiler Design Application and PDFDokument52 Seiten1c Low Mass Flux Once Through Boiler Design Application and PDFfrlamontNoch keine Bewertungen

- CHP - ECL Chairman Review PresentationDokument29 SeitenCHP - ECL Chairman Review PresentationdebajyotiNoch keine Bewertungen

- Project Review: CHP - Jhanjra, West BengalDokument12 SeitenProject Review: CHP - Jhanjra, West BengaldebajyotiNoch keine Bewertungen

- Dokumen - Tips Coal Handling Plant 589be8a41d9eaDokument29 SeitenDokumen - Tips Coal Handling Plant 589be8a41d9eaWasim MalkaniNoch keine Bewertungen

- Cleaning of Coal - 2008Dokument17 SeitenCleaning of Coal - 2008vineetakaushik83Noch keine Bewertungen

- S.No. Components Makes: 1 Grab Cranes - Gantry TypeDokument4 SeitenS.No. Components Makes: 1 Grab Cranes - Gantry TypeHarish KumarNoch keine Bewertungen

- Otsc - Control Final-BoilerDokument85 SeitenOtsc - Control Final-BoilerKumar100% (1)

- HAWK Sultan Acoustic Wave Series PDFDokument103 SeitenHAWK Sultan Acoustic Wave Series PDFJuan Carlos DavidNoch keine Bewertungen

- NTPC TrainingDokument32 SeitenNTPC TrainingparvejNoch keine Bewertungen

- CONDENSER Air ExtractionDokument2 SeitenCONDENSER Air Extractiontrung2iNoch keine Bewertungen

- Coal Handling PlantDokument39 SeitenCoal Handling PlantMukhtar AlamNoch keine Bewertungen

- Presentation ON Kota Super Thermal Power Plant KotaDokument22 SeitenPresentation ON Kota Super Thermal Power Plant KotaKaran MalhotraNoch keine Bewertungen

- Stg1 FA SystemDokument11 SeitenStg1 FA Systemit's mRFz Kavi100% (1)

- BoilerOpt Overview and Results 7-18-16-UsefulDokument53 SeitenBoilerOpt Overview and Results 7-18-16-Usefultrung2iNoch keine Bewertungen

- Paper 6 FRF-lube - Oil - MixingDokument34 SeitenPaper 6 FRF-lube - Oil - MixingsoorajssNoch keine Bewertungen

- C& I For SupercriticalDokument93 SeitenC& I For SupercriticalPrudhvi RajNoch keine Bewertungen

- GS IlmsDokument13 SeitenGS IlmsShashank HegdeNoch keine Bewertungen

- CMC - European SystemDokument2 SeitenCMC - European SystemNitin SinghNoch keine Bewertungen

- Benson BoilerDokument20 SeitenBenson BoilerjigsprajapatiNoch keine Bewertungen

- Lecture 27 Model Steam Turbine Gov SystemDokument60 SeitenLecture 27 Model Steam Turbine Gov Systempk cfctkNoch keine Bewertungen

- Plates Steel MetalDokument12 SeitenPlates Steel MetalAnonymous aWpx7nENoch keine Bewertungen

- Overview of Mejia Thermal Power StationDokument35 SeitenOverview of Mejia Thermal Power StationNitish KhalkhoNoch keine Bewertungen

- LUBE Oil System, BearingDokument54 SeitenLUBE Oil System, BearingHelal RahmanNoch keine Bewertungen

- Price Format 'A' (Main Equipment) For Wagon Tippler, Crushing and Conveying Plant Package For NTPC Vindhyachal STPP Stage III (2 X500 MW)Dokument4 SeitenPrice Format 'A' (Main Equipment) For Wagon Tippler, Crushing and Conveying Plant Package For NTPC Vindhyachal STPP Stage III (2 X500 MW)istyloankurNoch keine Bewertungen

- Presented By:: SHUBHAM MISHRA (1513231170) Electronics and Communication Branch 4 YearDokument19 SeitenPresented By:: SHUBHAM MISHRA (1513231170) Electronics and Communication Branch 4 YearShubham MishraNoch keine Bewertungen

- The NTPC Vindhyachal Coal Handling PlantDokument3 SeitenThe NTPC Vindhyachal Coal Handling Plantlaloo01Noch keine Bewertungen

- Poor Oil Gun Performance in BoilersDokument3 SeitenPoor Oil Gun Performance in BoilersRAPRATSINNoch keine Bewertungen

- Chapter 12Dokument12 SeitenChapter 12bhaskarNoch keine Bewertungen

- CHP Flow DiagramDokument2 SeitenCHP Flow DiagramShajal ChowdhuryNoch keine Bewertungen

- Flow Diagram of CHPDokument2 SeitenFlow Diagram of CHPNaresh Raju100% (1)

- Chapter-5 Steam TurbineDokument26 SeitenChapter-5 Steam Turbinehadush gebreNoch keine Bewertungen

- Construction Working and Maintenance of Equipments For Unloading Bulk MaterialsDokument26 SeitenConstruction Working and Maintenance of Equipments For Unloading Bulk MaterialsDead poolNoch keine Bewertungen

- Proportional Solenoid ValveDokument29 SeitenProportional Solenoid ValveRahul Dev GoswamiNoch keine Bewertungen

- Power Station Pumps-Condensate Extraction Pumps & Circulating Water PumpsDokument30 SeitenPower Station Pumps-Condensate Extraction Pumps & Circulating Water PumpsSakthi MuruganNoch keine Bewertungen

- Boiler Dantrubin Control Rembang Dan PacitanDokument39 SeitenBoiler Dantrubin Control Rembang Dan Pacitanbintang arcano lugasNoch keine Bewertungen

- Write Up On Crusher HouseDokument3 SeitenWrite Up On Crusher HouseKumaraswamyNoch keine Bewertungen

- Paper 1 Reduction in Coal Unloading TimeDokument31 SeitenPaper 1 Reduction in Coal Unloading TimezahoorNoch keine Bewertungen

- Dfds CompressorDokument54 SeitenDfds CompressorRahul Dev GoswamiNoch keine Bewertungen

- GEECO Enercon Pvt. Limited: Raph - Esp - CFD - Fea - Fes - Testing - TrainingDokument24 SeitenGEECO Enercon Pvt. Limited: Raph - Esp - CFD - Fea - Fes - Testing - TrainingAkasthiyanNoch keine Bewertungen

- Automatic Turbine Testor Gyanendra Sharma Npti DelhiDokument26 SeitenAutomatic Turbine Testor Gyanendra Sharma Npti DelhiNPTINoch keine Bewertungen

- Technical Specification For Fly Ash Handling System, R0Dokument7 SeitenTechnical Specification For Fly Ash Handling System, R0SumitskbNoch keine Bewertungen

- Chapter-1 Steam Turbine TheoryDokument17 SeitenChapter-1 Steam Turbine TheorybhaskarNoch keine Bewertungen

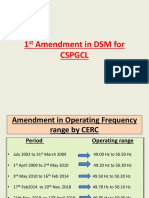

- 1 Amendment in DSM For CSPGCLDokument19 Seiten1 Amendment in DSM For CSPGCLashish jainNoch keine Bewertungen

- AnilDokument49 SeitenAnilAnil BhairatNoch keine Bewertungen

- 2B - 800MWKudgi - Ash Handling Vol I NTPC TenderDokument616 Seiten2B - 800MWKudgi - Ash Handling Vol I NTPC Tendersreedhar_blueNoch keine Bewertungen

- Boiler RajshahiDokument178 SeitenBoiler RajshahiKshirod007Noch keine Bewertungen

- Industrial TrainingDokument56 SeitenIndustrial TrainingKshirod Mohan BoseNoch keine Bewertungen

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesVon EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNoch keine Bewertungen

- DC & Ups: Engr. Kshirod Mohan Bose Executive Engineer (Mechanical) & (Operation) Ghorashal 3 Unit Repowered CCPPDokument31 SeitenDC & Ups: Engr. Kshirod Mohan Bose Executive Engineer (Mechanical) & (Operation) Ghorashal 3 Unit Repowered CCPPKshirod Mohan BoseNoch keine Bewertungen

- Iso EhsDokument6 SeitenIso EhsKshirod Mohan BoseNoch keine Bewertungen

- HSE Welcome Book For ContractorDokument58 SeitenHSE Welcome Book For ContractorHunterNoch keine Bewertungen

- Course Outline: Kshirod Mohan Bose Executive Engineer (Mechanical) 3rd Unit Re-Powered CCPP, Ghorashal Power StationDokument11 SeitenCourse Outline: Kshirod Mohan Bose Executive Engineer (Mechanical) 3rd Unit Re-Powered CCPP, Ghorashal Power StationKshirod Mohan BoseNoch keine Bewertungen

- Industrial TrainingDokument56 SeitenIndustrial TrainingKshirod Mohan BoseNoch keine Bewertungen

- Bab 5 Air and LarutanDokument16 SeitenBab 5 Air and Larutanjasonyeoh333Noch keine Bewertungen

- Synthesis and Magnetic Properties of Cobalt Ferrite (Cofe O) Nanoparticles Prepared by Wet Chemical RouteDokument18 SeitenSynthesis and Magnetic Properties of Cobalt Ferrite (Cofe O) Nanoparticles Prepared by Wet Chemical Routeprabhjot100Noch keine Bewertungen

- Water-Lithium Bromide Vapor Absorption SystemDokument15 SeitenWater-Lithium Bromide Vapor Absorption SystemSagar MoreNoch keine Bewertungen

- Solved Exercise MassDokument3 SeitenSolved Exercise MassMalak HindiNoch keine Bewertungen

- Name and Section: Score:: V P Constant V T Constant P V Constant PV ConstantDokument4 SeitenName and Section: Score:: V P Constant V T Constant P V Constant PV ConstantJohnnard BelenNoch keine Bewertungen

- Wall Boiling ModelsDokument10 SeitenWall Boiling ModelsMohsen SalehiNoch keine Bewertungen

- Chemical Engineering For Non-Chemical Engineers - Vol. 02 - DHARMSINH DESAI UNIVERSITYDokument150 SeitenChemical Engineering For Non-Chemical Engineers - Vol. 02 - DHARMSINH DESAI UNIVERSITYGustavo Gonzalez ServaNoch keine Bewertungen

- X-Ray Crystallography CHE4314Dokument67 SeitenX-Ray Crystallography CHE4314zahara99121Noch keine Bewertungen

- Compressed Air Systems PSD CEU 205nov13 0Dokument17 SeitenCompressed Air Systems PSD CEU 205nov13 0Ryan Carter100% (2)

- Design of Oil and Natural Gas PipelinesDokument13 SeitenDesign of Oil and Natural Gas PipelinesAhmed MoustafaNoch keine Bewertungen

- Pages From Centrifugal Pumps HandbookDokument4 SeitenPages From Centrifugal Pumps HandbookSHINoch keine Bewertungen

- L23 B - Energy BalanceDokument19 SeitenL23 B - Energy BalanceluckyluckNoch keine Bewertungen

- Design of CondenserDokument2 SeitenDesign of CondenserEngr Renato Arriola0% (1)

- Distillation ColumnDokument23 SeitenDistillation ColumnRanjani J DeepakNoch keine Bewertungen

- ch4 Test BankDokument9 Seitench4 Test BankJerry LouNoch keine Bewertungen

- Guide To Registration Rev 9 - February 2014Dokument5 SeitenGuide To Registration Rev 9 - February 2014Anton WelgemoedNoch keine Bewertungen

- SS1 Chemistry 2nd Term Lesson Note PDFDokument58 SeitenSS1 Chemistry 2nd Term Lesson Note PDFKelly Isaac100% (3)

- Chapter 6. Introduction To Convection: Eunseop Yeom Esyeom@pusan - Ac.krDokument11 SeitenChapter 6. Introduction To Convection: Eunseop Yeom Esyeom@pusan - Ac.krqusayNoch keine Bewertungen

- Bci - 750gpm@250psi PDFDokument2 SeitenBci - 750gpm@250psi PDFSergio ZegarraNoch keine Bewertungen

- SHS Gr.12 Chap 9Dokument23 SeitenSHS Gr.12 Chap 9Cj NacarioNoch keine Bewertungen

- Tablas Munson.2Dokument11 SeitenTablas Munson.2Juan Pablo GuevaraNoch keine Bewertungen

- TT P1Dokument4 SeitenTT P1Juan Manuel Uceda PérezNoch keine Bewertungen

- Absorption TheoryDokument67 SeitenAbsorption TheoryAnkita SharmaNoch keine Bewertungen

- Distillation Process and Application in Food IndustryDokument13 SeitenDistillation Process and Application in Food IndustryShannel Audrey BadlisNoch keine Bewertungen

- Chapter (3) - Properties of Pure SubstancesDokument34 SeitenChapter (3) - Properties of Pure Substancesweam nourNoch keine Bewertungen

- Sieve Plate Distillation ColumnDokument9 SeitenSieve Plate Distillation ColumnAshish VermaNoch keine Bewertungen

- 720-C-001 (Vent Wash Column)Dokument4 Seiten720-C-001 (Vent Wash Column)idilfitriNoch keine Bewertungen

- Class 10 p1 Thermal PhysicsDokument10 SeitenClass 10 p1 Thermal PhysicsSameer Abu MunsharNoch keine Bewertungen

- 03 Flowatch HS Field Calibration Proceduretest RevBDokument7 Seiten03 Flowatch HS Field Calibration Proceduretest RevBedwin_triana_9Noch keine Bewertungen

- Tutorial 9 Solutions 1Dokument5 SeitenTutorial 9 Solutions 1Henry TranNoch keine Bewertungen