Beruflich Dokumente

Kultur Dokumente

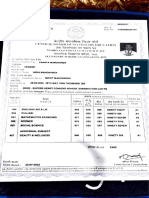

lEBJ) : Inspection Certificate

Hochgeladen von

PRANAY OMTECHOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

lEBJ) : Inspection Certificate

Hochgeladen von

PRANAY OMTECHCopyright:

Verfügbare Formate

~~~,!

JI;P}

CUSTOMER'S CONTROL'No.

~~1~~ ~lEBJ]~ ifiB~~in*iX(ai±

NIPPON STEEL & SUMlTOMO METAL CORPORATION

Jl ,i'J •. ~: '

CONTRACT No. 1-813-N2-1~4-E785 INSPECTION CERTIFICATE * tt :"flOO-807l .Jit~TttEllIRM:m=Ta 6~ 1~

.

lIlI . Ii. ;SEAMLESS STAINLESS STEEL PIPE HEAD 0 F F ICE :6·1 MARUNOUCHI2.CHOME CHIYODA·KU.TOKYO 100·8071JAPAN

COMMODITY ~'i';;U,tlitlftWi'llf8il: T743-8SlD wC~;'tm*~lir.EIl3 43 4 ~~

fr ~ .ASTM A312/ASME SA-312 GRADE • ..," INTERNATIONAL STEEL CORPORATION OITA WORKS (HIKARI PIPE & TUBE DIV.)

• TP 316L CUSTOMER : 3 U 4.S H I M4lA, H I KA R 1·5 HI, YA MAGUCHI, 7 43·8 51O,JAPA N

SI'JOCJFICATION

.., :I P}I '" ;t ~ .

CLIENT CERTIFICATE NO: 191452756-83

;.1 :It:; : ~rr~1'I8:

SHIPPER SUMITOMO CORPORATION DATE OF ISSUE 29 - 04 - 2019

A312-15/EN 10204.3,1 - PMI - INTERGRANULAR CORROSION TEST AS PER ASTM A262 PRACTICE - E

~3i~~ lIl.~t8:~ 11:;!F lit ~ CHEMICAL COMPOSITION (%) XIOO!I:XI,OOO•• :XIO,OOOlz

~IH1U9 TENSILE TEST

If~ml *If;;t~

'1 ;ii CRT

fir: A~ ~ Jl Url!i11J1011 INSPECTION No, PI~~ON

ITA DARD HARDNESSHYDROSTATIC

_ ~~.iii C Si Mn P S Ni Cr Mo N "

<.> m 'tl ~I~!:le!$.u TEST TEST

ITEM SI Z E NUMBEROF MASS U·BEND IUf,I~~ H t t t

.,

.,

e,

YS TS A262

.

:: MANUfACrultNG

No. 00 X THK RADIUS ~ KSI KSI E:L HRB PISG P R, E

PRODUCT Kg

...

Mo. HEAT No, P

(mm) ~ %

MIN 1000 1600 200 25 70 3.5

MAX 30 100 200 45 30 1400 1800 300 ro 95

1 1U' Nl:::!x::sch1U 55 9170 1 N754913 D782397 H 21 48 132 28 12 1129 1677 228 06 I L 37 89 41 189 1150 G

(5 -7 M) 5 Sec.

P 22 47 139 25 10 1124 1673 224 03

P 25 45 130 29 11 1128 1676 219 05

.•

'

~U,-q;:1; VISUAL & DIMENSIONS: GOOD l:uI "0 T £~'I~JIS(4:No.4. S:No.S. l:No.l1.A:No,I2A, 8:No.128, C:No.l3BJ, .l:!c;iX8bI;t. 1l(I~l:f~Q)m.ma:t.:I;tft~l:itE?"(~l§~.h.

Slrlp(E:l.0'1. F:3I4fn, G:lln). ~.FuJ1Stcllon, ;t-Q)~**.I.A~~~ l""(~ \.0;':' t:~IiIP)jl"a:T.

m.tlll1<Jl: (!}J L :IiI:11'~Longitudinal, T:III:II'1li Trlllsverse, G L :!li:Ma Gaug. Leng~

NON·DESTRUCTIVE INSPECTION

YS:Yleld Strength. TS:Tll1SIla Strength. EL: Eiongatlol\. c: tltl Good WE HEREBY CERTIFY THAT THE MATERIAL DESCRIBED HEREIN

UT: GOOD crr: hR' -tI:l:1iUl Charpy Impact Tut. CRT: IIUlliUl CoIR)$lon Tist HAS BEEN MADE IN ACCORDANCE WITH THE RULES OF THE CONTRACT. E 10

AGSfFGS: Hm~nz'm:aliUt Austenitic I FlnfVc Graln Sl~.No.

~ ~ !J HEATTREATMENT SP: ""n~~ Sulphw PM~ AP: ;Sill. Ampltuc!!l Permeability

SURVEYOR TO

SOLUTION

COOLING

ANNEALED 1050DEG. F X 1MIN. W, Q, N!.!I: n._1I'!l1ll Non Melal1ll: incluSion. HNT: IIlMI.I'. HarClanabilly Tnt

MOT: lIIJII.iIl~1iUl .'.la.IUllng Otc4,burl ••• d Ooplt> Test

HIP: SfiUtff/lIlIitff Heat Analysis I Product Maly""

"

--~-.£~-

g~~n:~f;;

SH: J:;S~1Il1l Solulfon Heat·treatment, BT: _If Bend Test

*~U1SHJi

PMI GOOD, G. L = 50 mm HEAD OF DEPARTMENT

NACE MR0103/NACE MR017511S015156 ETlUTiPT::AlRIMitlVll.IIlR.U. ECldy Crrent' UI\IaSOnk: I PeMtran! Test

QUAUTY

ASSURANCE DEPT.

OITAWORKS

PICKLED AND PASSIVATED CONDITION

Das könnte Ihnen auch gefallen

- 98240-31970 - Parts Catalogue S12r-Pta, Mpta, MPTK - Aug.1999Dokument373 Seiten98240-31970 - Parts Catalogue S12r-Pta, Mpta, MPTK - Aug.1999Ricky Burtonshaw78% (9)

- MF-220 Automatic Control Valve (Temp. Press. Level) PDFDokument75 SeitenMF-220 Automatic Control Valve (Temp. Press. Level) PDFThanh Nghị BùiNoch keine Bewertungen

- 15 Samss 502Dokument10 Seiten15 Samss 502Praba Hiruthya SNoch keine Bewertungen

- Yc Inox Co., LTD.: Inspection CertificateDokument1 SeiteYc Inox Co., LTD.: Inspection CertificateMuneer KonajeNoch keine Bewertungen

- 11m-4level SwitchDokument21 Seiten11m-4level SwitchHarry HNoch keine Bewertungen

- Ec-5 MotorDokument38 SeitenEc-5 MotorBorysNoch keine Bewertungen

- List No: Nishishiba Electric Co., LTDDokument17 SeitenList No: Nishishiba Electric Co., LTDBorys100% (1)

- Honda Goldwing Clarion Type I Radio Installation ManualDokument11 SeitenHonda Goldwing Clarion Type I Radio Installation ManualFrans BeeckxNoch keine Bewertungen

- List of Explosion-Proof Type Electrical Equipment PDFDokument54 SeitenList of Explosion-Proof Type Electrical Equipment PDFJOSEPH DIAS100% (1)

- 6987-LEPC1-SE-00-QC-PQ-0020 Rev. 01 - ITP For Radiographic TestingDokument7 Seiten6987-LEPC1-SE-00-QC-PQ-0020 Rev. 01 - ITP For Radiographic TestingSyed MoizuddinNoch keine Bewertungen

- TentDokument24 SeitenTenthanyassawy50% (2)

- GRAND TRADING Mrf-374 (DN No-196,197,198) (Burlap, Nails, Measuring Tape, Scrapper E.t.c) (FEB 06,, 2023)Dokument5 SeitenGRAND TRADING Mrf-374 (DN No-196,197,198) (Burlap, Nails, Measuring Tape, Scrapper E.t.c) (FEB 06,, 2023)sk mukhtarNoch keine Bewertungen

- 1M-4 Makers Address List of Machinery PartDokument5 Seiten1M-4 Makers Address List of Machinery PartAgastya SulinggihNoch keine Bewertungen

- Class 10 Marksheet PDFDokument1 SeiteClass 10 Marksheet PDFpadminni BalaNoch keine Bewertungen

- MF-09 Inspection RecordDokument22 SeitenMF-09 Inspection RecordpcatruongNoch keine Bewertungen

- Juki DDL-8700-7Dokument36 SeitenJuki DDL-8700-7Victor Hugo Tabares HerreraNoch keine Bewertungen

- 10th MarksheetDokument1 Seite10th MarksheetRanjeet Singh ChouhanNoch keine Bewertungen

- 3e-1 Magnetic CompassDokument34 Seiten3e-1 Magnetic Compasskedar444444Noch keine Bewertungen

- MF-104 Emergency Air Compressor (Including Test Record) PDFDokument13 SeitenMF-104 Emergency Air Compressor (Including Test Record) PDFThanh Nghị BùiNoch keine Bewertungen

- Certifcat Vannes de Coque Du Loud TunisieDokument10 SeitenCertifcat Vannes de Coque Du Loud TunisieBoulbaba Ben rejebNoch keine Bewertungen

- R831 Air Water Heat PumpDokument62 SeitenR831 Air Water Heat PumpRodrigoCisnerosNoch keine Bewertungen

- MF-215 Arrangement of StoreDokument2 SeitenMF-215 Arrangement of StoreThanh Nghị BùiNoch keine Bewertungen

- Spare Parts List - S 16 R - Mitsubishi PDFDokument626 SeitenSpare Parts List - S 16 R - Mitsubishi PDFGIGI100% (2)

- M30120B-531-002F - R1 - Domestic Water Service System PDFDokument17 SeitenM30120B-531-002F - R1 - Domestic Water Service System PDFirfanNoch keine Bewertungen

- 10 MarksheetDokument1 Seite10 MarksheetPrajwal BhandarkarNoch keine Bewertungen

- Catalago Cummins - Nta855-GDokument45 SeitenCatalago Cummins - Nta855-GAnonymous 9fCAFynM78% (9)

- Carbon Strip Skel 4303.rev 6Dokument1 SeiteCarbon Strip Skel 4303.rev 6praveenbharti1084Noch keine Bewertungen

- Juk MS-1190 1190MDokument28 SeitenJuk MS-1190 1190MRHoskaNoch keine Bewertungen

- DW083-P00-PSL-CON-MST-00001-04 RepDokument4 SeitenDW083-P00-PSL-CON-MST-00001-04 RepRaheelHashmiNoch keine Bewertungen

- Sanford and Son 509 My Fair Esther 1975Dokument46 SeitenSanford and Son 509 My Fair Esther 1975Tony EmmerNoch keine Bewertungen

- Ada 093491Dokument94 SeitenAda 093491legendxr58Noch keine Bewertungen

- E 18 DaylightDokument19 SeitenE 18 Daylightkaunghtet san1212Noch keine Bewertungen

- TT1500 1800 Series Electrical PT1H31UA03 PDFDokument138 SeitenTT1500 1800 Series Electrical PT1H31UA03 PDFGriffin Armament SuppressorsNoch keine Bewertungen

- Valvulas DEMBLADokument3 SeitenValvulas DEMBLAJose LuisNoch keine Bewertungen

- MF-159 Handling Manual and Construction Plan For Oil Heaters PDFDokument8 SeitenMF-159 Handling Manual and Construction Plan For Oil Heaters PDFThanh Nghị BùiNoch keine Bewertungen

- Ed-10 Magnetic CompassDokument7 SeitenEd-10 Magnetic CompassBorysNoch keine Bewertungen

- PG ClampDokument1 SeitePG ClampChandra Dwi SaputraNoch keine Bewertungen

- Digitalização 7 de Nov de 2017Dokument1 SeiteDigitalização 7 de Nov de 2017Anderson OliveiraNoch keine Bewertungen

- 10 THDokument1 Seite10 THAnkita SharmaNoch keine Bewertungen

- MF-144 Test & Inspection Record For Cargo Pumping SystemDokument14 SeitenMF-144 Test & Inspection Record For Cargo Pumping SystemThanh Nghị Bùi100% (1)

- 2019 11 10 FTB 4FDokument1 Seite2019 11 10 FTB 4FMohammed SabryNoch keine Bewertungen

- MF-01 Finished Drawing List For Machinery PartDokument16 SeitenMF-01 Finished Drawing List For Machinery PartpcatruongNoch keine Bewertungen

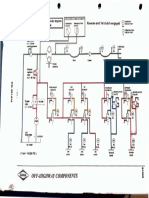

- JPO S&T Electrical PDFDokument11 SeitenJPO S&T Electrical PDFsantosh iyerNoch keine Bewertungen

- TMKDokument131 SeitenTMKSuperhypoNoch keine Bewertungen

- Genima ED4W-YD90-Serie-Spareparts-CatalogDokument33 SeitenGenima ED4W-YD90-Serie-Spareparts-Catalogcupid75Noch keine Bewertungen

- LJ G Frl'-1: LL - Lssi!J.Ujl.1. 1Dokument3 SeitenLJ G Frl'-1: LL - Lssi!J.Ujl.1. 1Denise CastilloNoch keine Bewertungen

- Intermediate Shaft BearingDokument22 SeitenIntermediate Shaft BearingTRANGNoch keine Bewertungen

- Juki T016Dokument18 SeitenJuki T016Ana Cecilia/aaron Amilivia CarabajalNoch keine Bewertungen

- MF-02 Machinery Particulars ListDokument9 SeitenMF-02 Machinery Particulars ListpcatruongNoch keine Bewertungen

- Vertikal Composite BoilerDokument21 SeitenVertikal Composite BoilerNur Salim ArisNoch keine Bewertungen

- 75 InstructionsDokument13 Seiten75 InstructionsSilverioNoch keine Bewertungen

- Partsbook Racing MCA-18KDokument27 SeitenPartsbook Racing MCA-18KMaskusyaniNoch keine Bewertungen

- MF-84 Inspection Report For Boiler Plant PDFDokument151 SeitenMF-84 Inspection Report For Boiler Plant PDFThanh Nghị BùiNoch keine Bewertungen

- FrontDokument1 SeiteFrontDusyanth KumarNoch keine Bewertungen

- Juk LG-158Dokument32 SeitenJuk LG-158RHoskaNoch keine Bewertungen

- Yd 490 Engine Partst CatlougeDokument33 SeitenYd 490 Engine Partst CatlougeP.p. Arul Ilancheeran67% (3)

- Adobe Scan 17 Sep 2023Dokument1 SeiteAdobe Scan 17 Sep 2023kaurn4446Noch keine Bewertungen

- 10 MarksheetDokument1 Seite10 MarksheetmanchandavaanyaNoch keine Bewertungen

- Wartsila 4R32 Spare Parts 1Dokument67 SeitenWartsila 4R32 Spare Parts 1mini1212Noch keine Bewertungen

- Coa - Cabosil m5 P Lot - 5l1415aDokument2 SeitenCoa - Cabosil m5 P Lot - 5l1415aHiral JagadNoch keine Bewertungen

- Cerj MS Id 555662Dokument9 SeitenCerj MS Id 555662احمد الدلالNoch keine Bewertungen

- Arbor Hotel - Bid FormDokument20 SeitenArbor Hotel - Bid FormJan Patrick AustriaNoch keine Bewertungen

- JKR20710 0001 11 PDFDokument13 SeitenJKR20710 0001 11 PDFGeneNoch keine Bewertungen

- Permacrib BrochureDokument4 SeitenPermacrib BrochureKamal Latif100% (1)

- Installation and Servicing Instructions: Alpha CD24C/32CDokument54 SeitenInstallation and Servicing Instructions: Alpha CD24C/32Cn67250Noch keine Bewertungen

- BMT Check Valve Series SHCV, Socv, Soacv, Sacv (En) - R3 (190601)Dokument10 SeitenBMT Check Valve Series SHCV, Socv, Soacv, Sacv (En) - R3 (190601)NnancyNoch keine Bewertungen

- Audible & Vibratory Pavement MarkingDokument4 SeitenAudible & Vibratory Pavement MarkingRoslan 'Abok' KamarudinNoch keine Bewertungen

- WOOD As A BUILDING MATERIAL 2Dokument9 SeitenWOOD As A BUILDING MATERIAL 2Jays Tioxon IIINoch keine Bewertungen

- Manual Reparación Gp30 Caja TransmisiónDokument94 SeitenManual Reparación Gp30 Caja Transmisiónyojar apazaNoch keine Bewertungen

- Fire Resistance Design ReferenceDokument16 SeitenFire Resistance Design ReferenceTing Sheng ChongNoch keine Bewertungen

- HPSR Road Pmgsy16Dokument62 SeitenHPSR Road Pmgsy16rajinder kutaal100% (2)

- Influence of Engineering Properties of Soils On Failures and Distresses of Earth Dams in North Eastern Nigeria IJERTV7IS010034Dokument8 SeitenInfluence of Engineering Properties of Soils On Failures and Distresses of Earth Dams in North Eastern Nigeria IJERTV7IS010034slv buildersNoch keine Bewertungen

- Commissioning Plan ExampleDokument59 SeitenCommissioning Plan Examplemikeo283% (12)

- Crack Repair by Gravity Feed With ResinDokument6 SeitenCrack Repair by Gravity Feed With ResinEladio Almengor100% (1)

- ABR PresentaitionDokument13 SeitenABR PresentaitionJony IslamNoch keine Bewertungen

- Types HousesDokument4 SeitenTypes HousesKaren CamargoNoch keine Bewertungen

- Asme Section II A Sa-395Dokument12 SeitenAsme Section II A Sa-395Anonymous GhPzn1xNoch keine Bewertungen

- Buena Mano Q3-2013 Greater Metro Manila Area CatalogDokument48 SeitenBuena Mano Q3-2013 Greater Metro Manila Area CatalogJay CastilloNoch keine Bewertungen

- Coil LoadDokument13 SeitenCoil LoadMakarand DeshpandeNoch keine Bewertungen

- Johnson Evinrude Water Circulation RepairsDokument14 SeitenJohnson Evinrude Water Circulation RepairsTonyNoch keine Bewertungen

- Piles CPWD Specs2009Dokument31 SeitenPiles CPWD Specs2009nipunNoch keine Bewertungen

- CE470 F07 Beam DesignDokument27 SeitenCE470 F07 Beam DesignMoisés Vázquez ToledoNoch keine Bewertungen

- 2.2.3 - DQR - PST Capacity-Rev B1Dokument7 Seiten2.2.3 - DQR - PST Capacity-Rev B1Sudip ShresthaNoch keine Bewertungen

- The Influence of Plugging On DriveabilityDokument12 SeitenThe Influence of Plugging On DriveabilityDedy DharmawansyahNoch keine Bewertungen

- Chapter 1B: Shell Structure: Lecture Notes of Building Construction IV Shells &domesDokument23 SeitenChapter 1B: Shell Structure: Lecture Notes of Building Construction IV Shells &domesRitika100% (1)

- OccupSftyAndHealthRegs1996 07 f0 00Dokument400 SeitenOccupSftyAndHealthRegs1996 07 f0 00FilipNoch keine Bewertungen

- MC117 PipingFailuresDokument3 SeitenMC117 PipingFailuresshakeelahmadjsrNoch keine Bewertungen

- Metallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoDokument1 SeiteMetallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoEmigdio MartinezNoch keine Bewertungen