Beruflich Dokumente

Kultur Dokumente

Thermalbond v2200 Foam Tape Tds 1067 PDF

Hochgeladen von

Dario DiazOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Thermalbond v2200 Foam Tape Tds 1067 PDF

Hochgeladen von

Dario DiazCopyright:

Verfügbare Formate

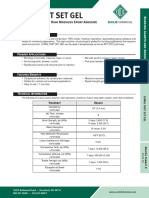

V2200 SERIES

High-Strength, Polyurethane Foam Spacer For

Structural Glazing

The Thermalbond® V2200 series is specially designed to

provide the following features: Extruded Mullion

• Open-cell structure allows air and moisture to reach the Thermalbond V2200

silicone for optimum curing of the silicone Thermalbond V2200

Structural Silicone Structural Silicone

• Semi-rigid polyurethane foam is compatible with all

silicone tested

• Low thermal conductivity improves the performance of

the wall and can support LEED points

• Excellent resistance to temperature variations, fungi and

oxidation APPLICATIONS

The Thermalbond V2200G272 configuration offers the same • Spacer for two- and four-

benefits as the standard configuration with addition of: sided structural glazing

• Gray foam core with UV stable gray pigmented adhesive systems

coatings

The Thermalbond Xpress® (TBX2) configuration offers the

same benefits as the standard configuration with addition of:

• Standard Thermalbond grade adhesive on one side

ensuring an aggressive bond to aluminum profiles

• Low friction coating eliminates trapped air pockets and

makes alignment of the glass simple and easy

• Adhesive will unwind from the specially treated top side

of the foam which eliminates the need to have a seperate

liner to remove and recycle

Available Sizes

Standard thickness: .125, .187, .250, .312 and .375 in.

(3.2, 4.8, 6.4, 7.9 and 9.5 mm)

Master roll size: 56 in. (1422 mm) width. Slit rolls also available.

Standard roll length varies with thickness.

Thermalbond V2200 Series www.tapesolutions.saint-gobain.com

Thermalbond V2200 Series – Properties

Performance tests are run using standard test procedures. The values presented are typical values and should

not be used for specification purposes.

Property Test Method Value or Rating

Density: lbs./cu. ft. (kg/m3) ASTM D1667 22 (352)

Hardness: Shore A ASTM D2240 30

Force to Compress 10%: psi (kPa) ASTM D1667 16 (110)

Dynamic Tensile Adhesion: psi (kPa)* (15 min. dwell) NTP-11 45 (310)

Dynamic Shear Adhesion: psi (kPa)* (15 min. dwell) NTP-5 30 (206)

Static Shear Adhesion: Hours 1 psi load* NTP-57 2000+

Tensile Strength: psi (kPa) ASTM D412 130 (896)

Elongation of Foam: % ASTM D412 105%

Thermal Conductivity K factor: BTU•in./hr.•ft2•°F (w/m•°C) ASTM C518 .55 (.08)

Migratory Staining of Acrylic Enamel: 200 hours of ultraviolet at 140°F ASTM D925 No Staining

* NTP = Norton Test Procedure.

* Adhesive properties do not apply for Thermalbond XPress.

Thermalbond V2200 Series– Standard Configurations

Black Adhesive Gray Adhesive Black Adhesive

Thickness in. (mm) Length in. (m)

2 Sides 2 Sides 1 Side

V2204 – TBX204 .125 (3.2) 50 (15.2)

V2206 V2206G272 TBX206 .1875 (4.8) 50 (15.2)

V2208 V2208G272 TBX208 .250 (6.4) 50 (15.2)

V2210 V2210G272 TBX210 .3125 (8.0) 25 (7.6)

V2212 V2212G272 TBX212 .375 (9.5) 25 (7.6)

3 in. I.D. cardboard cores standard

Liners

Easy release branded blue polyethylene liner is standard on V2200 and V2200G272.

Important Instructions

Refer to silicone manufacturer to confirm compatability information. Due to the numerous variables involved in a

structural glazing system, each project should be individually lab tested by the silicone manufacturer for compatability

between Thermalbond, the structural silicone and all other adjacent components.

Surfaces must be clean and free of oil, grease, moisture, dust and dirt. Isopropyl alcohol is good for cleaning the surface.

Apply a uniform pressure of 15 psi (103 kPa) to promote good contact between the material to be bonded and the tape.

The application temperature should be between 60°F and 125°F (16°C to 52°C). It is not recommended to apply these

tapes at temperatures below 60°F (16°C), as the adhesive does not flow in this condition and can result in poor bonding.

Recommended service temperature is between -40°F to 180°F (-40°C to 82°C).

Shelf Life

12 months after the date of sale when stored in original packaging at temperatures

up to 70°F (21°C) and 50% relative humidity.

IMPORTANT: It is the user’s responsibility to ensure the suitability and safety of Saint-Gobain Performance Plastics products

for all intended uses and that the materials to be used comply with all applicable regulatory requirements. Saint-Gobain

Performance Plastics assumes no responsibility for any product failures that occur due to misuse of the materials it provides

arising out of the design, fabrication or application of the products into which the materials are incorporated.

Performance Plastics - Tape Solutions WARRANTY: For a period of 6 months, Saint-Gobain Performance Plastics warrants this product(s) to be free from defects

in manufacturing. The only obligation under any applicable product warranty will be to replace any portion proving

North America | South America | Europe | Asia

defective, or at our option, to refund the purchase price thereof. SAINT-GOBAIN PERFORMANCE PLASTICS DISCLAIMS

For a full list of locations, please visit ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

tapesolutions.saint-gobain.com/contact-us Form #1067 | © Saint-Gobain July 2018 | Thermalbond, Thermalbond Xpress and Saint-Gobain are trademarks of Saint-Gobain.

Das könnte Ihnen auch gefallen

- FS 600 Data SheetDokument1 SeiteFS 600 Data SheetNguyen Hong67% (3)

- En 1993 09Dokument160 SeitenEn 1993 09Vio ChiNoch keine Bewertungen

- Thermalbond - v2200 Spec SheetDokument2 SeitenThermalbond - v2200 Spec SheetRex SirilanNoch keine Bewertungen

- Thermacool TC2007G Gap Filler TDS 1280Dokument2 SeitenThermacool TC2007G Gap Filler TDS 1280xingdrewNoch keine Bewertungen

- Castrol Perfecto XDokument3 SeitenCastrol Perfecto XHector Martin BarajasNoch keine Bewertungen

- 18 - Sikafloor - 264 - SGDokument6 Seiten18 - Sikafloor - 264 - SGPaul ManiquisNoch keine Bewertungen

- Ficha Tecnica Castrol Perfecto X RangeDokument3 SeitenFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNoch keine Bewertungen

- Sikaflex®-2c SL: Two-Component, Self-Levelling, Polyurethane Elastomeric SealantDokument3 SeitenSikaflex®-2c SL: Two-Component, Self-Levelling, Polyurethane Elastomeric SealantRay GongNoch keine Bewertungen

- Raychem WPCT Heat Shrink SleevesDokument4 SeitenRaychem WPCT Heat Shrink SleevesmngNoch keine Bewertungen

- Maincote™ Hg-31: Waterborne Acrylic Resin For Water and Corrosion-Resistant Industrial CoatingsDokument7 SeitenMaincote™ Hg-31: Waterborne Acrylic Resin For Water and Corrosion-Resistant Industrial CoatingsLong An DoNoch keine Bewertungen

- 3900 Prepreg SystemDokument5 Seiten3900 Prepreg SystemLiran KatzNoch keine Bewertungen

- CSNRI PS Atlas 15dec2022Dokument2 SeitenCSNRI PS Atlas 15dec2022Nithin MathaiNoch keine Bewertungen

- 226NDokument2 Seiten226NUmaibalanNoch keine Bewertungen

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDokument3 SeitenPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerNoch keine Bewertungen

- Tds - Jotun - Guard Classic EtDokument3 SeitenTds - Jotun - Guard Classic Etvijh van niemannNoch keine Bewertungen

- Bakelite PF 31Dokument3 SeitenBakelite PF 31dioguitomsolhaNoch keine Bewertungen

- Halene - H : Technical Data SheetDokument1 SeiteHalene - H : Technical Data SheetDaya Shanker PalNoch keine Bewertungen

- Polyken 4000 PrimerlessDokument2 SeitenPolyken 4000 PrimerlessKyaw Kyaw AungNoch keine Bewertungen

- 2018.9 Discontinuation of Molykote™ 1292 Long Life Bear..Dokument3 Seiten2018.9 Discontinuation of Molykote™ 1292 Long Life Bear..Phoenix GrangerNoch keine Bewertungen

- Epic Hydraulic Range TdsDokument2 SeitenEpic Hydraulic Range Tdsapi-375685829Noch keine Bewertungen

- Metal Silicone 2 Sealant Technical Data SheetDokument6 SeitenMetal Silicone 2 Sealant Technical Data Sheetremarkhb.maintenanceNoch keine Bewertungen

- Dural Fast Epoxy Gel EuclidDokument3 SeitenDural Fast Epoxy Gel Euclidpayaso1973Noch keine Bewertungen

- CATALOG - Final - Low ResulotionDokument66 SeitenCATALOG - Final - Low ResulotionKadiri El MoustaphaNoch keine Bewertungen

- Mobil DTE 10 Excel SeriesDokument3 SeitenMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNoch keine Bewertungen

- DOWLEX™ 2047G: Polyethylene ResinDokument3 SeitenDOWLEX™ 2047G: Polyethylene Resinujang sukartaNoch keine Bewertungen

- Technyl Star S 218 V30 BK 31NDokument3 SeitenTechnyl Star S 218 V30 BK 31Nratz23695Noch keine Bewertungen

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Dokument1 SeiteTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingNoch keine Bewertungen

- M705-ULT369 Technical Data - 1.0EDokument12 SeitenM705-ULT369 Technical Data - 1.0EQuýNguyễnNoch keine Bewertungen

- Exact 8201Dokument2 SeitenExact 8201Kashif MuhammadNoch keine Bewertungen

- Ark Emad 362Dokument13 SeitenArk Emad 362La Vita E BellaNoch keine Bewertungen

- SP-2888 RG PDSDokument5 SeitenSP-2888 RG PDSreza ashtariNoch keine Bewertungen

- Sikaflex® Precast: Product Data SheetDokument4 SeitenSikaflex® Precast: Product Data SheetRoyce MarchaNoch keine Bewertungen

- Supreme foamSP-5015RDokument1 SeiteSupreme foamSP-5015RAdrian LeeNoch keine Bewertungen

- Technical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Dokument6 SeitenTechnical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Pedro NavarroNoch keine Bewertungen

- 1 Wa-Catalog7Dokument1 Seite1 Wa-Catalog7johnNoch keine Bewertungen

- Hercules EngDokument1 SeiteHercules EngTAREK HAMADNoch keine Bewertungen

- Sikaproof 808Dokument4 SeitenSikaproof 808happyNoch keine Bewertungen

- LLDPE Dowlex 2645G TDSDokument3 SeitenLLDPE Dowlex 2645G TDSAli RazuNoch keine Bewertungen

- Thwi Tds (JK r2 0315) EnglishDokument2 SeitenThwi Tds (JK r2 0315) EnglishMasood KhanNoch keine Bewertungen

- Soft Natural Rubber Lining: Technical Data SheetDokument2 SeitenSoft Natural Rubber Lining: Technical Data SheetSantosh JayasavalNoch keine Bewertungen

- CYCLON HYDRAULIC - EN - Vja21Dokument1 SeiteCYCLON HYDRAULIC - EN - Vja21Jolie AbarcaNoch keine Bewertungen

- FILMTEC™ SW30-4040 Membranes: FeaturesDokument2 SeitenFILMTEC™ SW30-4040 Membranes: FeaturesAlejandro AliNoch keine Bewertungen

- XIAMETER™ RBB-2030-40 Base: Features & Benefits ApplicationsDokument3 SeitenXIAMETER™ RBB-2030-40 Base: Features & Benefits ApplicationsDaniela Alejandra Daza LancherosNoch keine Bewertungen

- Sikaflex 252 TDSDokument3 SeitenSikaflex 252 TDSxingobuilderNoch keine Bewertungen

- Dymonic 100 Data SheetDokument2 SeitenDymonic 100 Data SheetDavid LuongNoch keine Bewertungen

- SikaAnchorFix2Arctic PdsDokument4 SeitenSikaAnchorFix2Arctic PdsDragoș SturzoiuNoch keine Bewertungen

- DOWLEX™ 2038.68G: Polyethylene ResinDokument3 SeitenDOWLEX™ 2038.68G: Polyethylene ResinJosé PalmaNoch keine Bewertungen

- 06.19.2022 Mafco-Rapid Curing RC-50Dokument2 Seiten06.19.2022 Mafco-Rapid Curing RC-50Pangky AbasoloNoch keine Bewertungen

- Nukote Har: DescriptionDokument4 SeitenNukote Har: DescriptionMarco Dos Santos NevesNoch keine Bewertungen

- LLDPE-218BJ EditDokument3 SeitenLLDPE-218BJ EditChu ChuNoch keine Bewertungen

- Nap-Gard 7-2514 PDFDokument2 SeitenNap-Gard 7-2514 PDFPietro ViganNoch keine Bewertungen

- Sikafloor®-263 SLDokument6 SeitenSikafloor®-263 SLHalit Baris SertbakanNoch keine Bewertungen

- Membrane BWRO SUEZ-AG-LDokument2 SeitenMembrane BWRO SUEZ-AG-LEko SNoch keine Bewertungen

- Fluteck P7500 CA v01.19Dokument2 SeitenFluteck P7500 CA v01.19fprovitaliNoch keine Bewertungen

- Sikaflex® Construction: Product Data SheetDokument4 SeitenSikaflex® Construction: Product Data SheetFritz NatividadNoch keine Bewertungen

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Dokument4 SeitenAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiNoch keine Bewertungen

- Tds Atlantic Hydraulic OilsDokument1 SeiteTds Atlantic Hydraulic Oilsmgamal1080Noch keine Bewertungen

- Design Guidelines for Surface Mount TechnologyVon EverandDesign Guidelines for Surface Mount TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Hexoloy SP Sic TdsDokument4 SeitenHexoloy SP Sic TdsAnonymous r3MoX2ZMTNoch keine Bewertungen

- TOEFL-Reading Question Type Definitions and ExplanationDokument5 SeitenTOEFL-Reading Question Type Definitions and ExplanationSamara SampaioNoch keine Bewertungen

- All Worksheets MYSQLDokument33 SeitenAll Worksheets MYSQLSample1Noch keine Bewertungen

- OB Case Study Care by Volvo UK 2020Dokument1 SeiteOB Case Study Care by Volvo UK 2020Anima AgarwalNoch keine Bewertungen

- Aristotle Metaphysics Lambda Accessed 201111 Classicalk LibraryDokument19 SeitenAristotle Metaphysics Lambda Accessed 201111 Classicalk Librarygijsbo2000Noch keine Bewertungen

- Progressive Muscle Relaxation ExerciseDokument2 SeitenProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

- DA-I Question Bank From Module 1-3 of PHY1701 Course, Winter Semester 2020-21Dokument6 SeitenDA-I Question Bank From Module 1-3 of PHY1701 Course, Winter Semester 2020-21Likith MallipeddiNoch keine Bewertungen

- IES OBJ Civil Engineering 2000 Paper IDokument17 SeitenIES OBJ Civil Engineering 2000 Paper Itom stuartNoch keine Bewertungen

- Headlight Washer System: Current Flow DiagramDokument3 SeitenHeadlight Washer System: Current Flow DiagramLtBesimNoch keine Bewertungen

- Toftejorg TZ-75 Rotary Jet Head - Portable: Fast, Effective Impact CleaningDokument3 SeitenToftejorg TZ-75 Rotary Jet Head - Portable: Fast, Effective Impact CleaningSamo SpontanostNoch keine Bewertungen

- Waste Foundry Sand and Its Leachate CharDokument10 SeitenWaste Foundry Sand and Its Leachate CharJanak RaazzNoch keine Bewertungen

- Practice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDDokument8 SeitenPractice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDMarc Stanley YaoNoch keine Bewertungen

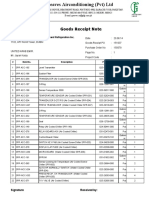

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDokument4 SeitenGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNoch keine Bewertungen

- DAY 3 STRESS Ielts NguyenhuyenDokument1 SeiteDAY 3 STRESS Ielts NguyenhuyenTĩnh HạNoch keine Bewertungen

- Cambridge: Global EnglishDokument34 SeitenCambridge: Global EnglishLinh Nguyễn Thùy100% (1)

- Hume 100 ReviewerDokument7 SeitenHume 100 ReviewerShai GaviñoNoch keine Bewertungen

- SQL - Day 2: Structured Query LanguageDokument10 SeitenSQL - Day 2: Structured Query LanguageNight KingNoch keine Bewertungen

- GATE Chemical Engineering 2015Dokument18 SeitenGATE Chemical Engineering 2015Sabareesh Chandra ShekarNoch keine Bewertungen

- Sop GC6890 MS5973Dokument11 SeitenSop GC6890 MS5973Felipe AndrinoNoch keine Bewertungen

- How To Install 64 Bits IDES On 32 Bits OSDokument1 SeiteHow To Install 64 Bits IDES On 32 Bits OSMuhammad JaveedNoch keine Bewertungen

- Causal Emergence - HoelDokument18 SeitenCausal Emergence - HoelFelipe LopesNoch keine Bewertungen

- Centrifugal Pumps: Turbo Machines Amit Pathania Roll No:09309 Mechanical EngineeringDokument4 SeitenCentrifugal Pumps: Turbo Machines Amit Pathania Roll No:09309 Mechanical EngineeringAmit PathaniaNoch keine Bewertungen

- Scope and Sequence 2020 2021...Dokument91 SeitenScope and Sequence 2020 2021...Ngọc Viễn NguyễnNoch keine Bewertungen

- (Word 365-2019) Mos Word MocktestDokument4 Seiten(Word 365-2019) Mos Word MocktestQuỳnh Anh Nguyễn TháiNoch keine Bewertungen

- Ab 2023Dokument5 SeitenAb 2023Cristelle Estrada-Romuar JurolanNoch keine Bewertungen

- CHASE SSE-EHD 1900-RLS LockedDokument2 SeitenCHASE SSE-EHD 1900-RLS LockedMarcos RochaNoch keine Bewertungen

- Void Engineers (Convention: Mage The Ascension)Dokument6 SeitenVoid Engineers (Convention: Mage The Ascension)Beth0% (1)

- NCRA Membership InformationDokument1 SeiteNCRA Membership Informationbkharkreader1301Noch keine Bewertungen