Beruflich Dokumente

Kultur Dokumente

EN 2-2004 Ex004

Hochgeladen von

yudhi putraOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EN 2-2004 Ex004

Hochgeladen von

yudhi putraCopyright:

Verfügbare Formate

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

EN 2-2004 Example 004

P-M INTERACTION CHECK FOR COMPRESSION-CONTROLLED RECTANGULAR COLUMN

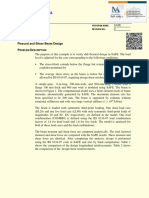

EXAMPLE DESCRIPTION

The Demand/Capacity ratio for a given axial loading and moment is tested in this

example. Detailed calculations are shown.

In this example, a reinforced concrete column is subjected to factored axial load N

= 10,000 kN and moments My_top = 200 kN-m, My_bottom = -140 kN-m, Mz_top = -160

kN-m, Mz_bottom = 140 kN-m. The column is pinned supported on the bottom and

restrained at the top from translation in the X and Y directions. This column is

reinforced with fourteen size-40 bars.

GEOMETRY, PROPERTIES AND LOADING

Z

N = 10,000 kN c = 60 mm

My_top = 200 kN-m c = 60 mm

Mz_top = -160 kN-m

h = 750 mm Y

A A 40 bar

L = 15200 mm b = 650 mm

6 2

Ec = 41x10 kN/m fck = 70 MPa

6 2 fyk = 500 MPa

My_bottom = -140 kN-m Es = 200x10 kN/m

Mz_bottom = 140 kN-m

Coefficients

𝛾𝑐 = 1.5 𝛼𝑐𝑐 = 0.85

𝛾𝑐𝐸 = 1.2 𝛼𝑒 = 15

𝛾𝑠 = 1.15 𝜑𝑒𝑓 = 1.21

EN 2-2004 Example 004 - 1

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

TECHNICAL FEATURES TESTED

➢ Tied reinforced concrete column design

RESULTS COMPARISON

Independent results are hand calculated and compared in the table below. The

results are shown for the minor axis of bending (Z-direction of bending) with the

governing permutation.

Important note: for the final biaxial bending ratio check, SAP2000 utilizes the

PMM interaction surface to determine the column demand/capacity ratio (See

Section 3.4.2.3 in the Concrete Frame Design Manual – Eurocode 2-2004 with 8-

2004). However, the independent results employ the simplified criterion provided

by Eurocode 2-2004 [Equation 5.39 in Section 5.8.9(4)]. As a result, modest

discrepancy is expected for the biaxial bending ratio between SAP2000 and

independent results.

Output Parameter Independent SAP2000 Ratio

Biaxial bending check

0.818 0.889 1.0868

(Nominal Curvature)

Biaxial bending check

0.322 0.58 1.8012

(Nominal Stiffness)

Imperfection moment, M imp (kN-m) 230.3 230.5 1.0009

Minimum moment, M min (kN-m) 216.7 216.7 1.0000

Second-order moment, M 2 (kN-m)

1726.4 1729.1 1.0016

(Nominal Curvature)

Final design moment, M Ed (kN-m)

-1996.7 -1999.6 1.0015

(Nominal Curvature)

Moment magnification factor, MMF

3.15 3.16 1.0032

(Nominal Stiffness)

Final design moment, M Ed (kN-m)

-851.5 -854.7 1.0038

(Nominal Stiffness)

Moment resistance, M Rd

2484.6 2484.6 1.000

(at N Ed = 10, 000 kN)

COMPUTER FILE: EN 2-2004 EX004

CONCLUSION

The computed results show an acceptable comparison with the independent results.

EN 2-2004 Example 004 - 2

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

HAND CALCULATION

The hand calculation considers nine (9) permutations in the design check for the section

at mid-height of the column, but only shows the details for three (3) permutations

including one with analysis moments, one with analysis moments plus imperfection

moment applied in the positive major axis of bending, and one with analysis moments,

imperfection moment, and second-order moments. Comparison between results in all

nine (9) permutations is made to determine the governing design.

Note:

a. The effective length, 𝑙𝑜 , is computed based on bracing condition and stiffness of the

structural members connected to the column top and bottom in the model. The value

of 𝑙𝑜 can be overwritten through the effective length factors in the View/Revise

Overwrites form of the program. For this example, the effective length factors in the

major and minor bending directions are assumed to be 0.93 and 0.91, respectively.

b. The radius of gyration of the cross section used in calculation of the slenderness ratio

only includes concrete without contribution of longitudinal reinforcement.

c. The slenderness limit ratio is calculated using first-order moments that include the

imperfection moment applied on each axis of bending one at a time.

1) Analysis moment (permutation #1)

Moment diagrams:

200 kN-m -160 kN-m

30 kN-m -10 kN-m

-140 kN-m 140 kN-m

Major Minor

EN 2-2004 Example 004 - 3

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

The calculation of the P-M interaction diagram on both axes of bending is carried out

similarly as shown in Example Ex003. The axial and moment capacity at the balance

point, and moment capacities at the applied axial load N = 10,000 kN are:

Pbal_Y = 6381.5 (kN)

Pbal_Z = 6185.2 (kN)

M Rd _Y = 2748.2 ( kN - m )

M Rd _ Z = 2484.6 ( kN - m )

Biaxial bending check:

0.042 500

N Rd = Ac f cd + As f yd = 0.75 0.65 39.667 + 14 = 26.987 (MN) = 26987 (kN)

4 1.15

N Ed 10,000

= = 0.371

N Rd 26987

0.371 − 0.1

a= (1.5 −1) + 1 = 1.226

0.7 − 0.1

a a

M Ed _ Z M Ed _Y 10 1.226 30 1.226

+ = + = 0.0051

M Rd _ Z M Rd _Y 2484.6 2748.2

2) Analysis moment plus imperfection moment applied on the negative major axis of

bending (permutation #3)

Imperfection moments

m =1

1 1

m = 0.5 1 + = 0.5 1 + = 1

m 1

2 2

h = = = 0.513 and 2 h 1 h = 2

3 3

l 15.2

0 = 1 200

1 2

i = 0 h m = 1 = 0.00333

200 3

i l0 _Y i kY l 0.00333 0.93 15.2

ei _Y = = = = 0.02354 ( m )

2 2 2

M imp_Y = N ed ei_Y = 10 , 000 0.02354 = 235.4 (kN - m)

EN 2-2004 Example 004 - 4

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

e0 _Y = max 20mm, h ( 30 ) (

= max 20mm, 750mm

30 )

= 25 ( mm )

M min _Y = N ed e0 _Y = 10 , 000 0.025 = 250 (kN - m)

i l0 _ Z i kZ l 0.00333 0.91 15.2

ei _ Z = = = = 0.02303 ( m )

2 2 2

M imp_Z = N ed ei_Z = 10 , 000 0.02303 = 230.3 (kN - m)

e0 _Z = max 20mm, b ( 30 ) (

= max 20mm, 650mm

30 )= 21.67 ( mm )

M min _Z = N ed e0 _Z = 10 , 000 0.02167 = 216.7 (kN - m)

Since the imperfection moment is only applied on the negative major axis of bending,

the design moments are:

M Ed_Y = M analysis + M imp_Y M min_Y = 250

=30 − 235.4 = −205.4 250 M Ed_Y = −250 (kN-m)

M Ed_Z = M analysis M min_Z = 216.7

= − 10 <273 M Ed_Z = −216.7 (kN-m)

Biaxial bending check:

a a

M Ed _ Z M Ed _Y 216.7 1.226 250 1.226

+ = + = 0.103

M Rd _ Z M Rd _Y 2484.6 2748.2

3) Analysis moment plus imperfection moment applied in negative minor axis of

bending and second-order moment (permutation #9)

( )

M 02 _Y = max M Y _ top , M Y _ bottom = max ( 200 , −140 ) = 200 ( kN − m )

M 02 _Y = 200 ( kN − m )

( )

M 01_Y = min M Y _ top , M Y _ bottom = min ( 200 , −140 ) = 140 ( kN − m ) M 01 = −140 (kN - m)

M 0 Ed_Y = 0.6M 02 _Y + 0.4M 01_Y 0.4M 02 _Y

= 0.6 200 + 0.4 ( −140 ) 0.4 200

= 80 (kN - m)

( ) ( )

M 02 _Z = sign max M Z _ top , M Z _ bottom max M Z _ top , M Z _ bottom − M imp_Z

= − max ( −160 , 140 ) − 230.3 = −390.3 ( kN − m )

EN 2-2004 Example 004 - 5

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

( ) ( )

M 01_Z = sign min M Z _ top , M Z _ bottom min M Z _ top , M Z _ bottom − M imp_Z

= min ( −160 , 140 ) − 230.3 = −90.3 ( kN − m )

M 0 Ed_Z = 0.6M 02 _Z + 0.4M 01_Z 0.4M 02 _Z

= 0.6 ( −390.3) + 0.4 ( −90.3) 0.4 ( −390.3 )

= -270.3 (kN - m)

Slenderness check

Radius of gyration:

A = h • b = 0.75 • 0.65 = 0.4875 (m 2 )

b • h 3 0.65 • 0.753

IY = = = 0.02285 (m 4 )

12 12

b• h 3

0.75 • 0.653

IZ = = = 0.01716 (m 4 )

12 12

I 0.02285

iY = Y = = 0.2165 (m)

A 0.4875

IZ 0.01716

iZ = = = 0.1876 (m)

A 0.4875

Effective length:

lo_Y = kY l = 0.93 15.2 = 14.136 (m)

lo_Z = kZ l = 0.91 15.2 = 13.832 (m)

Slenderness ratio:

l 14.136

Y = o_Y = = 65.3

iY 0.2165

l 13.832

Z = o_Z = = 73.7

iZ 0.1876

Limiting slenderness ratio:

f - 50 70 - 50

η = 1.0 - ck = 1.0 - = 0.9

200 200

f 70

fcd = cc ck = 0.85 = 39.6667 (MPa)

c 1.5

EN 2-2004 Example 004 - 6

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

0.042 500

As f yd 14

= = 4 1.15 = 0.3956

Ac f cd 0.75 0.65 39.6667

1MN

10 , 000kN

N ed 1000kN = 0.517

n= =

Ac f cd 0.75 0.65 39.6667

1 1

A= = = 0.805

1 + 0.2ef 1 + 0.2 1.21

B = 1 + 2 = 1 + 2 0.3956 = 1.3384

M 01_Y −140

rm_Y = = = −0.7

M 02 _Y 200

CY = 1.7 − rm_Y = 1.7 − ( −0.7 ) = 2.4

20 ABCY 20 0.805 1.3384 2.4

lim _Y = = = 71.9

n 0.517

M 01_Z −90.3

rm_Z = = = 0.2314

M 02 _Z −390.3

CZ = 1.7 − rm_Z = 1.7 − 0.2314 = 1.47

20 ABCZ 20 0.805 1.3384 1.47

lim _Z = = = 44.1

n 0.517

Slenderness condition:

Y = 65.3 71.9 = lim _Y the column is NOT slender in Y - direction

Z = 73.7 44.1 = lim _Z the column is slender in Z - direction

Second-order moment must be included in the final design moments in minor axis of

bending, and can be ignored in the major axis of bending

As the column is slender in minor axis of bending, the code allows two (2) different

methods to compute second-order moment including Nominal Curvature and

Nominal Stiffness. The following section 4 utilizes the Nominal Curvature method,

and the section 5 employs the Nominal Stiffness method.

EN 2-2004 Example 004 - 7

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

4) Final design moment (Nominal Curvature):

Pbal_Z 6185.2

nbal_Z = = 1000 = 0.32

Ac f cd 0.75 0.65 39.667

nu = 1 + = 1 + 0.3956 = 1.3956

n −n 1.3956 − 0.517

K r_Z = u = = 0.8168

nu − nbal_Z 1.3956 − 0.32

fck Z 70 73.7

Z = 0.35 + − = 0.35 + − = 0.2087

200 150 200 150

K _Z = 1 + Z ef = 1 + 0.2087 1.21 = 1.25

0.042 0.65

14 2

I s_Z = (Ai • d )= 2 5

2

− 0.06

i=1 4 2

0.042 0.65

2

+ 2 2 − 0.06 − 0.17667 = 0.0009217 (m 4 )

4 2

d2 0.042

As = 14 = 14 = 0.0176 (m 2 )

4 4

I s_Z 0.0009217

is_Z = = = 0.2288 (m)

As 0.0176

h 0.65

dZ = + iZ = + 0.2288 = 0.5538 (m)

2 2

Fyd 500 1.15

1 yd Es 200000 = 0.008723

= = =

r0 _Z 0.45d Z 0.45d Z 0.45 0.5538

1 1

= K r_Z K _Z = 0.8168 1.25 0.008723 = 0.008906

rZ r0 _Z

Since the first-order moment is double-curvature loading condition:

c = 2 = 9.87

1 1 1

e2 _Z = l02_Z = 0.008906 13.8322 = 0.17264 (m)

rZ c 9.87

M 2 _Z = Ned e2 _Z = 10,000 0.17264 = 1726.4 ( kN - m )

EN 2-2004 Example 004 - 8

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

Final design moments: (the second-order moment is added in the same direction as

M 0 Ed )

Since the column is not slender in the major axis of bending, equivalent moment is

not considered in the final design moment in the major axis of bending:

M Ed_Y = M analysis_Y M min_Y = 250

=30 30 250 M Ed_Y = 250 (kN-m)

M Ed _ Z = M 0 Ed_Z + M 2 _Z M min _Z = 216.7

= −270.3 − 1726.4 = −1996.7 −1996.7 250 M Ed _ Z = −1996.7 (kN - m)

Biaxial bending check:

a a

M Ed _ Z M Ed _Y 1996.7 1.226 250 1.226

+ = + = 0.818

M Rd _ Z M Rd _Y 2484.6 2748.2

5) Final design moment (Nominal Stiffness):

0.042

14

As

= = 4 = 0.036 0.002 K s = 1

A 0.75 0.65

f

k1 = ck = 70 = 1.87

20 20

73.7

k2 _Z = n Z 0.2 = 0.652 = 0.28 0.2 k2 _Z = 0.2

170 170

k1k2 _Z 1.87 0.2

Kc_Z = = = 0.17

1 + ef 1 + 1.21

Ecm 41 106

Ecd = = = 34.17 106 (kN / m 2 )

cE 1.2

b • h3 0.75 0.653

I c_Z = = = 0.01716 (m 4 )

12 12

EI Z = Kc_Z Ecd I c_Z + K s Es I s_Z = 0.17 34.17 106 0.01716 + 1 200 106 0.0009217

= 2.84 105 (kN - m2 )

2 EI Z 2 2.84 105

N B_Z = = = 14650 (kN)

l02_Z 13.8322

EN 2-2004 Example 004 - 9

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

Since the first-order moment is double-curvature loading condition:

c0 = 2 = 9.87

2

= =1

c0

Moment magnification factor:

MMFY = 1.0 since the column is NOT slender in major axis of bending.

1

MMFY = 1 + = 1+ = 3.15

N B_Y

−1

14650 −1

N Ed 10,000

M Ed _Y = max M analysis_Y MMFY ;M min_Y = max 30 1.0; 250 = 250 (kN - m)

M Ed _ Z = max M 0 Ed_Z MMFZ ;M min_ Z = max −270.3 3.15; 216.7 = −851.5 (kN - m)

a a

M Ed _ Z M Ed _Y 851.5 1.226 250 1.226

+ = + = 0.322

M Rd _ Z M Rd _Y 2484.6 2748.2

All four (4) axes of bending that the imperfection moment is applied on are positive

major, negative major, positive minor, and negative minor directions. Similar

calculations are carried out for the other permutations with the imperfection moment

applied in the other axes of bending one at a time. The final governing

demand/capacity ratio (D/C) turns out to be the permutation with the imperfection

moment applied in the negative minor axis of bending including analysis and second-

order moment.

D

For the Nominal Curvature method: = 0.818

C NC

D

For the Nominal Stiffness method: = 0.322

C NS

EN 2-2004 Example 004 - 10

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

Summary: shown for the governing permutation

Y-Axis Z-Axis

First-order moment

M 01 (kN-m) -140 -90.3

M 02 (kN-m) 200 -390.3

M 0 Ed (kN-m) 80 -270.3

Imperfection moment, M imp (kN-m) 235.4 230.3

Minimum moment, M min (kN-m) 250 216.7

Slenderness

Slenderness ratio, 65.3 73.7

Slenderness limit ratio, lim 71.9 44.1

Slenderness condition Short Slender

Second-order moment, M 2 (kN-m)

0.0 1726.4

(Nominal Curvature)

Final design moment, M Ed (kN-m)

250 -1996.7

(Nominal Curvature)

Moment magnification factor, MMF

1.0 3.15

(Nominal Stiffness)

Final design moment, M Ed (kN-m)

250 -851.5

(Nominal Stiffness)

Moment resistance, M Rd (at N Ed = 10, 000 kN) 2748.2 2484.6

EN 2-2004 Example 004 - 11

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 1

Comparison:

Important note: for the biaxial bending ratio checks, SAP2000 utilizes the PMM

interaction surface to determine the column demand/capacity ratio (See Section

3.4.2.3 in the Concrete Frame Design Manual – Eurocode 2-2004 with 8-2004).

However, the independent results employ the simplified criterion provided by

Eurocode 2-2004 [Equation 5.39 in Section 5.8.9(4)]. As a result, modest

discrepancy is expected for the biaxial bending ratio between SAP2000 and

independent results.

Z-direction (Minor axis): shown for the governing permutation

Hand Calculation SAP2000 Ratio

M 01 (kN-m) -90.3 -90.5 1.0022

M 02 (kN-m) -390.3 -390.5 1.0005

M 0 Ed (kN-m) -270.3 -270.5 1.0007

Imperfection moment, M imp (kN-m) 230.3 230.5 1.0009

Minimum moment, M min (kN-m) 216.7 216.7 1.0000

Slenderness ratio, 73.3 73.7 1.0054

Slenderness limit ratio, lim 44.1 44.0 1.0023

Second-order moment, M 2 (kN-m)

1726.4 1729.1 1.0016

(Nominal Curvature)

Final design moment, M Ed (kN-m)

-1996.7 -1999.6 1.0015

(Nominal Curvature)

Biaxial bending check

0.818 0.889 1.0868

(Nominal Curvature)

Moment magnification factor, MMF

3.15 3.16 1.0032

(Nominal Stiffness)

Final design moment, M Ed (kN-m)

-851.5 -854.7 1.0038

(Nominal Stiffness)

Biaxial bending check

0.322 0.58 1.8012

(Nominal Stiffness)

Moment resistance, M Rd

2484.6 2484.6 1.0000

(at N Ed = 10, 000 kN)

EN 2-2004 Example 004 - 12

Das könnte Ihnen auch gefallen

- Software Verification: NTC 2008 Example 004Dokument12 SeitenSoftware Verification: NTC 2008 Example 004yudhi putraNoch keine Bewertungen

- NTC 2008 Ex002 PDFDokument5 SeitenNTC 2008 Ex002 PDFputra wiraNoch keine Bewertungen

- NTC 2008 Ex002 PDFDokument5 SeitenNTC 2008 Ex002 PDFputra wiraNoch keine Bewertungen

- BS 8110-1997 Ex001Dokument5 SeitenBS 8110-1997 Ex001Mohamed Abo-ZaidNoch keine Bewertungen

- EN 2-2004 Ex002Dokument5 SeitenEN 2-2004 Ex002yudhi putraNoch keine Bewertungen

- KBC 2009 Example 001Dokument6 SeitenKBC 2009 Example 001yudhi putraNoch keine Bewertungen

- Software Verification: NTC 2008 Example 002Dokument4 SeitenSoftware Verification: NTC 2008 Example 002Antonius AjalahNoch keine Bewertungen

- NTC 2008 Ex001 PDFDokument6 SeitenNTC 2008 Ex001 PDFyudhi putraNoch keine Bewertungen

- Software Verification: IS 456-2000 Example 001Dokument4 SeitenSoftware Verification: IS 456-2000 Example 001Mohamed Abo-ZaidNoch keine Bewertungen

- RCDF 2004 Example 002Dokument4 SeitenRCDF 2004 Example 002RMMNoch keine Bewertungen

- RCDF 2004 Example 001Dokument5 SeitenRCDF 2004 Example 001RMMNoch keine Bewertungen

- EN 2-2004 Ex002Dokument4 SeitenEN 2-2004 Ex002Mohamed Abo-ZaidNoch keine Bewertungen

- TS 500-2000 Ex001Dokument4 SeitenTS 500-2000 Ex001Erik VelasteguíNoch keine Bewertungen

- EN 2-2004 Example 002Dokument4 SeitenEN 2-2004 Example 002RMMNoch keine Bewertungen

- As 3600-09 RC-SL-001Dokument4 SeitenAs 3600-09 RC-SL-001Bunkun15Noch keine Bewertungen

- IS 800-2007 Example 003rwerwerweDokument12 SeitenIS 800-2007 Example 003rwerwerwePrawiroYudhio Putro Indonesia NegoroNoch keine Bewertungen

- NTC 2008 Example 002 PDFDokument14 SeitenNTC 2008 Example 002 PDFMohamed Abo-ZaidNoch keine Bewertungen

- KBC 2009 Example 001Dokument6 SeitenKBC 2009 Example 001RMMNoch keine Bewertungen

- AS 3600-2009 Ex002Dokument4 SeitenAS 3600-2009 Ex002Antonius AjalahNoch keine Bewertungen

- TS 500-2000 (R2018) Example 001 PDFDokument4 SeitenTS 500-2000 (R2018) Example 001 PDFHenry TuganoNoch keine Bewertungen

- TS 500-2000 Example 001Dokument4 SeitenTS 500-2000 Example 001RMM100% (1)

- NTC 2008 Example 001Dokument6 SeitenNTC 2008 Example 001RMM0% (1)

- NTC 2018 Example 002Dokument14 SeitenNTC 2018 Example 002Mohamed Abo-ZaidNoch keine Bewertungen

- Software Verification: BS 5950-2000 Example 001Dokument5 SeitenSoftware Verification: BS 5950-2000 Example 001Boby CuliusNoch keine Bewertungen

- As 3600-01 PT-SL-001Dokument6 SeitenAs 3600-01 PT-SL-001seyedamir mohammadiNoch keine Bewertungen

- AS 3600-2018 PT-SL Example 001Dokument6 SeitenAS 3600-2018 PT-SL Example 001Aashu chaudharyNoch keine Bewertungen

- Software Verification: EXAMPLE Mexican RCDF-04 CO-FR-001Dokument4 SeitenSoftware Verification: EXAMPLE Mexican RCDF-04 CO-FR-001Joshep PalaciosNoch keine Bewertungen

- NZS 3101-2006 Example 002Dokument4 SeitenNZS 3101-2006 Example 002RMM100% (1)

- Software Verification: CSA A23.3-14 Example 001Dokument4 SeitenSoftware Verification: CSA A23.3-14 Example 001yudhi putra100% (1)

- NTC 2008 Example 001Dokument6 SeitenNTC 2008 Example 001Anitha Hassan KabeerNoch keine Bewertungen

- AS 4100-1998 Example 002 PDFDokument5 SeitenAS 4100-1998 Example 002 PDFMohamed Abo-ZaidNoch keine Bewertungen

- NZS 3101-2006 PT-SL Example 001Dokument6 SeitenNZS 3101-2006 PT-SL Example 001Fredy Sandro Rosas FloresNoch keine Bewertungen

- TS 500-2000 (R2018) Example 002Dokument4 SeitenTS 500-2000 (R2018) Example 002alejandro mantillaNoch keine Bewertungen

- AS 3600-2009 Ex001Dokument8 SeitenAS 3600-2009 Ex001Antonius AjalahNoch keine Bewertungen

- BS 8110-97 PT-SL-001Dokument6 SeitenBS 8110-97 PT-SL-001Merin OshwelNoch keine Bewertungen

- BS 8110-1997 PT-SL Example 001Dokument6 SeitenBS 8110-1997 PT-SL Example 001Aashu chaudharyNoch keine Bewertungen

- KBC 2009 Example 002Dokument4 SeitenKBC 2009 Example 002RMMNoch keine Bewertungen

- AS 4100-1998 Example 003Dokument6 SeitenAS 4100-1998 Example 003Mohamed Abo-ZaidNoch keine Bewertungen

- Software Verification: CSA A23.3-14 Example 002Dokument4 SeitenSoftware Verification: CSA A23.3-14 Example 002yudhi putraNoch keine Bewertungen

- NZS 3101-2006 Example 001Dokument8 SeitenNZS 3101-2006 Example 001RMM100% (1)

- EN 3-2005 Example 003Dokument5 SeitenEN 3-2005 Example 003PrawiroYudhio Putro Indonesia NegoroNoch keine Bewertungen

- Ts 500-2000 PT-SL Example 001Dokument6 SeitenTs 500-2000 PT-SL Example 001121528Noch keine Bewertungen

- AS 3600-2009 Example 002Dokument4 SeitenAS 3600-2009 Example 002RMMNoch keine Bewertungen

- Software Verification: Example Hong Kong Cp-04 Rc-Bm-001Dokument7 SeitenSoftware Verification: Example Hong Kong Cp-04 Rc-Bm-001renzo1221Noch keine Bewertungen

- EN 3-2005 Example 003Dokument5 SeitenEN 3-2005 Example 003dar.elhalNoch keine Bewertungen

- IS 456-2000 Example 001 PDFDokument4 SeitenIS 456-2000 Example 001 PDFwillowdoNoch keine Bewertungen

- Software Verification: EN 2-2004 RC-SL EXAMPLE 001Dokument7 SeitenSoftware Verification: EN 2-2004 RC-SL EXAMPLE 001Anthony Peña TimoteoNoch keine Bewertungen

- HK Cp-2013 PT-SL Example 001Dokument6 SeitenHK Cp-2013 PT-SL Example 001Aashu chaudharyNoch keine Bewertungen

- EC-3-2005 Example 003 PDFDokument5 SeitenEC-3-2005 Example 003 PDFJoshep PalaciosNoch keine Bewertungen

- CIS SAFE د ماجد البنا مقارنة الحل اليدوي والحل في برنامج 2Dokument7 SeitenCIS SAFE د ماجد البنا مقارنة الحل اليدوي والحل في برنامج 2bassam1911992Noch keine Bewertungen

- Monorail Crane Girder CalculationDokument4 SeitenMonorail Crane Girder Calculationrony100% (1)

- En 2-2004 RC-SL Example 001Dokument10 SeitenEn 2-2004 RC-SL Example 001Aashu chaudharyNoch keine Bewertungen

- Anna University Practical Lab Manuals For Engineering StudentsDokument13 SeitenAnna University Practical Lab Manuals For Engineering StudentsTinku RathoreNoch keine Bewertungen

- Software Verification: EN 3-2005 Example 002Dokument5 SeitenSoftware Verification: EN 3-2005 Example 002putra wiraNoch keine Bewertungen

- Software Verification: EXAMPLE Eurocode 2-04 PT-SL-001Dokument7 SeitenSoftware Verification: EXAMPLE Eurocode 2-04 PT-SL-001võ hoàng thái100% (1)

- CSA S16-14 Example 001 PDFDokument8 SeitenCSA S16-14 Example 001 PDFMohamed Abo-ZaidNoch keine Bewertungen

- Post Tension Slab Design ExampleDokument6 SeitenPost Tension Slab Design ExampleKiran D AnvekarNoch keine Bewertungen

- Perpustakaan - Uns.ac - Id Digilib - Uns.ac - Id: Structure Planning School Building 2nd FloorDokument18 SeitenPerpustakaan - Uns.ac - Id Digilib - Uns.ac - Id: Structure Planning School Building 2nd Flooryudhi putraNoch keine Bewertungen

- Software Verification: CSA A23.3-14 Example 002Dokument4 SeitenSoftware Verification: CSA A23.3-14 Example 002yudhi putraNoch keine Bewertungen

- EN 2-2004 Ex001Dokument7 SeitenEN 2-2004 Ex001yudhi putraNoch keine Bewertungen

- Software Verification: ACI 318-14 Example 002Dokument4 SeitenSoftware Verification: ACI 318-14 Example 002yudhi putraNoch keine Bewertungen

- NTC 2008 Ex001 PDFDokument6 SeitenNTC 2008 Ex001 PDFyudhi putraNoch keine Bewertungen

- KBC 2009 Example 001Dokument6 SeitenKBC 2009 Example 001yudhi putraNoch keine Bewertungen

- Software Verification: CSA A23.3-14 Example 001Dokument4 SeitenSoftware Verification: CSA A23.3-14 Example 001yudhi putra100% (1)

- Laser Types-Lecture (Dr. M Fadhali)Dokument29 SeitenLaser Types-Lecture (Dr. M Fadhali)Mohamed Fadhali100% (1)

- Fluid Flow OperationDokument2 SeitenFluid Flow OperationShubham imtsNoch keine Bewertungen

- SPT Correlation For Unit WeightDokument2 SeitenSPT Correlation For Unit WeightBilly Otniel100% (5)

- Ch2 Mechanical Properties of Matter 2013.ppsDokument45 SeitenCh2 Mechanical Properties of Matter 2013.ppsElwy Labib100% (1)

- University of Cape TownDokument154 SeitenUniversity of Cape TownDavis EscalonaNoch keine Bewertungen

- Phy102 Practise Problems For Exam2Dokument4 SeitenPhy102 Practise Problems For Exam2Renz Dane TametaNoch keine Bewertungen

- Wellbore Stability Effect of Mud Weight 1645782860Dokument27 SeitenWellbore Stability Effect of Mud Weight 1645782860Muhammad Husein MahfudzNoch keine Bewertungen

- Design HitsDokument45 SeitenDesign HitsLuisa Pérez LunaNoch keine Bewertungen

- Design of BearingsDokument24 SeitenDesign of BearingsFarrukh RizwanNoch keine Bewertungen

- Mechanical EngineeringDokument9 SeitenMechanical EngineeringbilqistazNoch keine Bewertungen

- Applied Thermal Engineering: Shaolin Mao, Changrui Cheng, Xianchang Li, Efstathios E. MichaelidesDokument9 SeitenApplied Thermal Engineering: Shaolin Mao, Changrui Cheng, Xianchang Li, Efstathios E. MichaelidesAnkit LonareNoch keine Bewertungen

- 50999219SZA7 - Antenna & Wave Propagation - Solution Manual PDFDokument52 Seiten50999219SZA7 - Antenna & Wave Propagation - Solution Manual PDFmboillaNoch keine Bewertungen

- PLAXIS-3D Dam StabilityDokument20 SeitenPLAXIS-3D Dam Stabilityjimmysatanco100% (1)

- 10th Physics Notes-1Dokument95 Seiten10th Physics Notes-1Waqar AmjadNoch keine Bewertungen

- Physical ScienceDokument36 SeitenPhysical ScienceDave VasquezNoch keine Bewertungen

- Worksheet 6 - Energy - and - MomentumDokument1 SeiteWorksheet 6 - Energy - and - MomentumJNZSeriesNoch keine Bewertungen

- 3 Cascade-Control DesignDokument2 Seiten3 Cascade-Control Designmiguel dumaniNoch keine Bewertungen

- Bigbang TheoryDokument13 SeitenBigbang TheoryRen-ren MacanNoch keine Bewertungen

- Bolt DesignDokument19 SeitenBolt DesignGaurav BedseNoch keine Bewertungen

- App DifferentiationDokument3 SeitenApp Differentiationairies92Noch keine Bewertungen

- Worm Gear Design ProcedureDokument7 SeitenWorm Gear Design ProcedureSzymon RosikNoch keine Bewertungen

- Friction Notes - Iit-Jee - Bitsat - Neet - AiimsDokument32 SeitenFriction Notes - Iit-Jee - Bitsat - Neet - Aiims145Ducks50% (10)

- Answer All Questions.: R F F FDokument3 SeitenAnswer All Questions.: R F F FChong Ken HinNoch keine Bewertungen

- USACE - Retaining and Flood WallsDokument448 SeitenUSACE - Retaining and Flood WallsHUGINoch keine Bewertungen

- Simulation of Shell & Tube Heat ExchangerDokument8 SeitenSimulation of Shell & Tube Heat ExchangerAnush KoreNoch keine Bewertungen

- Classical Mechanics MITDokument199 SeitenClassical Mechanics MITRavi RoyNoch keine Bewertungen

- 2019 Mid SemDokument2 Seiten2019 Mid SemAnand KumarNoch keine Bewertungen

- Experiments Physics Form 4Dokument52 SeitenExperiments Physics Form 4cikgusya67% (3)

- Worksheet TransformDokument2 SeitenWorksheet TransformOwen Radaza PiranteNoch keine Bewertungen

- Igcse Unit - C Forces Movement Shapeand MomentumDokument3 SeitenIgcse Unit - C Forces Movement Shapeand Momentumapi-255623302Noch keine Bewertungen

- The Compound Effect by Darren Hardy - Book Summary: Jumpstart Your Income, Your Life, Your SuccessVon EverandThe Compound Effect by Darren Hardy - Book Summary: Jumpstart Your Income, Your Life, Your SuccessBewertung: 5 von 5 Sternen5/5 (456)

- Summary of The Anxious Generation by Jonathan Haidt: How the Great Rewiring of Childhood Is Causing an Epidemic of Mental IllnessVon EverandSummary of The Anxious Generation by Jonathan Haidt: How the Great Rewiring of Childhood Is Causing an Epidemic of Mental IllnessNoch keine Bewertungen

- Summary of 12 Rules for Life: An Antidote to ChaosVon EverandSummary of 12 Rules for Life: An Antidote to ChaosBewertung: 4.5 von 5 Sternen4.5/5 (294)

- Summary: Atomic Habits by James Clear: An Easy & Proven Way to Build Good Habits & Break Bad OnesVon EverandSummary: Atomic Habits by James Clear: An Easy & Proven Way to Build Good Habits & Break Bad OnesBewertung: 5 von 5 Sternen5/5 (1636)

- Can't Hurt Me by David Goggins - Book Summary: Master Your Mind and Defy the OddsVon EverandCan't Hurt Me by David Goggins - Book Summary: Master Your Mind and Defy the OddsBewertung: 4.5 von 5 Sternen4.5/5 (386)

- Summary of The New Menopause by Mary Claire Haver MD: Navigating Your Path Through Hormonal Change with Purpose, Power, and FactsVon EverandSummary of The New Menopause by Mary Claire Haver MD: Navigating Your Path Through Hormonal Change with Purpose, Power, and FactsNoch keine Bewertungen

- Mindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessVon EverandMindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessBewertung: 4.5 von 5 Sternen4.5/5 (328)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseVon EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseBewertung: 3.5 von 5 Sternen3.5/5 (69)

- Summary of The Algebra of Wealth by Scott Galloway: A Simple Formula for Financial SecurityVon EverandSummary of The Algebra of Wealth by Scott Galloway: A Simple Formula for Financial SecurityNoch keine Bewertungen

- The 5 Second Rule by Mel Robbins - Book Summary: Transform Your Life, Work, and Confidence with Everyday CourageVon EverandThe 5 Second Rule by Mel Robbins - Book Summary: Transform Your Life, Work, and Confidence with Everyday CourageBewertung: 4.5 von 5 Sternen4.5/5 (329)

- The Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaVon EverandThe Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The War of Art by Steven Pressfield - Book Summary: Break Through The Blocks And Win Your Inner Creative BattlesVon EverandThe War of Art by Steven Pressfield - Book Summary: Break Through The Blocks And Win Your Inner Creative BattlesBewertung: 4.5 von 5 Sternen4.5/5 (274)

- The One Thing: The Surprisingly Simple Truth Behind Extraordinary ResultsVon EverandThe One Thing: The Surprisingly Simple Truth Behind Extraordinary ResultsBewertung: 4.5 von 5 Sternen4.5/5 (709)

- Summary and Interpretation of Reality TransurfingVon EverandSummary and Interpretation of Reality TransurfingBewertung: 5 von 5 Sternen5/5 (5)

- Knocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldVon EverandKnocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldBewertung: 3.5 von 5 Sternen3.5/5 (64)

- How To Win Friends and Influence People by Dale Carnegie - Book SummaryVon EverandHow To Win Friends and Influence People by Dale Carnegie - Book SummaryBewertung: 5 von 5 Sternen5/5 (557)

- Summary of Million Dollar Weekend by Noah Kagan and Tahl Raz: The Surprisingly Simple Way to Launch a 7-Figure Business in 48 HoursVon EverandSummary of Million Dollar Weekend by Noah Kagan and Tahl Raz: The Surprisingly Simple Way to Launch a 7-Figure Business in 48 HoursNoch keine Bewertungen

- A Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceVon EverandA Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceBewertung: 4 von 5 Sternen4/5 (51)

- Make It Stick by Peter C. Brown, Henry L. Roediger III, Mark A. McDaniel - Book Summary: The Science of Successful LearningVon EverandMake It Stick by Peter C. Brown, Henry L. Roediger III, Mark A. McDaniel - Book Summary: The Science of Successful LearningBewertung: 4.5 von 5 Sternen4.5/5 (55)

- The Whole-Brain Child by Daniel J. Siegel, M.D., and Tina Payne Bryson, PhD. - Book Summary: 12 Revolutionary Strategies to Nurture Your Child’s Developing MindVon EverandThe Whole-Brain Child by Daniel J. Siegel, M.D., and Tina Payne Bryson, PhD. - Book Summary: 12 Revolutionary Strategies to Nurture Your Child’s Developing MindBewertung: 4.5 von 5 Sternen4.5/5 (57)

- Extreme Ownership by Jocko Willink and Leif Babin - Book Summary: How U.S. Navy SEALS Lead And WinVon EverandExtreme Ownership by Jocko Willink and Leif Babin - Book Summary: How U.S. Navy SEALS Lead And WinBewertung: 4.5 von 5 Sternen4.5/5 (75)

- Summary of Atomic Habits by James ClearVon EverandSummary of Atomic Habits by James ClearBewertung: 5 von 5 Sternen5/5 (170)

- Steal Like an Artist by Austin Kleon - Book Summary: 10 Things Nobody Told You About Being CreativeVon EverandSteal Like an Artist by Austin Kleon - Book Summary: 10 Things Nobody Told You About Being CreativeBewertung: 4.5 von 5 Sternen4.5/5 (128)

- Summary of The Galveston Diet by Mary Claire Haver MD: The Doctor-Developed, Patient-Proven Plan to Burn Fat and Tame Your Hormonal SymptomsVon EverandSummary of The Galveston Diet by Mary Claire Haver MD: The Doctor-Developed, Patient-Proven Plan to Burn Fat and Tame Your Hormonal SymptomsNoch keine Bewertungen

- Blink by Malcolm Gladwell - Book Summary: The Power of Thinking Without ThinkingVon EverandBlink by Malcolm Gladwell - Book Summary: The Power of Thinking Without ThinkingBewertung: 4.5 von 5 Sternen4.5/5 (114)

- Summary of Eat to Beat Disease by Dr. William LiVon EverandSummary of Eat to Beat Disease by Dr. William LiBewertung: 5 von 5 Sternen5/5 (52)

- Essentialism by Greg McKeown - Book Summary: The Disciplined Pursuit of LessVon EverandEssentialism by Greg McKeown - Book Summary: The Disciplined Pursuit of LessBewertung: 4.5 von 5 Sternen4.5/5 (188)