Beruflich Dokumente

Kultur Dokumente

k041203 7377 150114033728 Conversion Gate02 PDF

Hochgeladen von

darkruseOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

k041203 7377 150114033728 Conversion Gate02 PDF

Hochgeladen von

darkruseCopyright:

Verfügbare Formate

International

OPEN ACCESS Journal

Of Modern Engineering Research (IJMER)

Design, Analysis & Balancing of 5 Cylinder Engine Crankshaft

Yogesh S. Khaladkar1, Lalit H. Dorik2, Gaurav M. Mahajan3, Anil V. Fajage4

1,2,3,4

B.E. Student, Dept. of Mech. Engg. Dr.D.Y. Patil Institute of Engg. & Tech. Ambi, University of Pune,

India.

Abstract: The crankshaft is a backbone of internal combustion engine. So the design & analysis is major

aspects to get high power transmission & efficiency. The selection of material is an important parameter

while designing any mechanical component. The material should be high strength & capacity to absorb

the shocks as well as fatigue. The material also have less wear tendency. The crankshaft should be high

torque transmitting capacity. So to achieve these objectives high carbon steel are used for design &

analysis purpose. This paper gives the idea about analysis as well as proper balancing of weights by using

these three materials. The modelling is done by using solid work software & then analysis by using ANSYS

software with Finite Element Analysis (FEA) method. The 5 cylinder engine gives the power stroke at 144

degree angle. By addition of counterweights & modified design these odd cylinders are balanced properly.

The Finite Element Analysis Method is used to determine stress, strains & deflection at most stressed point

which results into failure of shaft. Results obtained from analysis are used during weight optimization. The

Shaft is analyzed using static analysis. For absorbing vibrations proper damping material is used to

achieve the requirement of safe design. The optimization results into reduction of weight as well as cost.

Keywords: ANSYS, Crankshaft,Damping, Finite Element Analysis, Optimization.

I. Introduction

1.1) Design:

Mechanical design includes weight optimizationas well as optimum size, shape, etc. against

failureunder the application of operational loads. A good design should also minimize the cost of material and

cost of production. Failures that are commonly associated with mechanical components which are broadly

classified as:

(a) Failure by breaking of brittle materials and fatigue failure of ductile materials.

(b) Failure by yielding of ductile materials, subjected to non-repetitive loads.

(c) Failure by elastic deformation. The last two modes cause change of shape or size of the component rendering

it useless and, therefore, refer to functional or operational failure.

Most of the design problems refer to one of these two types of failures. Designing, thus, involves

estimation of stresses and deformations of the components at different critical points of a component for the

specified loads and boundary conditions, so as to satisfy operational constraints.

1.2) Finite Element method:

In FEM, actual component is replaced by a simplified model, identified by a finite number of elements

connected at common points called nodes, with an assumed behavior or response of each element to the set of

applied loads, and evaluating the unknown field variable (displacement, temperature) at thesefinite number of

points. The crankshaft is the most important moving part of internal combustion engine. It converts

reciprocating motion into rotary motion. Since the crankshaft experiences a large number of load cycles during

its working. The performance, durability, torque transmitting capacity, stress, strains, service life, fatigue failure

and durability of this component has to be considered in the design process. It must be strong enough to take the

downward force of the power stroked without excessive bending. So the reliability and life of internal

combustion engine depend on the strength of the crankshaft largely. The torsional vibration appears when a

power impulse hits a crankpin toward the front of the engine and the power stroke ends. If not controlled, it can

break the crankshaft. Strength calculation of crankshaft becomes a key factor to ensure the life of engine. This

study is about 5 cylinder engine crankshaft. The modelling of crankshaft is done by using solid work software.

The Finite Element Method is used to calculate stresses & deflection of crankshaft by using ANSYS software.

The main aim is to increase efficiency & balancing of crankshaft by weight optimization. Thus the reduction in

weight results into material reduction. So the cost will be lower than the conventional engine. The 5 cylinder

engine gives more efficiency than 4 cylinder engine. The material for crankshaft is Cast Iron. Other alternate

materials on which analysis has been done are, Forged steel, high carbon steel.

| IJMER | ISSN: 2249–6645 | www.ijmer.com | Vol. 4 | Iss.12| Dec. 2014 | 73|

Design, Analysis & Balancing of 5 Cylinder Engine Crankshaft

II. Literature Review

V. Vijaykumar [1] presented a paper on analysis of crankshaft using finite element analysis method

with ABAQUS software. The material specifications are reviewed. Paper gives idea about dynamic load acting

on crankshaft during operation. To find critical stresses and maximum load for crankpin is calculated by

analyzing the results obtained from ABAQUS.

Solanki et al.[2] gives the idea about the design of crankshaft depends upon dynamic loading and

optimization can lead to shaft diameter to fulfil the requirement of automobile.

V. Mallikarjuna Reddy[3] this gives the invention about the problem occurs in 6 cylinder diesel engine. The

model is made by using unigraphics and analyzed by using ANSYS.

III. Design Calculations for Crankshaft

The specification of diesel engine for Safari Dicor are tabulated as follows.

No. of cylinders 5

Bore(D) 85mm

Stroke 96mm

Displacement 2179cc

Compression Ratio 17.2:1

Max. Power 104.4KW @4000rpm

Max. Torque 320Nm @ 1700-2700rpm

Max. Gas Pressure 25bar

3.1) Deign of crankshaft:

When the crank is at an angle of Maximum bending moment. At this position of the crank, the

maximum gas pressure on the piston will transmit maximum force on the crankpin in the plane of the crank

causing only bending of the shaft.

Let „D‟ be the bore diameter in mm,

P= Pressure intensity in N/mm2

Fp= Gas load on piston in N.

Force on piston Fp= Area of bore× Max. Combustion pressure

= π/4*D2*25*105

=14.18KN.

In order to find thrust in connecting rod, we should find out angle of inclination of connecting rod with line of

stroke (i.e. angle φ)

Sinφ= Sinθ/(l/r)

= Sinθ/n =(sin35)/4

φ = 8.240.

Thrust in connecting rod FCR= Fp / cosφ

=14.32KN.

Thus, thrust in C.R. is in tangential as well as radial direction which are as follows,

a)Tangential force on crankshaft, FT= FCR sin (θ+ φ)

=9.81KN.

b) Radial force on crankshaft, FR= FCR cos (θ+ φ)

=10.43KN.

Now, the reactions at bearings due to tangential force are:

HT1= HT2=FT/2=4.9KN

Similarly, reactions due to radial force are:

HR1= HR2=FR/2=5.21KN.

3.2) Design of crankpin:-

Let dc be the diameter of crankpin. The bending moment at center of crankpin is given by

MC=HR1*b

=5.21*86=448.06Nm.

Twisting moment on crankpin is Tc=170.68Nm

The equivalent twisting moment

Te=(Mc2+ Tc2)1/2

=479.46Nm

Also equivalent twisting moment

| IJMER | ISSN: 2249–6645 | www.ijmer.com | Vol. 4 | Iss.12| Dec. 2014 | 74|

Design, Analysis & Balancing of 5 Cylinder Engine Crankshaft

Te=(π/4*dc3*Prem. Shear stress)

Permissible shear stress=35N/mm2

From above equation

479.46= π/4*dc3*35

dc =45mm.

Diameter of crankpin=45mm.

C) Von mises stresses Mev=((Kb*Mc)+(0.5*Kt*Tc))1/2

Mev=914.22N/mm2.

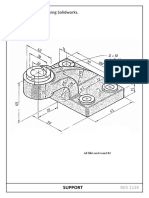

IV. Modelling Of Crankshaft

The software used for modelling is Solidwork. The solidwork includes following parameters:-

1.Part Design

2. Assembly Design

3. Drafting

4.Sketch

5.3D modelling.

V. Meshing of crankshaft

The Meshing (Discretization) is the first step of Finite Element Method. In this step the component or

part is divided into number of small parts. To analysis each element of the component meshing is done using

mesh tool in ANSYS.

| IJMER | ISSN: 2249–6645 | www.ijmer.com | Vol. 4 | Iss.12| Dec. 2014 | 75|

Design, Analysis & Balancing of 5 Cylinder Engine Crankshaft

VI. Loading & Boundary Conditions

Crankshaft is a constraint with a ball bearing from one side and with a journal on the other side. The

ball bearing is press fit to the crankshaft and does not allow the crankshaft to have any motion other than

rotation about its main axis. Since only 180 degrees of the bearing surfaces facing the load direction constraint

the motion of the crankshaft.

VII. Static Structural Analysis

After applying the boundary conditions & force the next step is that to perform static analysis of

crankshaft. In this we are concern with deflection of crankshaft & stresses produced in crankshaft. The total

deformation is shown in figure. The deformation is not same throught the length. It depends upon the load &

boundary conditions. The red colour portion shows the maximum deformation while blue colour shows the

minimum deformation. The maximum displacement is 5mm.

VIII. Results

By applying forces & boundary conditions, deformation of shaft generates stresses.

Sr.No. Type Of Stresses Theoretical FEA Analysis

1 Von-Misses 914.22 950.0

Stresses

2 Shear Stresses 110.25 120.7

| IJMER | ISSN: 2249–6645 | www.ijmer.com | Vol. 4 | Iss.12| Dec. 2014 | 76|

Design, Analysis & Balancing of 5 Cylinder Engine Crankshaft

IX. Conclusion

In this paper the crankshaft model is made by using solidworks and then analyzed by using ANSYS.

The conclusions are made from the results are as maximum stresses occurs at the centre of crankpin. The

maximum stress occurs at fillet between crank journal and crank cheeks. The edge of the crankshaft offers high

stress. The practical results are matches to theoretical results, so Finite Element Analysis(FEA) is best method

for analysis of permissible stresses. As there are 5 cylinders having efficiency equal to 6 cylinder, so our design

gives the weight optimization as well as low cost. The materials used are appropriate having high capacity to

absorb shocks and vibration with proper balancing.

REFERENCES

[1]. J. Meng, Y. Liu, R. Liu, (2011), “Finite Element analysis of 4-Cylinder Diesel Crankshaft” I.J. Image, Graphics and

Signal Processing, vol 5, pp. 22-29.

[2]. Sreeraj Nair K., Kiran Robert and Shamnadh M. (2014) “Stress Analysis of IC Engine Cylinder Head”. International

Review of Applied Engineering Research.ISSN 2248-9967 Volume 4, Number 2 (2014), pp. 123-128.

[3]. Momin Muhammad Zia Muhammad Idris(2013)“Crankshaft Strength Analysis Using Finite Element Method”.

Momin Muhammad Zia Muhammad Idris / International Journal of Engineering Research and Applications (IJERA)

ISSN: 2248-9622. Vol. 3, Issue 1, January -February 2013, pp.1694-1698.

[4]. V.Vijayakumar, T.Gopalakrishnan and Dr.R.Vivekananthan(2014) “Design and Contact Analysis of Crankshaft

Using Abaqus”. INTERNATIONAL JOURNAL OF RESEARCH IN AERONAUTICAL AND MECHANICAL

ENGINEERING. vol.2, Issue.3, March 2014.

[4]. V.B. Bhandari. “Design of Machine Element” Mc Graw Hill Education.

| IJMER | ISSN: 2249–6645 | www.ijmer.com | Vol. 4 | Iss.12| Dec. 2014 | 77|

Das könnte Ihnen auch gefallen

- Design and Analysis of Braking System For Formula Student CarDokument7 SeitenDesign and Analysis of Braking System For Formula Student CarInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- God Reborn - The Birth of God and The Creation of The UniverseDokument204 SeitenGod Reborn - The Birth of God and The Creation of The UniverseTony Bermanseder100% (1)

- Machine Design Elements and AssembliesVon EverandMachine Design Elements and AssembliesBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Design and Analysis of Ladder Frame Chassis Considering Support at Contact Region of Leaf Spring and Chassis FrameDokument9 SeitenDesign and Analysis of Ladder Frame Chassis Considering Support at Contact Region of Leaf Spring and Chassis FrameInternational Organization of Scientific Research (IOSR)Noch keine Bewertungen

- Cswa Solidworks Sample Exam 2007Dokument7 SeitenCswa Solidworks Sample Exam 2007Prathamesh BagweNoch keine Bewertungen

- Backlash (Engineering) - Wikipedia, The Free EncyclopediaDokument4 SeitenBacklash (Engineering) - Wikipedia, The Free EncyclopediadarkruseNoch keine Bewertungen

- Design and Analysis of Disc BrakDokument54 SeitenDesign and Analysis of Disc Braksrivc1988Noch keine Bewertungen

- Dynamic Response of An Overhead Cam Valve TrainDokument6 SeitenDynamic Response of An Overhead Cam Valve TraindarkruseNoch keine Bewertungen

- Cues Nursing Diagnosis Background Knowledge Goal and Objectives Nursing Interventions and Rationale Evaluation Subjective: Noc: NIC: Fluid ManagementDokument10 SeitenCues Nursing Diagnosis Background Knowledge Goal and Objectives Nursing Interventions and Rationale Evaluation Subjective: Noc: NIC: Fluid ManagementSkyla FiestaNoch keine Bewertungen

- Design, Analysis and Optimization of A 6 Cylinder Engine Crank ShaftDokument8 SeitenDesign, Analysis and Optimization of A 6 Cylinder Engine Crank ShaftIJMERNoch keine Bewertungen

- Design and Analysis of Crankshaft For Single Cylinder 4-Stroke Deisel EngineDokument3 SeitenDesign and Analysis of Crankshaft For Single Cylinder 4-Stroke Deisel EngineChetan GuptaNoch keine Bewertungen

- Modeling and Stress Analysis of Crankshaft Using Fem Package AnsysDokument7 SeitenModeling and Stress Analysis of Crankshaft Using Fem Package AnsysShreyas PaiNoch keine Bewertungen

- Design and Analysis of Crankshaft For Internal Combustion EngineDokument5 SeitenDesign and Analysis of Crankshaft For Internal Combustion EngineEditor IJTSRDNoch keine Bewertungen

- Design, Analysis &optimization of Crankshaft Using CAEDokument6 SeitenDesign, Analysis &optimization of Crankshaft Using CAEInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Design and Analysis of Crankshaft Used in Aerospace Applications and Comparision Using Different Materials.Dokument8 SeitenDesign and Analysis of Crankshaft Used in Aerospace Applications and Comparision Using Different Materials.Innovative Research PublicationsNoch keine Bewertungen

- Ijdmt: ©iaemeDokument11 SeitenIjdmt: ©iaemeIAEME PublicationNoch keine Bewertungen

- Seminar 2017-18: Analysis of Brake Disc For Composite MaterialsDokument20 SeitenSeminar 2017-18: Analysis of Brake Disc For Composite MaterialsMuthu GowdaNoch keine Bewertungen

- Dynamic Analysis of The Crank Shaft UsinDokument14 SeitenDynamic Analysis of The Crank Shaft UsinAVINASHNoch keine Bewertungen

- Structure Analysis of Cast Iron For Dry Clutch of Amphibious VehicleDokument4 SeitenStructure Analysis of Cast Iron For Dry Clutch of Amphibious VehicleseventhsensegroupNoch keine Bewertungen

- Indian Institute of Technology Roorkee Mechanical & Industrial DepartmentDokument13 SeitenIndian Institute of Technology Roorkee Mechanical & Industrial DepartmentGurpreet SinghNoch keine Bewertungen

- Dynamic Analysis of A Connecting Rod Using FEA: G. Sailaja, S. Irfan Sadaq, Shaik Vaseem YunusDokument4 SeitenDynamic Analysis of A Connecting Rod Using FEA: G. Sailaja, S. Irfan Sadaq, Shaik Vaseem YunusizudindNoch keine Bewertungen

- Strength Analysis of Diesel Engine Crankshaft Based On PRO/E and ANSYSDokument3 SeitenStrength Analysis of Diesel Engine Crankshaft Based On PRO/E and ANSYSMaiman LatoNoch keine Bewertungen

- Drive Shaft AnalysisDokument5 SeitenDrive Shaft AnalysisSachin PatelNoch keine Bewertungen

- Design of Braking System For Electric Golf-CartDokument6 SeitenDesign of Braking System For Electric Golf-Cartfariezulhakimi68Noch keine Bewertungen

- Aerospace Engineering, PG. Scholar (Aero), PG. Scholar (Aero), MLR Institute of Technology, Hyderabad, IndiaDokument8 SeitenAerospace Engineering, PG. Scholar (Aero), PG. Scholar (Aero), MLR Institute of Technology, Hyderabad, IndiaMasoud doskiNoch keine Bewertungen

- Flywheel DesignDokument9 SeitenFlywheel DesignTessema ShbruNoch keine Bewertungen

- Career Episode 2 Modelling and Simulation of Gas Turbine Blade Using Different MaterialsDokument7 SeitenCareer Episode 2 Modelling and Simulation of Gas Turbine Blade Using Different MaterialsNishar Alam Khan 19MCD0042Noch keine Bewertungen

- FEM Analysis of Connecting Rod of Different Materials Using AnsysDokument20 SeitenFEM Analysis of Connecting Rod of Different Materials Using AnsysjeffNoch keine Bewertungen

- Design and Optimization of Crankshaft For Four Cylinder 4-Stroke Spark Ignition Engine Using Transient Structural AnalysisDokument12 SeitenDesign and Optimization of Crankshaft For Four Cylinder 4-Stroke Spark Ignition Engine Using Transient Structural AnalysisTJPRC PublicationsNoch keine Bewertungen

- Dynamic Analysis of Single Cylinder Petrol Engine PDFDokument7 SeitenDynamic Analysis of Single Cylinder Petrol Engine PDFMannam Sarath SarathNoch keine Bewertungen

- Thermal Analysis and Optimization of IC Engine PisDokument6 SeitenThermal Analysis and Optimization of IC Engine PisLAKKANABOINA LAKSHMANARAONoch keine Bewertungen

- Amortisseur Ressort EtudeDokument11 SeitenAmortisseur Ressort EtudeSliim AmiriNoch keine Bewertungen

- Design and Dynamic Analysis of Flywheel: December 2016Dokument7 SeitenDesign and Dynamic Analysis of Flywheel: December 2016atiaNoch keine Bewertungen

- Research Article: Crankshaft Optimization Based On Experimental Design and Response Surface MethodDokument15 SeitenResearch Article: Crankshaft Optimization Based On Experimental Design and Response Surface MethodAmine EL FERHANINoch keine Bewertungen

- Under The Guidance of Associate ProfessorDokument10 SeitenUnder The Guidance of Associate ProfessorNasir AhsanNoch keine Bewertungen

- Design and Analysis of A Brake Caliper 1Dokument6 SeitenDesign and Analysis of A Brake Caliper 1sai kiranNoch keine Bewertungen

- Thermal Analysis and Optimization of I.C. Engine Piston Using Finite Element MethodDokument6 SeitenThermal Analysis and Optimization of I.C. Engine Piston Using Finite Element MethodAnirudhNoch keine Bewertungen

- Team Screwdriver'S: Dhole Patil Collage of Engineering PuneDokument38 SeitenTeam Screwdriver'S: Dhole Patil Collage of Engineering PuneAniket SankpalNoch keine Bewertungen

- Crankshaft Engdyn Rover KseriesDokument24 SeitenCrankshaft Engdyn Rover KseriesMGJasonNoch keine Bewertungen

- Static Stress Analysis of IC Engine Cylinder Head: Sreeraj Nair K., Kiran Robert and Shamnadh MDokument6 SeitenStatic Stress Analysis of IC Engine Cylinder Head: Sreeraj Nair K., Kiran Robert and Shamnadh M1DS18ME014 Ashish RNoch keine Bewertungen

- Determination of Heat Transfer Coefficient of Brake Rotor Disc Using CFD SimulationDokument9 SeitenDetermination of Heat Transfer Coefficient of Brake Rotor Disc Using CFD SimulationIAEME PublicationNoch keine Bewertungen

- SAMDokument38 SeitenSAMCHELVASERNoch keine Bewertungen

- Stress Analysis and Design Optimization of CrankpinDokument3 SeitenStress Analysis and Design Optimization of CrankpinAshokNoch keine Bewertungen

- Crankshaft VibrationDokument8 SeitenCrankshaft VibrationjohansolNoch keine Bewertungen

- Introduction To CNCDokument8 SeitenIntroduction To CNCharshNoch keine Bewertungen

- Disc Brake ProjectDokument3 SeitenDisc Brake ProjectPathan ShamsheerkhanNoch keine Bewertungen

- .Design and Failure Analysis of Single Cylinder Petrol Engine Crankshaft Using ANSYS SoftwareDokument7 Seiten.Design and Failure Analysis of Single Cylinder Petrol Engine Crankshaft Using ANSYS SoftwareAniket NehareNoch keine Bewertungen

- Ijmet 08 01 016Dokument6 SeitenIjmet 08 01 016Shri Hari .SNoch keine Bewertungen

- Sciencedirect: A Numerical Case Study: Bovet Approach To Design A Francis Turbine RunnerDokument10 SeitenSciencedirect: A Numerical Case Study: Bovet Approach To Design A Francis Turbine RunnerFilip StojkovskiNoch keine Bewertungen

- Static Analysis of Multi-Cylinder CrankshaftDokument35 SeitenStatic Analysis of Multi-Cylinder Crankshaftvenkatesh konigapoguNoch keine Bewertungen

- D1.8 Optimised Radial Turbine DesignDokument28 SeitenD1.8 Optimised Radial Turbine Designedwin flores mamaniNoch keine Bewertungen

- Design and Analysis of Gear-Box Using Spur Gear and Eliminating The Differential UnitDokument8 SeitenDesign and Analysis of Gear-Box Using Spur Gear and Eliminating The Differential UnitmohanNoch keine Bewertungen

- IJRAR2001831 - Braking System For Golf CartDokument7 SeitenIJRAR2001831 - Braking System For Golf CartVûmmïttî ChañðĥâñNoch keine Bewertungen

- Design & Analysis of Cam ShaftDokument38 SeitenDesign & Analysis of Cam ShaftVijiNoch keine Bewertungen

- Career Episode 3 Design and Analysis of Two-Stage Constant Reduction GearboxDokument7 SeitenCareer Episode 3 Design and Analysis of Two-Stage Constant Reduction GearboxNishar Alam Khan 19MCD0042Noch keine Bewertungen

- Stress Analysis of Propeller by Using FEMDokument10 SeitenStress Analysis of Propeller by Using FEMPavan KishoreNoch keine Bewertungen

- Irjet-V8i12267 2Dokument7 SeitenIrjet-V8i12267 2Om SinghNoch keine Bewertungen

- Simulation and Static Analysis of An Off-Road Vehicle Roll CageDokument8 SeitenSimulation and Static Analysis of An Off-Road Vehicle Roll CageIJMERNoch keine Bewertungen

- ISCA RJEngS 2012 090Dokument6 SeitenISCA RJEngS 2012 090Ganesh Anand GoparajuNoch keine Bewertungen

- Finite Element Analysis of Connecting Rod Using Ansys: Nikhil U.Thakare, Nitin D. Bhusale, Rahul P.Shinde, Mahesh M.PatilDokument5 SeitenFinite Element Analysis of Connecting Rod Using Ansys: Nikhil U.Thakare, Nitin D. Bhusale, Rahul P.Shinde, Mahesh M.Patilaravindan476Noch keine Bewertungen

- Optimization of A Motorcycle Wheel RimDokument6 SeitenOptimization of A Motorcycle Wheel RimAnoop A KNoch keine Bewertungen

- FEA Course Project ReportDokument13 SeitenFEA Course Project ReportA48Rayan PereiraNoch keine Bewertungen

- Propeller Shaft DesignDokument5 SeitenPropeller Shaft DesignJournalNX - a Multidisciplinary Peer Reviewed JournalNoch keine Bewertungen

- (I. 6) - UnknownDokument6 Seiten(I. 6) - UnknowndarkruseNoch keine Bewertungen

- Advanced Dynamic Analysis Using MSC Nastran: NAS102B WorkbookDokument140 SeitenAdvanced Dynamic Analysis Using MSC Nastran: NAS102B WorkbookdarkruseNoch keine Bewertungen

- PoweringforMediumSpeedWave PiercingCatamarans PDFDokument10 SeitenPoweringforMediumSpeedWave PiercingCatamarans PDFdarkruseNoch keine Bewertungen

- Advanced Dynamic Analysis Using MSC Nastran: NAS102B WorkbookDokument140 SeitenAdvanced Dynamic Analysis Using MSC Nastran: NAS102B WorkbookdarkruseNoch keine Bewertungen

- C&S16 - Yl - BaiDokument82 SeitenC&S16 - Yl - BaidarkruseNoch keine Bewertungen

- Design Basic in DDokument13 SeitenDesign Basic in DdarkruseNoch keine Bewertungen

- Homework 1: (Due On 09/06/2006) : Bytes GBDokument1 SeiteHomework 1: (Due On 09/06/2006) : Bytes GBdarkruseNoch keine Bewertungen

- Vibration 2017.1Dokument230 SeitenVibration 2017.1darkruseNoch keine Bewertungen

- Instructor Notes TTT: Mathcad Prime 3.0 Essentials (TRN-4010)Dokument9 SeitenInstructor Notes TTT: Mathcad Prime 3.0 Essentials (TRN-4010)darkruseNoch keine Bewertungen

- MASE 5510 Finite Element AnalysisDokument3 SeitenMASE 5510 Finite Element AnalysisdarkruseNoch keine Bewertungen

- Computational Mechanics & Manufacturing: Why Study at Sakarya University?Dokument2 SeitenComputational Mechanics & Manufacturing: Why Study at Sakarya University?darkruseNoch keine Bewertungen

- Create Solid Model Using Solidworks.: SupportDokument2 SeitenCreate Solid Model Using Solidworks.: SupportdarkruseNoch keine Bewertungen

- 0811 AgmaDokument4 Seiten0811 AgmadarkruseNoch keine Bewertungen

- Robe Draft Geotechnical Report - Edited by k2nDokument43 SeitenRobe Draft Geotechnical Report - Edited by k2nASAMNEW GULILATNoch keine Bewertungen

- Sequence Analytical and Vector Geometry at Teaching of Solid Geometry at Secondary SchoolDokument10 SeitenSequence Analytical and Vector Geometry at Teaching of Solid Geometry at Secondary SchoolJuan S. PalmaNoch keine Bewertungen

- Holiday Assignment (Dussehra Vacation) - 2022-23Dokument3 SeitenHoliday Assignment (Dussehra Vacation) - 2022-23yogeshNoch keine Bewertungen

- MC-8002 Mixer 2Dokument1 SeiteMC-8002 Mixer 2JAIDEV KUMAR RANINoch keine Bewertungen

- 热虹吸管相变传热行为CFD模拟 王啸远Dokument7 Seiten热虹吸管相变传热行为CFD模拟 王啸远小黄包Noch keine Bewertungen

- Tasha Giles: WebsiteDokument1 SeiteTasha Giles: Websiteapi-395325861Noch keine Bewertungen

- Salon Building Guidelines PDFDokument8 SeitenSalon Building Guidelines PDFtsnie toNoch keine Bewertungen

- HRIRDokument23 SeitenHRIRPhuong HoNoch keine Bewertungen

- Think Feel DoDokument3 SeitenThink Feel DoHardik MehtaNoch keine Bewertungen

- Tok EssayDokument2 SeitenTok EssayNeto UkpongNoch keine Bewertungen

- Comparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese CompaniesDokument7 SeitenComparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese Companiesrambabukomati472Noch keine Bewertungen

- File Server Resource ManagerDokument9 SeitenFile Server Resource ManagerBùi Đình NhuNoch keine Bewertungen

- Stacy Frysinger - Him ExperienceDokument2 SeitenStacy Frysinger - Him Experienceapi-250552115Noch keine Bewertungen

- 08 - Chapter 1Dokument48 Seiten08 - Chapter 1danfm97Noch keine Bewertungen

- Omran WalidDokument196 SeitenOmran WalidDébora AmougouNoch keine Bewertungen

- Worship Aid - May Crowning 2020Dokument5 SeitenWorship Aid - May Crowning 2020Kevin RyanNoch keine Bewertungen

- Debug and AssemblerDokument9 SeitenDebug and AssemblerManoj GurralaNoch keine Bewertungen

- Reading in MCJ 216Dokument4 SeitenReading in MCJ 216Shela Lapeña EscalonaNoch keine Bewertungen

- FS1 Worksheet Topic 6Dokument2 SeitenFS1 Worksheet Topic 6ALMALYN ANDIHNoch keine Bewertungen

- Concept of ConstitutionDokument32 SeitenConcept of ConstitutionDorepe Icon0% (1)

- Lean Six SigmaDokument5 SeitenLean Six SigmavinNoch keine Bewertungen

- Wec14 01 Rms 20230112Dokument23 SeitenWec14 01 Rms 20230112Shafay SheikhNoch keine Bewertungen

- Neoclassical CounterrevolutionDokument1 SeiteNeoclassical CounterrevolutionGraziella ValerioNoch keine Bewertungen

- Syntax Ps4Dokument6 SeitenSyntax Ps4blue_child86% (7)

- LPP - Problem Number 2Dokument9 SeitenLPP - Problem Number 2CT SunilkumarNoch keine Bewertungen

- 1) About The Pandemic COVID-19Dokument2 Seiten1) About The Pandemic COVID-19محسين اشيكNoch keine Bewertungen

- Quiz Application in Visual BasicDokument20 SeitenQuiz Application in Visual BasicShivangi SahaNoch keine Bewertungen

- Clay & Shale Industries in OntarioDokument193 SeitenClay & Shale Industries in OntarioJohn JohnsonNoch keine Bewertungen