Beruflich Dokumente

Kultur Dokumente

Accreditation Certificate-0269calibration Multiple

Hochgeladen von

ebbasinghOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Accreditation Certificate-0269calibration Multiple

Hochgeladen von

ebbasinghCopyright:

Verfügbare Formate

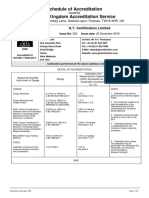

Schedule of Accreditation

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Staines-upon-Thames, TW18 3HR, UK

G B Quality Assurance (Consultants) & N.D.T. Limited

trading as G B Quality Assurance

Issue No: 027 Issue date: 09 April 2018

Unit 9 Contact: Tony Facey

0269 Chancel Way Tel: +44 (0)121-356 7430

Moor Lane Industrial Estate Fax: +44 (0)121-344 3837

Accredited to Birmingham E-Mail: tony.facey@gbqualityassurance.co.uk

ISO/IEC 17025:2005 B6 7AU Website: www.gbqualityassurance.co.uk

Calibration performed by the Organisation at the locations specified

Locations covered by the organisation and their relevant activities

Laboratory locations:

Location details Activity Location code

Address Contact: Tony Facey Dimensional A

Unit 9 Tel: +44 (0)121-356 7430

Chancel Way Fax: +44 (0)121-344 3837

Moor Lane Industrial Estate

E-Mail: tony.facey@gbqualityassurance.co.uk

Birmingham

B6 7AU

Site activities performed away from the locations listed above:

Location details Activity Location code

At customers premises Contact: Tony Facey Dimensional B

Assessment Manager: AT Page 1 of 6

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

G B Quality Assurance (Consultants) & N.D.T. Limited trading as G B

Quality Assurance

0269

Issue No: 027 Issue date: 09 April 2018

Accredited to

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

DETAIL OF ACCREDITATION

Calibration and

Measurement

Measured Quantity Capability (CMC) Location

Range Remarks

Instrument or Gauge Expressed as an Code

Expanded

Uncertainty (k = 2)

RANGE IN MILLIMETRES AND UNCERTAINTY IN MICROMETRES

UNLESS OTHERWISE STATED

LENGTH NOTES

Gauge block accessories As BS 4311:Part 2: 2009 1 The uncertainty A

0.1 to 12.5 0.50 quoted is for the departure

from flatness,

Thread measuring cylinders As BS 5590:1978 and specials straightness, parallelism, A

0.1 to 5 or squareness, i.e. the

0.50 distance separating the

two parallel planes which

Plain plug gauges (parallel), 1 to 50 diameter 0.80 just enclose the surface A

cylindrical setting standards 50 to 100 1.0 under consideration.

and rollers 100 to 150 1.5

150 to 300 2.0 2. Single start

symmetrical and

Plain plug gauges (taper) asymmetrical thread forms A

only.

Taper up to 1 in 8 3 to 50 diameter 3.0

on diameter 50 to 100 4.0 3. Single start,

100 to 150 5.0 symmetrical thread forms

only.

on diameter

Taper above 1 in 8 3 to 50 diameter 5.0

and up to 1 in 3 50 to 100 6.0 4. Includes use of check

plugs for screw rings from

on diameter 100 to 150 7.0

1 mm to 6mm diameter.

Plain ring gauges (parallel) 1 to 50 diameter 1.2 A

5. Functional test of size

and setting standards 50 to 100 1.4

using setting plugs

100 to 150 1.5

calibrated with a CMC of

150 to 225 2.0

3.0 µm

225 to 300 3.0

6. Simple height gauges

Plain ring gauges (taper) - vernier, dial and digital A

instruments designed only

Taper up to 1 in 8 3 to 50 diameter 4.0 for measuring distances

on diameter 50 to 100 5.0 parallel to the beam.

100 to 150 6.0

on diameter 7. Conformance

Taper above 1 in 8 3 to 50 diameter 6.0 statements cannot be

and up to 1 in 3 50 to 100 7.0 made against

on diameter 100 to 150 8.0 specifications whose

magnitudes are smaller

Length gauges, flat and 1 to 1000 1.0 + (8.0 x length in than the specified CMC A

spherical ended m) values

Plain gap gauges (parallel) 0.5 to 100 3.0 A

100 to 200 5.0

200 to 300 8.0

Parallels As BS 906: 1972 1.5 up to 5.0 A

5 to 50 x 100 x 400

Assessment Manager: AT Page 2 of 6

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

G B Quality Assurance (Consultants) & N.D.T. Limited trading as G B

Quality Assurance

0269

Issue No: 027 Issue date: 09 April 2018

Accredited to

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Calibration and

Measurement

Measured Quantity Capability (CMC) Location

Range Remarks

Instrument or Gauge Expressed as an Code

Expanded

Uncertainty (k = 2)

RANGE IN MILLIMETRES AND UNCERTAINTY IN MICROMETRES

UNLESS OTHERWISE STATED

LENGTH (cont’d)

Vee blocks As BS 3731:1987 2.5 to 5.0 A

20 to 150

Screw plug gauges (parallel) 1 to 100 diameter 3.0 A

including check and settings 100 to 150 4.0

plugs on pitch

See Note 2 diameter

2 to 100 diameter 4.0

Screw Plug Gauges (taper) 100 to 150 8.0

See Note 3

1 to 100 diameter 5.0

Screw ring gauges (parallel) 100 to 150 6.0

See Notes 2 See Note 4 on pitch

diameter

6 to 150 diameter 7.0

Screw Ring Gauges (Taper)

See Note 3

Screw pitch 0.2 to 8 1.5

Screw flank angle 0° to 52° 5.0 minutes of arc

Screw thread adjustable 1 to 150 diameter See Note 5 A

calliper gauges (parallel)

See Note 3

ANGLE

Squares A

Blade type As BS 939:2007

50 to 300 3.0

300 to 450 5.0

Cylindrical As BS 939:2007

75 to 300 2.0

300 to 600 4.0 On

600 to 900 6.0 Squareness

900 to 1200 8.0 See note 1

Block As BS 939:2007

50 to 300 3.0

300 to 600 5.0

600 to 900 8.0

900 to 1200 10.0

Angle plates and box angle As BS 5535:1978 Squareness: A

plates 50 to 600 3.0 + (1.0 per 100 mm)

Parallelism:

1.0 + (1.0 per 100 mm)

See note 1

Assessment Manager: AT Page 3 of 6

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

G B Quality Assurance (Consultants) & N.D.T. Limited trading as G B

Quality Assurance

0269

Issue No: 027 Issue date: 09 April 2018

Accredited to

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Calibration and

Measurement

Measured Quantity Capability (CMC) Location

Range Remarks

Instrument or Gauge Expressed as an Code

Expanded

Uncertainty (k = 2)

RANGE IN MILLIMETRES AND UNCERTAINTY IN MICROMETRES

UNLESS OTHERWISE STATED

ANGLE (cont’d)

Sine centres 0 to 300 length or between Linear dimensions:1.0 A

centres + (10 x length in m)

Overall performance:

3.0 seconds of arc

FORM

Surface plates As BS 817:2008 1.5 + (0.80 diagonal A, B

Granite 160 x 100 to 2500 x 1600 in m)

Cast iron See note 1

Straightedges A, B

Cast iron As BS 5204:Part 1:1975

300 to 5000 1.0 + (2.0x length in m)

Steel As BS 5204:Part 2:1977 See note 1

Granite 300 to 2000

Surface texture (excluding As BS 1134:Part 1:1988 A

measurement standards and Ra 0.02 µm to 80 µm 10% of measured

roughness comparison value

specimens)

MEASURING INSTRUMENTS AND MACHINES

Micrometres A

External As BS 870:2008 Heads: 2.0 between

0 to 600 any two points

Internal As BS 959:2008

0 to 900 Setting and

Depth As BS 6468:2008 extension rods:

0 to 300 1.0 + (5.0 x length in

m)

Micrometer,3 point bore 6 to 150 5.0 A

150 to 250 8.0

Micrometer heads As BS 1734:1951 1.0 A

0 to 100

Bench micrometer As NPL MOY/SCMI 22 Overall performance A

0 to 100 2.0

Vernier caliper, height and As BS 887:2008 Overall performance A

depth gauges 0 to 2000 10 + (30 x length in m)

As BS 1643:2008

0 to 1000

As BS 6365: 2008

0 to 600

Assessment Manager: AT Page 4 of 6

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

G B Quality Assurance (Consultants) & N.D.T. Limited trading as G B

Quality Assurance

0269

Issue No: 027 Issue date: 09 April 2018

Accredited to

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Calibration and

Measurement

Measured Quantity Capability (CMC) Location

Range Remarks

Instrument or Gauge Expressed as an Code

Expanded

Uncertainty (k = 2)

RANGE IN MILLIMETRES AND UNCERTAINTY IN MICROMETRES

UNLESS OTHERWISE STATED

MEASURING INSTRUMENTS AND MACHINES (cont’d)

Height gauges - (Simple) As BS EN ISO 13225:2012 Length measurement A

including vernier, dial and 0 to 1000 error (E):

digital types (See note 6 and 22 + (5 x length in

note 7) metres)

Dial gauges and dial test As BS 907:2008 and 1.0 A

indicators BS 2795:1981

0 to 50

Displacement transducers 0 to 10 0.50 A

(linear) 10 to 50 1.0

Height setting micrometer 0 to 300 Heads 1.0 A

Overall performance

3.0

Riser blocks for above 150 2.5 A

300 5.0

Bench centres 0 to 1000 between centres Linear dimensions A

1.0 + (10 x length in m)

Thread diameter measuring As NPL MOY/SCMI/ 9 A

0 to 300 Overall performance

1.5

Measuring machines A, B

Vertical 0 to 1500 1.0+(5.0 x length in m)

Horizontal

Profile projectors 10 to 100 magnification 125 at the screen A, B

0 to 200 5.0

0 to 360 4.0 minutes of arc

Toolmakers microscopes As NPL MOY/SCMI/2 125 at the screen A, B

0 to 300 5.0

0 to 360 4.0 minutes of arc

Bevel protractors As BS 1685:2008 A

0° to 360° 6.0 minutes of arc

Comparators (external) As BS 1054:1975 1.0 % of range A

250 to 10 000 magnifications Minimum 0.20

Assessment Manager: AT Page 5 of 6

S c he dul e of Ac c r e di ta ti on

issued by

United Kingdom Accreditation Service

2 Pine Trees, Chertsey Lane, Stai nes -upon-Tham es, TW 18 3HR, UK

G B Quality Assurance (Consultants) & N.D.T. Limited trading as G B

Quality Assurance

0269

Issue No: 027 Issue date: 09 April 2018

Accredited to

ISO/IEC 17025:2005

Calibration performed by the Organisation at the locations specified

Calibration and

Measurement

Measured Quantity Capability (CMC) Location

Range Remarks

Instrument or Gauge Expressed as an Code

Expanded

Uncertainty (k = 2)

RANGE IN MILLIMETRES AND UNCERTAINTY IN MICROMETRES

UNLESS OTHERWISE STATED

MEASURING INSTRUMENTS AND MACHINES (cont’d)

Steel rules As BS 4372:1968 A

0 to 4000 25 + (5.0 x length in m)

Spirit levels As BS 3509:1962 and

BS 958:1968 Means sensitivity

5 seconds of arc to 10% of nominal

60 minutes of arc nominal Minimum 0.50 seconds

sensitivity of arc

Electronic indicating levels 0 minutes of arc to 60 minutes of 1.0 % of range A

arc Minimum 0.50 seconds

of arc

Height gauges, electronic 0 to 1000 1.0 + (5.0 x length in A, B

m)

Clinometers 0° to 360° 10 seconds of arc A

Fineness of grind gauges As BS EN ISO 1524:2002, A

(Hegman type) BS 3900-C6:2000

0 to 100 µm 1.0

Feeler gauges BS 957:2008 2.0 A

(including setting shims) 0.025 to 1

END

Assessment Manager: AT Page 6 of 6

Das könnte Ihnen auch gefallen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument3 SeitenSchedule of Accreditation United Kingdom Accreditation ServiceashishtrueNoch keine Bewertungen

- Dimension Scope HelpDokument16 SeitenDimension Scope HelpEby JoyNoch keine Bewertungen

- 0103calibration SingleDokument1 Seite0103calibration Singledanielbo2220Noch keine Bewertungen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument5 SeitenSchedule of Accreditation United Kingdom Accreditation ServiceNoor N000rNoch keine Bewertungen

- Avery Weigh Tronix 054Dokument2 SeitenAvery Weigh Tronix 054huidhyiuodghNoch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument32 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncOSCAR YOBANY VEGA HERNANDEZNoch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument20 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncAlonso FraireNoch keine Bewertungen

- 0463calibration SingleDokument2 Seiten0463calibration Singlefajar_92Noch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument11 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncJoel MelendezNoch keine Bewertungen

- Acred 019 CDMXDokument7 SeitenAcred 019 CDMXVERONICANoch keine Bewertungen

- TM 215461 SRTDokument3 SeitenTM 215461 SRTömer cılızNoch keine Bewertungen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument3 SeitenSchedule of Accreditation United Kingdom Accreditation ServicetermmmNoch keine Bewertungen

- Wedge Anchor M10x150 CERTDokument1 SeiteWedge Anchor M10x150 CERTAlina DimaNoch keine Bewertungen

- Analog Outside Micrometer - 130262486 - 25 MM YDokument15 SeitenAnalog Outside Micrometer - 130262486 - 25 MM YishraqaliahsanNoch keine Bewertungen

- L22-51 Sistemas M Meril Cal MK ApprovalDokument8 SeitenL22-51 Sistemas M Meril Cal MK ApprovalIsaacNoch keine Bewertungen

- L19-456-2 Com FinalDokument7 SeitenL19-456-2 Com FinalVERONICANoch keine Bewertungen

- D 1587 - 94 Rde1odctukve PDFDokument6 SeitenD 1587 - 94 Rde1odctukve PDFLupita CarelyNoch keine Bewertungen

- TM 210728 SRTDokument3 SeitenTM 210728 SRTömer cılızNoch keine Bewertungen

- MT 14 465 T1 Report Supplier 1 48.3mm TubeDokument1 SeiteMT 14 465 T1 Report Supplier 1 48.3mm TubeHaseeb KhanNoch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument20 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncIsela ArrietaNoch keine Bewertungen

- Diplomate ServivveDokument1 SeiteDiplomate ServivveSunil Kumar GoudaNoch keine Bewertungen

- A2LA 1101 01 Valid To February 28 2017Dokument4 SeitenA2LA 1101 01 Valid To February 28 2017QA LAB ISMNoch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument26 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncVictor Arciga GranadosNoch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument19 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncFernando MarNoch keine Bewertungen

- Internal Calibration Procedure: Approved By: H. Woodyat Date: 2004Dokument2 SeitenInternal Calibration Procedure: Approved By: H. Woodyat Date: 2004GEO MSc Group-2016Noch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument4 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncAlberto GarciaNoch keine Bewertungen

- Certificate of Calibration: Havatek Makina Sanayi Erbil-IraqDokument2 SeitenCertificate of Calibration: Havatek Makina Sanayi Erbil-IraqYasir Yasir KovanNoch keine Bewertungen

- HSS - Recommended Procedures For Checking Dimensional ToleraDokument12 SeitenHSS - Recommended Procedures For Checking Dimensional ToleraJenner Volnney Quispe ChataNoch keine Bewertungen

- 84 A 226035Dokument6 Seiten84 A 226035Herman50% (2)

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument12 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncVictor Arciga GranadosNoch keine Bewertungen

- 24K Mech Lab-IS ExtDokument3 Seiten24K Mech Lab-IS ExtVikasNoch keine Bewertungen

- Specification Aa10109 1440410164 PDFDokument5 SeitenSpecification Aa10109 1440410164 PDFParthi NatarajNoch keine Bewertungen

- 0517calibration MultipleDokument7 Seiten0517calibration MultiplepchakkrapaniNoch keine Bewertungen

- 20807testing SingleDokument1 Seite20807testing SingleHayderr HassNoch keine Bewertungen

- Adobe Scan 02-Jul-2022Dokument5 SeitenAdobe Scan 02-Jul-2022Shamsher SinghNoch keine Bewertungen

- 0478calibration MultipleDokument67 Seiten0478calibration MultipleJose ramon cornelio torresNoch keine Bewertungen

- Instrument Calibration ProcedureDokument16 SeitenInstrument Calibration ProcedureRino SutrisnoNoch keine Bewertungen

- 24040EJW33C3Dokument4 Seiten24040EJW33C3mina eissaNoch keine Bewertungen

- Investment Castings, Surface Acceptance Standards, Visual ExaminationDokument2 SeitenInvestment Castings, Surface Acceptance Standards, Visual ExaminationJerry BeanNoch keine Bewertungen

- AccreditationDokument40 SeitenAccreditationWalid BdeirNoch keine Bewertungen

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Dokument2 SeitenNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNoch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument15 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncVictor Arciga GranadosNoch keine Bewertungen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument2 SeitenSchedule of Accreditation United Kingdom Accreditation ServiceebbasinghNoch keine Bewertungen

- Astm A997 08Dokument2 SeitenAstm A997 08Omar GruberNoch keine Bewertungen

- GK 223370 SRTDokument1 SeiteGK 223370 SRTömer cılızNoch keine Bewertungen

- Certificate of Calibration: Details of Standard Used Name Id No. Valid Upto TraceabilityDokument16 SeitenCertificate of Calibration: Details of Standard Used Name Id No. Valid Upto TraceabilitymaniNoch keine Bewertungen

- DWGB106Dokument6 SeitenDWGB106LucaNoch keine Bewertungen

- l21-413 New Tech Calibration Acreditacion Perry Johnson Jul-2021Dokument5 Seitenl21-413 New Tech Calibration Acreditacion Perry Johnson Jul-2021Alfredo AngelesNoch keine Bewertungen

- Mesuring Tape HE - mt.001Dokument2 SeitenMesuring Tape HE - mt.001Chethan Nagaraju KumbarNoch keine Bewertungen

- Investment Castings, Surface Acceptance Standards, Visual ExaminationDokument2 SeitenInvestment Castings, Surface Acceptance Standards, Visual ExaminationDarwin DarmawanNoch keine Bewertungen

- FM Full M10X1.5PX40 A193 B8 CL-2 ZN 30-003-1281680Dokument1 SeiteFM Full M10X1.5PX40 A193 B8 CL-2 ZN 30-003-1281680GauravNoch keine Bewertungen

- Alpha A2LA CertificateDokument5 SeitenAlpha A2LA CertificateNg Wei LihNoch keine Bewertungen

- Metrology 2Dokument2 SeitenMetrology 2Juan Francisco Velazco DiazNoch keine Bewertungen

- 0809 UKAS Calibration ScheduleDokument17 Seiten0809 UKAS Calibration ScheduleEdwin Osogo100% (1)

- Astm A 997-07Dokument2 SeitenAstm A 997-07Trushant Nakum100% (2)

- Product Specification Dimensioning and TolerancingDokument64 SeitenProduct Specification Dimensioning and TolerancingilroscioNoch keine Bewertungen

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDokument18 SeitenCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncPaulino MoranNoch keine Bewertungen

- Timken 22219EJW33-SphericalRollerBearings-SteelCageDokument4 SeitenTimken 22219EJW33-SphericalRollerBearings-SteelCageArief sitompulNoch keine Bewertungen

- Electro Surgical Analyzer 4038-01Dokument23 SeitenElectro Surgical Analyzer 4038-01ebbasinghNoch keine Bewertungen

- Reference scope-Electrical-Chance-Indiana-Standards-Laboratory-dbaDokument32 SeitenReference scope-Electrical-Chance-Indiana-Standards-Laboratory-dbaebbasingh100% (1)

- Flaw Detector Scope Sample PG 4-4150-01Dokument22 SeitenFlaw Detector Scope Sample PG 4-4150-01ebbasinghNoch keine Bewertungen

- Surge Generator 2067 01Dokument18 SeitenSurge Generator 2067 01ebbasinghNoch keine Bewertungen

- Calibration Laboratories For All of The Tests ListedDokument2 SeitenCalibration Laboratories For All of The Tests ListedebbasinghNoch keine Bewertungen

- FMD General Work Permit Updated As Per Mh-UaeuDokument1 SeiteFMD General Work Permit Updated As Per Mh-UaeuebbasinghNoch keine Bewertungen

- Hsgen-01-7-00090-1 Ohs Method Statement (5261652) (2305843009218962871)Dokument6 SeitenHsgen-01-7-00090-1 Ohs Method Statement (5261652) (2305843009218962871)ebbasinghNoch keine Bewertungen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument2 SeitenSchedule of Accreditation United Kingdom Accreditation ServiceebbasinghNoch keine Bewertungen

- 0866 01Dokument11 Seiten0866 01ebbasinghNoch keine Bewertungen

- 4986 02Dokument15 Seiten4986 02ebbasinghNoch keine Bewertungen

- 1877 01Dokument23 Seiten1877 01felipeNoch keine Bewertungen

- 1078 01Dokument51 Seiten1078 01ebbasinghNoch keine Bewertungen

- Certificate of Calibration: Name G.C. Thompson SignatureDokument3 SeitenCertificate of Calibration: Name G.C. Thompson SignatureebbasinghNoch keine Bewertungen

- 1297 01Dokument16 Seiten1297 01ebbasinghNoch keine Bewertungen

- ISO IEC 17025 Accreditation Cert+Scope-GCC AccreditationDokument23 SeitenISO IEC 17025 Accreditation Cert+Scope-GCC AccreditationebbasinghNoch keine Bewertungen

- 007 Guide For Documenting The Management System For A Testing Calibration LaboratoryDokument8 Seiten007 Guide For Documenting The Management System For A Testing Calibration LaboratoryebbasinghNoch keine Bewertungen

- Welding machine-CTRDokument1 SeiteWelding machine-CTRebbasinghNoch keine Bewertungen

- Good - Practices - For - Photometric - Laboratories - February 2016Dokument64 SeitenGood - Practices - For - Photometric - Laboratories - February 2016ebbasinghNoch keine Bewertungen

- Schedule of Accreditation United Kingdom Accreditation ServiceDokument2 SeitenSchedule of Accreditation United Kingdom Accreditation ServiceebbasinghNoch keine Bewertungen

- Reference scope-Electrical-Chance-Indiana-Standards-Laboratory-dbaDokument32 SeitenReference scope-Electrical-Chance-Indiana-Standards-Laboratory-dbaebbasingh100% (1)

- HPSC Electrical DiagramDokument1 SeiteHPSC Electrical DiagramebbasinghNoch keine Bewertungen

- Welding machine-CTR PDFDokument1 SeiteWelding machine-CTR PDFebbasinghNoch keine Bewertungen

- Groove micrometer-MN-3287Dokument1 SeiteGroove micrometer-MN-3287ebbasinghNoch keine Bewertungen

- 4700 Precision High Voltage MeterDokument4 Seiten4700 Precision High Voltage MeterEby JoyNoch keine Bewertungen

- Silicon Oil-MSDS & COC 10cStDokument6 SeitenSilicon Oil-MSDS & COC 10cStebbasinghNoch keine Bewertungen

- 4700 Precision High Voltage MeterDokument4 Seiten4700 Precision High Voltage MeterEby JoyNoch keine Bewertungen

- Silicon Oil-MSDS & COC 50cStDokument6 SeitenSilicon Oil-MSDS & COC 50cStebbasinghNoch keine Bewertungen

- Img 0014Dokument4 SeitenImg 0014ebbasinghNoch keine Bewertungen

- 02 BQR Basic Quality RequirementsDokument1 Seite02 BQR Basic Quality RequirementsebbasinghNoch keine Bewertungen

- Sumatif Bahasa InggrisDokument2 SeitenSumatif Bahasa InggrisRiyan KazeknightSevenfoldNoch keine Bewertungen

- 07-Pipe FittingsDokument1 Seite07-Pipe Fittingssopan kharcheNoch keine Bewertungen

- Catalog Strafcotools MediumDokument102 SeitenCatalog Strafcotools MediumAri BinukoNoch keine Bewertungen

- Knurling Grooving and Form TurningDokument33 SeitenKnurling Grooving and Form TurningTareef Hash100% (1)

- Replacing The Exhaust Fan Sensor 115Dokument2 SeitenReplacing The Exhaust Fan Sensor 115Al MalleyNoch keine Bewertungen

- SELAHPADS PUMP EQUIPMENT SCHEDULE 2-ModelDokument1 SeiteSELAHPADS PUMP EQUIPMENT SCHEDULE 2-ModelMark Anthony ValbuenaNoch keine Bewertungen

- 11 Valves 2020Dokument304 Seiten11 Valves 2020Tuesou MachereNoch keine Bewertungen

- GF - Soul-Snatcher Cults v2.50Dokument3 SeitenGF - Soul-Snatcher Cults v2.50Frédéric KempfNoch keine Bewertungen

- Crafts Radial Saw Instruction Manual Model 113.199250Dokument44 SeitenCrafts Radial Saw Instruction Manual Model 113.199250jandre61100% (2)

- ER Spring Collet Chuck System: Mounting Instructions For ER Collets DIN 6499-A and DIN 6499-BDokument10 SeitenER Spring Collet Chuck System: Mounting Instructions For ER Collets DIN 6499-A and DIN 6499-BdavicocasteNoch keine Bewertungen

- 1 stj4230 00 00 001 R1Dokument28 Seiten1 stj4230 00 00 001 R1Hritika PatelNoch keine Bewertungen

- Clutch Failure Symptoms Often IncludeDokument11 SeitenClutch Failure Symptoms Often IncludenielreeNoch keine Bewertungen

- Melway Madness Activity - AOS 5 Dimension and DirectionDokument2 SeitenMelway Madness Activity - AOS 5 Dimension and DirectionHaley JonesNoch keine Bewertungen

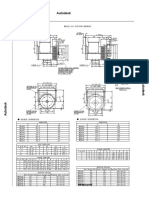

- GP33 Dimensional Drawings: Specifications SpecificationsDokument1 SeiteGP33 Dimensional Drawings: Specifications SpecificationsDAFUNoch keine Bewertungen

- Farquhar-Hill Rifle (Great Britain)Dokument3 SeitenFarquhar-Hill Rifle (Great Britain)blowmeasshole1911Noch keine Bewertungen

- Catalogue of MachinesDokument100 SeitenCatalogue of MachinesBMW V8Noch keine Bewertungen

- TLE7 - FISH PROCESSING Q1, Week 1Dokument16 SeitenTLE7 - FISH PROCESSING Q1, Week 1misty milesNoch keine Bewertungen

- List VMS Cantilever 5x2Dokument7 SeitenList VMS Cantilever 5x2Evi Puspita SariNoch keine Bewertungen

- Trunnion Check Calculation (Onsite) : Page No: Contract No: System NoDokument2 SeitenTrunnion Check Calculation (Onsite) : Page No: Contract No: System NoJ A S JAS0% (1)

- Current Fault Codes: Code Text StatusDokument13 SeitenCurrent Fault Codes: Code Text StatusAwanNoch keine Bewertungen

- Jayna Kitchen SinksDokument60 SeitenJayna Kitchen SinksSuma SharadhaNoch keine Bewertungen

- How To Mount and Operate Buck Adjust-Tru ChuckDokument4 SeitenHow To Mount and Operate Buck Adjust-Tru ChuckStronghold ArmoryNoch keine Bewertungen

- 1CEB30 - Overcenter ValveDokument2 Seiten1CEB30 - Overcenter ValveGloria AlvesNoch keine Bewertungen

- Skripsi Jaw CrusherDokument8 SeitenSkripsi Jaw Crushershavira afariNoch keine Bewertungen

- 2.5.2.9 Inspection Checklist Petcoke BRUDokument3 Seiten2.5.2.9 Inspection Checklist Petcoke BRUvikash kumarNoch keine Bewertungen

- Le6920 Oem1Dokument1 SeiteLe6920 Oem1ihiuhNoch keine Bewertungen

- 11 IM 240ANE HC Parts ListDokument38 Seiten11 IM 240ANE HC Parts ListBhavana ChaudharyNoch keine Bewertungen

- Werna 162-164Dokument1 SeiteWerna 162-164YANdalfNoch keine Bewertungen

- Sigma Fasteners & U BoltsDokument7 SeitenSigma Fasteners & U BoltsmaxhoNoch keine Bewertungen

- Bom Qap136Dokument54 SeitenBom Qap136OmkarNoch keine Bewertungen