Beruflich Dokumente

Kultur Dokumente

ID 204-JSEA-WS-003 Remove & Install Stick Cylinder Bucket Exc. 5110B

Hochgeladen von

leoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ID 204-JSEA-WS-003 Remove & Install Stick Cylinder Bucket Exc. 5110B

Hochgeladen von

leoCopyright:

Verfügbare Formate

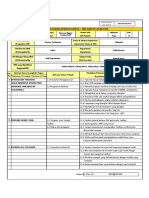

Leighton International Limited

JOB SAFETY AND ENVIRONMENTAL ANALYSIS WORKSHEET

Country Office / Project: Indonesia/ ID 204 MHU Coal Mine Project Tools and or Equipment required: JSA No: ID 204-JSA-WS-003

- Helmet, Safety Boot, Reflective

Job Location & Details: MHU, Remove & Install Stick Cylinder Bucket Exc. 5110B Date Prepared: 15 Feb 10

Vest, Hand Glove, Ear plug

JSA Participants: Suhar, Subekan - Safety Glasses, Etc

M. Thoha, Mujiko S, Jefri Mengi - Ladder/ Tangga Approved by PM:

Responsible Supervisor: Mujiko, Jefri Mengi - All Tools/ Semua Peralatan

- Crane Truck/ Manitou

- Lifting Chain/ Webbing sling

- Rope, Safety Harness

- Toolbox set

- Isolation tags Date: Sahala Aritonang

JOB STEP HAZARDS IDENTIFIED CONTROLS REQUIRED (Eg. Remove overhead cable or ACTION BY/RECORD

(Eg. Set Up Crane) (Eg. Electrocution from 11Kv Cables) isolate/sheath overhead or monitor with spotter) Training PPE Needs (Eg. Supervisor)

1. Park Machine and isolate 1.1 Worker slip/ Fall down/ 1.1.1 Ensure the woker wearing PPE and becareful while working/ 1.1.1.1 Supervisor, Mechanics

Crushed/ Injury/ Pekerja Pastikan pekerja memakai alat pelindung diri dan berhati-hati

disaat bekerja

1.2 Area not level condition 1.2.1 Ensure the area must be level and clean/ Pastikan area 1.2.1.1 Supervisor, Mechanics

harus di ratakan dan bersih

1.3 Equipment

1.3.1 Ensure have spotter fault/unit

to direct when adanya

moving. The operator must look at spotter not in his mirrors. / Pastikan ada 1.3.1.1 Operators

kerusakan

spotter pemandu ketika unit / berpindah. Operator harus melihat kea rah spotter bukan ke kaca spion

unit bergerak

1.4 Unit no Isolation/ Unit tidak di 1.4.1 Ensure fit”Out of Service tag” and Personal danger tag” / 1.4.1.1 Mechanics, supervisor

isolasi Pastikan pasang Out of service tag” and Personal Danger tag”

1.5 Tools set/ support equipment 1.5.1 Ensure check tools set/ support equipment in good condition/ 1.5.1.1 Supervisor, Mechanics

fault/ Alat-alat atau peralatan Pastikan pemeriksaan alat-alat/ peralatan pembantu dalam kondisi

pembantu rusak baik

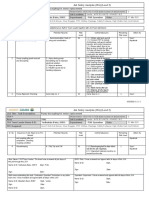

2. Remove & Install Stick 2.1 Worker injury/ Pekerja terluka 2.1.1 Ensure wearing PPE as standard (Hand gloves)/ Pastikan 2.1.1.1 Supervisor and Mechanics

Cylinder Bucket/ pakai alat pelindung diri

Melepaskan dan memasang

Stick Cylinder bucket

2.1.2 Ensure hands correct position when hold pin, arm hoist 2.1.2.1 Mechanics

cylinder/ Pastikan posisikan tangan dengan tepat ketika

Mar 2008 Page 1 of 3 LIL-HSE-FM001B(01)

Leighton International Limited

JOB SAFETY AND ENVIRONMENTAL ANALYSIS WORKSHEET

memegang pin, arm hoist cylinder

2.2 Falling / Impacted/ Terjatuh/ 2.2.1 The worker must be careful and concentration while working/ 2.2.1.1 Mechanics

Terjepit Pekerja harus berhati-hati dan konsentrasi ketika bekerja

2.2.2 Ensure working at high more 1,8m use safety harness belt as 2.2.2.1 Supervisor and Mechanics

standard./ Pastikan bekerja di ketinggian lebih dari 1,8m harus

pakai safety harness belt

2.2.3 Ensure use ladder agreeable/ Pastikan menggunakan tangga 2.2.3.1 Mechanics

yang sesuai

2.2.4 Ensure release hydraulic pressure/ Pastikan melepaskan 2.2.4.1 Mechanics

tekanan hidrolik

2.2.5 Ensure the workers not under load / radius lifting activity/

Pastikan pekerja tidak berada di bawah beban / radius

pengangkatan beban

2.3 Tools set/ Support equipment 2.3.1 Ensure use correct proper tools and lifting gear set(chain/belt) 2.3.1.1 Mechanics and Crane/

broken/ Alat-alat /peralatan / Pastikan menggunakan alat-alat dan peralatan bantu angkat- Manitou Operators

pembantu rusak mengangkat (rantai/ sabuk) yang benar.

2.4 Manual handling/ Mengangkat 2.4.1 Ensure correct manual handling procedure/ Pastikan 2.4.1.1 Mechanics

secara manual melakukan mengangkat manual dengan benar / sesuai prosedur

2.4.2 Ensure use lifting equipment to move stick cylinder/ Pastikan 2.4.2.1 Supervisor, Mechanics,

menggunakan alat angkat untuk memindahkan stick cylinder operator Crane/Manitou

2.4.3 Ensure use webbing sling to tie arm/stick cylinder/ Pastikan 2.4.3.1 Mechanics, Operator Crane/

menggunakan webbing sling untuk mengikat stik cylinder Manitou

2.4.4 Ensure use agreeable lifting chain/ webbing belt with weigh 2.4.4.1 Operator Crane/ Mechanics

stick cylinder/ Pastikan menggunakan rantai/ webbing belt sesuai

dengan berat stick cylinder

2.5 Missed communication/ salah 2.5.1 Ensure have rigger when lifting activities/ Pastikan ada rigger 2.5.1.1 Supervisor, Operator Crane/

pengertian saat berkomunikasi pemandu untuk kegiatan pengangkatan Manitou

2.5.2 Ensure the operator crane/ Manitou must concentration, only 2.5.2.1 Operator Crane/ Manitou

following signal from rigger ./ Pastikan operator crane/Manitou

memperhatikan, mengikuti signal, aba-aba rigger

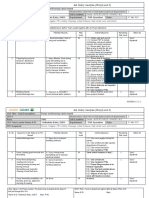

3. Job Finish/ Pekerjaan 3.1 No remove isolation tags/ 3.1 Ensure remove isolation tags from machine/ Pastikan 3.1.1 Mechanics

selesai Tidak melepaskan tanda isolasi melepaskan tanda isolasi dari unit

unit

3.2 Poor housekeeping at the 3.2.1 Cleaning and tidy up work area/ bersihkan dan rapihkan area 3.2.1.1 Supervisor, Mechanics

area/ area kurang bersih kerja

Mar 2008 Page 2 of 3 LIL-HSE-FM001B(01)

Leighton International Limited

JOB SAFETY AND ENVIRONMENTAL ANALYSIS WORKSHEET

I fully understand this Job Safety Analysis and will work according to it Job Description ,

Saya Sangat mengerti Analisa bekerja aman dan akan melakukan sebaik-baiknya. __________________________

__________________________

Date issued , _______________

JOB PARTICIPANT LIST

NO. Name Position Signature

01

02

03

04

05

06

07

08

09

10

Mar 2008 Page 3 of 3 LIL-HSE-FM001B(01)

Das könnte Ihnen auch gefallen

- Job Safety Analysis for MHU Coal Mine ProjectDokument4 SeitenJob Safety Analysis for MHU Coal Mine ProjectleoNoch keine Bewertungen

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDokument4 SeitenJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNoch keine Bewertungen

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDokument3 SeitenJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNoch keine Bewertungen

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDokument2 SeitenJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNoch keine Bewertungen

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDokument4 SeitenJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNoch keine Bewertungen

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDokument3 SeitenJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNoch keine Bewertungen

- Commisioning UnitDokument2 SeitenCommisioning UnitSATRIA MEILANANoch keine Bewertungen

- JSEA Install Grounding & Stick Earth BuildingDokument6 SeitenJSEA Install Grounding & Stick Earth BuildingGus PurNoch keine Bewertungen

- JSA JSDP PAKET 5 (Gerinda)Dokument3 SeitenJSA JSDP PAKET 5 (Gerinda)zidniilman990Noch keine Bewertungen

- Jsa Hse 028Dokument3 SeitenJsa Hse 028Safety DeptNoch keine Bewertungen

- Leighton International Limited Job Safety AnalysisDokument4 SeitenLeighton International Limited Job Safety AnalysisleoNoch keine Bewertungen

- HSE - 2017 - 022 - JSA Escort Unit LowboyDokument5 SeitenHSE - 2017 - 022 - JSA Escort Unit Lowboyarif ridwanNoch keine Bewertungen

- Adjusting Front Suspension Position on DA 433 DozerDokument4 SeitenAdjusting Front Suspension Position on DA 433 Dozerkurniarung oceandaNoch keine Bewertungen

- Belt Conveyor Bearing InspectionDokument3 SeitenBelt Conveyor Bearing InspectionKarthikeyan MNoch keine Bewertungen

- JOB SAFETY ANALYSISDokument21 SeitenJOB SAFETY ANALYSISThái Đạo Phạm Lê100% (1)

- Jsa Hse 034Dokument3 SeitenJsa Hse 034Safety DeptNoch keine Bewertungen

- JSA Remove Ripper Frame D10TDokument3 SeitenJSA Remove Ripper Frame D10TIndra SetiawanNoch keine Bewertungen

- MSHEM-02.11-C Level 2 JSA - Veolia - RO Pump Decoupling For Motor ReplacementDokument4 SeitenMSHEM-02.11-C Level 2 JSA - Veolia - RO Pump Decoupling For Motor ReplacementAbdullah AbedNoch keine Bewertungen

- MSHEM-02.11-C Level 2 JSA - Veolia - RO Units Pump Seal Bearing ReplacementDokument4 SeitenMSHEM-02.11-C Level 2 JSA - Veolia - RO Units Pump Seal Bearing ReplacementAbdullah AbedNoch keine Bewertungen

- 15.tube Bundle Puller.Dokument3 Seiten15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- JSA - T8420 Tank Cleaning - docFSPDokument3 SeitenJSA - T8420 Tank Cleaning - docFSPavinash100% (2)

- 5.confined Space EntryDokument6 Seiten5.confined Space EntryMohammad Fazal KhanNoch keine Bewertungen

- MSHEM-02.11-C Level 2 JSA - Veolia - RO Units Pipes Repairing and ReplacementDokument6 SeitenMSHEM-02.11-C Level 2 JSA - Veolia - RO Units Pipes Repairing and ReplacementAbdullah AbedNoch keine Bewertungen

- JSA Lifting With Equipment+Load ChartDokument13 SeitenJSA Lifting With Equipment+Load ChartBoas BoetarzNoch keine Bewertungen

- JHA - Earthing Lightning Protection & Cable Tray Instalation System - Docx - PCTLDokument8 SeitenJHA - Earthing Lightning Protection & Cable Tray Instalation System - Docx - PCTLOmkar MishraNoch keine Bewertungen

- JSA Format NEW Equipment ErectionDokument5 SeitenJSA Format NEW Equipment Erectionsakthi venkatNoch keine Bewertungen

- JSA - Manual Lifting and Installation (Using Chain Block, Sling Belt and Shackle)Dokument2 SeitenJSA - Manual Lifting and Installation (Using Chain Block, Sling Belt and Shackle)muiqbal.workNoch keine Bewertungen

- 19.hydro Pressure Testing.Dokument8 Seiten19.hydro Pressure Testing.Mohammad Fazal KhanNoch keine Bewertungen

- Jsa Hse 025Dokument1 SeiteJsa Hse 025Safety DeptNoch keine Bewertungen

- 010 JSA - Veolia - RO Units Membranes ReplacementDokument5 Seiten010 JSA - Veolia - RO Units Membranes ReplacementAbdullah AbedNoch keine Bewertungen

- T775 OmsDokument337 SeitenT775 OmsDrago LugonjaNoch keine Bewertungen

- 001 - Rev.03 Survey Work, Excavation, Backfilling and Compaction (1362)Dokument13 Seiten001 - Rev.03 Survey Work, Excavation, Backfilling and Compaction (1362)NIdhinNoch keine Bewertungen

- JSA For Electrical ActivitiesDokument14 SeitenJSA For Electrical Activitiesdrparihary100% (2)

- 21.removal and Refixing of 02SDV3301C.Dokument3 Seiten21.removal and Refixing of 02SDV3301C.Mohammad Fazal KhanNoch keine Bewertungen

- Qatar Liquefied Gas Company Limited JSA FormDokument7 SeitenQatar Liquefied Gas Company Limited JSA FormMohammad Fazal KhanNoch keine Bewertungen

- User - Manual: Thies T858Dokument124 SeitenUser - Manual: Thies T858Luis Morales100% (6)

- Risk Assessment For Chilled Water CladdingDokument2 SeitenRisk Assessment For Chilled Water CladdingHAMIDULLAH MNoch keine Bewertungen

- JSA - Manual Lifting (Using Chain Block, Sling Belt and Shackle)Dokument2 SeitenJSA - Manual Lifting (Using Chain Block, Sling Belt and Shackle)muiqbal.workNoch keine Bewertungen

- 061B Jsa Land Clearing 0+00Dokument10 Seiten061B Jsa Land Clearing 0+00sas13Noch keine Bewertungen

- Jsa Hse 063Dokument4 SeitenJsa Hse 063Safety DeptNoch keine Bewertungen

- SOP For Maintenance & Testing of 6.6KV BET-CETDokument2 SeitenSOP For Maintenance & Testing of 6.6KV BET-CETArbind NathNoch keine Bewertungen

- Spm-Jsea-001-Xii-2019 Pengangkatan Mash (Menggunakan Crane) Dari Low Boy Di Area Site Melak - GbuDokument3 SeitenSpm-Jsea-001-Xii-2019 Pengangkatan Mash (Menggunakan Crane) Dari Low Boy Di Area Site Melak - GbuSPM GBU MelakNoch keine Bewertungen

- JOB SAFETY ANALYSIS FOR WELDING AND GRINDINGDokument5 SeitenJOB SAFETY ANALYSIS FOR WELDING AND GRINDINGWiedz PrastNoch keine Bewertungen

- Jazan Refinery MV/LV Cable Testing JSADokument2 SeitenJazan Refinery MV/LV Cable Testing JSAlalmani bhusalNoch keine Bewertungen

- JSEA Project Cleaning and PaintingDokument6 SeitenJSEA Project Cleaning and PaintingazerNoch keine Bewertungen

- CE06 Use of Power SawDokument3 SeitenCE06 Use of Power SawTafireyi TeveraNoch keine Bewertungen

- Duct InstallationDokument2 SeitenDuct InstallationKrishna PatilNoch keine Bewertungen

- Draf Jsea Erection Tower CombatDokument16 SeitenDraf Jsea Erection Tower CombatalpianurrNoch keine Bewertungen

- VR Hackers - Risk Assesment Hacking-2Dokument3 SeitenVR Hackers - Risk Assesment Hacking-2Vikas RameshNoch keine Bewertungen

- Cable TestingDokument1 SeiteCable Testinglalmani bhusal100% (2)

- Pneumatic Scissor Lift ManualDokument14 SeitenPneumatic Scissor Lift ManualGptc ChekkanuraniNoch keine Bewertungen

- Rotary Actuator Service ManualDokument14 SeitenRotary Actuator Service ManualEmanuel Nicolas VillarruelNoch keine Bewertungen

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDokument2 SeitenJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNoch keine Bewertungen

- Adr Jsa 1711 002Dokument7 SeitenAdr Jsa 1711 002Dada KhalandarNoch keine Bewertungen

- Sky Trak 6036 ServicioDokument280 SeitenSky Trak 6036 ServicioCarlos IrabedraNoch keine Bewertungen

- Switch Board Erection Safety MeasuresDokument4 SeitenSwitch Board Erection Safety MeasuresvasudevanmNoch keine Bewertungen

- Jsa c0501 110 Hydrotesting Rev.00Dokument2 SeitenJsa c0501 110 Hydrotesting Rev.00Zubair Ahmed KhaskheliNoch keine Bewertungen

- 102.SOP - Lifting, Rigging & Slinging - Rev01Dokument4 Seiten102.SOP - Lifting, Rigging & Slinging - Rev01Arjuna PetroNoch keine Bewertungen

- 01 019CranesHoistsSlingsDokument6 Seiten01 019CranesHoistsSlingsmy TVNoch keine Bewertungen

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesVon EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesBewertung: 5 von 5 Sternen5/5 (1)

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDokument3 SeitenJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNoch keine Bewertungen

- ID 204-JSEA-WS-042 Remove & Install Bucket, Arm Cylinder Exc. Liebherr 994Dokument3 SeitenID 204-JSEA-WS-042 Remove & Install Bucket, Arm Cylinder Exc. Liebherr 994leoNoch keine Bewertungen

- Leighton International Limited Job Safety AnalysisDokument4 SeitenLeighton International Limited Job Safety AnalysisleoNoch keine Bewertungen

- Pipe Fittings PDFDokument164 SeitenPipe Fittings PDFjlvega18Noch keine Bewertungen

- Injector AutolubDokument4 SeitenInjector AutolubleoNoch keine Bewertungen

- SM PC300-8 SN01983-01Dokument44 SeitenSM PC300-8 SN01983-01aldy yasi77% (13)

- Multiple Choice Question (MCQ) of Alternator and Synchronous Motors PageDokument29 SeitenMultiple Choice Question (MCQ) of Alternator and Synchronous Motors Pagekibrom atsbha0% (1)

- Digital Booklet - Bach ConcertosDokument14 SeitenDigital Booklet - Bach Concertosppopgod33% (3)

- Gps Anti Jammer Gpsdome - Effective Protection Against JammingDokument2 SeitenGps Anti Jammer Gpsdome - Effective Protection Against JammingCarlos VillegasNoch keine Bewertungen

- Q&A Session on Obligations and ContractsDokument15 SeitenQ&A Session on Obligations and ContractsAnselmo Rodiel IVNoch keine Bewertungen

- Guidelines On Accreditation of CSOs (LSB Representation) - DILG MC 2019-72Dokument18 SeitenGuidelines On Accreditation of CSOs (LSB Representation) - DILG MC 2019-72Cedric Dequito100% (1)

- Sop EcuDokument11 SeitenSop Ecuahmed saeedNoch keine Bewertungen

- Project The Ant Ranch Ponzi Scheme JDDokument7 SeitenProject The Ant Ranch Ponzi Scheme JDmorraz360Noch keine Bewertungen

- Unit 1 2marksDokument5 SeitenUnit 1 2marksLokesh SrmNoch keine Bewertungen

- Ju Complete Face Recovery GAN Unsupervised Joint Face Rotation and De-Occlusion WACV 2022 PaperDokument11 SeitenJu Complete Face Recovery GAN Unsupervised Joint Face Rotation and De-Occlusion WACV 2022 PaperBiponjot KaurNoch keine Bewertungen

- 1990-1994 Electrical Wiring - DiagramsDokument13 Seiten1990-1994 Electrical Wiring - Diagramsal exNoch keine Bewertungen

- Week 3 SEED in Role ActivityDokument2 SeitenWeek 3 SEED in Role ActivityPrince DenhaagNoch keine Bewertungen

- Beams On Elastic Foundations TheoryDokument15 SeitenBeams On Elastic Foundations TheoryCharl de Reuck100% (1)

- Ayushman BharatDokument20 SeitenAyushman BharatPRAGATI RAINoch keine Bewertungen

- Advance Bio-Photon Analyzer ABPA A2 Home PageDokument5 SeitenAdvance Bio-Photon Analyzer ABPA A2 Home PageStellaEstel100% (1)

- Discursive Closure and Discursive Openings in SustainabilityDokument10 SeitenDiscursive Closure and Discursive Openings in SustainabilityRenn MNoch keine Bewertungen

- Milwaukee 4203 838a PB CatalogaciónDokument2 SeitenMilwaukee 4203 838a PB CatalogaciónJuan carlosNoch keine Bewertungen

- 2006-07 (Supercupa) AC Milan-FC SevillaDokument24 Seiten2006-07 (Supercupa) AC Milan-FC SevillavasiliscNoch keine Bewertungen

- Account STMT XX0226 19122023Dokument13 SeitenAccount STMT XX0226 19122023rdineshyNoch keine Bewertungen

- Debentures Issued Are SecuritiesDokument8 SeitenDebentures Issued Are Securitiesarthimalla priyankaNoch keine Bewertungen

- Marketing ManagementDokument14 SeitenMarketing ManagementShaurya RathourNoch keine Bewertungen

- RAP Submission Form, OBIDokument3 SeitenRAP Submission Form, OBIAhmed MustafaNoch keine Bewertungen

- FEM Lecture Notes-2Dokument18 SeitenFEM Lecture Notes-2macynthia26Noch keine Bewertungen

- Management Pack Guide For Print Server 2012 R2Dokument42 SeitenManagement Pack Guide For Print Server 2012 R2Quang VoNoch keine Bewertungen

- Programme Report Light The SparkDokument17 SeitenProgramme Report Light The SparkAbhishek Mishra100% (1)

- Queries With AND and OR OperatorsDokument29 SeitenQueries With AND and OR OperatorstrivaNoch keine Bewertungen

- Case Study 2 F3005Dokument12 SeitenCase Study 2 F3005Iqmal DaniealNoch keine Bewertungen

- Mayor Byron Brown's 2019 State of The City SpeechDokument19 SeitenMayor Byron Brown's 2019 State of The City SpeechMichael McAndrewNoch keine Bewertungen

- Sapkale Sandspit 2020Dokument5 SeitenSapkale Sandspit 2020jbs_geoNoch keine Bewertungen

- SAP ORC Opportunities PDFDokument1 SeiteSAP ORC Opportunities PDFdevil_3565Noch keine Bewertungen

- 13-07-01 Declaration in Support of Skyhook Motion To CompelDokument217 Seiten13-07-01 Declaration in Support of Skyhook Motion To CompelFlorian MuellerNoch keine Bewertungen