Beruflich Dokumente

Kultur Dokumente

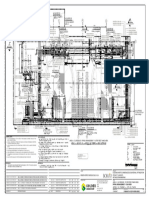

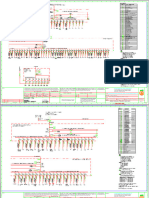

Case-Upper: Weld Weld

Hochgeladen von

Isaías AguilarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Case-Upper: Weld Weld

Hochgeladen von

Isaías AguilarCopyright:

Verfügbare Formate

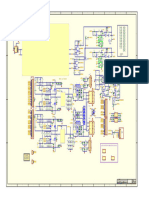

9D 4D 8D 14D 8D 6D 8D 14D 7D 7D 5D 12D 12D 4D 14D 12D 13D A 10D 6D 6D 1D 3D 3D 2D 11P

B C

40285023

48.87 1D THREADED HOLE LOCATION ASSEMBLY CLEARANCE

14 2D THREADED HOLE LOCATIONS ASSEMBLY CLEARANCE

11.75

14 3D CHAMFER DIMENSION ASSEMBLY CLEARANCE

C OF GEARCASE

11

4D INNER/OUTER PLATE RADIUS MAINTAIN SEAL CRUSH

21.17 2 N 5D CENTERLINE DISTANCE MAINTAIN SEAL CRUSH

6D SPLITLINE FASTENER LOCATIONS AVOID SHEAR LOADING

14 13 3

1 1 7D RING SURFACE DIAMETER MACHINED PINION SEAL FIT/PERFORMANCE

23.67 10.61

8D RING WALL THICKNESS MACHINED PINION SEAL FIT/PERFORMANCE

TYP

ITS.5,6 &7 TYP IT.10 TO IT.3 9D GEAR CLEARANCE PLATE CLEARANCE

TYP IT.9 TO IT.1 .12 4 5 8 7 6

NOTE 3 .12

10D TOP SURFACE PROFILE FINAL ASSEMBLY FIT/FUNCTION

1

GEAR CASE 11P NOTE 3 AVOID SOFT JOINTS

8.00 8.00

12D FLANGE DISTANCE SEAL CLEARANCE

6 13D WELD GRIND SEAL CLEARANCE

TYP IT.2 13 4.00 4.00 14D PINION RING RADIUS AVOID SHARP CORNERS

TO ITS.1 & 3 .12 2

NOTE 4 .12 10 15D BOLT HOLE WALL THICKNESS AVOID FLANGE CRACKING

EXCEPT AS NOTED .75

9

11 3

ITEM 2 TO BE CLEAR .030 A B C .75

OF THIS RADIUS .75

.75 THRU 21.58 8.50 8.50 10.29

3 .030 A B C

B .010 A B C .12 1.0-4.0

IT.9 TO IT.1

.12 1.0-4.0 C OPTIONAL MANUFACTURING

.75 THRU 9

FOR ITS.6,7,8 & ITS.4 & 5

AS ONE PIECE FLANGES

CROSSHATCHED AREA FOR

PROFILE CONTROL

17.00 6

R 16.75 8 12.53

TYP 14

9D .25

ITS.5,6 &7 2

NOTE 2 & 3 TYP ITS. 1, 2 & 3 13

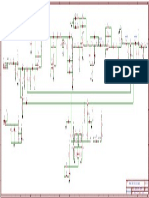

R 9.490 R 8.984

8.89

IT.4 TO IT.1

VIEW K 7D 7D

R 9.265 M NOTE 4 .25

4 11 (.25)

9

1

7D 11

R 7.94 .02 4D

8.89 IT.10 TO

R 10.00 IT.3 4

8

R 7.18 J

2.40 3 K 2.00

1.50 OPTIONAL WELD

2X 1.12 IT.2 TO IT.1 2.60

R 7.18 .02 INSIDE SURFACE

.01

12 SURFACES R 10.00

4D 4 E M 14D

4X R .12 J 8.25

GRIND WELDS ON

G B 2X R .12 TYP ITS.1 & 3 A 10D .75 MIN TYP

N ITS.10 & 14

IT.9 TO IT.11 IF NECESSARY 8

(.25) ITS. 4 THRU 8 5

14D

ALL TOP SURFACES 2 3

5 1

7 8

4 NOTE 4

11.195 18.31 .01 .12 TYP ITS.4 & 8

TO ITS.1 & 3

5D .12 CROSSHATCHED AREA FOR 6

NOTE 4

PROFILE CONTROL

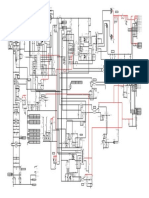

SECTION A-A 15

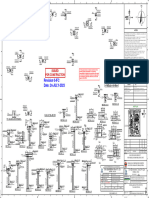

11

7

43.538

2 .12 1.0-4.0

39.315 IT.15 TO IT.1

.12 1.0-4.0 11

5

1

48.87

ITS.4 & 8 NOTE 4 1.75

.12 12D 4

TO IT.2 .12

NOTE 3 .12 NOTE 4 IT.15 TO IT.2

.12 NOTE 3 & 4 .25

8.15 MIN

14 2.62 .56 20.913 MACHINE IF 9.25

2

.93 NECESSARY 12D

3

.313 1.50 21.12

10.18 10.16 4 11

6 14X 3/8-16 UNC-2B THRU 3D

M-M 3/8-16 UNC-2B 1.25 +.06

D 1 SECTION .500 A .028 A B C

6D .50

-.00

.028 A B C

11

13

1 SECTION L-L

IT.10 TO .12 1.0-4.0

+.06 IT.3 .12 1.0-4.0

.50 19.19

.12 X 45 -.00

NOTE 4

.25 .12 14D 2X .06 X 45 3D

AFTER MACHINING

ITS.4 & 8 8D 8

.25

TO ITS.1,2 & 3

NOTE 3 & 4

12 5.079 L 5.45

+.00

-.04 GEAR CASE 4.979

12 5.079

L 5.64

1D 5.65 .05

4.604 .010 A A A A A 10

8D .45 .01

8.00 3.264 5.25 .06 8.00

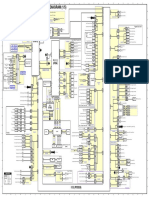

4 H TRACTION MOTOR 3

A A DRIVE END HOUSING

.03 A B C

A HOLD FOR CROSS HATCHED

A 1.639

2.625

2

VIEW G AREA AS SHOWN IN

TYP BOTH ENDS SECTIONS A-A & L-L

SUPPORT BEARING HOUSING

13 1.801

D

9.490 9.72

.56 .05

11 9.265

1 2 SECTION C-C 8.984

4.088 3 14

TYP ITS.

5,6,7 & 11

2D

3/8-16 UNC-2B THRU 4

G A

.38

.028 A 8.178 5

7 3/8-16 UNC-2B THRU

6D F

1 A .028 A B

6D 8.50 8.50 A

B 12.266 12D 12D

IT.4 TO IT.11 A C 5

NOTE 4 NOTE 4 16.356

.12 5

.97 .12 11

20.444 .12 IT.10 TO

1.18 .12 IT.5

.12 VIEW H-H

6

4

4 38.565

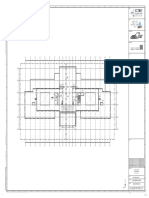

SHOWING ASSEMBLY BOGIE FRAME VIEW N-N

CLEARANCE REQUIREMENTS

3

NOTES:

OPTIONAL FABRICATION AI02571

43.163 1. USE ELECTRONIC MASTER MATH MODEL TO DEFINE

THE DESIGN INTENT. WELD BRAZE SPEC AI01651

WELD SYMBOLS AI01046

2. ITS.6,7 & 8 CAN BE MANUFACTURED AS ONE PIECE

12 47.760 AS WELL AS ITS.4 & 5. APL OF SEALANT AI02252

NOTE 4

.25 .25 V1050 *SURFACE FINISH RQMT AI02719

11P 3. MASK ALL MACHINED SURFACES DURING PAINTING.

AFTER MACHINING PAINT ALL INNER AND OUTER SURFACES PER AI 2719. FOR MANUFACTURING

.38 1 STRIP 40280374 15

ASM

17X .18 MIN 4. VERIFY WELDS ARE OIL TIGHT BY APPLYING DYE 1 FLANGE-1 PT 8058701 14

ALL HOLES TO SECTION D-D 4.15 .450 .005 8D PENETRANT TO ONE SURFACE, APPLYING DEVELOPER 1 FLANGE-3/4 PT 8024709 13 NONE

OUTSIDE EDGES TO THE OPPOSITE SURFACE, AND CHECKING FOR

THROUGH-WALL LEAKS. IF ASSEMBLY IS TO BE PAINTED, 1 CHANNEL ASM 40081066 12

NO NO

WHEEL TEST SHALL BE PERFORMED BEFORE PAINTING. NO LEAKS 1 RING-HALF 40277784 11

118.087

ALLOWED. REPAIRS SHALL BE RE-TESTED USING SAME PROCESS. 1 STRIP 40249128 10

IT.4 TO IT.11 53.563

SECTION J-J NOTE 3 & 4 5 1 STRIP 40277785 9

TYP ITS.5,6 & 7 SECTION B-B 5. INSIDE OF GEAR CASE MUST BE FREE OF SCALE, EA

SHOT, SLAG & ALL FOREIGN MATERIAL EXCEPT 1 BAR 40285057 8

FIRMLY FUSED WELD SPATTER. EMD STANDARD

IT.1 TO IT.11 4 1 BAR 40284965 7

1

MACHINE AFTER WELDING NOTE 3 & 4 6. PARTS TO BE FREE OF CHIPS, BURRS, DIRT AND 1 BAR 40284964 6 2016 Electro-Motive. All Rights Reserved.

TYP ITS.4 THRU 8

NOTE 4 OTHER DEBRIS. 1 BAR 40284961 5

02-SEP-2016

1 BAR 40284960 4 TATA

G 7. QUANTITATIVE CONTAMINATION LEVEL OF FLUID

E GEAR CASE-UPPER

1

CONDUITS NOT TO EXCEED 1.2mg. 1 PLATE-OUTER 40284950 3

VIEW VIEW F 1 PLATE 40251686 2

VIEW SHOWING A TYPICAL GEAR CASE 8. FINISH WHERE SHOWN. M.CONBOY N/A 40251358

APPLICATION IN AN ASSEMBLY 1 PLATE-INNER 40284938 1

1 1 1 1

40285023 -- 40285023 -- BRAKE UNIT NO.

REQD

MATL/NOTES NAME OF PART PART NO. ITEM

NO.

GT46AC

40285023

11/14/16 18:01 PM

Das könnte Ihnen auch gefallen

- Strip PAD: Fabrication AI02571 AI01651 AI01046 AI02525 OF AI02252 Finish AI02719Dokument1 SeiteStrip PAD: Fabrication AI02571 AI01651 AI01046 AI02525 OF AI02252 Finish AI02719Isaías AguilarNoch keine Bewertungen

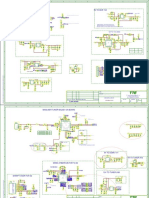

- Fuente APS 348 (GL3B) - 1 474 486 11 Sony TV KDL 32R4xxA SchematicDokument1 SeiteFuente APS 348 (GL3B) - 1 474 486 11 Sony TV KDL 32R4xxA Schematicjose peres100% (2)

- Dig 525 (061017)Dokument19 SeitenDig 525 (061017)Bernard MendisNoch keine Bewertungen

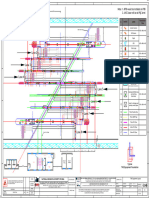

- 21466447-D-4132-PI-DWG-50002 - 1 - Status DDokument1 Seite21466447-D-4132-PI-DWG-50002 - 1 - Status Darturo loayza hinostrozaNoch keine Bewertungen

- 30lbe51br301 - Rev 0Dokument1 Seite30lbe51br301 - Rev 0Mohd Effiezool YaserNoch keine Bewertungen

- B01 TJ102MDokument1 SeiteB01 TJ102Malysamir.eetdNoch keine Bewertungen

- Schematics Hitachi CDH-LE39SMART14 MainBoard 40-N63EP2-MAB2HG PDFDokument14 SeitenSchematics Hitachi CDH-LE39SMART14 MainBoard 40-N63EP2-MAB2HG PDFJuan Carlos ZordanNoch keine Bewertungen

- B01 TJ101MDokument1 SeiteB01 TJ101Malysamir.eetdNoch keine Bewertungen

- 30lbe51br302 - Rev 0Dokument1 Seite30lbe51br302 - Rev 0Mohd Effiezool YaserNoch keine Bewertungen

- Power BD Connector 5V To DDR 1V5: Last SavedDokument9 SeitenPower BD Connector 5V To DDR 1V5: Last SavedDaniel ZorrillaNoch keine Bewertungen

- 14''/21'' Color TV Basic Schematic Diagram: CRT BoardDokument1 Seite14''/21'' Color TV Basic Schematic Diagram: CRT BoardSalim BlognetNoch keine Bewertungen

- 30lbe51br303 - Rev 0Dokument1 Seite30lbe51br303 - Rev 0Mohd Effiezool YaserNoch keine Bewertungen

- Osbourne, Ozzy - Crazy TrainDokument8 SeitenOsbourne, Ozzy - Crazy Trainjoccker7555Noch keine Bewertungen

- Don Juan de Marco: Bryan Adams 2 3 4Dokument1 SeiteDon Juan de Marco: Bryan Adams 2 3 4Clau GomesNoch keine Bewertungen

- Farewell To A FriendDokument3 SeitenFarewell To A FriendPaulNoch keine Bewertungen

- F. Durante 12 Partimenti Diminuiti With RealizationsDokument21 SeitenF. Durante 12 Partimenti Diminuiti With RealizationsValeria BisioNoch keine Bewertungen

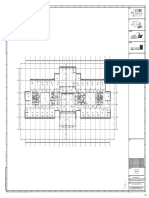

- 03.baramati TMS Layout - NEWDokument1 Seite03.baramati TMS Layout - NEWkrhimanshu0505Noch keine Bewertungen

- SCH - QD Amin 13en.01Dokument1 SeiteSCH - QD Amin 13en.01Christopher SotoNoch keine Bewertungen

- St150030 Aru Elc 06 z15 DRG Le 0006 s3 x01 Redline UpdatedDokument1 SeiteSt150030 Aru Elc 06 z15 DRG Le 0006 s3 x01 Redline UpdatedJamie CannellNoch keine Bewertungen

- Polar 37CTV3160 54CTV3160 U21AXTDokument1 SeitePolar 37CTV3160 54CTV3160 U21AXTalexmaster073Noch keine Bewertungen

- TMX5BP Electrical SchematicsDokument16 SeitenTMX5BP Electrical SchematicsSergioNoch keine Bewertungen

- A294 Point To Point Diagram 1/2: AC Drive Board (PCB 10) AC Line Block ChartDokument10 SeitenA294 Point To Point Diagram 1/2: AC Drive Board (PCB 10) AC Line Block ChartFábio Alessandro PereiraNoch keine Bewertungen

- 150 A Introducción: Standard TuningDokument2 Seiten150 A Introducción: Standard TuningFelipe JuarezNoch keine Bewertungen

- De 22 36 DWG PF CH PL 00 FF 110 00Dokument1 SeiteDe 22 36 DWG PF CH PL 00 FF 110 00Mahmoud A. HafeezNoch keine Bewertungen

- Bassbutler Final Corrected 3Dokument1 SeiteBassbutler Final Corrected 3Beckenbauer ErnstbergerNoch keine Bewertungen

- Ricoh C4502 D143 D144 and OPTIONS Point 2 Point Diagrams PDFDokument29 SeitenRicoh C4502 D143 D144 and OPTIONS Point 2 Point Diagrams PDFDawood AhmedNoch keine Bewertungen

- AngkurDokument1 SeiteAngkurJundiNoch keine Bewertungen

- MIP2H2Dokument1 SeiteMIP2H2Elyapanya ToshibaNoch keine Bewertungen

- Citi Housing SocietyDokument1 SeiteCiti Housing SocietyAhmad NawazNoch keine Bewertungen

- B01 TL101MDokument1 SeiteB01 TL101Malysamir.eetdNoch keine Bewertungen

- 21 C 1348 Preamp 2Dokument1 Seite21 C 1348 Preamp 2GökhanNoch keine Bewertungen

- LD PC CH.199+590Dokument4 SeitenLD PC CH.199+590Aerotide InfrastructuresNoch keine Bewertungen

- Activity Center Rear Elevation: Esj and Sons Construction and Construction Supply, IncDokument1 SeiteActivity Center Rear Elevation: Esj and Sons Construction and Construction Supply, IncGerard Paul CusiNoch keine Bewertungen

- G Board Schematic Diagram For 32" ModelDokument1 SeiteG Board Schematic Diagram For 32" Modeljose luisNoch keine Bewertungen

- Aps 348 349 350Dokument3 SeitenAps 348 349 350Andres AlegriaNoch keine Bewertungen

- Schematic - ODM-3 Overdrive Master - 2020-11-11 - 06-14-24Dokument1 SeiteSchematic - ODM-3 Overdrive Master - 2020-11-11 - 06-14-24Marcus FeilNoch keine Bewertungen

- Krp-Cd-Ele-1404-002 - Platform Level Plan Equipment LayoutDokument1 SeiteKrp-Cd-Ele-1404-002 - Platform Level Plan Equipment LayoutGourishankar MishraNoch keine Bewertungen

- China TD21P8 M61266, M37160, Tea1506p, La9302Dokument1 SeiteChina TD21P8 M61266, M37160, Tea1506p, La9302Luis Liammas PerezNoch keine Bewertungen

- Unit 6210Dokument1 SeiteUnit 6210Khairul IdhamNoch keine Bewertungen

- Epcc05 MDR 421 STR DWG 000 0072 15Dokument1 SeiteEpcc05 MDR 421 STR DWG 000 0072 15RANJEET PRATAP SINGHNoch keine Bewertungen

- Senate - 1 Ground FapaDokument1 SeiteSenate - 1 Ground FapaRaviNoch keine Bewertungen

- Bhatinda R 2 SLDDokument1 SeiteBhatinda R 2 SLDvineets058Noch keine Bewertungen

- PressedDokument6 SeitenPressedVijay KumarNoch keine Bewertungen

- 0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelDokument1 Seite0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelVivek VinayakumarNoch keine Bewertungen

- Omnitronic p1500 (1) SCH PDFDokument1 SeiteOmnitronic p1500 (1) SCH PDFMantasPuskoriusNoch keine Bewertungen

- Omnitronic p1500 (1) SCHDokument1 SeiteOmnitronic p1500 (1) SCHMantasPuskoriusNoch keine Bewertungen

- WWW - Fineprint.Cn: PDF PdffactoryDokument1 SeiteWWW - Fineprint.Cn: PDF PdffactoryLevi Duran100% (1)

- 4V Circuit DiagramDokument1 Seite4V Circuit DiagramwjcbaaNoch keine Bewertungen

- B01 TL104MDokument1 SeiteB01 TL104Malysamir.eetdNoch keine Bewertungen

- Gre Eec D 99 Co P 10036 03 057Dokument9 SeitenGre Eec D 99 Co P 10036 03 057Carlos GamarraNoch keine Bewertungen

- 21121-EL-DWG-0023 - AC Cable Route Layout & Cross SectionDokument2 Seiten21121-EL-DWG-0023 - AC Cable Route Layout & Cross SectionvishnutryNoch keine Bewertungen

- Sbdo Ppa 105 3011 00Dokument1 SeiteSbdo Ppa 105 3011 00Douglas de Melo FélixNoch keine Bewertungen

- Epcc05 MDR 421 STR DWG 000 0072 07Dokument1 SeiteEpcc05 MDR 421 STR DWG 000 0072 07RANJEET PRATAP SINGHNoch keine Bewertungen

- Granada (Jose Garcia) - Hoang BuuDokument3 SeitenGranada (Jose Garcia) - Hoang BuuSimon DinahNoch keine Bewertungen

- 穿越时空的思念Dokument2 Seiten穿越时空的思念仇怡Noch keine Bewertungen

- Notes:-: Timber Doors Key PlanDokument1 SeiteNotes:-: Timber Doors Key PlanKumudu PereraNoch keine Bewertungen

- Hyd. Plan Luffing TrainningDokument4 SeitenHyd. Plan Luffing TrainningMIGUEL PEÑANoch keine Bewertungen

- Www.Fineprint.Cn: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Dokument1 SeiteWww.Fineprint.Cn: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Lie NgoNoch keine Bewertungen

- Instant Assessments for Data Tracking, Grade 5: Language ArtsVon EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNoch keine Bewertungen

- Instant Assessments for Data Tracking, Grade 4: MathVon EverandInstant Assessments for Data Tracking, Grade 4: MathBewertung: 5 von 5 Sternen5/5 (2)

- Rezos de Los 16 Meyis Tablero 1Dokument3 SeitenRezos de Los 16 Meyis Tablero 1Isaías AguilarNoch keine Bewertungen

- HPR400XDDokument366 SeitenHPR400XDIsaías AguilarNoch keine Bewertungen

- SB 870810 R4 HPR400XDDokument2 SeitenSB 870810 R4 HPR400XDIsaías AguilarNoch keine Bewertungen

- A True Global Presence: Manual ClampingDokument346 SeitenA True Global Presence: Manual ClampingIsaías AguilarNoch keine Bewertungen

- Manual Clamping Accessories: MC-ACC-1Dokument10 SeitenManual Clamping Accessories: MC-ACC-1Isaías AguilarNoch keine Bewertungen

- Engineering Apparatus Instructions: B. A. Ristig 2400Dokument9 SeitenEngineering Apparatus Instructions: B. A. Ristig 2400Isaías AguilarNoch keine Bewertungen

- Engineering Apparatus Instructions: M. E. Oddie 2763Dokument3 SeitenEngineering Apparatus Instructions: M. E. Oddie 2763Isaías AguilarNoch keine Bewertungen

- Mach 3 Brochure enDokument3 SeitenMach 3 Brochure enIsaías AguilarNoch keine Bewertungen

- Consumable Care GuideDokument12 SeitenConsumable Care GuideIsaías AguilarNoch keine Bewertungen

- TDS Dismantling JointsDokument5 SeitenTDS Dismantling JointsTanmoy DuttaNoch keine Bewertungen

- 2930 1214 00 Parts GlossaryDokument35 Seiten2930 1214 00 Parts GlossaryMateo PaladinoNoch keine Bewertungen

- Lab Report 4Dokument6 SeitenLab Report 4MALIK MUHAMMAD HAMZA FAROOQ MALIK MUHAMMAD FAROOQNoch keine Bewertungen

- BGM Parts ManaualDokument58 SeitenBGM Parts ManaualDaniel Wellner86% (7)

- SOR-Vol3 PrintDokument518 SeitenSOR-Vol3 PrintSalakati NTPCNoch keine Bewertungen

- Repair Parts ManualDokument24 SeitenRepair Parts ManualManuel Fernandez MoraNoch keine Bewertungen

- 2AZ-FE Engine Mechanical PDFDokument80 Seiten2AZ-FE Engine Mechanical PDFNguyễn Minh HiếuNoch keine Bewertungen

- Manutencao 428EDokument58 SeitenManutencao 428EkhalilgtspNoch keine Bewertungen

- AS350Dokument57 SeitenAS350Danna PerezNoch keine Bewertungen

- Fro 15210C 0510Dokument36 SeitenFro 15210C 0510davisNoch keine Bewertungen

- PARSUN Common Parts CatalogueDokument12 SeitenPARSUN Common Parts CatalogueMarine Parts ChinaNoch keine Bewertungen

- Hoist Drum Assy 4100XPCDokument3 SeitenHoist Drum Assy 4100XPCFrancisco GonzalezNoch keine Bewertungen

- Hydraulic Circuitry (Work Cylinders) (Four Section Main Valve) - MT55Dokument3 SeitenHydraulic Circuitry (Work Cylinders) (Four Section Main Valve) - MT55Iliyan VasilevNoch keine Bewertungen

- Manual-Book-Kijang-Inova-Diesel (Google Tranlated Indonesian To English)Dokument508 SeitenManual-Book-Kijang-Inova-Diesel (Google Tranlated Indonesian To English)Orly Palomar Jr.100% (4)

- Lifan LF 200b 2008 Owners ManualDokument21 SeitenLifan LF 200b 2008 Owners ManualducmansNoch keine Bewertungen

- MTII 11-4129 LT-650 - Parts ManualDokument330 SeitenMTII 11-4129 LT-650 - Parts ManualAdan BenitezNoch keine Bewertungen

- 2005 S003 NBPG Rfi 04952 - R00Dokument1 Seite2005 S003 NBPG Rfi 04952 - R00RPDeshNoch keine Bewertungen

- 4.lever ReleaseDokument2 Seiten4.lever Releaseabdelrahman shaalanNoch keine Bewertungen

- February 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18Dokument9 SeitenFebruary 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18kevin gradinNoch keine Bewertungen

- Automobile Design (5051)Dokument4 SeitenAutomobile Design (5051)Ziyad KprNoch keine Bewertungen

- X016 Conductor Resistance PDFDokument1 SeiteX016 Conductor Resistance PDFŽeljko BokanovićNoch keine Bewertungen

- Loctite Industrial Gearbox Service ManualDokument13 SeitenLoctite Industrial Gearbox Service ManualDumitrescuNoch keine Bewertungen

- IEC Motor Data CalculatorDokument6 SeitenIEC Motor Data Calculatorsabill arasyidNoch keine Bewertungen

- Dodge Nitro KA - 2007 - Transfer Case Mp143Dokument47 SeitenDodge Nitro KA - 2007 - Transfer Case Mp143eephantomNoch keine Bewertungen

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument42 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768מאור רווחNoch keine Bewertungen

- Piaggio MP3 LT 250 I.E.Dokument346 SeitenPiaggio MP3 LT 250 I.E.ManuallesNoch keine Bewertungen

- Yz250f 2013Dokument63 SeitenYz250f 2013Gabriel ZamoraNoch keine Bewertungen

- Material Stud Anhor Masonry For Hilti - 3 PDFDokument23 SeitenMaterial Stud Anhor Masonry For Hilti - 3 PDFAndy MdlNoch keine Bewertungen

- Morse Test On Multi Cylinder Petrol EngineDokument4 SeitenMorse Test On Multi Cylinder Petrol EnginealagurmNoch keine Bewertungen

- Upd: 02 JAN 2006 5441 7742140 - 02B - 02B-1050 D100A, TD100A, D100BDokument2 SeitenUpd: 02 JAN 2006 5441 7742140 - 02B - 02B-1050 D100A, TD100A, D100BManuel Pedro InácioNoch keine Bewertungen