Beruflich Dokumente

Kultur Dokumente

Daewoo Matiz 2000-2013 Clutch PDF

Hochgeladen von

Felix Rafael AlvaradoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Daewoo Matiz 2000-2013 Clutch PDF

Hochgeladen von

Felix Rafael AlvaradoCopyright:

Verfügbare Formate

SECTION 5C

CLUTCH

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in B unless otherwise

noted.

TABLE OF CONTENTS

Description and Operation . . . . . . . . . . . . . . . . . . 5C-2 Pressure Plate, Clutch Disc and

Driving Members . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-2 Input Shaft Bearing . . . . . . . . . . . . . . . . . . . . . . . . 5C-6

Driven Members . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-2 Clutch Release Bearing, Shaft and Bushing . . . 5C-8

Operating Members . . . . . . . . . . . . . . . . . . . . . . . 5C-2 Clutch Release Arm . . . . . . . . . . . . . . . . . . . . . . 5C-10

Component Locator . . . . . . . . . . . . . . . . . . . . . . . . 5C-3 Clutch Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-11

Clutch Components . . . . . . . . . . . . . . . . . . . . . . . . 5C-3 Clutch Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-12

Diagnostic Information and Procedures . . . . . 5C-4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-13

General Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . 5C-4 General Specifications . . . . . . . . . . . . . . . . . . . . 5C-13

Clutch Pedal Operation . . . . . . . . . . . . . . . . . . . . 5C-5 Fastener Tightening Specifications . . . . . . . . . . 5C-13

Clutch Cable Adjustment . . . . . . . . . . . . . . . . . . . 5C-5 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-14

Repair Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-6 Special Tools Table . . . . . . . . . . . . . . . . . . . . . . . 5C-14

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-6

DAEWOO M-150 BL2

5C – 2 CLUTCH

DESCRIPTION AND OPERATION

DRIVING MEMBERS The driving and driven members are held in contact by

spring pressure. This pressure is exerted by a dia-

The driving members consist of two flat surfaces ma-

phragm spring in the pressure plate assembly.

chined to a smooth finish. One of these is the rear face

of the engine flywheel, and the other is the pressure

plate. The pressure plate is fitted into a steel cover, OPERATING MEMBERS

which is bolted to the flywheel. The clutch release system consists of the clutch pedal,

the clutch release shaft, the clutch cable, the release

DRIVEN MEMBERS arm and the release bearing. When pressure is applied

to the clutch pedal, the clutch release shaft pushes

The driven member is the clutch disc with a splined hub

against the release bearing by rotating. The bearing

which is free to slide lengthwise along the splines of the

then pushes against the diaphragm spring in the pres-

input shaft, but which drives the input shaft through

sure plate assembly, thereby releasing the clutch.

these same splines.

DAEWOO M-150 BL2

CLUTCH 5C – 3

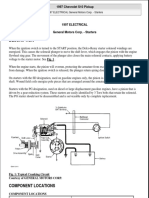

COMPONENT LOCATOR

CLUTCH COMPONENTS

D13C4011

1 Clutch Disc 7 Release Shaft Seal

2 Pressure Plate 8 Release Arm

3 Release Bearing 9 Clutch Cable Adjusting Nut

4 Release Shaft 10 Clutch Cable

5 Release Shaft Bushing (No.1) 11 Clutch Pedal

6 Release Shaft Bushing (No.2)

DAEWOO M-150 BL2

5C – 4 CLUTCH

DIAGNOSTIC INFORMATION AND PROCEDURES

GENERAL DIAGNOSIS

Condition Probable Cause Correction

Slipping Clutch D Improper clutch cable adjustment. D Adjust clutch cable.

D Worn or oily contamination on clutch disc D Replace clutch disc.

surface.

D Worn or oily contamination on pressure D Replace pressure plate, flywheel.

plate, flywheel surface.

D Damaged or weakened diaphragm spring. D Replace pressure plate.

D Rusted clutch cable. D Replace clutch cable.

Dragging Clutch D Improper clutch cable adjustment. D Adjust clutch cable.

D Worn or weakened diaphragm spring. D Replace pressure plate.

D Worn or rusted splines of input shaft or D Replace input shaft or clutch disc.

clutch disc.

D Excessively wobbly clutch disc. D Replace clutch disc.

D Worn clutch disc. D Replace clutch disc.

Fails to Release D Bent or damaged clutch disc. D Replace clutch disc.

D Worn or rusted splines of input shaft or D Replace input shaft or clutch disc.

clutch disc.

D Improper operation of clutch release shaft. D Replace clutch release shaft.

Pedal Stays on Floor D Interfered clutch release bearing. D Lubricate and adjust clutch release

When Disengaged bearing.

D Weakened diaphragm spring. D Replace pressure plate.

Clutch Vibration D Clutch facing with oily contamination. D Replace clutch disc.

D Release bearing slides unsmoothly on input D Lubricate retainer release bearing.

shaft bearing retainer.

D Wobbly clutch disc or poor facing contact. D Replace clutch disc.

D Loose clutch disc rivets. D Replace clutch disc.

D Weakened clutch disc torsion spring. D Replace clutch disc.

D Distorted pressure plate or flywheel D Replace pressure plate or flywheel.

surface.

D Weakened engine mounting or loosened D Retighten or replace mounting.

installing bolt or nut.

Clutch Noise D Worn or broken release bearing. D Replace release bearing.

D Worn input shaft bearing. D Replace input shaft bearing.

D Cracked clutch disc. D Replace clutch disc.

D Pressure plate and diaphragm spring D Replace pressure plate.

rattling.

D Improper clutch cable adjustment. D Adjust clutch cable.

Grabbing Clutch D Clutch disc facing with oily contamination. D Replace clutch disc.

D Excessively worn on clutch disc facing. D Replace clutch disc.

D Rivet head showing out of facing. D Replace clutch disc.

D Weakened clutch torsion spring. D Replace clutch disc.

DAEWOO M-150 BL2

CLUTCH 5C – 5

CLUTCH PEDAL OPERATION CLUTCH CABLE ADJUSTMENT

D103C302

If clutch connection / disconnection is operated un-

smoothly, adjust the clutch cable by adjusting clutch

cable adjust nut.

D103C301

Clutch pedal free travel

It is designed that there is no clutch pedal free travel.

ÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁ

Clutch pedal travel (A)

ÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ

Pedal Travel 100–110 mm (3.9–4.3 in.)

Clearance between pedal and floor just

before clutch connection (B)

After starting the engine, check if the clearance between

pedal and floor is within specified range in condition of

idling, lifting, parking brake and drawing out clutch ped-

ÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁ

al.

ÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁ

Clearance Between Pedal and Floor 30–40 mm

ÁÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁ

just Before Clutch Connection (1.2–1.6 in.)

Caution: During inspection, take care on sudden

departure.

DAEWOO M-150 BL2

5C – 6 CLUTCH

INSTRUCTION REPAIR

ON–VEHICLE SERVICE

PRESSURE PLATE, CLUTCH DISC

AND INPUT SHAFT BEARING

Tools Required

09917–58010 Input Shaft Bearing Remover

09924–17810 Flywheel Holder

09925–98210 Input Shaft Bearing Installer

DW110–021 Engine Fixture

DW210–010 Clutch Center Guide

Removal Procedure

1. Remove the transaxle from the vehicle. Refer to Sec-

D13B5151 tion 5B, Manual Transaxle.

2. Support the engine to normal position using the en-

gine fixture DW110–021.

Notice: The abnormal position of the engine may dam-

age to the related parts and interfere with them. You

must support the engine to normal position after remov-

ing the transaxle.

D103B516

3. Remove the pressure plate and the clutch disc.

D Fix the fly wheel using the fly wheel holder 09924–

17810.

D Remove the pressure plate bolts (1).

D Remove the pressure plate and the clutch disc (2).

D13C5021

DAEWOO M-150 BL2

CLUTCH 5C – 7

4. Remove the transaxle input shaft bearing using the

input shaft bearing remover 09917–58010, the fly-

wheel holder 09924–17810 and a spanner.

D13C5031

Inspection Procedure – Pressure Plate

and Clutch Disc

1. Pressure plate inspection .

D Check the weak and damaged diaphragm spring

(1).

D Check the polluted face by the oil, grease (2).

D13C5041

2. Clutch disc inspection

D Measure rivet head depth from clutch disc surface

and replace if below limit.

ÁÁÁÁÁÁÁ

ÁÁÁÁÁÁ

ÁÁÁÁÁÁÁ ÁÁÁÁÁÁ Unit : mm (in.)

ÁÁÁÁÁÁ

ÁÁÁÁÁÁÁ ÁÁÁÁÁÁ

Rivet Head Depth

Standard

1.2 (0.047)

Limit

0.5 (0.02)

D Replace the clutch disc if clutch disc surface is

contaminated or clutch disc rivets are loosen.

D103C505

3. Clutch disc runout in rotational direction inspection.

D Measure runout in rotational direction and replace

if runout exceeds limit.

ÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁ

Unit : mm (in.)

ÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁ

Disc Runout Limit in Rotational

0.7 (0.028)

ÁÁÁÁÁÁÁÁÁÁÁÁ

ÁÁÁÁÁÁ

Direction (Periphery)

D103C506

DAEWOO M-150 BL2

5C – 8 CLUTCH

Installation Procedure

1. Install in the reverse order of removal.

2. Install the input shaft bearing using the input shaft

bearing installer 09925–98210 and the flywheel hold-

er 09924–17810.

D13C5071

3. Install the pressure plate and the clutch disc.

D Install the clutch disc.

D Install the pressure plate (1).

D Align the pressure plate and the clutch disc onto the

flywheel using the clutch center guide DW210–010

and the flywheel holder 09924–17810.

D Install the pressure plate bolts.

Tighten

Tighten the bolts to 18–28 NSm (13–21 lb-ft).

D13C508B

CLUTCH RELEASE BEARING, SHAFT

AND BUSHING

Tools Required

09923–46040 Bushing Joint Pipe

09925–48220 Bushing Remover/Installer

09930–30102 Sliding Shaft

09943–88211 Bushing, Bearing Installer

Removal Procedure

1. Remove the transaxle from the vehicle. Refer to Sec-

tion 5B, Manual Transaxle.

D103C509 2. Remove the release arm. Refer to “Clutch Release

Arm” in this section.

3. Remove the release bearing.

4. Remove the release shaft and bushing.

D Remove the bushing (No.2) and seal using the

bushing remover 09925–48220 and hammer.

D Remove the release shaft (1).

D103C510

DAEWOO M-150 BL2

CLUTCH 5C – 9

D Insert the tap (M14X1.5) to the busing (No.1) (2).

D103C511

D Insert the bushing joint pipe 09923–46040 to the

tab.

D Connect the sliding shaft 09930–30102 to the end

of the bushing joint pipe 09923–46040.

D Remove the bushing (No.1) by pulling.

D13C512A

Inspection Procedure – Release Bearing

and Shaft

1. Release bearing inspection

D Check for noisy, worn and damaged release bear-

ing.

D Check for a grabbing rotation of release bearing.

D Replace the release bearing if necessary.

D103C513

2. Release shaft inspection

D Check for a warped shaft (1).

D Check for a worn fork (2).

D Replace the shaft if necessary.

D103C514

DAEWOO M-150 BL2

5C – 10 CLUTCH

Installation Procedure

1. Install in the reverse order of removal.

2. Install the release shaft bushing (No.1) using the

bushing joint pipe 09923–46040, bushing, bearing in-

staller 09943–88211 and a hammer.

D103C515

3. Install the release shaft bushing (No.2) and seal using

the bushing remover/installer 09925–48220 and a

hammer.

D103C516

4. Install the release bearing.

D Coat the spline of transaxle input shaft with multi–

purpose grease (1).

D Coat the release bearing bore and the connecting

of release shaft with multi–purpose grease (2).

D Install the release bearing.

D103C517

CLUTCH RELEASE ARM

Removal Procedure

1. Disconnect the clutch cable.

D Remove the adjusting nut (1).

D Disconnect the cable (2).

D103C518

DAEWOO M-150 BL2

CLUTCH 5C – 11

2. Remove the clutch release arm.

D Remove the bolt and nut (1).

D Remove the release arm (2).

D103C519

Installation Procedure

1. Install in the reverse order of removal.

2. Install the clutch release arm.

D Install the clutch release arm matching to punched

mark (1).

Tighten

Tighten the bolt and nut to 10–16 NSm (7.5–12 lb-ft).

3. Adjust the clutch cable. Refer to “Diagnosis” in this

section.

D13C520A

CLUTCH CABLE

(Left–Hand Drive Shown, Right–Hand

Drive Similar)

Removal Procedure

1. Disconnect the clutch cable from the transaxle.

D Remove the adjusting nut (1).

D Disconnect the cable from the wire clip (2).

D Pull and remove the cable from the transaxle

mount hole (3).

D103B506

2. Disconnect the clutch cable from the pedal.

D Pull upward and disconnect the cable from the

pedal hook (1).

D13C5211

DAEWOO M-150 BL2

5C – 12 CLUTCH

3. Remove the battery. Refer to Section 1E, Engine

Electrical.

4. Remove the clutch cable.

D Remove the nuts (1).

D Remove the cable grommet (2).

D Remove the cable from the pedal (3).

D103C522

Installation Procedure

1. Install the clutch cable.

2 Install the battery.

3. Connect the clutch cable to the pedal.

4. Connect the clutch cable to the transaxle.

5. Adjust the clutch cable. Refer to “Diagnosis” in this

section.

D103C302

CLUTCH PEDAL

(Left–Hand Drive Shown, Right–Hand

Drive Similar)

Removal Procedure

1. Disconnect the clutch cable. Refer to “Clutch Cable”

in this section.

2. Remove the clutch pedal.

D Release the pedal return spring.

D Remove the nut (1).

D Remove the clutch pedal (2).

D Remove the bushing (3).

D103C524 D Remove the pedal return spring (4).

Installation Procedure

1. Install the pedal return spring.

2. Install the bushings.

3. Install the clutch pedal.

4. Install the nut.

5. Fix the pedal return spring.

6. Connect the clutch cable.

7. Adjust the clutch cable. Refer to “Diagnosis” in this

section.

D103C302

DAEWOO M-150 BL2

CLUTCH 5C – 13

SPECIFICATIONS

GENERAL SPECIFICATIONS

ÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

ÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Application Description Unit Standard Limit

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Type – Single Dry Plate –

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Outside Diameter mm (in.) 170 (6.7) –

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Inside Diameter mm (in.) 110 (4.3) –

Clutch Disc

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Thickness mm (in.) 7.15 (0.281) –

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Rivet Head Depth mm (in.) 1.2 (0.047) 0.5 (0.020)

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Disc Runout Limit in Rotational Direction mm (in.) – 0.7 (0.028)

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Pedal Free Travel mm (in.) 0 (0) –

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

100 – 110

Pedal Travel mm (in.) –

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Clutch Pedal (3.9 – 4.3)

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Clearance between pedal and floor just 30 – 40

mm (in.) –

before clutch connection (1.2 – 1.6)

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ ÁÁÁÁÁÁ

FASTENER TIGHTENING SPECIFICATIONS

ÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Application NSm Lb-Ft Lb-In

ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁÁÁÁÁ

Pressure Plate Bolt 18 – 28 13 – 21 –

Clutch Release Arm Bolt and Nut 10 – 16 7.5 – 12 –

DAEWOO M-150 BL2

5C – 14 CLUTCH

SPECIAL TOOLS

SPECIAL TOOLS TABLE

09917–58010

Input Shaft Bearing 09930–30102

Sliding Shaft

Remover

D103C101 D103C106

09943–88211

09923–46040 Bushing, Bearing

Bushing Joint Pipe

Installer

D103C105 D103C107

DW110–021

09924–17810

Engine Assembly

Fly Wheel Holder

Support Fixture

D102B116 D103B103

09925–48220

Bushing Remover/ DW210–010

Clutch Center Guide

Installer

D103C104 D103C103

09925–98210

Input Shaft Bearing

Installer

D103C102

DAEWOO M-150 BL2

Das könnte Ihnen auch gefallen

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesVon EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesNoch keine Bewertungen

- LSD Manual PDFDokument13 SeitenLSD Manual PDFHector Muñoz SepulvedaNoch keine Bewertungen

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Von EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Bewertung: 3 von 5 Sternen3/5 (1)

- Ringendgap Piston Ring 4jb1Dokument3 SeitenRingendgap Piston Ring 4jb1Shimmer CrossbonesNoch keine Bewertungen

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualVon EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualBewertung: 2.5 von 5 Sternen2.5/5 (2)

- 2007 Dodge Caliber ManualDokument360 Seiten2007 Dodge Caliber ManualJinyuan FangNoch keine Bewertungen

- ECM-641A Camshaft Control, Exhaust. Faulty Signal, B5254T2: Diagnostic Trouble Code (DTC) InformationDokument4 SeitenECM-641A Camshaft Control, Exhaust. Faulty Signal, B5254T2: Diagnostic Trouble Code (DTC) Informationapek1Noch keine Bewertungen

- Headlamp Adjustments 2007 Nissan VersaDokument2 SeitenHeadlamp Adjustments 2007 Nissan Versachrisban35Noch keine Bewertungen

- Dw10 FC: EURO 6 Step 1 Diesel Engine Automotive Application VersionDokument2 SeitenDw10 FC: EURO 6 Step 1 Diesel Engine Automotive Application VersionArturHeiseNoch keine Bewertungen

- 3587ADokument45 Seiten3587Aainginer100% (2)

- FAW CA4GA5 Engine Maintenance ManualDokument135 SeitenFAW CA4GA5 Engine Maintenance ManualjamesNoch keine Bewertungen

- Failure Analysis Guide: Eaton Fuller Clutches February 2008Dokument48 SeitenFailure Analysis Guide: Eaton Fuller Clutches February 2008Angel DlsgNoch keine Bewertungen

- 2.0L ENGINE Chevy Tracker 1999Dokument52 Seiten2.0L ENGINE Chevy Tracker 1999andres german romeroNoch keine Bewertungen

- LF-Timing-Chain. Mazda 3 2.0Dokument11 SeitenLF-Timing-Chain. Mazda 3 2.0marquin84Noch keine Bewertungen

- Workshop Repair Manual: Diesel ENGINE High Pressure Common Rail Cast Iron 4 CylindersDokument134 SeitenWorkshop Repair Manual: Diesel ENGINE High Pressure Common Rail Cast Iron 4 Cylindersbogdanxp2000Noch keine Bewertungen

- Adjust Valve Clearance 2AZ-FE EngineDokument9 SeitenAdjust Valve Clearance 2AZ-FE EngineMarcos EmmanuelNoch keine Bewertungen

- Service Manual for Clarion AM/FM CD/MP3 Car StereoDokument0 SeitenService Manual for Clarion AM/FM CD/MP3 Car StereoEl Mostafa KahlouchNoch keine Bewertungen

- 5. YUEJIN车桥结构简介与故障分析处理 Brief Introduction to Yuejin Axles and Fault Analysis and RemediesDokument73 Seiten5. YUEJIN车桥结构简介与故障分析处理 Brief Introduction to Yuejin Axles and Fault Analysis and RemediescristianNoch keine Bewertungen

- Daewoo Nubira 1997-2004 General InformationDokument29 SeitenDaewoo Nubira 1997-2004 General InformationHenry SilvaNoch keine Bewertungen

- Engine MechanicallDokument119 SeitenEngine MechanicallGabriel BalcazarNoch keine Bewertungen

- P 1464Dokument8 SeitenP 1464Yargen GonzalezNoch keine Bewertungen

- Engine Temperature Control Actuator - N493-, CHECKING: General DescriptionDokument3 SeitenEngine Temperature Control Actuator - N493-, CHECKING: General Descriptionbyungchul kimNoch keine Bewertungen

- 1973 AMC Technical Service ManualDokument21 Seiten1973 AMC Technical Service Manualfernan blancoNoch keine Bewertungen

- DTC P0135 Ford ExplorerDokument1 SeiteDTC P0135 Ford ExplorerORLANDONoch keine Bewertungen

- Low Range HD 2 Inch Body Lift Kit (Sidekick, GV, Vitara, Tracker, X90)Dokument45 SeitenLow Range HD 2 Inch Body Lift Kit (Sidekick, GV, Vitara, Tracker, X90)Cesar Jesus Castellanos TrejoNoch keine Bewertungen

- ABS and Traction Control DiagnosisDokument38 SeitenABS and Traction Control DiagnosisThibault ChapelNoch keine Bewertungen

- CHEVROLET (DAEWOO) Lacetti (J200) 1.8 16V F18D3: Timing Belt: Removal/installationDokument7 SeitenCHEVROLET (DAEWOO) Lacetti (J200) 1.8 16V F18D3: Timing Belt: Removal/installationJuan Jesus FernandesNoch keine Bewertungen

- Diagrama de Caja de Fusibles Ford f150 Año 1992Dokument3 SeitenDiagrama de Caja de Fusibles Ford f150 Año 1992Oscar Gutiérrez100% (2)

- Great Wall Hover PartesDokument7 SeitenGreat Wall Hover PartesLojan Coronel José HumbertoNoch keine Bewertungen

- Actyon A0 A06005Dokument10 SeitenActyon A0 A06005Arimbi GembiekNoch keine Bewertungen

- 11 SM PDFDokument102 Seiten11 SM PDFPANHA MENNoch keine Bewertungen

- Kyron Actyon Transmission PDFDokument123 SeitenKyron Actyon Transmission PDFAdriano Alves Silva100% (1)

- Dream Xxi-N 6.0.7 Ic SW Manual - EngDokument30 SeitenDream Xxi-N 6.0.7 Ic SW Manual - Engags387100% (1)

- Starter Chevrolet S10Dokument22 SeitenStarter Chevrolet S10Maxi SardiNoch keine Bewertungen

- Operating Manual (Deh-2350ub) - Eng - Esp - PorDokument64 SeitenOperating Manual (Deh-2350ub) - Eng - Esp - PorDan HerreraNoch keine Bewertungen

- Robotic gearbox solenoid valve informationDokument3 SeitenRobotic gearbox solenoid valve informationadinxNoch keine Bewertungen

- Circuit Diagram For CityStar 3Dokument105 SeitenCircuit Diagram For CityStar 3Jezuz ZarmientoNoch keine Bewertungen

- Engine IdentificationDokument47 SeitenEngine Identificationgerber damianNoch keine Bewertungen

- Presion de Compresion Toyota Tacoma 2005 2RZDokument2 SeitenPresion de Compresion Toyota Tacoma 2005 2RZGustavo GamezNoch keine Bewertungen

- Diagramas Prelude H22A1Dokument53 SeitenDiagramas Prelude H22A1Rodríguez AndrésNoch keine Bewertungen

- Luv Dmax Diagramas ElectricosDokument198 SeitenLuv Dmax Diagramas ElectricosAlan100% (1)

- Embrague CitroenDokument9 SeitenEmbrague CitroenJoseNoch keine Bewertungen

- Timing Belt Replacement Guide for 5S−FE EngineDokument14 SeitenTiming Belt Replacement Guide for 5S−FE EnginechasquareNoch keine Bewertungen

- EWD Kia Rio 2004-2011 1.5LDokument98 SeitenEWD Kia Rio 2004-2011 1.5LRaul Ardila100% (1)

- 2007 Toyota Yaris 9218Dokument11 Seiten2007 Toyota Yaris 9218Roberto AmaristaNoch keine Bewertungen

- Lower Control Arm Assy LH: ReplacementDokument30 SeitenLower Control Arm Assy LH: ReplacementMusat Catalin-Marian100% (1)

- Caja Automatica Optra Ingles-Libre 1Dokument50 SeitenCaja Automatica Optra Ingles-Libre 1Plinio SuarezNoch keine Bewertungen

- Engine - Repair - 1997-2000 EV Repair ManualDokument327 SeitenEngine - Repair - 1997-2000 EV Repair ManualJorge Sepulveda100% (1)

- 29CB-Injectors CUMMINS CATALOGO PDFDokument15 Seiten29CB-Injectors CUMMINS CATALOGO PDFDiegoD'AmbrosioNoch keine Bewertungen

- 13OBDG09 Engine DiagnosticsDokument562 Seiten13OBDG09 Engine DiagnosticsEric Joseph GoldenNoch keine Bewertungen

- r32 - Rb26dett Ecu PinoutDokument1 Seiter32 - Rb26dett Ecu PinouttospotNoch keine Bewertungen

- Sprinter Turbo Vacuum Valve Circuito Valvula Control Turbo SprinterDokument1 SeiteSprinter Turbo Vacuum Valve Circuito Valvula Control Turbo SprinterFacu BertoldoNoch keine Bewertungen

- M35c ClutchDokument14 SeitenM35c ClutchJesus TimaureNoch keine Bewertungen

- DAEWOO J-100 CLUTCH DIAGNOSIS AND REPAIR GUIDEDokument24 SeitenDAEWOO J-100 CLUTCH DIAGNOSIS AND REPAIR GUIDEJarry PotterNoch keine Bewertungen

- 1999 Jeep TJ Wrangler Service Manual - 06. ClutchDokument14 Seiten1999 Jeep TJ Wrangler Service Manual - 06. Clutchbfranklin33100% (1)

- Clutch: Section 5CDokument18 SeitenClutch: Section 5CClaudio Cerda MNoch keine Bewertungen

- Hyundai Excel X2 1989-1998 Clutch System CableDokument11 SeitenHyundai Excel X2 1989-1998 Clutch System CableAshraf MuhmdNoch keine Bewertungen

- ClutchDokument14 SeitenClutchArt DoeNoch keine Bewertungen

- Fiesta 3Dokument1 SeiteFiesta 3sheoNoch keine Bewertungen

- Transfer Cemu Shader Cache to Another PCDokument1 SeiteTransfer Cemu Shader Cache to Another PCsheoNoch keine Bewertungen

- Motor X18xeDokument4 SeitenMotor X18xesheoNoch keine Bewertungen

- 800 Release InfoDokument2 Seiten800 Release InfoAnonymous mE6MEje0Noch keine Bewertungen

- Daewoo Matiz 2000-2013 Airbags 1-6 PDFDokument6 SeitenDaewoo Matiz 2000-2013 Airbags 1-6 PDFsheoNoch keine Bewertungen

- Bugs (Known and How To Report)Dokument4 SeitenBugs (Known and How To Report)Johan GalloNoch keine Bewertungen

- WD Chrysler 206671Dokument1 SeiteWD Chrysler 206671sheoNoch keine Bewertungen

- Costs Along The Service Cascades For HIV Testing.11 Lectura 5Dokument10 SeitenCosts Along The Service Cascades For HIV Testing.11 Lectura 5sheoNoch keine Bewertungen

- Mitchell OnDemand 5 FullDokument1 SeiteMitchell OnDemand 5 FullsheoNoch keine Bewertungen

- InfoDokument1 SeiteInfosheoNoch keine Bewertungen

- Xpadder Bug Hunter SquadDokument1 SeiteXpadder Bug Hunter SquadsheoNoch keine Bewertungen

- Seek and DestroyDokument1 SeiteSeek and DestroysheoNoch keine Bewertungen

- Daewoo Matiz 2000-2013 Body Rear EndDokument5 SeitenDaewoo Matiz 2000-2013 Body Rear EndsheoNoch keine Bewertungen

- Daewoo Matiz 2000-2013 Audio SystemDokument12 SeitenDaewoo Matiz 2000-2013 Audio SystemsheoNoch keine Bewertungen

- Daewoo M-150 Bumper and Fascia Removal GuideDokument8 SeitenDaewoo M-150 Bumper and Fascia Removal GuidesheoNoch keine Bewertungen

- Engine ImmobilizerDokument51 SeitenEngine ImmobilizerYargen Gonzalez100% (4)

- 2001 Nissan Sentra 50259Dokument346 Seiten2001 Nissan Sentra 50259sheo100% (1)

- Rom InfoDokument1 SeiteRom InfosheoNoch keine Bewertungen

- Audi A3 Quick Reference Guide: Adjusting Front SeatsDokument4 SeitenAudi A3 Quick Reference Guide: Adjusting Front SeatsgordonjairoNoch keine Bewertungen

- Lending Tree PDFDokument14 SeitenLending Tree PDFAlex OanonoNoch keine Bewertungen

- Pathways-Childrens Ministry LeaderDokument16 SeitenPathways-Childrens Ministry LeaderNeil AtwoodNoch keine Bewertungen

- Paygilant - Frictionless Fraud PreventionDokument17 SeitenPaygilant - Frictionless Fraud PreventionGlobalys LtdNoch keine Bewertungen

- An RNA Vaccine Drives Expansion and Efficacy of claudin-CAR-T Cells Against Solid TumorsDokument9 SeitenAn RNA Vaccine Drives Expansion and Efficacy of claudin-CAR-T Cells Against Solid TumorsYusuf DemirNoch keine Bewertungen

- American Woodworker No 171 April-May 2014Dokument76 SeitenAmerican Woodworker No 171 April-May 2014Darius White75% (4)

- Hercules SegersDokument15 SeitenHercules SegerssuneelaamjadNoch keine Bewertungen

- 114 ArDokument254 Seiten114 ArJothishNoch keine Bewertungen

- Chapter 04Dokument3 SeitenChapter 04gebreNoch keine Bewertungen

- Introduction To Global Positioning System: Anil Rai I.A.S.R.I., New Delhi - 110012Dokument19 SeitenIntroduction To Global Positioning System: Anil Rai I.A.S.R.I., New Delhi - 110012vinothrathinamNoch keine Bewertungen

- Arcelor Mittal - Bridges PDFDokument52 SeitenArcelor Mittal - Bridges PDFShamaNoch keine Bewertungen

- 4 DiscussionDokument2 Seiten4 DiscussiondreiNoch keine Bewertungen

- COP2251 Syllabus - Ellis 0525Dokument9 SeitenCOP2251 Syllabus - Ellis 0525Satish PrajapatiNoch keine Bewertungen

- SMChap 018Dokument32 SeitenSMChap 018testbank100% (8)

- Drupal 8 User GuideDokument224 SeitenDrupal 8 User Guideibrail5Noch keine Bewertungen

- Illegal FishingDokument1 SeiteIllegal FishingDita DwynNoch keine Bewertungen

- Recent Advances in Active Metal Brazing of Ceramics and Process-S12540-019-00536-4Dokument12 SeitenRecent Advances in Active Metal Brazing of Ceramics and Process-S12540-019-00536-4sebjangNoch keine Bewertungen

- PCG Master Consultancy Services AgreementDokument12 SeitenPCG Master Consultancy Services Agreementawscobie100% (1)

- Diferencias Gas LP y Gas Natural: Adminigas, S.A. de C.VDokument2 SeitenDiferencias Gas LP y Gas Natural: Adminigas, S.A. de C.VMarco Antonio Zelada HurtadoNoch keine Bewertungen

- Networks Lab Assignment 1Dokument2 SeitenNetworks Lab Assignment 1006honey006Noch keine Bewertungen

- Indra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043Dokument28 SeitenIndra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043AnhTuấnPhanNoch keine Bewertungen

- Questions - TrasportationDokument13 SeitenQuestions - TrasportationAbhijeet GholapNoch keine Bewertungen

- Module 3 Paired and Two Sample T TestDokument18 SeitenModule 3 Paired and Two Sample T TestLastica, Geralyn Mae F.Noch keine Bewertungen

- Lte Numbering and AddressingDokument3 SeitenLte Numbering and AddressingRoderick OchiNoch keine Bewertungen

- CM Template For Flora and FaunaDokument3 SeitenCM Template For Flora and FaunaJonathan Renier Verzosa0% (1)

- Outstanding 12m Bus DrivelineDokument2 SeitenOutstanding 12m Bus DrivelineArshad ShaikhNoch keine Bewertungen

- SCIENCE 5 PERFORMANCE TASKs 1-4 4th QuarterDokument3 SeitenSCIENCE 5 PERFORMANCE TASKs 1-4 4th QuarterBALETE100% (1)

- Activity2 Mba 302Dokument2 SeitenActivity2 Mba 302Juan PasyalanNoch keine Bewertungen

- Developmen of Chick EmbryoDokument20 SeitenDevelopmen of Chick Embryoabd6486733Noch keine Bewertungen

- Wei Et Al 2016Dokument7 SeitenWei Et Al 2016Aline HunoNoch keine Bewertungen

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesVon EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesBewertung: 4.5 von 5 Sternen4.5/5 (21)

- ISO 50001: A strategic guide to establishing an energy management systemVon EverandISO 50001: A strategic guide to establishing an energy management systemNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Operational Amplifier Circuits: Analysis and DesignVon EverandOperational Amplifier Circuits: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Way Home: Tales from a life without technologyVon EverandThe Way Home: Tales from a life without technologyBewertung: 4 von 5 Sternen4/5 (45)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- The Grid: The Fraying Wires Between Americans and Our Energy FutureVon EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureBewertung: 3.5 von 5 Sternen3.5/5 (48)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentVon EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Renewable Energy: A Very Short IntroductionVon EverandRenewable Energy: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Asset Integrity Management for Offshore and Onshore StructuresVon EverandAsset Integrity Management for Offshore and Onshore StructuresNoch keine Bewertungen

- The Rare Metals War: the dark side of clean energy and digital technologiesVon EverandThe Rare Metals War: the dark side of clean energy and digital technologiesBewertung: 5 von 5 Sternen5/5 (2)

- Build Your Own Electric Vehicle, Third EditionVon EverandBuild Your Own Electric Vehicle, Third EditionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Shorting the Grid: The Hidden Fragility of Our Electric GridVon EverandShorting the Grid: The Hidden Fragility of Our Electric GridBewertung: 4.5 von 5 Sternen4.5/5 (2)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyVon EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNoch keine Bewertungen

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Industrial Piping and Equipment Estimating ManualVon EverandIndustrial Piping and Equipment Estimating ManualBewertung: 5 von 5 Sternen5/5 (7)

- Handbook on Battery Energy Storage SystemVon EverandHandbook on Battery Energy Storage SystemBewertung: 4.5 von 5 Sternen4.5/5 (2)

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsVon EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNoch keine Bewertungen

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksVon EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNoch keine Bewertungen

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AVon EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ABewertung: 5 von 5 Sternen5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)