Beruflich Dokumente

Kultur Dokumente

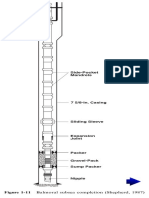

18.625 CSG & CMT Plan

Hochgeladen von

Mohamed AbozeimaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

18.625 CSG & CMT Plan

Hochgeladen von

Mohamed AbozeimaCopyright:

Verfügbare Formate

GAME PLAN

WELL: SHYBAH-0479 RIG: ADC-12 DATE: 17TH JUN- 2014.

18-5/8”, 115#, R-3 (BTC)

PICK UP HANDLING EQUIPMENT. RIG UP SAME.

CARRY OUT FUNCTIONAL TEST OF CSG HANDLING EQUIPMENT.

PUT CENTRALIZER ON 1ST FIVE JOINTS.

TIGHT ALL JOINTS UP TO BASE OF TRIANGLE.

HPJSM - PICK UP 1ST JOINT W/TAG WELD SHOE. AND CHECK FLOAT

W/WATER @ V-DOOR.

TAG WELDS FIRST FIVE JOINTS.

PUT CENTRALIZER EVERY THIRD JOINT & ONE ACROSS EACH CMT BASKET

ASPER MENTIONED IN CSG TALLEY.

PLACE 02NOS CMT BASKET @ 100FT & 120 FT IN 40TH JOINTS.

TOTAL JOINTS TO RUN-42NOS (39 PLAIN+03 COATED) ONLY.

FILL THE CSG W/MUD AVOID FLOATING, .M/U CMT CIRCULATING HEAD,

TAG TO BOTTOM W/CIRC ONLY,

R/UP FALSE ROTARY. DRIFT W/3” DRIFT & RUN 5” DP STDS W/ISC STINGER

W/CENTRALIZER (5”X18-5/8”).

STING IN ONE ATTEMPT. MU SURFACE LINE W/CIRC SUB.

CHAIN DN INNER STRING W/CSG.

FILL 5”X 18-5/8” ANNULUS W/MUD.

CIRC THROUGH DRILL STRING & OBSERVE ANY LEAK IN ANNULUS.

CIRC BOTTOM’S UP W/MUD TO REMOVE HI-VIS.

PJSM, PT CMT LINE TO 2000PSI FOR 10 MIN & FOLLOW NEXT CMTG PLAN

THINK FOR SAFETY. DO NOT COMPROMISE W/SAFETY

FOREMAN

GAME PLAN

CMT JOB

WELL: SHYBAH-0479 RIG: ADC-12 DATE: 17TH JUN- 2014.

PJSM, HALL ENERGY SERVICES FLUSH & PUMP 20 BBLS WATER AS SPACER.

PT CMT LINE TO 2000PSI FOR 10 MIN & FOLLOW NEXT CMTG PLAN.

HALLIBURTON PUMP W/2066SX/438 BBLS/118 PCF CEMENT SLURRY TILL

GOOD CMT COMES TO SURFACE.

DROP THE DART PLUG HALLIBURTON PUMP W/3 BBLS CMT

SLURRY+27.5BBLS WATER BEHIND PLUG.BUMP PLUG TO 1000PSI .KEEP FOR

5 MIN.IF PLUG DOES NOT BUMP. PL DO NOT OVER DISPLACE. BLEED OFF

SLOWELY & PRESSURE UP AGAIN TO 500PSI & STING OUT THE ISC STINGER.

POOH INNER STRING W/ISC STINGER & L/DN FALSE ROTARY. STINGER &

CENTRALIZER.

FOLLOW UP THE TOP UP JOB IF WELL HAVE LOSSES W/ BLENDED

CMT/118PCF W/2% CACL2.

IF DON’T GET CMT TO SURFACE AFTER ONE HR.

REPEAT THE TOP UP JOB CENTRE THE 18-5/8” CSG.

CLEAN CELLAR & DO NOT LEAVE CMT SEATH IN CELLAR.

W.O.C. MEAN WHILE PREPARE STANDS & RACKBACK ON DERRICK.

N/D 30”DIVERTOR ASSY. CUT & DRESS 18-5/8” CSG STUB. FILL CMT IN

CASING ANNULUS.WELD ¾” STEEL PLATE IN ANNULUS (24’X18-5/8”).

MU & WELD 20-3/4”X18-5/8”SOW,3M CAMERON WELL HEAD ON CASING

NU 21-1/4” X 20-3/4”3M DSA & 21-1/4”, 3M SPACER SPOOL W/ 21-1/4”, 3M

DIVERTOR ASSY.

CONNECT DIVERTOR ASSY W/KOOMY & MAKE FUNCTION TEST ASSY.

TIH 16” DIR BHA FOR DRILLING. FOLLOW NEXT PLAN

THINK FOR SAFETY.SAFETY IS OUR GOAL.

FOREMAN

Das könnte Ihnen auch gefallen

- Mike Bara - Ancient Aliens and Secret Societies PDFDokument183 SeitenMike Bara - Ancient Aliens and Secret Societies PDFlavendercloud100% (12)

- World Regional GeographyDokument225 SeitenWorld Regional GeographyMark A. FosterNoch keine Bewertungen

- BHA Tally: Customer: Well Name: Job Number: Drillstring IADC Rig BHA# 0100 Run# 100Dokument2 SeitenBHA Tally: Customer: Well Name: Job Number: Drillstring IADC Rig BHA# 0100 Run# 100Animesh ChoudharyNoch keine Bewertungen

- Pymble 2006 Year 10 Science YearlyDokument17 SeitenPymble 2006 Year 10 Science YearlyMiriam Mikhail100% (1)

- Documents - MX How To Run and Cement Liners Part 1.PDFDokument6 SeitenDocuments - MX How To Run and Cement Liners Part 1.PDFKhaledFekairNoch keine Bewertungen

- #12 Rig Up and Run CasingDokument1 Seite#12 Rig Up and Run Casingkhurram100% (1)

- Plugback CementingDokument67 SeitenPlugback CementingpdakovNoch keine Bewertungen

- Space Scoundrels RPG Adventure Book 001Dokument42 SeitenSpace Scoundrels RPG Adventure Book 001Jonathan ReadNoch keine Bewertungen

- Lesson 8b Introduction To UBDDokument57 SeitenLesson 8b Introduction To UBDbon1ngNoch keine Bewertungen

- Hole Cleaning-Total Best PracticesDokument13 SeitenHole Cleaning-Total Best PracticesMohamed AbozeimaNoch keine Bewertungen

- Drilling Abbreviations For ReportingDokument10 SeitenDrilling Abbreviations For ReportingLeon Monsalve100% (1)

- CDAMnemonicsDokument18 SeitenCDAMnemonicsvanthodcNoch keine Bewertungen

- Redback Operations ManualDokument11 SeitenRedback Operations ManualDon BraithwaiteNoch keine Bewertungen

- How To Run and Cement Liners Part 3Dokument4 SeitenHow To Run and Cement Liners Part 3Anwar SaeedNoch keine Bewertungen

- TCP Perforating ProgrammeDokument3 SeitenTCP Perforating ProgrammeYougchu LuanNoch keine Bewertungen

- Department of Mining Engineering MCQS: (B) FluoriteDokument23 SeitenDepartment of Mining Engineering MCQS: (B) FluoriteWajid Hussain100% (3)

- CSG Design by AmrDokument19 SeitenCSG Design by AmrSudish BhatNoch keine Bewertungen

- Drilling Contracts: Contract Type Effect On Operator Effect On ContractorDokument206 SeitenDrilling Contracts: Contract Type Effect On Operator Effect On ContractorMohammed Zubair AhmedNoch keine Bewertungen

- Casing Cutting Procedure - WFDDokument5 SeitenCasing Cutting Procedure - WFDprateek132106Noch keine Bewertungen

- Core (STEM) - EarthScience-SLMG11Q1W1-Identify Common Rock-Forming Minerals Using Their Physcial and Chemical PropertiesDokument18 SeitenCore (STEM) - EarthScience-SLMG11Q1W1-Identify Common Rock-Forming Minerals Using Their Physcial and Chemical PropertiesRM L. JamandronNoch keine Bewertungen

- Best Practices Drilling 26 inDokument6 SeitenBest Practices Drilling 26 inmanuelperdomotNoch keine Bewertungen

- Squeeze ProcedureDokument4 SeitenSqueeze Proceduresaa6383Noch keine Bewertungen

- Rig Stuck Pipe Assessment FormDokument13 SeitenRig Stuck Pipe Assessment FormBalkis FatihaNoch keine Bewertungen

- Field Measurements of Annular Pressure and Temperature During Primary CementingDokument5 SeitenField Measurements of Annular Pressure and Temperature During Primary CementingDoni KurniawanNoch keine Bewertungen

- Spe 196232 MSDokument18 SeitenSpe 196232 MShijoetigreNoch keine Bewertungen

- Plugbak Sidetracks - Open HoleDokument5 SeitenPlugbak Sidetracks - Open HoleAdel Ahmed AlkhaligyNoch keine Bewertungen

- Kicks and Well ControlDokument57 SeitenKicks and Well ControlOlvis GuillenNoch keine Bewertungen

- Final Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Dokument21 SeitenFinal Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Acceptance Check ListDokument2 SeitenAcceptance Check ListMohamed HamdyNoch keine Bewertungen

- 13 38 in TP-194 (HAS-2) Cement Program V1Dokument21 Seiten13 38 in TP-194 (HAS-2) Cement Program V1hakoubNoch keine Bewertungen

- IPM-PR-WCI-005 Cement Placement PDFDokument4 SeitenIPM-PR-WCI-005 Cement Placement PDFOscarCajamarcaNoch keine Bewertungen

- AC-0021 Practical Assessment - Notice To AssessorsDokument1 SeiteAC-0021 Practical Assessment - Notice To AssessorsairlinemembershipNoch keine Bewertungen

- Tut-126 ProgramDokument28 SeitenTut-126 Programhamdi1000Noch keine Bewertungen

- UL G 9-46 Unit #2H WBD PDFDokument7 SeitenUL G 9-46 Unit #2H WBD PDFMilad Ebrahimi DastgerdiNoch keine Bewertungen

- CMT Programm Spd18a-07 - 3Dokument9 SeitenCMT Programm Spd18a-07 - 3nabiNoch keine Bewertungen

- Fishing Lecture NotesDokument47 SeitenFishing Lecture Notes1234jj100% (1)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsVon EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNoch keine Bewertungen

- 09 Plug Setting Best PractisesDokument1 Seite09 Plug Setting Best Practiseshamora33Noch keine Bewertungen

- Drilling Mechanics - 7 Optimizing ROPDokument14 SeitenDrilling Mechanics - 7 Optimizing ROPMaría MarquinaNoch keine Bewertungen

- Kicks IndicatorsDokument17 SeitenKicks IndicatorsGhavban DavidNoch keine Bewertungen

- Pick Up Drill PipeDokument5 SeitenPick Up Drill PipeinfonexusNoch keine Bewertungen

- Off-Bottom Drilling PracticesDokument3 SeitenOff-Bottom Drilling PracticesAdel Ahmed AlkhaligyNoch keine Bewertungen

- Mud/Gas Separator Sizing and Evaluation: G.R. MacdougallDokument6 SeitenMud/Gas Separator Sizing and Evaluation: G.R. MacdougallDiego AraqueNoch keine Bewertungen

- CTD Liner Running & CementingDokument6 SeitenCTD Liner Running & CementingAdel Ahmed AlkhaligyNoch keine Bewertungen

- Bullheading Calculation ExampleDokument9 SeitenBullheading Calculation Exampleivan villabonaNoch keine Bewertungen

- DRRR Learning Module Fisrt QuarterDokument63 SeitenDRRR Learning Module Fisrt QuarterLANY T. CATAMINNoch keine Bewertungen

- 04-LEK 1050 - 9.625 Casing & Cement Adjusted For HALL Stage ToolDokument5 Seiten04-LEK 1050 - 9.625 Casing & Cement Adjusted For HALL Stage ToolDrilling Engineering ChannelNoch keine Bewertungen

- Technology Transfer Volumetric StrippingDokument28 SeitenTechnology Transfer Volumetric StrippingHüseyin AyazlıNoch keine Bewertungen

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- RasGasl Mud Cap Drilling ProceduresDokument33 SeitenRasGasl Mud Cap Drilling ProceduresE Schon100% (1)

- FHWA - Stream Stability at Highway Structures PDFDokument260 SeitenFHWA - Stream Stability at Highway Structures PDFFreddy Miguel ChNoch keine Bewertungen

- GAME PLAN RTTS RBP Wellhead WorkDokument1 SeiteGAME PLAN RTTS RBP Wellhead WorkMohamed AbozeimaNoch keine Bewertungen

- 13.375 in Casing Cement Ops PlanDokument2 Seiten13.375 in Casing Cement Ops PlanMohamed AbozeimaNoch keine Bewertungen

- Workover Daily Report WQ1-039Dokument3 SeitenWorkover Daily Report WQ1-039kareem100% (1)

- 10 - Drilling 12 1.4 in HoleDokument1 Seite10 - Drilling 12 1.4 in HoleMohamed AbozeimaNoch keine Bewertungen

- Running Procedure 5Dokument2 SeitenRunning Procedure 5Pesireron RoberthNoch keine Bewertungen

- Well Data Summary ProgramDokument13 SeitenWell Data Summary ProgramTemitope BelloNoch keine Bewertungen

- Alaska Drilling and Wells Recommended Practice: Lost CirculationDokument4 SeitenAlaska Drilling and Wells Recommended Practice: Lost CirculationAdel Ahmed AlkhaligyNoch keine Bewertungen

- Maintenance Bulletin 1062-BDokument13 SeitenMaintenance Bulletin 1062-BmashanghNoch keine Bewertungen

- CMT Prac 2004 Sec 6 BReverse CementingDokument8 SeitenCMT Prac 2004 Sec 6 BReverse CementingcharlessimoNoch keine Bewertungen

- Drilling Program WOEN-5 PDFDokument69 SeitenDrilling Program WOEN-5 PDFHouria HouriaNoch keine Bewertungen

- Banda East Well Montage 28sept08 A4 SizeDokument1 SeiteBanda East Well Montage 28sept08 A4 SizeSyed IrtazaNoch keine Bewertungen

- TCP-DST-01 String Diagram Rajian-07 PDFDokument1 SeiteTCP-DST-01 String Diagram Rajian-07 PDFRizwan FaridNoch keine Bewertungen

- Petani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)Dokument30 SeitenPetani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)handokoNoch keine Bewertungen

- Wellhead - Manual S2100559Dokument47 SeitenWellhead - Manual S2100559Parag PadoleNoch keine Bewertungen

- Drilling BHA - General AssemblyDokument3 SeitenDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNoch keine Bewertungen

- Cement Plug SidetrackDokument2 SeitenCement Plug SidetrackAnilNoch keine Bewertungen

- Petroleum Well Construction PWC02F01Dokument1 SeitePetroleum Well Construction PWC02F01Mohamed AbozeimaNoch keine Bewertungen

- PWC01F06Dokument1 SeitePWC01F06Mohamed AbozeimaNoch keine Bewertungen

- Petroleum Well Construction WC01F11Dokument1 SeitePetroleum Well Construction WC01F11Mohamed AbozeimaNoch keine Bewertungen

- Petroleum Well Construction PWC02F03Dokument1 SeitePetroleum Well Construction PWC02F03Mohamed AbozeimaNoch keine Bewertungen

- PWC01F07Dokument1 SeitePWC01F07Mohamed AbozeimaNoch keine Bewertungen

- 1-3 Drilling Fundamentals: 1-3.1 EquipmentDokument1 Seite1-3 Drilling Fundamentals: 1-3.1 EquipmentMohamed AbozeimaNoch keine Bewertungen

- PWC01F05Dokument1 SeitePWC01F05Mohamed AbozeimaNoch keine Bewertungen

- PrefaceDokument1 SeitePrefaceMohamed AbozeimaNoch keine Bewertungen

- Petroleum Well Construction - ContribDokument1 SeitePetroleum Well Construction - ContribMohamed AbozeimaNoch keine Bewertungen

- Low Profile Spider Elevator 400 PDFDokument2 SeitenLow Profile Spider Elevator 400 PDFMohamed AbozeimaNoch keine Bewertungen

- Flush-Joint Elevator: Runs Flush-Joint Pipe Without The Need To Use Threaded Lift NubbinsDokument1 SeiteFlush-Joint Elevator: Runs Flush-Joint Pipe Without The Need To Use Threaded Lift NubbinsMohamed AbozeimaNoch keine Bewertungen

- RMS 3000 Rotary-Mounted Slips and Elevator: ApplicationsDokument1 SeiteRMS 3000 Rotary-Mounted Slips and Elevator: ApplicationsMohamed AbozeimaNoch keine Bewertungen

- Cleaning and Dressing PBR PDFDokument5 SeitenCleaning and Dressing PBR PDFMohamed AbozeimaNoch keine Bewertungen

- NBR-575 Operation Game Plan HRDH-1201 Running 4 '' Completion Nov 18, 2014 To: RM/NTP, DR, Ad, Me, Baker Eng, Franks. Al-Mansori S/LDokument2 SeitenNBR-575 Operation Game Plan HRDH-1201 Running 4 '' Completion Nov 18, 2014 To: RM/NTP, DR, Ad, Me, Baker Eng, Franks. Al-Mansori S/LMohamed Abozeima100% (1)

- GAME PLAN Retrieve Whipstock Mill BPDokument1 SeiteGAME PLAN Retrieve Whipstock Mill BPMohamed AbozeimaNoch keine Bewertungen

- General Hints / Tips Emergency Action Recipes .. Blowout - Barite PlugDokument2 SeitenGeneral Hints / Tips Emergency Action Recipes .. Blowout - Barite PlugMohamed AbozeimaNoch keine Bewertungen

- Drilling 12 1.4 in HoleDokument1 SeiteDrilling 12 1.4 in HoleMohamed AbozeimaNoch keine Bewertungen

- Decision Tree For EWL FishingDokument1 SeiteDecision Tree For EWL FishingMohamed AbozeimaNoch keine Bewertungen

- Cleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedDokument1 SeiteCleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedMohamed AbozeimaNoch keine Bewertungen

- ID Eksplorasi Hidrokarbon Dengan Metode GeoDokument14 SeitenID Eksplorasi Hidrokarbon Dengan Metode GeoI2OI2OII2 JulyAkbarNoch keine Bewertungen

- Sop BorewellDokument28 SeitenSop BorewellAjay kumarNoch keine Bewertungen

- 2017 Target2017 AbstractsDokument177 Seiten2017 Target2017 AbstractsLaraNigroNoch keine Bewertungen

- Dynamic CompactionDokument10 SeitenDynamic CompactionAmit SomwanshiNoch keine Bewertungen

- Analytical Fingerprint of Columbite-Tantalite (Coltan) Mineralisation in Pegmatites - Focus On AfricaDokument10 SeitenAnalytical Fingerprint of Columbite-Tantalite (Coltan) Mineralisation in Pegmatites - Focus On AfricaLeonardo JaimesNoch keine Bewertungen

- Rock Mec Assignement No 3 by Prof UK SinghDokument2 SeitenRock Mec Assignement No 3 by Prof UK SinghChinmoyee SharmaNoch keine Bewertungen

- How Index Fossils Help Define Geologic TimeDokument2 SeitenHow Index Fossils Help Define Geologic Timelasxdkasdas sdadwdacNoch keine Bewertungen

- Reflection The Planet Earth Is A Gift From GodDokument2 SeitenReflection The Planet Earth Is A Gift From GodPrince JosephNoch keine Bewertungen

- Lapidary Works of Art, Gemstones, Minerals and Natural HistoryDokument132 SeitenLapidary Works of Art, Gemstones, Minerals and Natural HistoryWalterNoch keine Bewertungen

- ZYP2122 - Text 1Dokument15 SeitenZYP2122 - Text 1Аружан ЖадырасынNoch keine Bewertungen

- Journal of Structural Geology: Peter J. Hudleston, Susan H. TreagusDokument30 SeitenJournal of Structural Geology: Peter J. Hudleston, Susan H. TreagusRizky Dwi RenaldyNoch keine Bewertungen

- Emerald National Dex LocationsDokument9 SeitenEmerald National Dex Locationseduardo diasNoch keine Bewertungen

- Calculation Improvement of The Clay Content in The Hydrocarbon Formation RocksDokument3 SeitenCalculation Improvement of The Clay Content in The Hydrocarbon Formation RocksMujtabaNoch keine Bewertungen

- (Ieag, 1979) Classification of Rocks and Soils For Engineering Geological MappingDokument8 Seiten(Ieag, 1979) Classification of Rocks and Soils For Engineering Geological MappingCarolina LemosNoch keine Bewertungen

- Mid Term Advanced Soil Mechanics-II Spring 2021Dokument1 SeiteMid Term Advanced Soil Mechanics-II Spring 2021Faheem ShahNoch keine Bewertungen

- Erosion and TransportationDokument17 SeitenErosion and TransportationbibsNoch keine Bewertungen

- MDSW Meghalaya07Dokument33 SeitenMDSW Meghalaya07miningnova1100% (1)

- Tunnelling and Underground Space Technology: SciencedirectDokument9 SeitenTunnelling and Underground Space Technology: SciencedirectEduardo CepedaNoch keine Bewertungen

- Polyphase Deformation and Strain Migration On The Septentrional-Oriente Fault Zone in The Windward Passage, Northern Caribbean Plate BoundaryDokument25 SeitenPolyphase Deformation and Strain Migration On The Septentrional-Oriente Fault Zone in The Windward Passage, Northern Caribbean Plate BoundaryAlana SéguierNoch keine Bewertungen

- Lecture-5 & 6 CanalsDokument59 SeitenLecture-5 & 6 CanalsqasimhassanietNoch keine Bewertungen

- Homework 3 Earthquake PreparednessDokument2 SeitenHomework 3 Earthquake PreparednessGil GameshNoch keine Bewertungen

- Baloc Sto. Domingo, Nueva Ecija: A. Quiz 4: A & B B. Activity 4: Plate Tectonic Cut-OutsDokument2 SeitenBaloc Sto. Domingo, Nueva Ecija: A. Quiz 4: A & B B. Activity 4: Plate Tectonic Cut-OutsMark Allen LabasanNoch keine Bewertungen