Beruflich Dokumente

Kultur Dokumente

Revolutionizing The Prediction of Reservoir Performance

Hochgeladen von

Sundus TahirOriginaltitel

Copyright

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Revolutionizing The Prediction of Reservoir Performance

Hochgeladen von

Sundus TahirCopyright:

Reservoir Management

Revolutionising the scenarios in minutes, all based on the experience of the asset’s 400 (a)

MEERA Al

petroleum engineers. A reservoir model that is constantly 350

Simulator

being updated has the major advantage of allowing reliable

Prediction of Reservoir

Observed

maps of remaining hydrocarbons to be made, which can then

Oil Production Rate (sm3/day)

300

be used to select optimum infill drilling locations. It also 250

helps to provide stable and auditable cash-flow predictions to

Performance

SINA MOHAJERI and shareholders. 200

MATTHIAS HARTUNG, In comparison to purely data-driven processes, which mainly 150

Target Energy Solutions capture near-well behaviours, the system, known as MEERA

Coupling deep learning methods with dynamic reservoir models can Simulation, considers the whole reservoir’s interconnected 100

behaviour and therefore all inter-well effects. This makes it ideal

result in tremendous time saving and more reliable production forecasts. 50

for studying the effects of processes like well injection, as well as

0

for looking at how major structures like fractures and faults in the 1995 1997 1998 1999 2001 2002

Reservoir models are vitally important in the oil and gas subsurface data with machine learning acquired through the reservoir may impact the production rates. 100

(b) MEERA Al

industry, for example for estimating remaining oil and gas stream of ‘big data’ coming from production. 90 Simulator

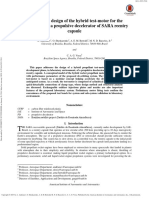

reserves and providing production forecasts. Managing the Case Study 1: History Matching Observed

80

operational and financial performance of an E&P asset is A Revolutionary Breakthrough The benefits of the utilisation of a system like this can be seen by

Oil Production Rate (sm3/day)

also heavily dependent upon having access to a current and This hybrid AI/physics-based system uses a conventional looking at some completed projects. One example comes from a 70

reliable prediction of the dynamic reservoir behaviour. All 3D, 3-phase numerical reservoir simulator coupled with a field that had started producing in 1985 and now has more than 60

this information is crucial for creating development and complex deep learning engine. The first step is to simply 80 production wells, with strong aquifer support. In this case 50

operational plans and providing an auditable cash flow to integrate an asset’s optimum dynamic reservoir model into study, production data was matched up to 2010 and the period 40

shareholders. It is therefore important to have an up-to-date Target’s platform MEERATM, and its AI-Simulation framework 2010–2018 was used for blind test prediction. Each full field 30

and accurate reservoir model. therein. This is done by re-assembling the components of the simulation run took 7 to 8 hours using commercial simulators,

20

However, E&P asset operators have an issue, in that their original conventional model, so it meshes into the machine but when using MEERA Simulation, each history simulation

optimum history matched dynamic reservoir models are learning framework. Various parameters are extracted took 12 minutes, while prediction simulations took 50–70 10

becoming quickly out-of-date and ‘dormant’, due to the length from the original reservoir model, some of which, based on milliseconds, all on the same IT infrastructure. 0

1996 1998 2001 2004 2006 2009 2012 2015 2017

of time it takes to update models. This means that frequent a comprehensive correlation analysis, are selected as key These faster results meant the engineers could run

40

model updates are simply unaffordable. Engineers therefore reservoir elements to be used for machine learning training multiple simulations in minutes to generate lots of different (c) MEERA Al

Simulator

often resort to using simpler approximation models to and prediction. New production data is then incorporated, potential scenarios, thereby allowing for better optimisation 35

Observed

forecast production and remaining reserves, as these methods creating a rapidly self-updating live dynamic reservoir model of development strategies. In this case study, the field history

30

are faster and cheaper to use, although at the price of losing that can be used as a reliable production forecasting and proved to be matched better using this system than with the

Oil Production Rate (sm3/day)

prediction accuracy. scenario-testing tool for operational planning and budgeting. traditional commercial simulators, and in particular the blind 25

This industry dilemma led engineers and scientists of It takes just minutes to train the AI using historic production test prediction was more accurate than the traditional simulation

20

the international technology and services company Target data, while successive prediction simulations take merely historical-matching of the same wells. The better the history

Energy Solutions to develop a new hybrid modelling method milliseconds. matching quality, the better the understanding of the reservoir, 15

Target Energy Solutions

that couples conventional simulation with modern machine The lack of time constraints means that it is possible which in turn leads to a better production optimisation and re- 10

learning, thereby combining engineering knowledge of to optimise a development strategy by running numerous development decisions.

5

Graphic describing the high-level workflow. Case Study 2: Lack of Data 0

Lack of available data is often another issue that asset operators 2009 2010 2012 2013 2014 2016 2017 2019 2020

face. Confronted with this problem, a company that had been Case study 1: Comparison of MEERA vs. conventional simulator in

using a model built on a reservoir modelling tool suite widely predicting oil production rates per well : (a) example in history match

used in the industry decided to test using MEERA Simulation mode only, i.e. prior to 2010; (b) in both history match and prediction

mode; and (c) well example in prediction mode only.

to build their models. As a result of the machine learning built

into the software, the lack of data was not such an issue and the

client found that not only was it quicker to build models through Evergreen Model Predictions

this system, but that the history matching was more reliable than Field development decision making needs reliable

before. However, it must be emphasised that although machine predictive calculations, so a hybrid approach to reservoir

learning can fi ll in data gaps, the more data that is available, the modelling, using a fully coupled simulator with an AI/

more accurate the outcome will be. machine learning engine, is an obvious way forward. The

A key feature seen across both these case studies is that a result benefits from the history matching capabilities of

tool like this, that includes machine learning, has the ability to artificial intelligence combined with the proven forecasting

integrate with other industry reservoir modelling applications, capabilities of a conventional reservoir simulator, while

allowing it to read and write from these applications using data- preserving local and global physical consistency.

exchange industry standards such as RESCUE. In addition, the With their evergreen model predictions and machine

tool also possesses a wide range of professional and easy-to-use learning abilities, tools like MEERA Simulation have the

data-handling utilities and visualisers, including 3D and 2D potential to revolutionise the way that reservoir models

Target Energy Solutions models, a chart visualiser and a histogram visualiser. are built and producing fields are developed.

56 GEOExPro March 2020 GEOExPro March 2020 57

Das könnte Ihnen auch gefallen

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessVon EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNoch keine Bewertungen

- HP0906 Gonzalez PDFDokument5 SeitenHP0906 Gonzalez PDFBesan LaduNoch keine Bewertungen

- A Study of the Supply Chain and Financial Parameters of a Small BusinessVon EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNoch keine Bewertungen

- Design of Solar PVFuel Cell Hybrid Microgrid Power SystemDokument1 SeiteDesign of Solar PVFuel Cell Hybrid Microgrid Power Systemlaithismail200018Noch keine Bewertungen

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesVon EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesBewertung: 5 von 5 Sternen5/5 (1)

- Bol Filter ManualDokument7 SeitenBol Filter ManualAmster Limatog100% (2)

- Geo Expro Feb 16 Article en 82116Dokument2 SeitenGeo Expro Feb 16 Article en 82116Víctor Eduardo Salas OlguínNoch keine Bewertungen

- Stockpile and Cut-Off Optimization ModuleDokument1 SeiteStockpile and Cut-Off Optimization ModuleRicardo Contreras BNoch keine Bewertungen

- Buffer StockpilesDokument1 SeiteBuffer StockpilesRicardo Contreras BNoch keine Bewertungen

- Combustion Modeling of Dual-Fuel Engines - 2Dokument2 SeitenCombustion Modeling of Dual-Fuel Engines - 2helenNoch keine Bewertungen

- Brewery: Utilities Plantweb in ActionDokument6 SeitenBrewery: Utilities Plantweb in ActionjoacochacomanNoch keine Bewertungen

- Baffa Ut 1989Dokument19 SeitenBaffa Ut 1989jahidNoch keine Bewertungen

- Blending SiloTechniquesDokument6 SeitenBlending SiloTechniquesYaserElkelawy100% (1)

- SG4 15 PosterDokument1 SeiteSG4 15 Posterbalasubramaniam0% (1)

- 0.-Rules of Thumb (Walas)Dokument7 Seiten0.-Rules of Thumb (Walas)Bryan PiguaveNoch keine Bewertungen

- Exchange PosterDokument1 SeiteExchange Postergururajmvs100% (2)

- PTC Tempo - BiopharmaDokument2 SeitenPTC Tempo - Biopharmaakhil4006Noch keine Bewertungen

- Free Breeze PS500-500kW EnglishDokument6 SeitenFree Breeze PS500-500kW EnglishRey Martial RodriguezNoch keine Bewertungen

- Ambr250m Biostatstr Upstream Microbial Process A0poster en Sartorius DataDokument1 SeiteAmbr250m Biostatstr Upstream Microbial Process A0poster en Sartorius Datacharles.wongNoch keine Bewertungen

- Presentation of Overhauling CEP Motor-B Rev-1Dokument16 SeitenPresentation of Overhauling CEP Motor-B Rev-1aminullahsharifNoch keine Bewertungen

- Dew-Point Evaporative Comfort Cooling: Jesse DeanDokument39 SeitenDew-Point Evaporative Comfort Cooling: Jesse DeanNaziman AzlyeNoch keine Bewertungen

- 3 - PROCESS CONTROL - 2010 - Chemical Process EquipmentDokument21 Seiten3 - PROCESS CONTROL - 2010 - Chemical Process Equipmentalbertol_bilaNoch keine Bewertungen

- MC 100 Cargador de ExplosivosDokument8 SeitenMC 100 Cargador de ExplosivosWiwa Hernandez Donoso100% (1)

- Ageh 2010Dokument11 SeitenAgeh 2010Việt Toàn ĐỗNoch keine Bewertungen

- DevOps CertificationDokument3 SeitenDevOps CertificationKeerthi KeerthanaNoch keine Bewertungen

- SPIE2006 PaperpdfDokument1 SeiteSPIE2006 PaperpdffalascojNoch keine Bewertungen

- Iptc 11205 MS PDokument8 SeitenIptc 11205 MS PRalf JonesNoch keine Bewertungen

- Staircase Tower 9m Acrow-ModelDokument1 SeiteStaircase Tower 9m Acrow-Modelrichard richNoch keine Bewertungen

- Results: Fleet Optimization For Productivity ImprovementDokument1 SeiteResults: Fleet Optimization For Productivity ImprovementdileepNoch keine Bewertungen

- The Lube Oil Centrifugal Filter: A Retrofittable Cleaning SystemDokument2 SeitenThe Lube Oil Centrifugal Filter: A Retrofittable Cleaning SystemAnonymous alQXB11EgQNoch keine Bewertungen

- EBI DiagramaDokument1 SeiteEBI DiagramaJULIAN MENESESNoch keine Bewertungen

- Project Title Approval: College of Computer StudiesDokument1 SeiteProject Title Approval: College of Computer Studiesragz autenticNoch keine Bewertungen

- Fundamentals of Turbine/ Generator Speed ControlDokument7 SeitenFundamentals of Turbine/ Generator Speed ControlAMIRNoch keine Bewertungen

- Cost Audit and Its Excellences What WhyDokument1 SeiteCost Audit and Its Excellences What WhyJKonsultoresNoch keine Bewertungen

- Cost Audit and Its Excellences What Why PDFDokument1 SeiteCost Audit and Its Excellences What Why PDFFahmida AkhterNoch keine Bewertungen

- Productspecificaties Linde H100 H180 Zware HeftrucksDokument2 SeitenProductspecificaties Linde H100 H180 Zware HeftrucksJan Hendriks50% (2)

- WASv7 AuditLab PDFDokument34 SeitenWASv7 AuditLab PDFAnahat80Noch keine Bewertungen

- Plastic Gears: An Excellent Metal Replacement Successful ApplicationsDokument4 SeitenPlastic Gears: An Excellent Metal Replacement Successful ApplicationsApoorva PanchalNoch keine Bewertungen

- Sumtech FMG Series: Physical PropertiesDokument1 SeiteSumtech FMG Series: Physical PropertiesCarlos MNoch keine Bewertungen

- EPilot Catalog v2023.2Dokument90 SeitenEPilot Catalog v2023.2Augustus CaesarNoch keine Bewertungen

- 05-20-45EE256 Motors, Variable Speed Drivers and Generators - Troubleshooting, Maintenance & Protection Course Outline PDFDokument2 Seiten05-20-45EE256 Motors, Variable Speed Drivers and Generators - Troubleshooting, Maintenance & Protection Course Outline PDFSIVARASU RATHINAVELUNoch keine Bewertungen

- Rag Tss Folder Engl 160215Dokument5 SeitenRag Tss Folder Engl 160215Alexander Aristizábal PeñalozaNoch keine Bewertungen

- IAC Acoustic Louvres 6ppDokument2 SeitenIAC Acoustic Louvres 6ppE Hammam El MissiryNoch keine Bewertungen

- VSL Strand Post Tensioning SystemsDokument41 SeitenVSL Strand Post Tensioning SystemsDevendraNoch keine Bewertungen

- VSL Strand Post Tensioning Systems PDFDokument41 SeitenVSL Strand Post Tensioning Systems PDFJonathan GallegosNoch keine Bewertungen

- Coating and CorrosionDokument76 SeitenCoating and CorrosionIntegridad de Equipos y Gestión de Activos Nelcam100% (1)

- Unified Process: Introduction To TheDokument8 SeitenUnified Process: Introduction To TheSevNoch keine Bewertungen

- Real-Time Production Optimization of Oil and Gas PDokument9 SeitenReal-Time Production Optimization of Oil and Gas Paldo subiranaNoch keine Bewertungen

- Wind Power ApplicationsDokument2 SeitenWind Power Applicationsmiguel itsonNoch keine Bewertungen

- ProductionScheduler SeniorDokument1 SeiteProductionScheduler SeniorAdnene ChouchiNoch keine Bewertungen

- 2015 03 03 Multiflash FINALDokument4 Seiten2015 03 03 Multiflash FINALPasquale CutriNoch keine Bewertungen

- Turbine Life ExtensionDokument2 SeitenTurbine Life Extensionhery jauhariNoch keine Bewertungen

- Technical Feasibility Analysis of Utilizing Special Purpose Machine ToolsDokument13 SeitenTechnical Feasibility Analysis of Utilizing Special Purpose Machine ToolsCA-VIJAY MORE3344Noch keine Bewertungen

- Defense Acquisition Life Cycle Wall Chart v1.3Dokument2 SeitenDefense Acquisition Life Cycle Wall Chart v1.3joe TNoch keine Bewertungen

- Sample Structural DrawingDokument1 SeiteSample Structural DrawingCherish Taguinod Aliguyon100% (1)

- Concept and Design of The Hybrid Test-Motor For SARADokument12 SeitenConcept and Design of The Hybrid Test-Motor For SARAThiago cosmeNoch keine Bewertungen

- Day3 Function FMEADokument56 SeitenDay3 Function FMEAPaul StarkNoch keine Bewertungen

- Insulation Reformulation Development: Project Manager(s) /lead(s)Dokument2 SeitenInsulation Reformulation Development: Project Manager(s) /lead(s)ennho.sky117Noch keine Bewertungen

- SSW 0701Dokument2 SeitenSSW 0701bijan_ldce@yahoo.co.inNoch keine Bewertungen

- CV 2022 EnglishDokument2 SeitenCV 2022 EnglishKevin SuazaNoch keine Bewertungen

- Research On Surface Roughness by Laser CDokument5 SeitenResearch On Surface Roughness by Laser CfatmirhusejniNoch keine Bewertungen

- 19C Financials WNDokument60 Seiten19C Financials WNbishwabengalitolaNoch keine Bewertungen

- Google-Analytics 01Dokument28 SeitenGoogle-Analytics 01Smm Store24Noch keine Bewertungen

- Circular Motion ProblemsDokument4 SeitenCircular Motion ProblemsGheline LexcieNoch keine Bewertungen

- RVT Liquid DistributorDokument5 SeitenRVT Liquid DistributorimeagorNoch keine Bewertungen

- Good Practice On The Project "Improve The Food Security of Farming Families Affected by Volatile Food Prices" (Nutrition Component) in CambodiaDokument2 SeitenGood Practice On The Project "Improve The Food Security of Farming Families Affected by Volatile Food Prices" (Nutrition Component) in CambodiaADBGADNoch keine Bewertungen

- Statement of Facts:: State of Adawa Vs Republic of RasasaDokument10 SeitenStatement of Facts:: State of Adawa Vs Republic of RasasaChristine Gel MadrilejoNoch keine Bewertungen

- Title To The ProjectDokument14 SeitenTitle To The ProjectJatinChadhaNoch keine Bewertungen

- Unilever Financial PerformanceDokument9 SeitenUnilever Financial PerformanceAbdul QayumNoch keine Bewertungen

- Inkt Cables CabinetsDokument52 SeitenInkt Cables CabinetsvliegenkristofNoch keine Bewertungen

- BSC IT SyllabusDokument32 SeitenBSC IT Syllabusஜூலியன் சத்தியதாசன்Noch keine Bewertungen

- Burndown Sample ClayDokument64 SeitenBurndown Sample ClaybluemaxNoch keine Bewertungen

- County Project Name Cycle Project Address Proj City Proj Zip Applicant/Owner Name HDGP $ Home $ FHTF $ Lihtc9 $ Help $ Oahtc $ Ghap $ HPF $ Lihtc4 $Dokument60 SeitenCounty Project Name Cycle Project Address Proj City Proj Zip Applicant/Owner Name HDGP $ Home $ FHTF $ Lihtc9 $ Help $ Oahtc $ Ghap $ HPF $ Lihtc4 $Mamello PortiaNoch keine Bewertungen

- CH7Dokument34 SeitenCH7Abdul AzizNoch keine Bewertungen

- Variable Length Subnet MasksDokument4 SeitenVariable Length Subnet MaskszelalemNoch keine Bewertungen

- ETA-1 Service PDFDokument44 SeitenETA-1 Service PDFgansolNoch keine Bewertungen

- Gamboa-Roces vs. Judge PerezDokument1 SeiteGamboa-Roces vs. Judge PerezDiane Dee YaneeNoch keine Bewertungen

- Datasheet HFS60Dokument3 SeitenDatasheet HFS60RajeswaranNoch keine Bewertungen

- Man 3Dokument38 SeitenMan 3Paylo KatolykNoch keine Bewertungen

- CS 148 - Introduction To Computer Graphics and ImagingDokument3 SeitenCS 148 - Introduction To Computer Graphics and ImagingMurtaza TajNoch keine Bewertungen

- Project Proposal - Articulation SessionsDokument8 SeitenProject Proposal - Articulation SessionsJhay-are PogoyNoch keine Bewertungen

- Water Cooled Centrifugal Chiller (150-3000RT)Dokument49 SeitenWater Cooled Centrifugal Chiller (150-3000RT)remigius yudhiNoch keine Bewertungen

- Chapter 3: Classical Production Models: News Vendor ModelDokument85 SeitenChapter 3: Classical Production Models: News Vendor ModelmauriciovendraminNoch keine Bewertungen

- Applicant Details : Government of Tamilnadu Application Form For Vehicle E-Pass For Essential ServicesDokument1 SeiteApplicant Details : Government of Tamilnadu Application Form For Vehicle E-Pass For Essential ServicesŠářoĵ PrinceNoch keine Bewertungen

- Questions & Answers On CountersDokument24 SeitenQuestions & Answers On Counterskibrom atsbha100% (2)

- Modeling Cover Letter No ExperienceDokument7 SeitenModeling Cover Letter No Experienceimpalayhf100% (1)

- Financial Analysis of OGDCLDokument16 SeitenFinancial Analysis of OGDCLsehrish_sadaqat7873100% (1)

- La Naval Drug Co Vs CA G R No 103200Dokument2 SeitenLa Naval Drug Co Vs CA G R No 103200UE LawNoch keine Bewertungen

- People/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMDokument8 SeitenPeople/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMPola OsamaNoch keine Bewertungen

- Motion To DismissDokument24 SeitenMotion To DismisssandyemerNoch keine Bewertungen

- Algorithms to Live By: The Computer Science of Human DecisionsVon EverandAlgorithms to Live By: The Computer Science of Human DecisionsBewertung: 4.5 von 5 Sternen4.5/5 (722)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityVon EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityBewertung: 5 von 5 Sternen5/5 (1)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyVon EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyBewertung: 4 von 5 Sternen4/5 (51)

- Cyber War: The Next Threat to National Security and What to Do About ItVon EverandCyber War: The Next Threat to National Security and What to Do About ItBewertung: 3.5 von 5 Sternen3.5/5 (66)

- AI Superpowers: China, Silicon Valley, and the New World OrderVon EverandAI Superpowers: China, Silicon Valley, and the New World OrderBewertung: 4.5 von 5 Sternen4.5/5 (398)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldVon EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (107)

- Generative AI: The Insights You Need from Harvard Business ReviewVon EverandGenerative AI: The Insights You Need from Harvard Business ReviewBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Future of Geography: How the Competition in Space Will Change Our WorldVon EverandThe Future of Geography: How the Competition in Space Will Change Our WorldBewertung: 4 von 5 Sternen4/5 (6)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyVon EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyBewertung: 3.5 von 5 Sternen3.5/5 (111)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldVon EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (55)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyVon EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNoch keine Bewertungen

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessVon EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNoch keine Bewertungen

- Chip War: The Quest to Dominate the World's Most Critical TechnologyVon EverandChip War: The Quest to Dominate the World's Most Critical TechnologyBewertung: 4.5 von 5 Sternen4.5/5 (228)

- System Error: Where Big Tech Went Wrong and How We Can RebootVon EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNoch keine Bewertungen

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Von EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Noch keine Bewertungen

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumVon EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumBewertung: 3 von 5 Sternen3/5 (12)

- YouTube Secrets: The Ultimate Guide on How to Start and Grow Your Own YouTube Channel, Learn the Tricks To Make a Successful and Profitable YouTube ChannelVon EverandYouTube Secrets: The Ultimate Guide on How to Start and Grow Your Own YouTube Channel, Learn the Tricks To Make a Successful and Profitable YouTube ChannelBewertung: 4.5 von 5 Sternen4.5/5 (48)

- Reality+: Virtual Worlds and the Problems of PhilosophyVon EverandReality+: Virtual Worlds and the Problems of PhilosophyBewertung: 4 von 5 Sternen4/5 (24)

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeVon EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeBewertung: 4.5 von 5 Sternen4.5/5 (99)

- The Knowledge: How to Rebuild Our World from ScratchVon EverandThe Knowledge: How to Rebuild Our World from ScratchBewertung: 3.5 von 5 Sternen3.5/5 (133)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveVon EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNoch keine Bewertungen

- Four Battlegrounds: Power in the Age of Artificial IntelligenceVon EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceBewertung: 5 von 5 Sternen5/5 (5)

- Solutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesVon EverandSolutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesNoch keine Bewertungen

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterVon EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterBewertung: 5 von 5 Sternen5/5 (3)