Beruflich Dokumente

Kultur Dokumente

Sem 656D PDF

Hochgeladen von

pejabatkorupOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sem 656D PDF

Hochgeladen von

pejabatkorupCopyright:

Verfügbare Formate

Machine Applications Main Specifications

The sturdy design of the SEM 656D makes it the perfect

machine for port cargo handling, mineral yards, steel mills

Items SEM656D Items SEM656D SEM656D

Wheel Loader

Main Specifications Engine

and other high demand applications Rated Load kg 5 000 Model Weichai WD10G

In Quarry and Aggregate and Coal Mining applications Operating Weight with Standard Bucket kg 16 900 Rated Power kW 162

the 656D can load more, move faster and burn less fuel Bucket Capacity m³ 2.7-4.5 Rated Speed r/min 2 000

Multiple work tools are available for increased versatility Wheel Base mm 3 300 Displacement L 9.726

Overall Dimension mm 8 279x2 963x3 457 Implement Hydraulic

Operating Specifications Implement System Type Single load sensing flow sharing system

Breakout Force kN 178 Boom Raise Time s 5.13

Dump Clearance mm 3 113 Hydraulic Cycle Time s 9.3

Articulated Angle ° 38±1 System Presure Setting Mpa 18

Transmission Brake System

Transmission Type Countershaft, power shift Service Brake Dry & caliper, air to oil control

Drum type shoe brake, spring

Transmission Gears F4/R4 Parking Brake

applied & oil released

Torque Converter Type Sigle stage 3 elements Steering System

Maker & Type TR200 System Type Flow amplifying

Forward I/ Reverse I km/h 7.8/7.8 Steering Pump Type Piston pump

Forward II/ Reverse II km/h 15/15 System Presure Setting Mpa 16

Forward III/ Reverse III km/h 22/22 Steering Angle (L/R) ° 38±1

Forward IV/ Reverse IV km/h 39/39 Tires

Axle SO32 Size 23.5-25

Main Drive Type Spiral bevel gear, single stage Type Bias

Final Drive Reduction Type Planetary type, singe stage Layer 16

Work Tool Options Rear - Oscillating +/- ° ±11 Textured Type L3/E3

Machine Dimensions

54.5°

Hay Fork Pipe Gripper Log Gripper (Corresponding Teeth)

45° * Installed with Weichai Engine

1461 ※ Featured machines in photos may include optional equipment

5609

4162

2871

2250

3457

3113

Marble Fork GP Bucket Pallet Fork Side Dump Bucket 50°

45°

Product Advantage

SEM656D

7

460

R6

6

R58

88

63 3300 29 38° High Productivity

6

63

8279 Excellent Fuel Economy

Best-in-class Reliability and Durability

Outstanding Operator Comfort

Log Gripper Material Handling Arm Log Gripper (Upper Teeth Combined) Note: the above dimensions are based on the standard configuration.

PT TRI SWARDANA UTAMA

Gedung TMT 1, 1st Floor,

Caterpillar (Qingzhou) Ltd. Address: No.12999 Nanhuan Road,Caterpillar Industrial Park, Qingzhou City,Shandong Province, Zip Code: 262500 P.R.China

Jl. Cilandak KKO No.1

© Materials and specifications are subject to change without notice. Featured machines in photos may include optional equipment. See your SEM dealer for available options.

Jakarta - Indonesia

© 2017 Caterpillar (Qingzhou) Ltd. All Rights Reserved. SEM Machinery, SEM, their respective logos, trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar (Qingzhou) Ltd.

and may not be used without permission.

Telephone +62-21 2997 6677

QC Rock Bucket Rock Bucket Side Dump Bucket Quick Coupler Arrangement Version: February 2017 - Weichai Facsimile +62-21 2997 6708

www.tsu.co.id

a member of Tiara Marga Trakindo Group www.semmachinery.com

Optimized Engine Reliable Drivetrain Serviceability

Low speed engine with E-fan provides increased operating efficiency Countershaft transmission with upgraded core Centralized lubrication points reduce maintenance time

Enhanced fuel pre-filter eliminates water and contaminant from fuel for best fuel system protection components provides high reliability System pressure test ports are standard

The air cleaner provides machine reliability even in the most severe applications Large rim-pull in 1st gear and higher speed in Easy access to external air charge connecting port

2nd gear provide high efficiency for load and Engine hood grill opens for easy service access

carry applications

Torque convertor is isolated from transmission making it easy to service

Clutch cutoff selection switch ensures stable

and safe operation

The SEM designed and built axle provides best

in class performance in heavy duty applications

Advanced Cooling System

The standard cooling package provides high reliability in 50 ambient conditions.

Shock p ad mounts ensure reliability under severe applications

Efficient Hydraulic System

The advanced load sensing hydraulic system

with flow sharing circuits improves efficiency

Solid Structure Safety

World Class hydraulic components ensure

high reliability

The optimized hydraulic system paired with Safety design complies with all regulatory

the drive train reduces machine cycle time Structures undergo Finite Element Analysis (FEA) and On Machine Stress Analysis (OMSA) requirements

and increases productivity to ensure durability Machine is designed with 3 points of contact

Performance Series (PS) buckets improve loading capability to ensure operator safety

A backup alarm, horn and beacon ensure

operational safety with ground personnel

Operator Station

Caterpillar Production System (CPS) leveraged

in manufacturing process

Premium operator station with increased space and Environmentally friendly painting process

superior visibility

Sliding side window and AC with fresh air circulation

provide operator comfort

Joystick hydraulic control for easy and precise operation

Multi-function instrument dashboard with 3-level alarm

Adjustable suspension seat

Das könnte Ihnen auch gefallen

- Terex TR 60 SpecDokument6 SeitenTerex TR 60 Specarimbi jatisasongko100% (2)

- M-208-04R1 Distribuidor de Agregados PDFDokument66 SeitenM-208-04R1 Distribuidor de Agregados PDFFernando GaiborNoch keine Bewertungen

- Bishop and Knight CheckmateDokument14 SeitenBishop and Knight Checkmatejeffreyschess100% (1)

- JOB SAFETY ANALYSISDokument8 SeitenJOB SAFETY ANALYSISOlavilam Prakash100% (3)

- CH2009 Dim MakDokument50 SeitenCH2009 Dim Makfedericoasensio100% (6)

- DL311 7Dokument4 SeitenDL311 7Vanessa Astudillo RNoch keine Bewertungen

- Sports Writing Reviewer: Noren Dave AsuncionDokument15 SeitenSports Writing Reviewer: Noren Dave AsuncionNoren Dave Poli Asuncion100% (1)

- Bomag BW 900-2 Operators and Maintenance ManualDokument72 SeitenBomag BW 900-2 Operators and Maintenance ManualIslam AttiaNoch keine Bewertungen

- Formula Motor Racing RulesDokument8 SeitenFormula Motor Racing RulesTheEnglishAssassinNoch keine Bewertungen

- Manual de Miller Maquina de SoldarDokument108 SeitenManual de Miller Maquina de Soldaredgarlimas100% (1)

- Kato NK250-v2 25-tonne truck crane specificationsDokument6 SeitenKato NK250-v2 25-tonne truck crane specificationsgroshan20Noch keine Bewertungen

- Brunei Driving LicenceDokument18 SeitenBrunei Driving Licenceapi-3051162580% (10)

- MDSM-7: User ManualDokument12 SeitenMDSM-7: User ManualJesus TorresNoch keine Bewertungen

- Upright X20 Scissor LiftDokument2 SeitenUpright X20 Scissor LiftNixon Blanco100% (2)

- SEM660D Wheel Loader - TSU - LowDokument2 SeitenSEM660D Wheel Loader - TSU - LowRivandho AnangNoch keine Bewertungen

- Created On 20 June 2023 at 5:14:37 AM UTCDokument4 SeitenCreated On 20 June 2023 at 5:14:37 AM UTCLeandro CariasoNoch keine Bewertungen

- Epiroc Boomer s2Dokument164 SeitenEpiroc Boomer s2Jerson MieresNoch keine Bewertungen

- EPX25I 부품 10010Dokument111 SeitenEPX25I 부품 10010mt thanh nguyen100% (1)

- CY 6102BG - 36 型柴油机备件目录: Model Cy6102Bg-36 Diesel Engine Spare Parts CatalogueDokument72 SeitenCY 6102BG - 36 型柴油机备件目录: Model Cy6102Bg-36 Diesel Engine Spare Parts Cataloguesobirin100% (1)

- 7FBR English PDFDokument16 Seiten7FBR English PDFVadivelNoch keine Bewertungen

- TSG-416 Base Industrial Engine EFI 1.6-Litre 4-CylinderDokument4 SeitenTSG-416 Base Industrial Engine EFI 1.6-Litre 4-CylinderMárcioNoch keine Bewertungen

- Enerpac Torque Wrench ManualDokument10 SeitenEnerpac Torque Wrench ManualM Saad KhanNoch keine Bewertungen

- Manual de Operacion y Mantenimiento r1600g-LhdDokument372 SeitenManual de Operacion y Mantenimiento r1600g-LhdRenan TomasNoch keine Bewertungen

- Efficient Multipurpose Rail-Road Loader Technical SpecificationsDokument27 SeitenEfficient Multipurpose Rail-Road Loader Technical SpecificationsEnrique Palacios RubioNoch keine Bewertungen

- Sem 636D PDFDokument2 SeitenSem 636D PDFpejabatkorupNoch keine Bewertungen

- Sem 636D PDFDokument2 SeitenSem 636D PDFpejabatkorupNoch keine Bewertungen

- Sem 636D PDFDokument2 SeitenSem 636D PDFpejabatkorupNoch keine Bewertungen

- BT3 Parts ManualDokument274 SeitenBT3 Parts ManualEmmanuel R. SiwilaNoch keine Bewertungen

- Lux M10Dokument40 SeitenLux M10simonNoch keine Bewertungen

- Diagnosis Twin-3 Without PC-GINADokument5 SeitenDiagnosis Twin-3 Without PC-GINAJasonNoch keine Bewertungen

- Grove-GMK7550 Product GuideDokument56 SeitenGrove-GMK7550 Product GuideabguyNoch keine Bewertungen

- To l2l'5" Lift: kW/95 Wt. Kell+gtl ToaderDokument18 SeitenTo l2l'5" Lift: kW/95 Wt. Kell+gtl ToaderRoberto GuillenNoch keine Bewertungen

- Dozers: 145-205 Net HorsepowerDokument24 SeitenDozers: 145-205 Net HorsepowerWilfredo AchoNoch keine Bewertungen

- Me Piston Replacement ProcedureDokument6 SeitenMe Piston Replacement ProcedureGaurav MaithilNoch keine Bewertungen

- 1400 Maintenance ManualDokument6 Seiten1400 Maintenance ManualJesus MatteyNoch keine Bewertungen

- Genie z45Dokument175 SeitenGenie z45Carlos Armando Zapata Merodio100% (1)

- Armado de Bulldozer D8T PDFDokument41 SeitenArmado de Bulldozer D8T PDFMarlon Montenegro100% (1)

- SD310 (ZF) Om 2014.01.24Dokument140 SeitenSD310 (ZF) Om 2014.01.24sergio mata100% (1)

- Toro 006Dokument2 SeitenToro 006Eric CNoch keine Bewertungen

- Sem 656D PDFDokument2 SeitenSem 656D PDFpejabatkorupNoch keine Bewertungen

- Sem 656D PDFDokument2 SeitenSem 656D PDFpejabatkorupNoch keine Bewertungen

- Sem 656D PDFDokument2 SeitenSem 656D PDFpejabatkorupNoch keine Bewertungen

- Sem 656D PDFDokument2 SeitenSem 656D PDFpejabatkorupNoch keine Bewertungen

- Sem 656D PDFDokument2 SeitenSem 656D PDFpejabatkorupNoch keine Bewertungen

- Photocopiables (Smart Planet 1)Dokument21 SeitenPhotocopiables (Smart Planet 1)AlbaGP83Noch keine Bewertungen

- Backhoe Loader: Key FeaturesDokument2 SeitenBackhoe Loader: Key FeaturesMaureen MillerNoch keine Bewertungen

- English - ComponentesDokument2 SeitenEnglish - ComponentesChristopher Jesus Reàtegui OlivaresNoch keine Bewertungen

- BEML Motor GraderDokument4 SeitenBEML Motor GraderVivek AnandNoch keine Bewertungen

- Mastil y HorquillasDokument43 SeitenMastil y HorquillasFredy ReyesNoch keine Bewertungen

- Codigo Producto Codigo NuevoDokument422 SeitenCodigo Producto Codigo Nuevofiltros y lubricantes la nacionalNoch keine Bewertungen

- JCB VIBROMAX Self-Propelled Vibratory Roller Compaction EquipmentDokument2 SeitenJCB VIBROMAX Self-Propelled Vibratory Roller Compaction Equipmentgreicel marianjas sihombingNoch keine Bewertungen

- CG Backhoe Loader CG Backhoe Loader CG Backhoe Loader CG Backhoe LoaderDokument28 SeitenCG Backhoe Loader CG Backhoe Loader CG Backhoe Loader CG Backhoe LoaderHongwei ZhangNoch keine Bewertungen

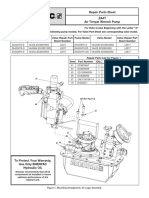

- Repair Parts Sheet Pro Series Electric Torque Wrench Pump Model ZU4Dokument16 SeitenRepair Parts Sheet Pro Series Electric Torque Wrench Pump Model ZU4Jhon VargasNoch keine Bewertungen

- JCB Engine Brochure Tier4 FINAL PDFDokument16 SeitenJCB Engine Brochure Tier4 FINAL PDFMd SattarNoch keine Bewertungen

- XCMG Forklifts BrochureDokument1 SeiteXCMG Forklifts BrochureОлег СкладремонтNoch keine Bewertungen

- Aircon & Heating Electrical SystemDokument2 SeitenAircon & Heating Electrical SystemFajrin niswatinNoch keine Bewertungen

- Brochure en Excavator CX220CDokument12 SeitenBrochure en Excavator CX220CYew LimNoch keine Bewertungen

- Ficha Tecnica - HP-2402Dokument10 SeitenFicha Tecnica - HP-2402Benjamin MillerNoch keine Bewertungen

- 789C Prueba de Calado ConvertidorDokument5 Seiten789C Prueba de Calado ConvertidorSergio Velarde Romay100% (1)

- JCB Lubricants - 2021Dokument19 SeitenJCB Lubricants - 2021Сергій БоженкоNoch keine Bewertungen

- Material Handler Specifications SummaryDokument2 SeitenMaterial Handler Specifications SummaryAdriano Alves Silva0% (1)

- Maestro Perkins-ZF ENG - 102B-SDokument1 SeiteMaestro Perkins-ZF ENG - 102B-SAmin SaidiNoch keine Bewertungen

- MRTHD Komac KB350 - Equipos 60000248 PDFDokument1 SeiteMRTHD Komac KB350 - Equipos 60000248 PDFJairresistenciagt123Noch keine Bewertungen

- Hyundai Hsl650 7 Skid Steer Loader ManualDokument1 SeiteHyundai Hsl650 7 Skid Steer Loader ManualVictor Balboa100% (1)

- Grasa Multiproposito CatDokument2 SeitenGrasa Multiproposito Catrolex21Noch keine Bewertungen

- Compactadora PN4200 SierraDokument2 SeitenCompactadora PN4200 SierraJorgeCheroNoch keine Bewertungen

- Hydra Mac Skid Steer Loader Operators ManualDokument8 SeitenHydra Mac Skid Steer Loader Operators ManualRoy Ramos50% (2)

- 120SXJ Maintenance and Service ManualDokument112 Seiten120SXJ Maintenance and Service ManualTecnico Reach Stacker Tecnico Reach StackerNoch keine Bewertungen

- ct300 DYNAPACDokument1 Seitect300 DYNAPACingraulitoNoch keine Bewertungen

- Rhino Hammers PDFDokument8 SeitenRhino Hammers PDFBudi WaskitoNoch keine Bewertungen

- Catalog-F7-05-47 Elevated Monitor PDFDokument3 SeitenCatalog-F7-05-47 Elevated Monitor PDFAhmed Hassan100% (1)

- A35e Final DriveDokument2 SeitenA35e Final DriveMuhammad P RNoch keine Bewertungen

- Dictionary of Pictograph Symbols: Excerpted From Operation & Maintenance Manual (SEBD0400-03-01)Dokument82 SeitenDictionary of Pictograph Symbols: Excerpted From Operation & Maintenance Manual (SEBD0400-03-01)Franciscley CardosoNoch keine Bewertungen

- Airo SG 1000 New eDokument2 SeitenAiro SG 1000 New e36Noch keine Bewertungen

- Kent Razor 24DC 28DCDokument42 SeitenKent Razor 24DC 28DCNestor Marquez-DiazNoch keine Bewertungen

- Dumper TH 540 PDFDokument13 SeitenDumper TH 540 PDFhernan avNoch keine Bewertungen

- Autodesk Student Version DocumentDokument1 SeiteAutodesk Student Version DocumentFélix MontañezNoch keine Bewertungen

- Sem Sem655dDokument2 SeitenSem Sem655dAhmad SmadiNoch keine Bewertungen

- Sem 656DDokument2 SeitenSem 656DPriyonggo PrabowoNoch keine Bewertungen

- SEM660D Wheel LoaderDokument2 SeitenSEM660D Wheel LoaderAhmad SmadiNoch keine Bewertungen

- v1 PT Jalur Trias - Disposisi 1 PDFDokument7 Seitenv1 PT Jalur Trias - Disposisi 1 PDFpejabatkorupNoch keine Bewertungen

- Reeves Sleeve - Instruction GuideDokument8 SeitenReeves Sleeve - Instruction GuideSaferightNoch keine Bewertungen

- 01fjmc2016 PDFDokument26 Seiten01fjmc2016 PDFSaad AtherNoch keine Bewertungen

- Full Results & PositionsDokument6 SeitenFull Results & Positionsgavin_holburnNoch keine Bewertungen

- Micro Merlin With HandbrakeDokument1 SeiteMicro Merlin With HandbrakeCarlos GutiérrezNoch keine Bewertungen

- PAINE FIELD AERODROME CHART FOR EVERETT WADokument13 SeitenPAINE FIELD AERODROME CHART FOR EVERETT WAmvd spotterNoch keine Bewertungen

- Wiring Diagram PDFDokument20 SeitenWiring Diagram PDFhastoNoch keine Bewertungen

- Regulament Receptie ConstructiiDokument1 SeiteRegulament Receptie ConstructiiFlorian RapanuNoch keine Bewertungen

- Pharmacist 01-2015 Room AssignmentDokument17 SeitenPharmacist 01-2015 Room AssignmentPRC Baguio0% (1)

- NCAA DI ChampionshipsDokument7 SeitenNCAA DI ChampionshipsAnonymous Pd2DfLcRZNoch keine Bewertungen

- English File: Grammar, Vocabulary, and PronunciationDokument5 SeitenEnglish File: Grammar, Vocabulary, and Pronunciationm daneshpour0% (1)

- "Hot-Dogging Into History": How Modern Surfing Was Introduced To Australia.Dokument20 Seiten"Hot-Dogging Into History": How Modern Surfing Was Introduced To Australia.Martin DolheguyNoch keine Bewertungen

- Httpswww.tpss.Euresults2586drawsheets20juniors.pdfDokument20 SeitenHttpswww.tpss.Euresults2586drawsheets20juniors.pdflanames1706Noch keine Bewertungen

- Bab 7 LanjutanDokument1 SeiteBab 7 LanjutanMr JuNoch keine Bewertungen

- Grammar and vocabulary rules for complete sentencesDokument3 SeitenGrammar and vocabulary rules for complete sentencesshiomara jhamilet0% (2)

- PCE Exams Candidate Ref ListDokument3 SeitenPCE Exams Candidate Ref Listsathish Lakshmanan100% (1)

- The Model of Oppenheimer and Snyder of A Collapsing StarDokument27 SeitenThe Model of Oppenheimer and Snyder of A Collapsing StarDr Abhas MitraNoch keine Bewertungen

- Follow The Instructions For R.I.C.EDokument2 SeitenFollow The Instructions For R.I.C.Eayatolla ayatollaTMNoch keine Bewertungen

- Cricket Mandi 80 - Players List - 230204 - 144111Dokument5 SeitenCricket Mandi 80 - Players List - 230204 - 144111Hariharan BaskharNoch keine Bewertungen