Beruflich Dokumente

Kultur Dokumente

Safety Relief Valves BSV 8: Instructions

Hochgeladen von

Paweł HejmowskiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Safety Relief Valves BSV 8: Instructions

Hochgeladen von

Paweł HejmowskiCopyright:

Verfügbare Formate

Instructions

Safety relief valves

BSV 8

148R9506

148R9506

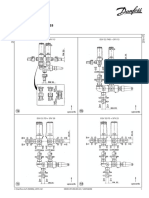

Installation

Fig. 2

Fig. 1 Fig. 3

BSV mounted as safety valve: BSV mounted as pilot valve for POV:

with fitting 148F3019 with fitting 2469+069

Fig. 4

© Danfoss A/S (AC-MCI/MWA), 2012-03 DKRCI.PI.IC0.A2.02 / 520H4689 1

ENGLISH Assembly

Remove welding slag and dirt from tubes

and housing before the valve is mounted.

Installation Mount the valve as shown in fig. 4.

Refrigerants

Applicable to all common non-flammable Colours and identification

refrigerants, including R717 and non- The valves are Zinc-Chromated in the

corrosive gases/liquids dependent on factory. If further corrosion protection

sealing material compatability. is required, it can be painted. Precise

Special types required for flammable identification of the valve is made via the

hydrocarbones. The valve is only ID label on the valve housing.

recommended for use in closed circuits. For In cases of doubt, please contact Danfoss.

further information please contact Danfoss. Danfoss accepts no responsibility for

errors and omissions. Danfoss Industrial

Refrigeration reserves the right to make

Temperature range changes to products and specifications

Temperature range for BSV used as an without prior notice.

external safety relief valve:

–30/+100°C (–22/+212°F)

Temperature range for BSV used as a pilot

valve for POV:

–50/+100°C (–58/+212°F)

Note:

For temperatures below –30°C (–22°F), the

valve may not re-seat to a 100% gas

tightness when activated.

Pressure range

The valve is designed for a max. working

pressure of 25 bar g (362 psi g). Danfoss

Industrial Refrigeration A/S is supplying

safety valves adjusted for a certain pressure

(indicated on the ID-plate) and sealed.

Danfoss Industrial Refrigeration guarantees

correct pressure as long as the seal remains

unbroken.

Installation

The valve should be installed with the

spring housing upwards (fig. 1).

By mounting of the safety valve it is

important to avoid the influence of thermic

and dynamic stress (vibrations) (fig. 2).

The valve is designed to withstand a high

internal pressure. However, the piping

system should be designed to avoid liquid

traps and reduce the risk of hydraulic

pressure caused by thermal expansion. It

must be ensured that the valve is protected

from pressure transients like “liquid

hammer” in the system.

Welding

If welding fittings are applied, these

should be dismounted during the welding

process (fig. 3). Only materials and welding

methods, compatible with the flange

material, must be welded to the flange.

Avoid welding debris and dirt in the

threads of the housing and pipes.

2 DKRCI.PI.IC0.A2.02 / 520H4689 © Danfoss A/S (AC-MCI/MWA), 2012-03

Das könnte Ihnen auch gefallen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Safety Valves and Double Stop ValvesDokument24 SeitenSafety Valves and Double Stop ValvesRahul PatilNoch keine Bewertungen

- 8b Dados TecnicosDokument2 Seiten8b Dados TecnicosWeyvson SilvaNoch keine Bewertungen

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsVon EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNoch keine Bewertungen

- Stop and Check ValvesDokument24 SeitenStop and Check ValvesRahul PatilNoch keine Bewertungen

- Instructions: SCA/CHV 50-125Dokument4 SeitenInstructions: SCA/CHV 50-125PRASANNANoch keine Bewertungen

- Quick Closing Oil Drain Valve, Type QDV 15Dokument8 SeitenQuick Closing Oil Drain Valve, Type QDV 15abdur rafayNoch keine Bewertungen

- I PM380-125 07 05 enDokument8 SeitenI PM380-125 07 05 enOmprakash_janaNoch keine Bewertungen

- Serie BPV/-S: Installation and Maintenance Instructions For The Back Pressure ValveDokument12 SeitenSerie BPV/-S: Installation and Maintenance Instructions For The Back Pressure ValvexyzeeepdpdpdpNoch keine Bewertungen

- Butterfly ValveDokument4 SeitenButterfly ValveCatalina NutaNoch keine Bewertungen

- AI175286423559en 000801Dokument14 SeitenAI175286423559en 000801bonifasius.thNoch keine Bewertungen

- FlowCon EVS Instruction 04 2012Dokument8 SeitenFlowCon EVS Instruction 04 2012Jeff Anderson CollinsNoch keine Bewertungen

- Safety Relief Valves BSV-8: Technical BrochureDokument10 SeitenSafety Relief Valves BSV-8: Technical BrochureVasti Diaz AguilarNoch keine Bewertungen

- Valvetop D-Series With AS-interface: Installation, Operation & Maintenance ManualDokument16 SeitenValvetop D-Series With AS-interface: Installation, Operation & Maintenance ManualAdeel RazaNoch keine Bewertungen

- SV5 Safety Valve-Installation Maintenance ManualDokument12 SeitenSV5 Safety Valve-Installation Maintenance ManualGOKUL PRASADNoch keine Bewertungen

- SISTO-Diaphragm Valves: 1. Installation InstructionsDokument1 SeiteSISTO-Diaphragm Valves: 1. Installation InstructionsEric LarrondoNoch keine Bewertungen

- FRIALEN Product RangeDokument96 SeitenFRIALEN Product RangestavrarusNoch keine Bewertungen

- EbroDokument15 SeitenEbroDang Quang HopNoch keine Bewertungen

- AZ-Operating Instructions - ENDokument4 SeitenAZ-Operating Instructions - ENborodichNoch keine Bewertungen

- Flowcon ABM InstructionDokument4 SeitenFlowcon ABM InstructionJeff Anderson CollinsNoch keine Bewertungen

- 2020 Vexve Long Stem Ball Valves Manual enDokument36 Seiten2020 Vexve Long Stem Ball Valves Manual env.cheliuh22Noch keine Bewertungen

- 2inch RICHTER Ball ValveDokument28 Seiten2inch RICHTER Ball ValverobertNoch keine Bewertungen

- SC Fepa Sa Bârlad: Installation, Operation&Maintenance Ball Valve Type RSD-BBDokument15 SeitenSC Fepa Sa Bârlad: Installation, Operation&Maintenance Ball Valve Type RSD-BBtoader56Noch keine Bewertungen

- KDC InstallationDokument2 SeitenKDC InstallationJIANG LUNoch keine Bewertungen

- Katalog p310 - 07Dokument7 SeitenKatalog p310 - 07agustinusidNoch keine Bewertungen

- Worcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance InstructionsDokument14 SeitenWorcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance Instructionsافضح الكوارثNoch keine Bewertungen

- Hydraulic DampersDokument23 SeitenHydraulic DampersRubenAntezanaVerdeNoch keine Bewertungen

- Frialen Ai FriatecDokument32 SeitenFrialen Ai FriatecOscar MoralNoch keine Bewertungen

- Series 270 & 270h RegulatorDokument12 SeitenSeries 270 & 270h RegulatorSergio Gaete CovarrubiasNoch keine Bewertungen

- Safety Relief ValvesDokument52 SeitenSafety Relief ValvesHamza NoumanNoch keine Bewertungen

- Crane - Series.rs Center LineDokument23 SeitenCrane - Series.rs Center LinenedwestNoch keine Bewertungen

- VDLSE502 - VRB2-3 - Danfoss VentiliDokument8 SeitenVDLSE502 - VRB2-3 - Danfoss VentilizigicsasaNoch keine Bewertungen

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFDokument7 Seiten52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeNoch keine Bewertungen

- Globe Shut-Off or Control V Alve: Series HV, HVRDokument16 SeitenGlobe Shut-Off or Control V Alve: Series HV, HVRSenthilNoch keine Bewertungen

- Model BFV-N Butterfly Valve Grooved End Technical Data General DescriptionDokument4 SeitenModel BFV-N Butterfly Valve Grooved End Technical Data General DescriptionPatricio SabettaNoch keine Bewertungen

- Instalación y Mantenimiento de Válvulas RotativasDokument4 SeitenInstalación y Mantenimiento de Válvulas RotativasGustavo León CarreraNoch keine Bewertungen

- Mantenimiento Valvulas LVFDokument45 SeitenMantenimiento Valvulas LVFmelimonteNoch keine Bewertungen

- BFV STD - SpecdamperDokument39 SeitenBFV STD - Specdamperkselvan_1Noch keine Bewertungen

- 80 125 Vertical Flue InstructionsDokument16 Seiten80 125 Vertical Flue Instructionstrabant424Noch keine Bewertungen

- EN Stubbe DN8PN10Dokument16 SeitenEN Stubbe DN8PN10babuliuNoch keine Bewertungen

- DCV Spirax PDFDokument2 SeitenDCV Spirax PDFVaitheeswaran PalaniNoch keine Bewertungen

- Installation, Operating and Maintenance Manual Gas Pressure Regulator Type SBV 11Dokument6 SeitenInstallation, Operating and Maintenance Manual Gas Pressure Regulator Type SBV 11Mohamed El Hadi RedjaimiaNoch keine Bewertungen

- SV 3 Safety ValveDokument7 SeitenSV 3 Safety ValveWanderley FonsecaNoch keine Bewertungen

- GF System Specification PVC-U BS InchDokument14 SeitenGF System Specification PVC-U BS InchDale CokleyNoch keine Bewertungen

- And Manufacturer's Declaration As Per Directive 98/37/ECDokument8 SeitenAnd Manufacturer's Declaration As Per Directive 98/37/ECtree_99Noch keine Bewertungen

- Instruction Manual Air Compressor HL2/140Dokument12 SeitenInstruction Manual Air Compressor HL2/140juanpabloizuNoch keine Bewertungen

- Vitodens 200 W LowLossHeaderDokument8 SeitenVitodens 200 W LowLossHeaderdupangNoch keine Bewertungen

- Valves SpecificationDokument13 SeitenValves Specificationkselvan_1Noch keine Bewertungen

- Accumulator Block - Hydac - SAFDokument26 SeitenAccumulator Block - Hydac - SAFBenAbrahamSamuelNoch keine Bewertungen

- Topworx Position SwitchDokument60 SeitenTopworx Position SwitchsarkaftNoch keine Bewertungen

- FlowCon EVC Instr USDokument4 SeitenFlowCon EVC Instr USb82monicaNoch keine Bewertungen

- Birkett Safety Relief Valves: Simply Photocopy and Fax To Us For More Information On..Dokument52 SeitenBirkett Safety Relief Valves: Simply Photocopy and Fax To Us For More Information On..Mark RomeroNoch keine Bewertungen

- Operation-And Maintenance Manual For Explosion Relief Valves Type EVODokument18 SeitenOperation-And Maintenance Manual For Explosion Relief Valves Type EVOFlor De Maria Serrano100% (2)

- PFS Mcquay Manual 01 PDFDokument30 SeitenPFS Mcquay Manual 01 PDFevrimk75% (4)

- Sisto-C: 1. InstallationDokument1 SeiteSisto-C: 1. InstallationEric LarrondoNoch keine Bewertungen

- Operating and Maintenance Norms For Cylinders and ServocylindersDokument5 SeitenOperating and Maintenance Norms For Cylinders and ServocylindersJesus N RodriguezNoch keine Bewertungen

- TIB-722-GB-0711 2-Way Control Valves With Pneum - Actuator PDFDokument58 SeitenTIB-722-GB-0711 2-Way Control Valves With Pneum - Actuator PDFnguyenvanhai19031981Noch keine Bewertungen

- Crane Katalog-RS AngDokument29 SeitenCrane Katalog-RS AngNNNoch keine Bewertungen

- Trokraki On - Off VentilDokument12 SeitenTrokraki On - Off VentilAdvokat HadziTonicNoch keine Bewertungen

- Liquid SpearatorDokument1 SeiteLiquid SpearatorPaweł HejmowskiNoch keine Bewertungen

- Eco LineDokument4 SeitenEco LinePaweł HejmowskiNoch keine Bewertungen

- Calculations RefrDokument6 SeitenCalculations RefrPaweł HejmowskiNoch keine Bewertungen

- Nuova Fima MGS18 - 100150mmDokument2 SeitenNuova Fima MGS18 - 100150mmPaweł HejmowskiNoch keine Bewertungen

- Henry - 022 Safety ValvesDokument3 SeitenHenry - 022 Safety ValvesPaweł HejmowskiNoch keine Bewertungen

- Nuova Fima MGS10 - 100150mmDokument2 SeitenNuova Fima MGS10 - 100150mmPaweł HejmowskiNoch keine Bewertungen

- Henry Shut Off ValvesDokument1 SeiteHenry Shut Off ValvesPaweł HejmowskiNoch keine Bewertungen

- Pressure Relief Valves Standard Range: Safety DevicesDokument2 SeitenPressure Relief Valves Standard Range: Safety DevicesPaweł HejmowskiNoch keine Bewertungen

- Tempress 1-41GB-Duplex-Pressure-Gauge-A11 PDFDokument1 SeiteTempress 1-41GB-Duplex-Pressure-Gauge-A11 PDFPaweł HejmowskiNoch keine Bewertungen

- Nuova Fima MGS18 - 63mmDokument2 SeitenNuova Fima MGS18 - 63mmPaweł HejmowskiNoch keine Bewertungen

- Nuova Fima MGS10 - 63mm PDFDokument2 SeitenNuova Fima MGS10 - 63mm PDFPaweł HejmowskiNoch keine Bewertungen

- Grasso Self-Limiting Automatic Purger Ce Ped: Installation and Maintenance Manual (IMM) 0089293Dokument28 SeitenGrasso Self-Limiting Automatic Purger Ce Ped: Installation and Maintenance Manual (IMM) 0089293Paweł HejmowskiNoch keine Bewertungen

- Danfoss DKRCC - PD.EK0.A8.02 - SG - MS PDFDokument9 SeitenDanfoss DKRCC - PD.EK0.A8.02 - SG - MS PDFPaweł HejmowskiNoch keine Bewertungen

- Danfoss Gas Detection Sensors TEM STS Rev 04Dokument1 SeiteDanfoss Gas Detection Sensors TEM STS Rev 04Paweł HejmowskiNoch keine Bewertungen

- Danfoss Filtry Akcesoria PYFN0A402 - FIA 15-200Dokument1 SeiteDanfoss Filtry Akcesoria PYFN0A402 - FIA 15-200Paweł HejmowskiNoch keine Bewertungen

- Alfa Laval Fan Evap ERC00146ENDokument2 SeitenAlfa Laval Fan Evap ERC00146ENPaweł HejmowskiNoch keine Bewertungen

- Danfoss DKRCI - PD.HQ0.A3.02 - OFVDokument12 SeitenDanfoss DKRCI - PD.HQ0.A3.02 - OFVPaweł HejmowskiNoch keine Bewertungen

- Danfoss DKRCI - PD.GD0.A4.02 - AKS38Dokument8 SeitenDanfoss DKRCI - PD.GD0.A4.02 - AKS38Paweł HejmowskiNoch keine Bewertungen

- Danfoss SCA 50-125 Spara Parts PYFL0A202 - SCA 15-40Dokument1 SeiteDanfoss SCA 50-125 Spara Parts PYFL0A202 - SCA 15-40Paweł HejmowskiNoch keine Bewertungen

- Danfoss ICS50 - ICLX50 - Repair Kit - 027H5015Dokument2 SeitenDanfoss ICS50 - ICLX50 - Repair Kit - 027H5015Paweł HejmowskiNoch keine Bewertungen

- Heat Exchanger Type HE: Data SheetDokument5 SeitenHeat Exchanger Type HE: Data SheetPaweł HejmowskiNoch keine Bewertungen

- Solvay R134aDokument29 SeitenSolvay R134aPaweł HejmowskiNoch keine Bewertungen

- SP-Chapter 14 PresentationDokument83 SeitenSP-Chapter 14 PresentationLoiDa FloresNoch keine Bewertungen

- (20836104 - Artificial Satellites) Investigation of The Accuracy of Google Earth Elevation DataDokument9 Seiten(20836104 - Artificial Satellites) Investigation of The Accuracy of Google Earth Elevation DataSunidhi VermaNoch keine Bewertungen

- The Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDokument30 SeitenThe Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDusen VanNoch keine Bewertungen

- CATaclysm Preview ReleaseDokument52 SeitenCATaclysm Preview ReleaseGhaderalNoch keine Bewertungen

- CFD Turbina Michell BankiDokument11 SeitenCFD Turbina Michell BankiOscar Choque JaqquehuaNoch keine Bewertungen

- Jul - Dec 09Dokument8 SeitenJul - Dec 09dmaizulNoch keine Bewertungen

- Vitamins - CyanocobalaminDokument12 SeitenVitamins - CyanocobalaminK PrashasthaNoch keine Bewertungen

- ADokument54 SeitenActyvteNoch keine Bewertungen

- Song Book Inner PagesDokument140 SeitenSong Book Inner PagesEliazer PetsonNoch keine Bewertungen

- Boom-Block Gambit: Redemption'S RiseDokument44 SeitenBoom-Block Gambit: Redemption'S RiseNone OfyourbuisnessNoch keine Bewertungen

- Mathmatcs Joint Form TwoDokument11 SeitenMathmatcs Joint Form TwoNurudi jumaNoch keine Bewertungen

- Csir Life Sciences Fresh Instant NotesDokument4 SeitenCsir Life Sciences Fresh Instant NotesAlps Ana33% (3)

- Conducting Focus GroupsDokument4 SeitenConducting Focus GroupsOxfam100% (1)

- John DrydenDokument3 SeitenJohn DrydenDunas SvetlanaNoch keine Bewertungen

- Alaba Adeyemi AdediwuraDokument12 SeitenAlaba Adeyemi AdediwuraSchahyda ArleyNoch keine Bewertungen

- Simon Ardhi Yudanto UpdateDokument3 SeitenSimon Ardhi Yudanto UpdateojksunarmanNoch keine Bewertungen

- Sample CVFormat 1Dokument2 SeitenSample CVFormat 1subham.sharmaNoch keine Bewertungen

- Design of Reinforced Cement Concrete ElementsDokument14 SeitenDesign of Reinforced Cement Concrete ElementsSudeesh M SNoch keine Bewertungen

- Contemporary Strategic ManagementDokument2 SeitenContemporary Strategic ManagementZee Dee100% (1)

- 11.3.1 Some Special CasesDokument10 Seiten11.3.1 Some Special CasesSiddharth KishanNoch keine Bewertungen

- 220245-MSBTE-22412-Java (Unit 1)Dokument40 Seiten220245-MSBTE-22412-Java (Unit 1)Nomaan ShaikhNoch keine Bewertungen

- Importance of Skill Based Education-2994Dokument5 SeitenImportance of Skill Based Education-2994João Neto0% (1)

- HUMSS - Introduction To World Religions & Belief Systems CGDokument13 SeitenHUMSS - Introduction To World Religions & Belief Systems CGAliuqus SirJasper89% (18)

- Module 6 Metal Properties and Destructive TestingDokument46 SeitenModule 6 Metal Properties and Destructive TestingMiki Jaksic100% (6)

- SEILDokument4 SeitenSEILGopal RamalingamNoch keine Bewertungen

- G10 Lesson2 DLPDokument13 SeitenG10 Lesson2 DLPAngeles, Mark Allen CNoch keine Bewertungen

- Culture 2007 2013 Projects Overview 2018-03-18Dokument133 SeitenCulture 2007 2013 Projects Overview 2018-03-18PontesDeboraNoch keine Bewertungen

- 3D Printing & Embedded ElectronicsDokument7 Seiten3D Printing & Embedded ElectronicsSantiago PatitucciNoch keine Bewertungen

- Perdarahan Uterus AbnormalDokument15 SeitenPerdarahan Uterus Abnormalarfiah100% (1)

- Generation III Sonic Feeder Control System Manual 20576Dokument32 SeitenGeneration III Sonic Feeder Control System Manual 20576julianmataNoch keine Bewertungen