Beruflich Dokumente

Kultur Dokumente

Chapter 2 X-Ray Diffraction PDF

Hochgeladen von

Mina SamyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chapter 2 X-Ray Diffraction PDF

Hochgeladen von

Mina SamyCopyright:

Verfügbare Formate

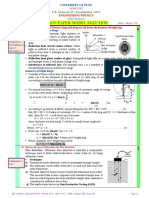

Chapter 2 Determination of Crystal Structure

2

DETERMINATION OF

CRYSTAL

STRUCTURE

2.1 METHODS OF DETERMINING CRYSTAL STRUCTURE

Studying the structure of crystals is very useful in theoretical and practical applications.

We mean by crystal structure that corresponding to relationship between atomic planes in

the crystal and determination of the lattice parameters. The following methods are widely

used for determining crystal structure

(i) X-ray diffraction: This includes the following methods

(a) Bragg’s spectrometer method

(b) Laue’s method

(c) Powder method

(ii) Electron diffraction and

(iii) Neutron diffraction

2.2 X-RAY DIFFRACTION

X-rays provide a powerful tool for the study of crystal structure. X-rays, being

electromagnetic radiations, also undergo the phenomenon of diffraction as observed for

visible light. The ordered arrangement of atoms in a crystal with interatomic spacing of the

order of few angstroms behaves like a three-dimensional diffraction grating for X-rays.

One can easily verify this. Let us consider sodium metal whose density equals 1.013 ×

103 kg/m3 and molecular weight, M is 23 respectively. The structure of sodium is BCC and

hence the number of atoms/unit volume = 2. The crystal density , accordingly the

Solid State Physics 32

Chapter 2 Determination of Crystal Structure

cell constant is ( ) So, we have

where NA is Avogadro’s number (= 6.023 × 1026 atom/kmol).

Thus the wavelength of the radiation required for diffraction by sodium metal is of the

order of a few angstroms which is clearly in the range of X-rays.

BRAGG’S LAW

In 1912, Laue suggested that a crystal which consisted of a three-dimensional array of

regularly spaced atoms could serve as a grating. On the suggestion of Laue, his associates

succeeded in diffracting X-rays by passing them through a thin crystal of Zinc blende. The

diffraction pattern obtained by them consists of a central spot and a series of spots

arranged in a definite pattern around the central spot. This symmetrical pattern of spots is

known as Laue pattern.

The explanation for this was given by Bragg. According to Bragg, the spots are produced

due to the reflection of some of the incident X-rays from the various sets of parallel crystal

planes (called as Bragg’s planes), which contain a large number of atoms.

Consider a ray PA reflected at atom A in the direction AR from plane I and another ray QB

reflected at another atom B in the direction BS (Fig. 2.1).

The two reflected rays AR and BS will be in phase or out of phase depending on the path

difference.

When the path difference, CB + BD is a whole wavelength , or multiple of whole

wavelength (n ), then the two rays will reinforce each other and produce an intense spot

due to constructive interference.

Solid State Physics 33

Chapter 2 Determination of Crystal Structure

Fig. 2.1 Reflection of X-rays from lattice planes in a crystal

Obviously, the condition of reinforcement, i.e. constructive interference is:

CB + BD = n

CB = BD = d sin

where is the angle between the incident ray and the planes of reflection and called as

glancing angle. Therefore, we have

2d sin =n

where d is the interplanar spacing of planes, i.e. distance between the same set of planes

and n = 1, 2, 3,. . . stand for first order, second order, third order maxima respectively.

This equation is known as Bragg’s law. We must note that the Bragg’s reflection can

occur only for ≤ 2d.

The directions along which the maxima are observed can be obtained from Bragg’s law,

by giving different values of ; i.e.,

As the order of spectrum increases, the intensity goes on decreasing.

Solid State Physics 34

Chapter 2 Determination of Crystal Structure

We must note that the Bragg equation is not limited to atomic planes parallel to the crystal

surface; it is applied to all planes in the crystal.

BRAGG’S X-RAY SPECTROMETER

The apparatus used in X-ray crystal diffraction is denoted by diffractometer as shown in

Fig. 2.2.

The X-rays from the target T of an X-ray tube pass through two slits S1 and S2 in thick

lead sheets. They then fall on the single crystal D mounted on a turn table. The crystal is

rotated by means of the turn-table so as to increase the glancing angle at which X-rays

are incident at the exposed face of the crystal. The position of the crystal can be read with

the help of the vernier v and a circular scale. An ionisation chamber I is mounted on an

arm which can rotate about the same axis as that of the crystal table. The ionisation

chamber or photographic plate is used for measuring the intensities of reflected rays.

Fig. 2.2 Bragg’s X-ray spectrometer

By measuring glancing angles ( ) at which reflection occurs, one can determine the

interplanar spacings knowing the wavelength of X-rays according to Bragg equation: 2d

sin =n .

As an example, consider X-ray diffraction from rock salt (NaCl) cubic crystal, the

Solid State Physics 35

Chapter 2 Determination of Crystal Structure

variation of ionization current against glancing angle is shown in Fig. 2.3.

Fig. 2.3 Variation of ionization current with glancing angle

This curve is obtained when X-rays from a tube containing a platinum target were

reflected by the crystal. The experimental results have shown that the first order reflection

maxima occurred at 5.9°, 8.4° and 5.2° for (100), (110) and (111) planes respectively.

For first order reflection, n = 1 and hence

One can follow this procedure for other crystals.

Bragg’s equation can be used to calculate the lattice constant. Figure 2.4 shows the

diffraction pattern of tungsten metal. The numbers on the peak are the Miller indices of the

planes which produce that peak. One can compute the interplanar spacings by measuring

the value of and using Bragg’s law

Solid State Physics 36

Chapter 2 Determination of Crystal Structure

In cubic lattice

√

Then

√

The wavelength of the X-ray value is known, for first order diffraction n = 1, and from

the X-ray diffraction chart (indicated from Fig. 2.4) we can determine the angle at

layer (h k l).

Therefore the lattice constant a for the investigated sample can be determined.

Fig. 2.4 Diffraction pattern intensity at various angle

LAUE’S METHOD

This is one of the principal methods to study X-ray diffraction and to determine crystal

structure. Fig. 2.4 shows Lau apparatus. In this method, a single crystal is placed in the

path of X-rays beam and the glancing angle is kept constant. Continuous spectra of X-

ray, having wide range of wavelengths, are allowed to fall on the crystal at 90°on the plane

of the crystal. Each set of crystal plane d selects appropriate value of wavelength and

produces a spot which fulfills Bragg’s law:

2d sin =n

When primary rays are allowed to pass through the crystal, they produce a black spot at B

Solid State Physics 37

Chapter 2 Determination of Crystal Structure

(Fig. 2.5) on photographic plate PP. Different Wavelengths are included in the primary X-

rays and hence they will produce spots around this central spot, which are less

pronounced as depicted in Fig. 2.6.

Fig. 2.5 Laue’s Method

Let ab represent the position of one of the possible Bragg’s plane, the corresponding

angle and A any spot (other than central spot) on PP. From the triangle OAOB, one finds

AB = R tan 2 . Knowing AB and R, one can find for the corresponding plane.

Fig. 2.6 Laue pattern for a crystal

POWDER METHOD

This method is quite useful when single crystals of large size are not available. The sample

used is in the form of a fine powder containing a large number of tiny crystallites with

random orientations. The powder is placed in a capillary tube. This powder specimen is

Solid State Physics 38

Chapter 2 Determination of Crystal Structure

mounted at the centre around which a strip of circular photographic film is positioned (Fig.

2.7).

A collimated beam of monochromatic X-rays strikes the specimen through a small hole.

Let us consider that the incident beam make an angle with a set of parallel crystal plane.

Fig. 2.7 Powder method

If Bragg condition is satisfied, then there will be reflection. Since there are a large number

of randomly oriented crystals in the powder sample and hence there are several possible

orientations of this set of planes of same angle . The reflected rays will not be in the form

of parallel beam but they will lie on the surface of a cone with its apex at the sample and

the semivertical angle 2 (Fig. 2.8). Different cones are observed for different sets of d

and for a particular value of n, and also for different combinations of and n for a

particular value of d (Fig. 2.9).

Fig. 2.8 A cone produced by reflection of X-rays in powder method

Solid State Physics 39

Chapter 2 Determination of Crystal Structure

Fig. 2.9 The X-ray powder diffraction pattern for cubic crystal

2.3 ELECTRON AND NEUTRON DIFFRACTION

Since waves are diffracted by a crystal, we can also use electrons and neutrons instead of

X-rays, provided the wavelengths of matter waves associates with these particles are in the

range of 1 to 10 Å.

Wavelength for neutron

Where is in Angstroms and E in eV. Thus the energy of a neutron of wavelength of 1 Å

is = 0.08 eV. The thermal neutrons in a atomic reactor have the energy = 0.08 eV and

hence can be used for the study of crystal diffraction.

We must note that there are many differences between neutron diffraction X-ray

diffraction. X-rays are scattered by electrons, whereas neutrons are scattered by nuclei.

Using this property of neutrons, one can study many low atomic weight elements by

neutron diffraction where X-rays are incapable of giving precise results.

Solid State Physics 40

Chapter 2 Determination of Crystal Structure

Wavelength for electron

where is in Angstroms and E is in kilo eV.

Like X-rays or neutrons, electrons can also be used. However, the electrons are much

more easily scattered and hence the penetration depth is small. This is why electron

diffraction method is used in surface studies-bonds, defects, energy states, etc.

2.4 RECIPROCAL LATTICE

We have seen that the diffraction of X-rays occurs from various sets of parallel planes

having different orientations (slopes) and interplanar spacings. In certain situations

involving the presence of a number of sets of parallel planes with different orientations, it

becomes difficult to visualize all such planes because of their two-dimensional nature. To

solve the problem, Ewald introduced a new type of lattice known as the reciprocal lattice.

The idea underlying the development was that each set of parallel planes could be

represented by a normal to these planes having length equal to the reciprocal of the

interplanar spacing. Thus the direction of each normal represents the orientation of the

corresponding set of parallel planes and its length is proportional to the reciprocal of the

interplanar spacing. These points form a regular arrangement which is called a reciprocal

lattice. One can construct a reciprocal lattice to a direct lattice using the following

procedure:

(i) Take origin at some arbitrary point and draw normals to every set of parallel planes of

the direct lattice

(ii) Take length of each normal equal to the reciprocal of the interplanar spacing for the

corresponding set of planes. The terminal points of these normals form the

Solid State Physics 41

Chapter 2 Determination of Crystal Structure

reciprocal lattice

Let us consider, as an example for the construction of reciprocal lattice, the unit cell of a

monoclinic crystal looking along its unique axis, i.e. c-axis.

For simplicity, we may consider planes belonging to a single zone. This makes the

normal to all parallel planes belonging to the zone axis, i.e., normal to the c-axis.

Fig. 2.10 Graphical construction of two dimensional reciprocal lattice

In Fig. 2.10, we can see that the zone axis lies perpendicular to the plane of the diagram

and hence all normals to the parallel planes of the family of the zone will lie in the plane

of the diagram. Figure 2.10 also shows the edge views of four (h k l) planes, viz., (100),

(110), (120) and (010) all belonging to [001] zone. We must note that the normals to the

family of planes (100), (200), (300) etc. are parallel. Further d100 = 2d200 = 3dS00 =

4d400 etc.

Obviously, while

Solid State Physics 42

Chapter 2 Determination of Crystal Structure

where K is a scale factor chosen for the construction of the reciprocal lattice. Clearly, the

distance of the reciprocal lattice point representing the set of parallel planes (nh 0 0) from

the origin will be n times greater than the distance of the reciprocal lattice point from the

origin representing the set of parallel planes (300) will be at a distance from the origin

equal to three times the distance of the reciprocal lattice point representing the set of

parallel planes (100).

In reciprocal lattice, it is the convention to represent the reciprocal lattice point

representing the set of parallel planes with Miller indices (h, k l) by the same Miller

indices without the parenthesis. We can see in Fig. 2.10 that the reciprocal lattice points

representing the set of parallel planes (100), (200), (300) etc . . ., are indicated by 100,

200, 300 etc . . . .

We have taken the planes belonging to [001] zone and after plotting the reciprocal lattice

points of all the (h k o) planes, we obtained a two dimensional lattice (Fig. 2.10). A

reciprocal lattice vector, , is defined as a vector having magnitude equal to the

reciprocal of the interplanar spacing and direction coinciding with normal to (h k l)

planes. Thus, we have

where nˆ is the unit vector normal to the (h k l) planes.

Denoting the fundamental reciprocal vectors , and by a*, b* and c*

respectively, one obtains

⃑

⃑⃑⃑⃑

⃑

⃑⃑⃑⃑

⃑

Solid State Physics 43

Chapter 2 Determination of Crystal Structure

⃑

⃑⃑⃑

⃑

where ⃑ is the volume of the direct cell.

Solid State Physics 44

Chapter 2 Determination of Crystal Structure

2.5 PROBLEMS

Problem 2.1 Determine the interplanar spacing when a beam of X-ray of wavelength 1.54

Å is directed towards the crystal at angle 20.3° to the atomic plane.

Problem 2.2 X-rays with wavelength of 0.58 Å are used for calculating d200 in nickel. The

reflection angle is 9.5°. What is the size of unit cell?

Problem 2.3 Calculate the Bragg angle if (111) planes of a cube (a = 3.57 Å) crystal are

exposed to X-rays (wavelength = 1.54 Å)

Problem 2.4 For a certain BCC crystal, the (110) plane has a separation of 1.181 Å. These

planes are indicated with X-ray of wavelength 1.540 Å. Show that the maximum order of

the Bragg’s reflection that can be observed is n = 1.

Problem 2.5 The glancing angle of 10° is observed in first order Bragg’s reflection. Show

that the angle for 3rd order reflection is 31.S9°.

Problem 2.6 A diffraction pattern of a cubic crystal of lattice parameter a = 3.16 Å is

obtained with a monochromatic X-ray beam of wavelength 1.54 Å. The first line on this

pattern was observed to have = 20.3°. Obtain the interplanar spacing and Miller

indices of the reflecting plane.

Problem 2.7 Determine interatomic spacing when glancing angle of 30° is observed

during first order reflection in a crystal having Miller indices as (111). The Wavelength of

X-rays is 2 Å.

Solid State Physics 45

Das könnte Ihnen auch gefallen

- 10 X-Ray DiffractionDokument8 Seiten10 X-Ray DiffractionProf.Dr.Mohamed Fahmy Mohamed Hussein100% (1)

- Electron Beam-Specimen Interactions and Simulation Methods in MicroscopyVon EverandElectron Beam-Specimen Interactions and Simulation Methods in MicroscopyNoch keine Bewertungen

- XRD - Materials Science Refresher CourseDokument16 SeitenXRD - Materials Science Refresher CourseAnonymous sGHvSUoNoch keine Bewertungen

- Advances in Structure Research by Diffraction Methods: Fortschritte der Strukturforschung mit BeugungsmethodenVon EverandAdvances in Structure Research by Diffraction Methods: Fortschritte der Strukturforschung mit BeugungsmethodenW. HoppeNoch keine Bewertungen

- Bragg's Law-TwinkleGraceDasDokument5 SeitenBragg's Law-TwinkleGraceDasgrinneNoch keine Bewertungen

- X-ray Absorption Spectroscopy for the Chemical and Materials SciencesVon EverandX-ray Absorption Spectroscopy for the Chemical and Materials SciencesNoch keine Bewertungen

- X - Ray Diffraction (XRD)Dokument26 SeitenX - Ray Diffraction (XRD)Ajith KumarNoch keine Bewertungen

- X-Ray Diffraction MethodsDokument24 SeitenX-Ray Diffraction MethodsNandhan100% (1)

- 3 LectDokument8 Seiten3 LectaliNoch keine Bewertungen

- 5-X Ray DiffractionDokument24 Seiten5-X Ray DiffractionYagnesh Rohit100% (1)

- Tugas 1 Difraksi BraggDokument37 SeitenTugas 1 Difraksi BraggRachmad Almi PutraNoch keine Bewertungen

- Braggs Law ChemistryDokument14 SeitenBraggs Law ChemistrySaime IlltutmishNoch keine Bewertungen

- X RaydiffractionDokument27 SeitenX Raydiffractionboyapati venupriyaNoch keine Bewertungen

- Https - Myguru - Upsi.edu - My - Documents - 2019 - Courses - SFT3053 - Material - K00926 - 20191001220515 - Chapter 2 FLS PDFDokument46 SeitenHttps - Myguru - Upsi.edu - My - Documents - 2019 - Courses - SFT3053 - Material - K00926 - 20191001220515 - Chapter 2 FLS PDFNurazin RizalNoch keine Bewertungen

- Metal Detection by XRDDokument29 SeitenMetal Detection by XRDDeb RathNoch keine Bewertungen

- Unit 4 Structure Unfolding TechniquesDokument29 SeitenUnit 4 Structure Unfolding TechniquesvijayNoch keine Bewertungen

- Basics of X-Ray DiffractionDokument13 SeitenBasics of X-Ray Diffractionleizar_death64Noch keine Bewertungen

- X Ray Diffraction PDFDokument9 SeitenX Ray Diffraction PDFYousef Adel HassanenNoch keine Bewertungen

- X-Ray Diffraction - Final Version PDFDokument30 SeitenX-Ray Diffraction - Final Version PDFMuthu KumarNoch keine Bewertungen

- XRD BasicsDokument5 SeitenXRD Basics777894292Noch keine Bewertungen

- 04 X-Ray DiffractionDokument9 Seiten04 X-Ray DiffractionSampath KumarNoch keine Bewertungen

- X-Ray Diffraction (XRD)Dokument31 SeitenX-Ray Diffraction (XRD)Yulianto NugrohoNoch keine Bewertungen

- 2021 MM 06Dokument4 Seiten2021 MM 06Ayyan AnwarNoch keine Bewertungen

- Electron Diffraction2Dokument8 SeitenElectron Diffraction2Marcos Denilson Rodrigues OliveiraNoch keine Bewertungen

- Assignment PH 101 SCDokument3 SeitenAssignment PH 101 SCAbhishekBhowmickNoch keine Bewertungen

- Leitura 4Dokument6 SeitenLeitura 4Alexandre BezerraNoch keine Bewertungen

- X-Ray DiffractionDokument6 SeitenX-Ray DiffractionAhmed Al-AwamiNoch keine Bewertungen

- Rigaku Journal 32-2-35-43Dokument9 SeitenRigaku Journal 32-2-35-43Acácio CruzNoch keine Bewertungen

- 8 XRDDokument14 Seiten8 XRDWahyu Eko PrasetyoNoch keine Bewertungen

- X-Ray Diffraction and The Bragg EquationDokument3 SeitenX-Ray Diffraction and The Bragg EquationJorge Andres Hernandez GaleanoNoch keine Bewertungen

- Chapter 2 EssayDokument4 SeitenChapter 2 EssayarjunNoch keine Bewertungen

- BraggsDokument5 SeitenBraggsJeffrey PiggottNoch keine Bewertungen

- Lecture 10 - 0Dokument69 SeitenLecture 10 - 0yhjklNoch keine Bewertungen

- Reciprocal LatticeDokument9 SeitenReciprocal LatticeSREERAGHAV KNoch keine Bewertungen

- Nanoparticle LabDokument12 SeitenNanoparticle Labglen-576661Noch keine Bewertungen

- Solid State Structures of Simple ABDokument24 SeitenSolid State Structures of Simple ABAnene Augustine IkechukwuNoch keine Bewertungen

- XXXRDDokument5 SeitenXXXRDAmir AkmalNoch keine Bewertungen

- Crystal Structures and X-Ray DiffractionDokument5 SeitenCrystal Structures and X-Ray DiffractionV V Satyanarayana PasupuletiNoch keine Bewertungen

- Bragg's Law of X-Ray DiffractionDokument4 SeitenBragg's Law of X-Ray Diffractionrajendra kumar . rayalaNoch keine Bewertungen

- Laue Method AssignmentDokument26 SeitenLaue Method AssignmentAmir AliNoch keine Bewertungen

- Chapter 2Dokument75 SeitenChapter 2蘇翊愷Noch keine Bewertungen

- XRD TechnicsDokument90 SeitenXRD TechnicsAloke VermaNoch keine Bewertungen

- XRD - Ag NPGDokument90 SeitenXRD - Ag NPGUdy Maudy100% (1)

- X-Ray Diffraction (XRD) : A Seminar Talk OnDokument18 SeitenX-Ray Diffraction (XRD) : A Seminar Talk OnArraafi FadhillahNoch keine Bewertungen

- Multidirectionally Distributed Feedback Photonic Crystal LasersDokument8 SeitenMultidirectionally Distributed Feedback Photonic Crystal LasersJohn pengNoch keine Bewertungen

- XRD Theory PresentationDokument47 SeitenXRD Theory Presentationsimongerardgerona50% (2)

- XRD Lab ReportDokument3 SeitenXRD Lab ReportArman Boroomand67% (3)

- XRD 2023Dokument90 SeitenXRD 2023John Gerald OdhiamboNoch keine Bewertungen

- Solid State ChemistryDokument36 SeitenSolid State ChemistrySoumya BullaNoch keine Bewertungen

- Electron Diffraction Lab Report - KatzerDokument7 SeitenElectron Diffraction Lab Report - Katzerapi-489811472Noch keine Bewertungen

- X Ray DiffractionDokument12 SeitenX Ray DiffractionSiddraKhalidNoch keine Bewertungen

- Coherent Bremsstrahlung in A Bent CrystalDokument15 SeitenCoherent Bremsstrahlung in A Bent CrystalBayer MitrovicNoch keine Bewertungen

- What Is Bragg's Law?Dokument3 SeitenWhat Is Bragg's Law?suba lakshmiNoch keine Bewertungen

- Fundamentals X-Ray DiffractionDokument14 SeitenFundamentals X-Ray DiffractionArif MamonNoch keine Bewertungen

- Fiting FeSb2Dokument39 SeitenFiting FeSb2Syed Abdul Qadir GilaniNoch keine Bewertungen

- Chem 406: Biophysical Chemistry Lecture 7: Structure Determination by X-Ray CrystallographyDokument11 SeitenChem 406: Biophysical Chemistry Lecture 7: Structure Determination by X-Ray CrystallographyPuspa BhattaraiNoch keine Bewertungen

- Preparation of Dichlorobis - (Ethylenediamine) Cobalt (Iii) Chloride and Characterization With Single Crystal X-Ray DiffractionDokument7 SeitenPreparation of Dichlorobis - (Ethylenediamine) Cobalt (Iii) Chloride and Characterization With Single Crystal X-Ray DiffractionJ Mora GañanNoch keine Bewertungen

- SPPU PHYSICS QP Solution 2012-13 sem-IIDokument8 SeitenSPPU PHYSICS QP Solution 2012-13 sem-IIHemantNoch keine Bewertungen

- Exercises - ReciprocalSpaces and XRDDokument2 SeitenExercises - ReciprocalSpaces and XRDtackyjc0% (1)

- Eco-Friendly Polymer Composites For Green Packaging Future Vision PDFDokument10 SeitenEco-Friendly Polymer Composites For Green Packaging Future Vision PDFAncuţa-IonelaPartinNoch keine Bewertungen

- Me22 E02 Tumangan M2a2Dokument3 SeitenMe22 E02 Tumangan M2a2Jihoo JungNoch keine Bewertungen

- Agua Purificada PH EurDokument2 SeitenAgua Purificada PH Eursarasa100% (1)

- Gamma RayDokument5 SeitenGamma RayDenisha Betaci GultomNoch keine Bewertungen

- Welding For Design EngineersDokument518 SeitenWelding For Design EngineersHumberto Magno FukeNoch keine Bewertungen

- Volume 5Dokument25 SeitenVolume 5Gerald See TohNoch keine Bewertungen

- Physiol PH v25n3p189 enDokument4 SeitenPhysiol PH v25n3p189 enJin SniperNoch keine Bewertungen

- Liquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Dokument12 SeitenLiquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Edu CordonNoch keine Bewertungen

- Science Focus 4 CBDokument343 SeitenScience Focus 4 CBmusic_stefan98100% (2)

- Phytochemical Studies and Qualitative Analysis by TLC of Murraya Koenigii Bark ExtractDokument6 SeitenPhytochemical Studies and Qualitative Analysis by TLC of Murraya Koenigii Bark ExtractBaru Chandrasekhar Rao0% (1)

- 坦客人哦Dokument9 Seiten坦客人哦Ajay SinghNoch keine Bewertungen

- Citrus Bioflavanoids 60% (FEMAS) : Cambridge CommoditiesDokument16 SeitenCitrus Bioflavanoids 60% (FEMAS) : Cambridge Commoditiesibad muhammedNoch keine Bewertungen

- Ionic and Covalent BondingDokument51 SeitenIonic and Covalent BondingBilly STEVENoch keine Bewertungen

- Claytone Af TDS (En)Dokument2 SeitenClaytone Af TDS (En)محمد عزت100% (1)

- Boiler Water Treatment: Product InformationDokument1 SeiteBoiler Water Treatment: Product InformationJunaid Jamil100% (1)

- A Guide To The Language of SteelDokument7 SeitenA Guide To The Language of SteelIwona AnkaNoch keine Bewertungen

- Phytochemical StudyDokument4 SeitenPhytochemical StudyBayanmunkh AltangerelNoch keine Bewertungen

- Bacte Comprehensive ReviewDokument116 SeitenBacte Comprehensive ReviewFaith Theresa OroscoNoch keine Bewertungen

- AgrinosDokument19 SeitenAgrinosAgroteknologi umparNoch keine Bewertungen

- 2022 Selangor Chemistry K2 Set - 2 JawapanDokument14 Seiten2022 Selangor Chemistry K2 Set - 2 JawapanNuan Ting NgNoch keine Bewertungen

- Lab Report - Tensile TestingDokument19 SeitenLab Report - Tensile Testingapi-404653452100% (1)

- CU-ATS Exam Set 1Dokument13 SeitenCU-ATS Exam Set 1suppermarkxNoch keine Bewertungen

- F.4 Acids and Exercise)Dokument69 SeitenF.4 Acids and Exercise)arielshy100% (5)

- Poly 103Dokument20 SeitenPoly 103Sharifah Zulaikha BenYahyaNoch keine Bewertungen

- GR9 NATURAL SC (English) June 2018 Possible AnswersDokument8 SeitenGR9 NATURAL SC (English) June 2018 Possible Answers18118Noch keine Bewertungen

- Gasteiger-2003-Handbook of Chemoinformatics - F PDFDokument1.915 SeitenGasteiger-2003-Handbook of Chemoinformatics - F PDFLuis OzNoch keine Bewertungen

- Waterproofing and Weatherproofing MaterialsDokument37 SeitenWaterproofing and Weatherproofing MaterialsSanjay Areyoukiddingme Somnath50% (2)

- Ugiweb 52492Dokument5 SeitenUgiweb 52492badrNoch keine Bewertungen

- Out of The Fiery Furnace The Impact of Metals On The History ofDokument296 SeitenOut of The Fiery Furnace The Impact of Metals On The History ofLeland Stanford0% (1)

- Air Quality MonitoringDokument43 SeitenAir Quality MonitoringTulika GalaniNoch keine Bewertungen

- A Brief History of Time: From the Big Bang to Black HolesVon EverandA Brief History of Time: From the Big Bang to Black HolesBewertung: 4 von 5 Sternen4/5 (2193)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseVon EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseBewertung: 3.5 von 5 Sternen3.5/5 (69)

- A Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceVon EverandA Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceBewertung: 4 von 5 Sternen4/5 (51)

- Knocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldVon EverandKnocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldBewertung: 3.5 von 5 Sternen3.5/5 (64)

- Giza: The Tesla Connection: Acoustical Science and the Harvesting of Clean EnergyVon EverandGiza: The Tesla Connection: Acoustical Science and the Harvesting of Clean EnergyNoch keine Bewertungen

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessVon EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessBewertung: 4 von 5 Sternen4/5 (6)

- Summary and Interpretation of Reality TransurfingVon EverandSummary and Interpretation of Reality TransurfingBewertung: 5 von 5 Sternen5/5 (5)

- Packing for Mars: The Curious Science of Life in the VoidVon EverandPacking for Mars: The Curious Science of Life in the VoidBewertung: 4 von 5 Sternen4/5 (1395)

- Lost in Math: How Beauty Leads Physics AstrayVon EverandLost in Math: How Beauty Leads Physics AstrayBewertung: 4.5 von 5 Sternen4.5/5 (125)

- The Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismVon EverandThe Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismBewertung: 4 von 5 Sternen4/5 (500)

- Midnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterVon EverandMidnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterBewertung: 4.5 von 5 Sternen4.5/5 (410)

- The Beginning of Infinity: Explanations That Transform the WorldVon EverandThe Beginning of Infinity: Explanations That Transform the WorldBewertung: 5 von 5 Sternen5/5 (60)

- Let There Be Light: Physics, Philosophy & the Dimensional Structure of ConsciousnessVon EverandLet There Be Light: Physics, Philosophy & the Dimensional Structure of ConsciousnessBewertung: 4.5 von 5 Sternen4.5/5 (57)

- Chasing Heisenberg: The Race for the Atom BombVon EverandChasing Heisenberg: The Race for the Atom BombBewertung: 4.5 von 5 Sternen4.5/5 (8)

- The Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldVon EverandThe Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldBewertung: 4.5 von 5 Sternen4.5/5 (54)

- Black Holes: The Key to Understanding the UniverseVon EverandBlack Holes: The Key to Understanding the UniverseBewertung: 4.5 von 5 Sternen4.5/5 (13)

- The Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectVon EverandThe Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectBewertung: 4.5 von 5 Sternen4.5/5 (20)

- Beyond Weird: Why Everything You Thought You Knew about Quantum Physics Is DifferentVon EverandBeyond Weird: Why Everything You Thought You Knew about Quantum Physics Is DifferentBewertung: 4 von 5 Sternen4/5 (25)

- Quantum Physics: What Everyone Needs to KnowVon EverandQuantum Physics: What Everyone Needs to KnowBewertung: 4.5 von 5 Sternen4.5/5 (49)

- The Holographic Universe: The Revolutionary Theory of RealityVon EverandThe Holographic Universe: The Revolutionary Theory of RealityBewertung: 4.5 von 5 Sternen4.5/5 (76)

- The End of Everything: (Astrophysically Speaking)Von EverandThe End of Everything: (Astrophysically Speaking)Bewertung: 4.5 von 5 Sternen4.5/5 (157)

- The Universe: The book of the BBC TV series presented by Professor Brian CoxVon EverandThe Universe: The book of the BBC TV series presented by Professor Brian CoxBewertung: 5 von 5 Sternen5/5 (27)