Beruflich Dokumente

Kultur Dokumente

Garment Factory Auditor Certification Training Schedule

Hochgeladen von

Hazem NusiratOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Garment Factory Auditor Certification Training Schedule

Hochgeladen von

Hazem NusiratCopyright:

Verfügbare Formate

Garment Factory Auditor Certification Training Schedule

All Supplier Final Auditors (FA) need to undergo training to understand adidas-Group quality

standards, requirements and procedures. The attached is a typical training schedule spread out over 3

months.

Note: To keep all Manuals up to date is under factory responsibility!

Schedule Activity

Week 1 Introduction of Factory Auditor certification program

CFA Training Schedule

CFA Job Description

Necessary Documentation for Garment Final Inspection

Purchase order sheet

140 list

Final Audit SOP

Beautiful Audit SOP

AQL Tables

How to fill in Final Inspection report

Final Inspection Report

Week 2 Article Description (AD)

Explanation

Updates/Filling.

Workmanship Standards Manuals

Size key

Adidas & Reebok Manuals for Labels and Hangtags position

Core Originals Manual

Adidas & Reebok Special Packaging draw cords

Care symbols Master Files

Sealing Sample Policy

Sample Tag

Week 3 adidas-Group Inspection Methods

Clock wise inspection method sketches. Practice clock-wise inspection method with several

product types

Clock wise inspection method videos

How to Measure Garments

Review and practice How to Measure Manuals

Standard Logo Position Guideline

Defect Classification list for Garments/Cap/Knitwear

Defect classification list/A,B,C zones.

Defect classification list for Garment -Visual catalog

Beautiful Product 9 Criteria

3 stripes Position Manual

Pucker Standard

Week 4 Labeling and Packing Manuals

Labeling & Packing Share Point introduction

Different type of L&P Manuals EU, Asia, USA.

How to find information in L&P Manuals, special customers

(Practical part, L&P manuals or Share Point access are required)

Regional standards

Updates / Filling

Packing Samples (establish approved packing samples in factory).

Manual for Chinese HG-Labels control

Visual Control Boards (VCB)

Week 5 General Exercises to practice activities learnt during weeks

1 through 4

Correlation Exercise-Classification of defects in garments pre-inspected by adidas Quality auditor.

Review of defects found by CFA during final inspection, by adidas Quality Auditor to ensure correct

understanding of standards.

Week 6 Color Manual

Garment Factory Auditor Certification Training Schedule

Color Management Accreditation

Lab Accreditation

Fabric reports-Lap Dip, 1st Bulk Approval, Color Continuity, Test Reports

Material Quality Manual

Fabric inspection

AO-1 Policy

Trim & Accessories Quality Manual

A-Z Manual

Fabric Relaxation

Accessories and Fabrics Received Procedure

Materials Training

Week 7 adidas Group Print procedure

Heat Transfer Print Quality Procedure

Print & Embroidery approvals

Artwork Approval Sheet

Embroidery Manuals-adidas and Reebok

Print & Embroidery control

Follow up chart for approvals (example)

Week 8 Product Performance (Product Safety & Wash Test Procedures)

Finish Garment Wash Test Procedure

Seam elongation

Kid Safety Requirements

Tie cord ends Pull test

US CPSIA

Metal Free Policy (MFP)

General implementation

MFP reports

Metal Inspection Survey (MIS)/ Product Safety Audit

Special requirements for Japan

Metal detection report for Japan

Week 9 Final Audit:

How to fill in Weekly Final Inspection Report

Weekly Final Inspection Report

Warehouse claim procedure

adiComp Policy, adiComp Defect Codes & photos, adiComp Statistic, adiComp Share

point

adiComp and Warehouse returns

RFT End Line Inspection

Quality KPI’s –will be updated

Week 10 Final Training week

Final inspection video (needs to be updated)

Inspection Room organization

Re-practice of all training while performing final inspections.

Week 11 Examination

Theoretical exam

Practical exam

Supplier Factory Auditor Certificate

Das könnte Ihnen auch gefallen

- Best Practice of Garments Washing Factory SOP WORKDokument20 SeitenBest Practice of Garments Washing Factory SOP WORKMd IslamNoch keine Bewertungen

- Factory Tour ExplainDokument8 SeitenFactory Tour ExplainLâmViênNoch keine Bewertungen

- Quality Manual: September 2003Dokument25 SeitenQuality Manual: September 2003Swas SwastiNoch keine Bewertungen

- Certified Factory Auditor Job DescriptionDokument1 SeiteCertified Factory Auditor Job DescriptionHazem Nusirat100% (1)

- 20-49-15 Carterstestingprocedures, Requirementsandvendorreferencemanual February2013Dokument109 Seiten20-49-15 Carterstestingprocedures, Requirementsandvendorreferencemanual February2013Nowhere ManNoch keine Bewertungen

- Fabric Knowledge For MerchandisersDokument1 SeiteFabric Knowledge For Merchandisers1234ritu100% (2)

- # What Is Industrial Engineering ?Dokument27 Seiten# What Is Industrial Engineering ?Shahin MahmudNoch keine Bewertungen

- BBW Nicer Work ReportDokument32 SeitenBBW Nicer Work Reportrahib203Noch keine Bewertungen

- Internal Audit Checklist of Garments Manufacturing Industry - Garments AcademyDokument6 SeitenInternal Audit Checklist of Garments Manufacturing Industry - Garments AcademyAriful HasanNoch keine Bewertungen

- Bon-Ton Qa Inspection ManualDokument41 SeitenBon-Ton Qa Inspection ManualYogesh KadianNoch keine Bewertungen

- 1-Day Awareness Course On Co$T of Quality: Presented by Neville-Clarke InternationalDokument85 Seiten1-Day Awareness Course On Co$T of Quality: Presented by Neville-Clarke Internationaldyogasara2Noch keine Bewertungen

- IE SOP - Standard Operating Procedure of Industrial Engineering Department - Garments-InfoDokument3 SeitenIE SOP - Standard Operating Procedure of Industrial Engineering Department - Garments-InfoSayed Aasim JawaidNoch keine Bewertungen

- Guidelines For Quality Assurance SystemDokument20 SeitenGuidelines For Quality Assurance SystemP. LakshmanakanthNoch keine Bewertungen

- Industrial Eng and Garment PDFDokument9 SeitenIndustrial Eng and Garment PDFrifat azimNoch keine Bewertungen

- Standardization of Apparel Manufacturing Industry Focusing On "Cutting Section"Dokument8 SeitenStandardization of Apparel Manufacturing Industry Focusing On "Cutting Section"Anish RajNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument145 SeitenNew Microsoft Office Word DocumentMohammad AzharuddinNoch keine Bewertungen

- QM0012 Statistical Process Control & Process CapabilityDokument19 SeitenQM0012 Statistical Process Control & Process CapabilityajayvmehtaNoch keine Bewertungen

- Mba201 - Production and Operation ManagementDokument8 SeitenMba201 - Production and Operation ManagementSiya KandpalNoch keine Bewertungen

- Quality Management Highlights and DefinitionsDokument23 SeitenQuality Management Highlights and DefinitionsakshaynnaikNoch keine Bewertungen

- Internal Customer SatisfactionDokument30 SeitenInternal Customer Satisfactionmind2008Noch keine Bewertungen

- Apparel Quality AttributesDokument143 SeitenApparel Quality AttributesAvinash SinghNoch keine Bewertungen

- Vaisistha Aqm Ii Assignment IDokument7 SeitenVaisistha Aqm Ii Assignment IVaisistha BalNoch keine Bewertungen

- 03 Global Quality and International Quality StandardsDokument50 Seiten03 Global Quality and International Quality StandardsM Sayid DwiNoch keine Bewertungen

- Pre-production process overviewDokument7 SeitenPre-production process overviewsanyaNoch keine Bewertungen

- Total Quality Management (Solutions)Dokument9 SeitenTotal Quality Management (Solutions)Ankit SinghNoch keine Bewertungen

- Mine ManagementDokument20 SeitenMine ManagementsunilsinghmNoch keine Bewertungen

- Project and Sourcing ManagementDokument28 SeitenProject and Sourcing ManagementDEEPANSHI SONINoch keine Bewertungen

- The Correct Way To Implement LeanDokument43 SeitenThe Correct Way To Implement LeanHadee SaberNoch keine Bewertungen

- World Cat - Global Quality Assurance: Title: Best Practice Factory Handbook To: (PUMA/WC,)Dokument68 SeitenWorld Cat - Global Quality Assurance: Title: Best Practice Factory Handbook To: (PUMA/WC,)zoomerfins22Noch keine Bewertungen

- Wages and Salary AdministrationDokument47 SeitenWages and Salary Administrationsaha apurvaNoch keine Bewertungen

- Sewing Defects in Apparel IndustryDokument3 SeitenSewing Defects in Apparel IndustryMadhavi Ajay NagarNoch keine Bewertungen

- Aldo JuryDokument16 SeitenAldo JuryankurmakhijaNoch keine Bewertungen

- Quality costs analysis and trackingDokument47 SeitenQuality costs analysis and trackingramakanta_mishraNoch keine Bewertungen

- New Microsoft Word DocumentDokument8 SeitenNew Microsoft Word Documentrajurana25Noch keine Bewertungen

- Vital Role of Sampling in Garment ManufacturingDokument5 SeitenVital Role of Sampling in Garment ManufacturingHasan TarekNoch keine Bewertungen

- Cutting Room Planning: ATDC, BhubaneswarDokument37 SeitenCutting Room Planning: ATDC, BhubaneswarBinoy MundaNoch keine Bewertungen

- National Institute of Fashion Technology Quality Management SystemDokument54 SeitenNational Institute of Fashion Technology Quality Management SystemSwapnil LalNoch keine Bewertungen

- The Role of Retail Product ManagersDokument30 SeitenThe Role of Retail Product ManagersLibin R PhilipNoch keine Bewertungen

- Bullwhip Effect in Supply Chain: Solution Suggested/available Leveraging On ICTDokument13 SeitenBullwhip Effect in Supply Chain: Solution Suggested/available Leveraging On ICTali_awaisNoch keine Bewertungen

- Cost Concepts & ClassificationDokument24 SeitenCost Concepts & ClassificationAbhishek MishraNoch keine Bewertungen

- RBACodeofConduct7.0 EnglishDokument16 SeitenRBACodeofConduct7.0 EnglishMariaCecilia AnteNoch keine Bewertungen

- Quality QuestionsDokument12 SeitenQuality Questionshridi147Noch keine Bewertungen

- Standard Operating Procedures for Pre-Inspection Quality ChecksDokument1 SeiteStandard Operating Procedures for Pre-Inspection Quality ChecksSayed Aasim Jawaid100% (2)

- Principles of 5 S: SeiriDokument4 SeitenPrinciples of 5 S: SeiriravishuklaNoch keine Bewertungen

- Training and Development of Supervisor For Garment Manufacturing IndustriesDokument16 SeitenTraining and Development of Supervisor For Garment Manufacturing IndustriesNaresh Yadav100% (1)

- 5S Implementation in Apparel IndustryDokument9 Seiten5S Implementation in Apparel IndustryAlpha Excellence consultingNoch keine Bewertungen

- Quality Standards and Quality GradeDokument44 SeitenQuality Standards and Quality GradeP. Lakshmanakanth100% (2)

- MRU Customer Complaint ProcessDokument4 SeitenMRU Customer Complaint ProcessSIS AuditorNoch keine Bewertungen

- AQL GoodoneDokument4 SeitenAQL GoodonemehrasunilNoch keine Bewertungen

- SOP MerchandiseDokument6 SeitenSOP MerchandiseAnonymous eSjcWuULRNoch keine Bewertungen

- 10 Key Factors of Sewing Thread Consumption3Dokument19 Seiten10 Key Factors of Sewing Thread Consumption3sabberNoch keine Bewertungen

- RAGS BBW Year 2 Leaflet - Bangladesh 30052012Dokument8 SeitenRAGS BBW Year 2 Leaflet - Bangladesh 30052012Ranjit RoyNoch keine Bewertungen

- Roles and Responsibilities of A FASHION DESIGNERDokument10 SeitenRoles and Responsibilities of A FASHION DESIGNERFatimah TabassumNoch keine Bewertungen

- Basic IE knowledge for garment jobsDokument2 SeitenBasic IE knowledge for garment jobssoban adilNoch keine Bewertungen

- BUYER - Role and ResponsibilitiesDokument17 SeitenBUYER - Role and ResponsibilitiesRitu JainNoch keine Bewertungen

- Garment Inspection Criteria CodesDokument9 SeitenGarment Inspection Criteria CodesKarthick Jayaram Karthick JayaramNoch keine Bewertungen

- H&M AQL Table RequirementDokument4 SeitenH&M AQL Table RequirementMoklesur RahmanNoch keine Bewertungen

- Lean Manufacturing: Presented by Vineeta Kanwal ID No. 44316Dokument35 SeitenLean Manufacturing: Presented by Vineeta Kanwal ID No. 44316Vineeta KanwalNoch keine Bewertungen

- Logistics And Supply Chain Management System A Complete Guide - 2020 EditionVon EverandLogistics And Supply Chain Management System A Complete Guide - 2020 EditionNoch keine Bewertungen

- Strategic Service Management A Complete Guide - 2020 EditionVon EverandStrategic Service Management A Complete Guide - 2020 EditionNoch keine Bewertungen

- Morning Meeting 5 / 0 Report Mesurment Report Heat Seal Fusing Report Zipper Test Report Wash Test Report Q.C Activity Chart End Line Mid LineDokument1 SeiteMorning Meeting 5 / 0 Report Mesurment Report Heat Seal Fusing Report Zipper Test Report Wash Test Report Q.C Activity Chart End Line Mid LineHazem NusiratNoch keine Bewertungen

- 1) CFA Training IntroductionDokument9 Seiten1) CFA Training IntroductionHazem Nusirat100% (2)

- Daily Process Report UpdatedDokument7 SeitenDaily Process Report UpdatedHazem NusiratNoch keine Bewertungen

- Style # Order Recive Date: Jcpenny Sp'18 Order DetailsDokument10 SeitenStyle # Order Recive Date: Jcpenny Sp'18 Order DetailsHazem NusiratNoch keine Bewertungen

- NotedDokument32 SeitenNotedHazem NusiratNoch keine Bewertungen

- Lean Thi Nki NGDokument13 SeitenLean Thi Nki NGHazem NusiratNoch keine Bewertungen

- Quality Control SystemDokument3 SeitenQuality Control SystemHazem NusiratNoch keine Bewertungen

- Detailed Analysis of 55 Logic Games from 1993-2008 LSATsDokument3 SeitenDetailed Analysis of 55 Logic Games from 1993-2008 LSATsbirdbeard100% (2)

- Under Armour Pivot88 Vendor Training - 2017.11.10Dokument31 SeitenUnder Armour Pivot88 Vendor Training - 2017.11.10Hazem Nusirat100% (2)

- Printing Process AuditDokument11 SeitenPrinting Process AuditHazem NusiratNoch keine Bewertungen

- HASHEMDokument2 SeitenHASHEMHazem NusiratNoch keine Bewertungen

- CFA Final Inspection ChecklistDokument4 SeitenCFA Final Inspection ChecklistHazem NusiratNoch keine Bewertungen

- Process Data SheetDokument18 SeitenProcess Data SheetHazem NusiratNoch keine Bewertungen

- Apparel Label Standards GuideDokument71 SeitenApparel Label Standards GuideHazem NusiratNoch keine Bewertungen

- SanDisk SecureAccessV3.0 QSG PDFDokument25 SeitenSanDisk SecureAccessV3.0 QSG PDFAnonymous SX8ODClMeNoch keine Bewertungen

- Appendix P - STORM RequirementsDokument19 SeitenAppendix P - STORM RequirementsHazem NusiratNoch keine Bewertungen

- Appendix L - Neck Stretch Gauge Order Form - UADokument1 SeiteAppendix L - Neck Stretch Gauge Order Form - UAHazem NusiratNoch keine Bewertungen

- InspectionReport 1029004Dokument12 SeitenInspectionReport 1029004Hazem NusiratNoch keine Bewertungen

- Appendix M - Graphic Strikeoff Requests Armoury InstructionsDokument17 SeitenAppendix M - Graphic Strikeoff Requests Armoury InstructionsHazem NusiratNoch keine Bewertungen

- Appendix C - ISO Stitch Type GuideDokument3 SeitenAppendix C - ISO Stitch Type GuideHazem Nusirat100% (1)

- PO Status Qty SKU Inspection ReportDokument2 SeitenPO Status Qty SKU Inspection ReportHazem NusiratNoch keine Bewertungen

- Detailed Analysis of 55 Logic Games from 1993-2008 LSATsDokument3 SeitenDetailed Analysis of 55 Logic Games from 1993-2008 LSATsbirdbeard100% (2)

- Appendix A - Under Armour Logo Mark PDFDokument4 SeitenAppendix A - Under Armour Logo Mark PDFHazem NusiratNoch keine Bewertungen

- DownloadForMac SanDiskSecureAccessV3.0Dokument1 SeiteDownloadForMac SanDiskSecureAccessV3.0Gherca OvidiuNoch keine Bewertungen

- Buy Season Style Color Performance Report # Report StatusDokument3 SeitenBuy Season Style Color Performance Report # Report StatusHazem NusiratNoch keine Bewertungen

- POs StatusDokument42 SeitenPOs StatusHazem NusiratNoch keine Bewertungen

- Apparel product teams and style priority listDokument5 SeitenApparel product teams and style priority listHazem NusiratNoch keine Bewertungen

- Pivot88 Inspection Status.Dokument4 SeitenPivot88 Inspection Status.Hazem NusiratNoch keine Bewertungen

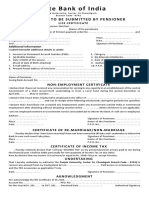

- SBI - Certificate To Be Submitted by Pensioner - ChandigarhDokument1 SeiteSBI - Certificate To Be Submitted by Pensioner - ChandigarhMsinghNoch keine Bewertungen

- Sugar Reseach in AustraliaDokument16 SeitenSugar Reseach in AustraliaJhonattanIsaacNoch keine Bewertungen

- ĐỀ THI THU TNTHPT SỐ 17Dokument4 SeitenĐỀ THI THU TNTHPT SỐ 17Nguyên Hà NguyễnNoch keine Bewertungen

- Radioimmunoassay MarketDokument5 SeitenRadioimmunoassay MarketRajni GuptaNoch keine Bewertungen

- Honda PCX150Dokument137 SeitenHonda PCX150Akchu KadNoch keine Bewertungen

- 632 MA Lichauco vs. ApostolDokument2 Seiten632 MA Lichauco vs. ApostolCarissa CruzNoch keine Bewertungen

- Recombinant DNA TechnologyDokument14 SeitenRecombinant DNA TechnologyAnshika SinghNoch keine Bewertungen

- Regional Ecology Test ScoringDokument14 SeitenRegional Ecology Test Scoringaisyah Wardah201Noch keine Bewertungen

- Research PaperDokument12 SeitenResearch PapershreyanshNoch keine Bewertungen

- Flexible and Alternative Seating: in ClassroomsDokument5 SeitenFlexible and Alternative Seating: in ClassroomsweningNoch keine Bewertungen

- Test Units and Accessories: Sinteso™Dokument22 SeitenTest Units and Accessories: Sinteso™Imad QsnNoch keine Bewertungen

- CanteenDokument8 SeitenCanteenmahesh4uNoch keine Bewertungen

- NTS - Candidate (Portal)Dokument1 SeiteNTS - Candidate (Portal)Noureen FatimaNoch keine Bewertungen

- Adult Congenital Heart Disease Board ReviewDokument76 SeitenAdult Congenital Heart Disease Board ReviewOQAB13Noch keine Bewertungen

- Rachael-Lyn Anderson CHCPRT001 - Assessment 4 Report of Suspected Child AbuseDokument3 SeitenRachael-Lyn Anderson CHCPRT001 - Assessment 4 Report of Suspected Child AbuseAndrea AndersonNoch keine Bewertungen

- Treating Thyroid Emergencies: Myxedema Coma and Thyroid StormDokument17 SeitenTreating Thyroid Emergencies: Myxedema Coma and Thyroid StormMarlon UlloaNoch keine Bewertungen

- TSB 20230831 - Reconnect FATL WM Error Code & Troubleshooting GuideDokument6 SeitenTSB 20230831 - Reconnect FATL WM Error Code & Troubleshooting GuideNavjot KaurNoch keine Bewertungen

- Bibie Evana OsmanDokument6 SeitenBibie Evana OsmanStabat Jaya TrademarkNoch keine Bewertungen

- Chemistry CHM 1311C 2012 Test 1 BlankDokument6 SeitenChemistry CHM 1311C 2012 Test 1 BlankSimon HagosNoch keine Bewertungen

- Schneider - Cptg010 en (Print)Dokument16 SeitenSchneider - Cptg010 en (Print)el_koptan00857693Noch keine Bewertungen

- BOD FormatDokument4 SeitenBOD FormatSkill IndiaNoch keine Bewertungen

- Supplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDDokument29 SeitenSupplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDAdam Andrew OngNoch keine Bewertungen

- Khatr Khola ISP District RatesDokument56 SeitenKhatr Khola ISP District RatesCivil EngineeringNoch keine Bewertungen

- Afforestation in Arid and Semi Arid RegionsDokument68 SeitenAfforestation in Arid and Semi Arid RegionsMilian Marian SanduNoch keine Bewertungen

- NMC Confirmation FormDokument3 SeitenNMC Confirmation FormGianina AvasiloaieNoch keine Bewertungen

- Terminal Tractors and Trailers 6.1Dokument7 SeitenTerminal Tractors and Trailers 6.1lephuongdongNoch keine Bewertungen

- 4 6051111060339957657Dokument361 Seiten4 6051111060339957657Oviedo OviedoNoch keine Bewertungen

- Darnell's Father Goes StrictDokument2 SeitenDarnell's Father Goes StrictDavid Theodore Richardson IIINoch keine Bewertungen

- Keys To Biblical CounselingDokument7 SeitenKeys To Biblical CounselingDavid Salazar100% (6)

- Mri 7 TeslaDokument12 SeitenMri 7 TeslaJEAN FELLIPE BARROSNoch keine Bewertungen