Beruflich Dokumente

Kultur Dokumente

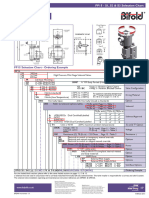

F612/F627/F626B: Semi-Lugged Gearbox Operated Butterfly Valves PN16

Hochgeladen von

RonaldOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

F612/F627/F626B: Semi-Lugged Gearbox Operated Butterfly Valves PN16

Hochgeladen von

RonaldCopyright:

Verfügbare Formate

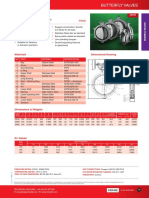

BUTTERFLY VALVES

F612/F627/ F626B F612

Semi-lugged gearbox operated

Butterfly Valves

GENERAL VALVES

PN16

Features & Benefits

• Robust, ductile iron valve body for long life service

• The anti-blow out stem design provides a safe and secure operation

• Valve body semi-lugged to fit PN16 or ANSI Class 125 flanges DN50 PICTURED

• Fully bonded epoxy paint system for superior corrosion resistance DATASHEET

DATASHEET DRAWING

DRAWINGVIEWS

VIEWS

ANDAND

DIMENSIONS

DIMENSIONS

• Suitable for applications where Level 3 C3 (Medium) corrosion

H

DATASHEET DRAWING VIEWS

protection is required Dimensional

ANDF612

F612 DIMENSIONS

/ F622

/ F622

/ F627

/ F627

/ /

Hh

h

F626B

F626B

• Maintenance free valve design, reducing downtime Drawing

F612 / F622 / F627 /

h

F626B

• Sizes 50-300mm are suitable for use with flanges conforming E E

to BS EN 1092-2 PN10 or PN16 and ANSI B16.1 Class 125. E

• Sizes 350-600mm are for PN16 flanges only

ØF

ØF

M

M

D

ØF

M

D

Materials FLANGE

FLANGE

A

SLOT

SLOT

PART MATERIAL FLANGE

A

SLOT

Body Ductile Iron ASTM A536 64-45-12 (Epoxy Paint)

Disc Aluminium Bronze C954 ASTM B148

B

Liner (F612) Nitrile Temp. -10 to 90°C

B

Liner (F627/F626B) EPDM (High Temperature) Temp. -10 to 130°C

C C

Shaft Stainless Steel Type 410

C

Taper Pin Stainless Steel Type 410 G G

O-Ring Buna-N G

Bushing PTFE Pressure/Temperature Ratings

SIZE SIZEA B

A C

B D

C E

D F

E G

F H

G h

H M

h M FLANGEFLANGE

SLOTS TO

SLOTS

BARESHAFT

VALVE

BARESHAFT

SUIT TO SUIT WT (kg) WT (kg)

GEARBOXGEARBOX

VALVE

OPERATED

OPERATED

WT (kg) WT (kg)

Gearbox Cast Iron

DN50 DN50

109 109

72 43

72 32

43 157

32 150

157 52.9

150 52.9

45 54

45 39

54 39 DN50 PN16

DN50

/ 2"PN16

CL125

/ 2" CL125 2.1 2.1 7.1 7.1

F612 F627/ F626B

BARESHAFT GEARBOX

DN65 DN65

131.5 131.5

82 46

82 32

46 157

32 150

157 64.6

150 64.6

45 54

45 39

54 39 DN65 PN16

DN65

/ 2.1/2"

PN16CL125

/ 2.1/2" CL125 VALVE

3.0 3.0 OPERATED

7.9 7.9

SIZE

DN80 A

DN80

134 B

134

95 C

46

95 D

32

46 E

157

32 F

150

157 G

150

79 H

45

79 h

54

45 M

39

54 39 FLANGE SLOTS

DN80 PN16

DN80 TO SUIT

/ 3"PN16

CL125

/ 3" CL125 WT

3.2(kg) 3.2 WT

8.2(kg) 8.2

DN100

DN50 DN100

163

109 115

163

72 115

52

43 32

52

32 157

32

157 150

157

150 104.4

150

52.9 104.4

45

45 54

45

54 39

54

39 39 DN100 PN16

DN100

DN50 PN16 //2"

4"PN16

CL125

CL125/ 4" CL125 4.2

2.1 4.2 9.1

7.1 9.1

MAX TEMPERATURE (°C)

DN125

DN65 DN125

DN150

169

131.5

DN80 DN150

179

134

125

169

82

142

179

95

125

56

46

142

56

46

32

56

32

40

56

32

157

32

157

157

40

157

150

157

150

150

157

150

123.5

150

64.6

155.8

150

79

123.5

45

45

155.8

45

45

-10 to 90

54

45

54

54

45

54

39

54

39

39

54

39

39

39

DN125

DN65

DN150

PN16

DN125

PN16

PN16

DN150

DN80 PN16

/ 5"PN16

/ 2.1/2"

//3"

CL125

6"PN16

CL125

CL125

/ 5" CL125

CL125

/ 6" CL125

-10 to 130

6.0

3.0

7.8

3.2

6.0 10.9

7.9

7.8 12.7

8.2

10.9

12.7

DN200

DN100 DN200

224

163 170

224

115 170

60

52 40

60

32 238

40

157 300

238

150 202.7

300

104.4 202.7

45

45 54

45

54 39

54

39 39 DN200 PN16

DN100 PN16

DN200

// 4"

8"PN16

CL125

/ 8" CL125

CL125 12.7

4.2 12.7 19.6

9.1 19.6

PRESSURE (BAR)

DN250 DN250

DN125 264

169

DN300 DN300

DN150 299

179

215

264

125

240

299

142

215

68

56

240

78

56

40

68

32

40

78

40

238

40

157

223.5

40

157

300

238

150

223.5

300

150

250.7

300

123.5

301.9

300

155.8

250.7

63

45

301.9

78

45

81

63

54

81

78

54

16

41.5

81

39

38.3

81

39

41.5

38.3

DN250

DN125 PN16

DN300

DN250

PN16

DN150PN16

// 8"

DN300

PN16

5"PN16

//12"

CL125

/ 8" CL125

CL125

6"PN16

CL125

/ 12" CL125

CL125

28.4

6.0

41.0

7.8

15.7

28.4 10.9

38.8

41.0 12.7

54.0

38.8

54.0

DN350 DN350

DN200 368

224 264

368

170 264

78

60 78

-

40 223.5

-

238 223.5

300

300 334

300

202.7 334

78

45 81

78

54 46.5

81

39 46.5 DN350

DN200PN16

DN350

PN16 //14"

8"PN16

CL125

/ 14" CL125

CL125 -

12.7 - 56.2

19.6 56.2

DN400 DN400

400 305

400 305

86 86

- 277

- 450

277 390

450 390

78 81

78 39

81 39 DN400

DN250PN16

DN400

//16"

8"PN16

CL125

/ 16" CL125 - - 88.4 88.4

Dimensions & Weights Intermediate pressure ratings shall be determined

DN250 264 215 68 40 238 300 250.7 63 81 41.5 PN16 CL125 28.4 38.8

DN450 DN450

DN300 422

299 317

422

240 105

317

78 105

-

40 325

-

223.5 450

325

300 441

450

301.9 185

441

78 160

185

81 120

160

38.3 120 DN450 PN16

DN300 PN16

DN450

// 12"

18"

PN16

CL125

/ 18" CL125

CL125 -

41.0 - 110.2

54.0 110.2

DN500 DN500

DN350 479

368 352

479

264 130

352

78 130

-- 325

-

223.5 450

325

300 492

450

334 185

492

78 160

185

81 120

160

46.5 120 DN500 PN16

DN350 PN16

DN500

// 14"

20"

PN16

CL125

/ 20" CL125

CL125 -- - 160.5

56.2 160.5

by interpolation. WRAS approved -10 to 80˚C

DN600 DN600

DN400

DN450

562

400

422

444

562

305

317

154

444

86

105

154

-

-- 340

-

277

325

450

340

450

450

597

450

390

441

185

597

78

185

160

185

81

160

126

160

39

120

126 DN600 PN16

DN400 PN16

DN600

// 16"

24"

PN16

CL125

/ 24" CL125

CL125

DN450 PN16 / 18" CL125

--

-

- 260.0

88.4

110.2

260.0

BARESHAFT GEARBOX DN500 479 352 130 - 325 450 492 185 160 120 DN500 PN16 / 20" CL125 - 160.5

VALVE OPERATED DN600 562 444 154 - 340 450 597 185 160 126 DN600 PN16 / 24" CL125 - 260.0

SIZE WEIGHT WEIGHT A B C D E F G H h M FLANGE SLOTS

Kv

(mm) (kg) (kg) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) TO SUIT

50 2.1 7.1 109 72 43 32 157 150 52.9 45 54 39 98 DN50 PN16 / 2” CL125

65 3.0 7.9 131.5 82 46 32 157 150 64.6 45 54 39 167 DN65 PN16 / 2.1/2” CL125

80 3.2 8.2 134 95 46 32 157 150 79 45 54 39 258 DN80 PN16 / 3” CL125

100 4.2 9.1 163 115 52 32 157 150 104.4 45 54 39 512 DN100 PN16 / 4” CL125

125 6.0 10.9 169 125 56 32 157 150 123.5 45 54 39 872 DN125 PN16 / 5” CL125

150 7.8 12.7 179 142 56 40 157 150 155.8 45 54 39 1,347 DN150 PN16 / 6” CL125

200 12.7 19.6 224 170 60 40 238 150 202.7 45 54 39 2,675 DN200 PN16 / 8” CL125

250 28.4 38.8 264 215 68 40 238 300 250.7 63 81 41.5 4,555 DN250 PN16 / 8” CL125

300 41.0 54.0 299 240 78 40 223.5 300 301.9 78 81 38.3 7,037 DN300 PN16 / 12” CL125

*Kv coefficient denotes valves in fully open position

PRESSURE RATING: PN16 / ANSI CLASS 125 MEDIUM:

TEST PRESSURES: F612 - Suitable for Group 1 and 2 gases and Group 1 and 2 liquids as

Shell: 24 Bar Seat: 17.6 Bar defined by the Pressure Equipment Directive 2014/68/EU.*

SPECIFICATION: Gearbox operated epoxy coated Ductile Iron Body. F627/F626B - Suitable Group 2 liquids as defined by the Pressure Equipment

Semi-lugged. Aluminium disc. EPDM or Nitrile liner. To suit flange connections Directive 2014/68/EU.*

BS EN 1092-2 PN10 or PN16 and ANSI B16.1 Class 125. Valves may be used

for flow regulation. Valve design conforms to BS EN 593. Face to face conforms

Vaild as of 220319

to BS EN 558. Bareshaft option available, F626B 50-300mm. * See page xxx for more information

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Crane Ltd assumes no responsibility or liability for typographical errors or

omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

TECHNICAL HELPLINE: +44 (0)1473 277400

1

E: enquiries@cranefs.com W: www.cranefs.com

Das könnte Ihnen auch gefallen

- 2 Acceleration Questions and AnswersDokument2 Seiten2 Acceleration Questions and Answersapi-272986951100% (2)

- World MultipleDokument271 SeitenWorld MultipleatrkpoleNoch keine Bewertungen

- The Champion Legal Ads: 11-02-23Dokument58 SeitenThe Champion Legal Ads: 11-02-23Donna S. SeayNoch keine Bewertungen

- RMC Case StudyDokument2 SeitenRMC Case StudyAmer RahmahNoch keine Bewertungen

- I61-04 - Typical DetailsDokument1 SeiteI61-04 - Typical DetailsTAHANoch keine Bewertungen

- Longitudinal Elevation: Issue RecordDokument1 SeiteLongitudinal Elevation: Issue RecordSwapan Kumar BoseNoch keine Bewertungen

- Misc-008 Ret. Wall R0 - RCC Above 3m SR EdgeDokument1 SeiteMisc-008 Ret. Wall R0 - RCC Above 3m SR EdgeBIKASHNoch keine Bewertungen

- Mini SystemDokument20 SeitenMini Systemmadmax6666Noch keine Bewertungen

- Great Lakes CabinetDokument4 SeitenGreat Lakes CabinetwipiriNoch keine Bewertungen

- p2ab-Ifc-Amalgamated File-Structure 221229 110135Dokument125 Seitenp2ab-Ifc-Amalgamated File-Structure 221229 110135ZABIHULLAH HABIBNoch keine Bewertungen

- SWIVEL FITTINGS PROVIDE STRENGTH AND FLEXIBILITY FOR INSULATED GLASS UNITSDokument1 SeiteSWIVEL FITTINGS PROVIDE STRENGTH AND FLEXIBILITY FOR INSULATED GLASS UNITSNajib KiwanNoch keine Bewertungen

- Wall Types and NotesDokument1 SeiteWall Types and NotesAbid AyubNoch keine Bewertungen

- Multi-spindle head technical specs and optionsDokument1 SeiteMulti-spindle head technical specs and optionsJosip ZrilićNoch keine Bewertungen

- Electrical Layout Symbols and DescriptionsDokument1 SeiteElectrical Layout Symbols and DescriptionsVincent FilomenaNoch keine Bewertungen

- Electrical Layout 3Dokument1 SeiteElectrical Layout 3suchita sharmaNoch keine Bewertungen

- DiagramsDokument106 SeitenDiagramsElber Luis Chavez BarriosNoch keine Bewertungen

- Staircase Detailed Plans: 3"X3" SQUARE Steel HandrailDokument1 SeiteStaircase Detailed Plans: 3"X3" SQUARE Steel HandrailBatWing ZNoch keine Bewertungen

- MACS-MODULE-01 To 05Dokument1 SeiteMACS-MODULE-01 To 05niazthegr8Noch keine Bewertungen

- SIANA SPP - StructuralDokument5 SeitenSIANA SPP - StructuralYugi Oh MelvzNoch keine Bewertungen

- A B C E F G H D: Planet Fitness ManagementDokument1 SeiteA B C E F G H D: Planet Fitness ManagementUday KumarNoch keine Bewertungen

- Hig Lower 38 WestDokument4 SeitenHig Lower 38 WestShivani SoniNoch keine Bewertungen

- RMD3201-000 en PDFDokument1 SeiteRMD3201-000 en PDFThái Mai ĐìnhNoch keine Bewertungen

- STR NewDokument24 SeitenSTR NewMahmoud Al-NemrNoch keine Bewertungen

- MBR SKY LOUNGE DECO CHANDELIER SHOP DRAWINGDokument1 SeiteMBR SKY LOUNGE DECO CHANDELIER SHOP DRAWINGrbelduaNoch keine Bewertungen

- Schedule of SlabsDokument1 SeiteSchedule of SlabsJericho Jon IlocoNoch keine Bewertungen

- 341864-2 IdwDokument1 Seite341864-2 IdwRubenNoch keine Bewertungen

- Tanque Vu 570 m3 DSN-RCT275-50Dokument2 SeitenTanque Vu 570 m3 DSN-RCT275-50Comercial FirenoNoch keine Bewertungen

- Qvil Tgac TB Ar XX SD 3104Dokument1 SeiteQvil Tgac TB Ar XX SD 3104Zaido Al HalabiNoch keine Bewertungen

- Aluminium Cladding for Roof Terraces and Lower RoofsDokument1 SeiteAluminium Cladding for Roof Terraces and Lower RoofsZaido Al HalabiNoch keine Bewertungen

- Mark Up Basement and Footing ConcordDokument2 SeitenMark Up Basement and Footing ConcordSaiful IslamNoch keine Bewertungen

- 02 ADMIN-Layout1Dokument1 Seite02 ADMIN-Layout1azamNoch keine Bewertungen

- Center Line Block-1Dokument1 SeiteCenter Line Block-1Sandeep VarmaNoch keine Bewertungen

- Model FP15 Solenoid Valve Catalogue BFD90 November 13Dokument1 SeiteModel FP15 Solenoid Valve Catalogue BFD90 November 13BRUNONoch keine Bewertungen

- M36 BoltDokument1 SeiteM36 Boltpmf engineering limitedNoch keine Bewertungen

- Parts list and exploded assembly diagram for belt tightenerDokument4 SeitenParts list and exploded assembly diagram for belt tightenerpanji100% (1)

- SANDVIK Electrical Diagram TH 551iDokument132 SeitenSANDVIK Electrical Diagram TH 551iEfrahim SimaNoch keine Bewertungen

- Eplb ChartsDokument3 SeitenEplb ChartsjazzmanPL100% (1)

- Ficha Tecnica Mod 2-5002Dokument2 SeitenFicha Tecnica Mod 2-5002Nestor Augusto Duran SanchezNoch keine Bewertungen

- Vama Vor Rwy 23Dokument1 SeiteVama Vor Rwy 23xikex91345Noch keine Bewertungen

- Al-Arifi Villas: Structural Drawings List (VILLA 1 & 2)Dokument26 SeitenAl-Arifi Villas: Structural Drawings List (VILLA 1 & 2)LeMasters ArabiaNoch keine Bewertungen

- MS 02 312Dokument7 SeitenMS 02 312thecarsNoch keine Bewertungen

- Butterfly Valve Selection-Velocity Chart: HDU/HD Series ValvesDokument2 SeitenButterfly Valve Selection-Velocity Chart: HDU/HD Series Valveseder_peruchNoch keine Bewertungen

- 74LS123Dokument10 Seiten74LS123jonat09Noch keine Bewertungen

- ND11 - 615 ND11 - 625 ND11 - 1512 ND11 - 1520: Edition: 2002 - AugustDokument32 SeitenND11 - 615 ND11 - 625 ND11 - 1512 ND11 - 1520: Edition: 2002 - AugustvkdanshulNoch keine Bewertungen

- EW2025R ECCO 8.5x11Dokument1 SeiteEW2025R ECCO 8.5x11Steven Quintero saldarriagaNoch keine Bewertungen

- Wr-2105-Ele-Lay-209 R2Dokument1 SeiteWr-2105-Ele-Lay-209 R2Moges BojaNoch keine Bewertungen

- Rectangular Duct & FittingsDokument26 SeitenRectangular Duct & Fittingsmakmak90% (1)

- Nearby Circular Column DrawingDokument1 SeiteNearby Circular Column DrawingBoopathi RajaNoch keine Bewertungen

- ORM.) Engineers: India Limited Ladder Rungs For Manhole / DemisterDokument1 SeiteORM.) Engineers: India Limited Ladder Rungs For Manhole / DemistersahilNoch keine Bewertungen

- Folq Vu Ds Fy, Ekud Fofunsz'K: Standard Specification For BlastingDokument8 SeitenFolq Vu Ds Fy, Ekud Fofunsz'K: Standard Specification For Blastingresp-ectNoch keine Bewertungen

- Ground Floor Plan: Comfort Design ArchitectsDokument1 SeiteGround Floor Plan: Comfort Design Architectssanjay gautamNoch keine Bewertungen

- 01 ADMIN-Layout1Dokument1 Seite01 ADMIN-Layout1azamNoch keine Bewertungen

- Foundtion Plan PDFDokument1 SeiteFoundtion Plan PDFAditiNoch keine Bewertungen

- Asf City Motorway M-9 Karachi: S R ConsultantsDokument1 SeiteAsf City Motorway M-9 Karachi: S R ConsultantsshergulNoch keine Bewertungen

- A2-Floor Plan, ElevationsDokument1 SeiteA2-Floor Plan, ElevationsRonnel John CruzNoch keine Bewertungen

- Eprz ChartsDokument3 SeitenEprz ChartsjazzmanPLNoch keine Bewertungen

- Power TransmissionDokument718 SeitenPower Transmissionv8wfm8d8r7Noch keine Bewertungen

- Tra-Dcv-Sdg-Id-Gen-20007 - Rev.00 - Elevations Specon StampedDokument1 SeiteTra-Dcv-Sdg-Id-Gen-20007 - Rev.00 - Elevations Specon StampedErtugrulsurucuNoch keine Bewertungen

- General notes for tankage flare drumDokument1 SeiteGeneral notes for tankage flare drumHadi SuagungNoch keine Bewertungen

- A B C D E F: SCALE 1:60 Slab Thickness 3"Dokument1 SeiteA B C D E F: SCALE 1:60 Slab Thickness 3"Sumaya TabassumNoch keine Bewertungen

- Caparroso - Exercise9 - KitchenDokument1 SeiteCaparroso - Exercise9 - KitchenNicole CaparrosoNoch keine Bewertungen

- Annotated Floor Plan 1: KeynotesDokument11 SeitenAnnotated Floor Plan 1: KeynotesShelby JohnsonNoch keine Bewertungen

- Fully-lugged gearbox operated butterfly valvesDokument1 SeiteFully-lugged gearbox operated butterfly valvesRonaldNoch keine Bewertungen

- Semi-Lugged Gearbox Operated Butterfly Valves PN16Dokument1 SeiteSemi-Lugged Gearbox Operated Butterfly Valves PN16RonaldNoch keine Bewertungen

- FM638 & FM639: Fully Lugged Butterfly Valve PN25Dokument1 SeiteFM638 & FM639: Fully Lugged Butterfly Valve PN25RonaldNoch keine Bewertungen

- Butterfly Valves: Large Diameter Butterfly Valve PN16Dokument1 SeiteButterfly Valves: Large Diameter Butterfly Valve PN16RonaldNoch keine Bewertungen

- Fig F611 F621 F626 Butterfly CraneFS DS 1702 P77 PDFDokument1 SeiteFig F611 F621 F626 Butterfly CraneFS DS 1702 P77 PDFmarchus09Noch keine Bewertungen

- FM700 / FM701 & FM700B: Butterfly ValvesDokument1 SeiteFM700 / FM701 & FM700B: Butterfly ValvesRonaldNoch keine Bewertungen

- Semi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsDokument1 SeiteSemi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsRonaldNoch keine Bewertungen

- F615/F629/F628B: Fully-Lugged Gearbox Operated Butterfly Valves PN16Dokument1 SeiteF615/F629/F628B: Fully-Lugged Gearbox Operated Butterfly Valves PN16RonaldNoch keine Bewertungen

- Fig 151XU Globe CraneFS DS 1702 P154 1Dokument1 SeiteFig 151XU Globe CraneFS DS 1702 P154 1RonaldNoch keine Bewertungen

- Check Valves: Bronze Swing Check Valve With Metal Disc PN25Dokument1 SeiteCheck Valves: Bronze Swing Check Valve With Metal Disc PN25Leon ArangoNoch keine Bewertungen

- Butterfly Valves: Large Diameter Butterfly Valve PN16Dokument1 SeiteButterfly Valves: Large Diameter Butterfly Valve PN16RonaldNoch keine Bewertungen

- Fig 47xu F Gate Cranefs Ds 1702 p136 1Dokument1 SeiteFig 47xu F Gate Cranefs Ds 1702 p136 1RonaldNoch keine Bewertungen

- Guia de Autoevaluacion AmbientalDokument6 SeitenGuia de Autoevaluacion AmbientalSergio LorenzoNoch keine Bewertungen

- Fig 47xu F Gate Cranefs Ds 1702 p136 1Dokument1 SeiteFig 47xu F Gate Cranefs Ds 1702 p136 1RonaldNoch keine Bewertungen

- Air Cooled Screw Chiller Performance SpecificationDokument2 SeitenAir Cooled Screw Chiller Performance SpecificationDajuko Butarbutar100% (1)

- DUPLICATE BILL TITLEDokument8 SeitenDUPLICATE BILL TITLEMohammed AhmedNoch keine Bewertungen

- IIT BOMBAY RESUME by SathyamoorthyDokument1 SeiteIIT BOMBAY RESUME by SathyamoorthySathyamoorthy VenkateshNoch keine Bewertungen

- Vaje 3 - Macionis in PlummerDokument2 SeitenVaje 3 - Macionis in PlummerLazar DjondricNoch keine Bewertungen

- Private Void BtnDeleteActionPerformedDokument12 SeitenPrivate Void BtnDeleteActionPerformedDDDNoch keine Bewertungen

- DodupukegakobemavasevuDokument3 SeitenDodupukegakobemavasevuMartian SamaanNoch keine Bewertungen

- Kerala University 2013 Admission ProspectusDokument50 SeitenKerala University 2013 Admission ProspectusMuneer SainulabdeenNoch keine Bewertungen

- Carbon SteelDokument1 SeiteCarbon SteeldexterNoch keine Bewertungen

- Creative WritingDokument2 SeitenCreative WritingSharmaine AsoyNoch keine Bewertungen

- Arduino - Decision Making StatementsDokument20 SeitenArduino - Decision Making StatementsJohn Clifford Ambaic JayomaNoch keine Bewertungen

- Aw MD700 Manual G10 150706Dokument73 SeitenAw MD700 Manual G10 150706Heraldo Ulguim Luis OliveiraNoch keine Bewertungen

- An Introduction To Muscle Response Testing MRTDokument14 SeitenAn Introduction To Muscle Response Testing MRTJuan Aguilar HernándezNoch keine Bewertungen

- Drainage PDFDokument1 SeiteDrainage PDFSwapnil JainNoch keine Bewertungen

- CM Group Marketing To Gen Z ReportDokument20 SeitenCM Group Marketing To Gen Z Reportroni21Noch keine Bewertungen

- Physical Layer:: SwitchingDokument27 SeitenPhysical Layer:: SwitchingPKSachanNoch keine Bewertungen

- Carl Rogers, Otto Rank, and "The BeyondDokument58 SeitenCarl Rogers, Otto Rank, and "The BeyondAnca ElenaNoch keine Bewertungen

- Methanol Technical Data Sheet FactsDokument1 SeiteMethanol Technical Data Sheet FactsmkgmotleyNoch keine Bewertungen

- MDS Report Substances of Assemblies and Materials: 1. Company and Product NameDokument17 SeitenMDS Report Substances of Assemblies and Materials: 1. Company and Product Namejavier ortizNoch keine Bewertungen

- Efficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar ExtractionsDokument10 SeitenEfficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar Extractionsxiaoxin zhangNoch keine Bewertungen

- Dayal Bagh: Spircon 2013: Book of AbstractsDokument202 SeitenDayal Bagh: Spircon 2013: Book of AbstractsSant Mat100% (2)

- Kompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminDokument9 SeitenKompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminHendrayana RamdanNoch keine Bewertungen

- 10 ExtSpringsDokument27 Seiten10 ExtSpringsresh27Noch keine Bewertungen

- Shadow The Hedgehog (Sonic Boom)Dokument11 SeitenShadow The Hedgehog (Sonic Boom)Tamajong Tamajong PhilipNoch keine Bewertungen

- ZSL National Red List of Nepal's Birds Volume 2Dokument636 SeitenZSL National Red List of Nepal's Birds Volume 2Tushita LamaNoch keine Bewertungen

- Analisis Efektivitas Inklusi Keuangan Di BMT Syariah Riyal: PendahuluanDokument25 SeitenAnalisis Efektivitas Inklusi Keuangan Di BMT Syariah Riyal: PendahuluanEma Rina SafitriNoch keine Bewertungen

- Cartoon Network, Boomerang & TCM TV Rate Card July - SeptemberDokument11 SeitenCartoon Network, Boomerang & TCM TV Rate Card July - SeptemberR RizalNoch keine Bewertungen