Beruflich Dokumente

Kultur Dokumente

4BTA3.9-C110 Curve and Datasheet-FR90024

Hochgeladen von

Alexander LopezOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4BTA3.9-C110 Curve and Datasheet-FR90024

Hochgeladen von

Alexander LopezCopyright:

Verfügbare Formate

Basic Engine Model: Curve Number: Industrial

CUMMINS ENGINE COMPANY, INC Pg. No.

Columbus, Indiana 47202-3005

4BTA3.9-C110 FR-90024

4BTA3.9

Engine Family: CPL Code: Date:

71

Engine Performance Curve D38 2351 8Jan03

Displacement: 3.9 litre (239 in.3) Aspiration: Turbocharged & JWAC

Bore: 102 mm. (4.02 in.) Rating Type: Continuous kW (BHP) @ RPM

Stroke: 120 mm (4.72 in.) No. of Cylinders: 4 82 (110) 2200

Emission Control: NONE Fuel System: Bosch A/RSV/LDA 8% Governor Regulation

All data are based on the engine operating with fuel system, water pump, lubricating oil pump, and 250 mm H2O (10 in. H2O) inlet air restriction and with

50 mm Hg (2.0 in. Hg) exhaust restriction; not included are alternator, fan, optional equipment and driven components.

TORQUE

CONTINUOUS RATING RPM N•m lb.-ft.

1000 271 (200)

1100 271 (200)

1300 511 (377)

1500 450 (332)

1700 430 (317)

1900 407 (300)

2100 380 (280)

2200 357 (263)

POWER OUTPUT

RPM kW BHP

1000 28 (38)

1100 31 (42)

1300 69 (93)

1500 71 (95)

1700 77 (103)

1900 81 (109)

2100 84 (112)

2200 82 (110)

FUEL CONSUMPTION

RPM g/kW•hr lb/BHP-HR

1000 232 (.381)

1100 227 (.374)

1300 216 (.355)

1500 210 (.345)

1700 210 (.346)

1900 217 (.356)

2100 223 (.366)

2200 226 (.372)

Curves shown above represent gross engine performance capabilities obtained and corrected in accordance with SAE J1995 conditions of 100

kPa (29.61 in. Hg) barometric pressure [91 m (300 ft.) altitude], 25°C (77°F) inlet air temperature, and 1 kPa (0.30 in. Hg) water vapor pressure

with No.2 diesel fuel. The engine may be operated without changing the fuel setting up to 2438 m (8,000 ft.) altitude.

Consult Cummins customer engineering for operation above this altitude.

TECHNICAL DATA DEPT. CERTIFIED WITHIN 5% CHIEF ENGINEER

Industrial

Pg. No.

4BTA3.9

72 PERFORMANCE DATA

Low Idle Set Speed...................... ...........................................................................................................................—rpm 950

Minimum Low Idle Speed ........... ...........................................................................................................................—rpm 800

Maximum Governed Speed

—@ 15 psi Check Point for PT Fuel System .............................................................—rpm N/A

—@ 10% of Rated Torque for Pump-Line-Nozzle Fuel System ................................—rpm (1) 2457

Maximum Overspeed Capability ...........................................................................................................................—rpm 3750

Closed Throttle Torque @ 700 rpm (for 950 rpm Low Idle Speed) .............................................................—N•m (lb.-ft.) TBD

Throttle Angle

—High Idle .................................................................................................................... Deg. 106±10

—Low Idle..................................................................................................................... Deg. 85±10

—Delta.......................................................................................................................... Deg. 21±6

Maximum Power Available from the Front of the Crankshaft - Consult Cummins Application Engineer for Information

EMISSIONS:

Estimated Free Field Sound Pressure Level At 50 ft. (15 m) and Full-Load Governed Speed

(Excludes Noise from Intake, Exhaust, Cooling System and Driven Components)

—Right Side ............................................................................................................ —dBa N.A.

—Left Side ............................................................................................................... —dBa N.A.

—Front ..................................................................................................................... —dBa N.A.

—Rear ...................................................................................................................... —dBa N.A.

Gaseous Emissions per ISO 8178:

—Weight-Specific NOx .................................................................................... —g/bhp-hr. (2) 6.6

—Weight-Specific HC ...................................................................................... —g/bhp-hr. (2) 0.4

—Weight-Specific CO ...................................................................................... —g/bhp-hr. (2) 0.6

—Weight-Specific Particulates ......................................................................... —g/bhp-hr. (2) 0.1

CONTINUOUS

MAXIMUM PEAK

RATED POWER POINT TORQUE

Fuel Rating Option used for these Data: FR-90024

Engine Speed ................................................................... —rpm 2200 1500

Gross Power Output ................................................. —kW (bhp) 82 (110) 71 (95)

Torque .................................................................. —N•m (lb.-ft.) 357 (263) 450 (332)

Intake Manifold Pressure ................................ —mm Hg (in. Hg) 991 (39) 737 (29)

Motoring Friction Horsepower..................................... —kW (hp) TBD TBD

(3) Turbocharger Compressor Outlet Pressure.... —mm Hg (in. Hg) N/A N/A

Intake Air Flow .................................................. —litre/sec. (cfm) 107 (227) 83 (176)

(3) Intake Air Flow .............................................. —kg/min. (lb./min.) N/A N/A

Exhaust Gas Flow ............................................ —litre/sec. (cfm) TBD TBD

(3) Turbocharger Compressor Outlet Temperature ...........—°C (°F) N/A N/A

Exhaust Gas Temperature - Dry Stack.........................—°C (°F) 430 (806) 475 (887)

Heat Rejection to Ambient (Dry Manifold) ....... —kW (BTU/min.) 14.7 (834) 12.1 (692)

(4) Heat Rejection to Coolant (Dry Manifold) ........ —kW (BTU/min.) 54.4 (3100) 42.8 (2440)

Heat Rejection to Fuel ..................................... —kW (BTU/min.) 0.2 (14) 0.1 (7)

(4) Engine Coolant Flow ..............................—litre/sec. (U.S. gpm) 3.1 (49.5) 1.8 (28.5)

External Cooling Circuit Resistance @ 2500 rpm .—kPa (psi) 20.7 (3.0) 20.7 (3.0)

Altitude Limitations:

—Intermittent. ................................................................ —m (ft.) 3048 (10,000) 3048 (10,000)

—Continuous ................................................................. —m (ft.) 2255 (7400) 2255 (7400)

Steady State Smoke ...................................................—Bosch 1.5 1.5

All performance data are based on: the engine operating with fuel system, water pump, lubricating oil pump, air cleaner, and muffler; not included are alternator, compressor,

fan, optional equipment and driven components. Data represent gross engine performance capabilities obtained and corrected in accordance with SAE J1995 conditions of

100 kPa (29.61 in. Hg) barometric pressure [91 m (300 ft.) altitude], 25°C (77°F) inlet air temperature, and 1 kPa (0.30 in. Hg) water vapor pressure with No. 2 diesel fuel or a

fuel corresponding to ASTM D2.

(1) Speed Calculated from Governor Break RPM and Percent Governor Regulation.

(2) This rating is certified to applicable Tier 1 EPA and CARB emission requirements for nonroad engines. The actual certification engine for this family may have been of a

different rating. Data provided is based upon the test procedures included in 40CFR89 and is believed to be representative of typical engines of this particular rating;

however, this data may have been derived from potentially limited testing or from interpolation/extrapolation of test data from similar ratings using good engineering

judgement. This data is subject to instrumentation, measurement, and engine-to-engine variability.

(3) Data Required for Charge Air Aftercooler Circuit.

(4) Coolant Flow and Heat Rejection Data Based on a Coolant Mixture of 50% Water and 50% Ethylene Glycol.

(5) Note For Naturally Aspirated Engines: When operating naturally aspirated engines above SAE J1995 conditions, it should be noted that smoke levels will increase

due to combustion inefficiencies associated with a reduction in the air to fuel mixture.

TBD = To Be Decided N/A = Not Applicable N.A. = Not Available

All data is subject to change without notice, bold data indicates a revision since the last update.

Use with Base Engine Data Sheet: DS-D383026 Configuration: D383026CX02

Industrial

Cummins Engine Company, Inc. Pg. No.

Base Engine Data Sheet 4BTA3.9

9

ENGINE MODEL: 4BTA3.9-C INSTALLATION DRAWINGS: DATA SHEET: DS-D383026

CONFIGURATION NUMBER: D383026CX02 FAN to FLYWHEEL: 3626417 DATE 25May99

AFTER COOLING SYSTEM: Jacket Water WIRING DIAGRAM: N/A RESTRICTED PRODUCT:

FUEL SYSTEM: Bosch A Pump CPL NUMBER: See Perf. Curve If yes, documented approval

required per AEB 26.01

CERTIFICATION: See Perf. Curve

PRODUCT INFORMATION: AEB 10.48

GENERAL ENGINE DATA

Engine Wet Weight (Pricing Configuration) ................................................................................. —kg. (lb.) 350 (772)

Moment of Inertia of Rotating Components (Excluding Flywheel) .............................— kg•m 2 (in.-lb.-sec.2) 0.015 (1.26)

Center of Gravity from Front Face of Block ................................................................................ — mm (in.) 262 (10.3)

Center of Gravity above Crankshaft Centerline ..........................................................................— mm (in.) 160 (6.3)

Crankshaft Thrust Bearing Load Limit

—Maximum Intermittent ................................................................. — N (lb.) 3425 (770)

—Maximum Continuous................................................................. — N (lb.) 1112 (250)

ENGINE MOUNTING

Maximum (Static) Bending Moment at Front Support Mounting Surface...............................— N•m (lb.-ft.) 435 (321)

Maximum (Static) Bending Moment at Side Pad Mounting Surface ......................................— N•m (lb.-ft.) Ref. 3382769

Maximum (Static) Bending Moment at Rear Face of Block ...................................................— N•m (lb.-ft.) 1356 (1000)

Moment of Inertia of Complete Engine

— Roll Axis.......................................................................— kg•m2 (in.-lb.-sec.2 ) 11.1 (98)

— Pitch Axis .....................................................................— kg•m2 (in.-lb.-sec.2 ) 19.1 (169)

— Yaw Axis .......................................................................—kg•m2 (in.-lb.-sec.2 ) 14.7 (130)

EXHAUST SYSTEM

Maximum Back Pressure .................................................................................................— mm Hg (in. Hg) 76 (3.0)

Exhaust Pipe Size Normally Acceptable .................................................................................... — mm (in.) 75 (3)

Maximum Static Supported Weight at the Turbocharger Outlet Flange ................................— N•m (lb.-ft.) 13.5 (10)

Exhaust Manifold Insulation Acceptable ....................................................................................... —Yes/No No

Turbocharger Insulation Acceptable ............................................................................................. —Yes/No No

AIR INTAKE SYSTEM

Maximum Intake Air Restriction with Heavy Duty Air Cleaner

— Clean Element ...............................................................— mm H2O (in. H2O) 381 (15)

— Dirty Element ..................................................................— mm H2O (in. H2O) 635 (25)

Minimum Dirt Holding Capacity with Heavy Duty Air Cleaner..................................... — g/litre/sec. (g/cfm) 53 (25)

Maximum Temperature Rise from Ambient to the Inlet of the Turbocharger................................. —°C (°F) 17 (30)

(1)

Maximum Pressure Drop from the Turbocharger Outlet to the Intake Manifold ..............— mm Hg (in. Hg) 102 (4)

NOTE: Conditions refer to rated power and speed unless otherwise noted.

TBD - To Be Determined N/A - Not Applicable N.A. - Not Available

(1) Data Required for Charge Air Aftercooler Circuit

(2) Data Required for Low Temperature Aftercooler Circuit DS - D383026

Industrial

Pg. No.

4BTA3.9

10

COOLING SYSTEM

Coolant Capacity - Engine Only......................................................................................... —litre (U.S. gal.) 8.3 (2.2)

Maximum Engine Cooling Circuit External Resistance .............................................................. —kPa (psi) TBD

Minimum Pump Inlet Pressure with Open Thermostat and no Pressure Cap .................— mm Hg (in. Hg) See AEB 90.24

Maximum Static Head of Coolant Above Engine Crankshaft Centerline ........................................— m (ft.) TBD

Standard (modulating) Thermostat Range ................................................................................... — °C (°F) 82-93(180-200)

Maximum Block Coolant Pressure with Closed Thermostat and no Pressure Cap................... — kPa (psi) TBD

Minimum Pressure Cap ............................................................................................................. —kPa (psi) 50 (7)

Maximum Engine Coolant Temperature at Engine Outlet ............................................................ — °C (°F) 100 (212)

Maximum Engine Coolant Temperature for Engine Protection Devices........................................ —°C (°F) 101.6 (215)

Minimum Engine Coolant Temperature ........................................................................................ —°C (°F) 71 (160)

Minimum Fill Rate ..................................................................................................... —litre/min. (U.S. gpm) 19 (5)

Maximum Initial Fill Time .................................................................................................................. — min. 5

Minimum Coolant Expansion Space...................................................................... —% of System Capacity 6

Maximum Deaeration Time .............................................................................................................. — min. 25

Minimum Drawdown .................................................................................... — % of Total System Capacity 11%

(Drawdown Must Exceed the Volume Not Filled at Initial Fill & Must Not Include Expansion Space)

(2)

Maximum External Resistance in Aftercooler Circuit ................................................................ — kPa (psi) N/A

(2)

Minimum Coolant Flow Through the Aftercooler Circuit with Open Thermostat...... — U.S. gpm (litre/min.) N/A

(2)

Coolant Temperature at Aftercooler Radiator Inlet at Maximum Engine Coolant Outlet Temperature— °C (°F) N/A

(2)

Maximum Water Temperature into the Aftercooler at Maximum Engine Coolant Outlet Temperature—°C (°F) N/A

(1)

Maximum Intake Manifold Temperature ....................................................................................... — °C (°F) N/A

(1)

Maximum Intake Manifold-to-Ambient Temperature Differential (IMTD) ...................................... — °C (°F) N/A

Fan-on Engine Coolant Outlet Temperature................................................................................. — °C (°F) 93 (200)

Shutter Opening Coolant Outlet Temperature .............................................................................. — °C (°F) 85 (185)

(1)(2)

Shutter Opening Intake Manifold Air Temperature ....................................................................... — °C (°F) 65.6 (150)

(1)

Winterfronts Must Not Restrict Air Passage Area Below 120 sq. in. (774 sq. cm)

LUBRICATION SYSTEM

Normal Operating Oil Pressure Range ...................................................................................... — kPa (psi) 69-345 (10-50)

Maximum Lube Oil Flow for Engine Accessories .................................................... — litre/min. (U.S. gpm) 4.0 (1)

Maximum Sump Oil Temperature.................................................................................................. —°C (°F) 127 (260)

Minimum Engine Oil Pressure for Engine Protection Devices:

— At Rated Speed and Load ............................................................ — kPa (psi) 276 (40)

— At Torque Peak Speed and Load ................................................. — kPa (psi) 207 (30)

— At Low Idle ..................................................................................... —kPa (psi) 69 (10)

Minimum Required Lube System Capacity - Sump plus Filters........................................ — litre (U.S. gal.) 9.0 (2.5)

By-pass Filtration Required ......................................................................................................... — Yes/No No

Angularity of Standard Oil Pan: (Values stated are for intermittent operation only): OP

— Front Down .................................................................................... — degrees 45

— Front Up......................................................................................... — degrees 45

— Side to Side ................................................................................... — degrees 45

NOTE: Conditions refer to rated power and speed unless otherwise noted.

TBD - To Be Determined N/A - Not Applicable N.A. - Not Available

(1) Data Required for Charge Air Aftercooler Circuit

(2) Data Required for Low Temperature Aftercooler Circuit DS - D383026

Industrial

Pg. No.

4BTA3.9

11

CRANKING SYSTEM 12 Volt 24 Volt

Minimum Battery Capacity - Cold Soak at 0°F (–18°C) or Above

— Engine Only - Cold Cranking Amperes ............................................... — CCA 800 400

— Engine Only - Reserve Capacity......................................................... — min. 160 80

Maximum Starting Circuit Voltage Drop @ ----Amperes.................................................................. — Volts TBD

Minimum Ambient Temperature for Unaided Cold Start............................................................... — °C (°F) -12 (10)

Minimum Cranking Speed Required for Unaided Cold Start ............................................................. — rpm 125

Breakaway Torque at Minimum Unaided Start Temperature ................................................— N•m (lb.-ft.) TBD

Cranking Torque at Minimum Unaided Start Temperature....................................................— N•m (lb.-ft.) TBD

Cranking Torque at -10°F ......................................................................................................— N•m (lb.-ft.) TBD

FUEL SYSTEM

CENTRY: Installations of CENTRY-equipped engines will require information contained in:

AEB 15.03 CENTRY Technical Package

AEB 27.03 CENTRY Installation Recommendation, Bulletin 3884651

CELECT: Installations of CELECT-equipped engines will require information contained in:

AEB 15.01 CELECT Technical Package

AEB 21.11 CELECT Installation Recommendation, Bulletin 3884575

Maximum Fuel Flow on the Supply Side of the Fuel Pump ................................................—kg./hr. (lb./hr.) 97 (213)

Maximum Fuel Inlet Restriction

— with clean fuel filter .............................................................— mm Hg (in. Hg) 102 (4)

— with dirty fuel filter .............................................................. — mm Hg (in. Hg) 203 (8)

Maximum Fuel Drain Restriction

— with check valves ............................................................... — mm Hg (in. Hg) N/A

— less check valves ............................................................... — mm Hg (in. Hg) 510 (20)

Maximum Fuel Inlet Temperature ................................................................................................. —°C (°F) 71 (160)

Minimum Fuel Tank Air Venting Capability Required at 6 in. H2O Back Pressure .......... — litre/hr. (ft.3/hr.) 340 (12)

NOTE: Conditions refer to rated power and speed unless otherwise noted.

TBD - To Be Determined N/A - Not Applicable N.A. - Not Available

(1) Data Required for Charge Air Aftercooler Circuit

(2) Data Required for Low Temperature Aftercooler Circuit DS - D383026

Industrial

Pg. No.

4BTA3.9

12

This Page Intentionally left Blank.

Das könnte Ihnen auch gefallen

- Manual de Operacion - Xas 185 JD7 IngDokument27 SeitenManual de Operacion - Xas 185 JD7 IngAlexander Lopez100% (2)

- Backhoe Loader B877F: Available With Standard or Extendable ArmDokument3 SeitenBackhoe Loader B877F: Available With Standard or Extendable ArmJoshwa SimamoraNoch keine Bewertungen

- International Standard: Truck and Bus Tyres and Rims (Metric Series) - RimsDokument8 SeitenInternational Standard: Truck and Bus Tyres and Rims (Metric Series) - RimsAndres ValdezNoch keine Bewertungen

- 10WR (WR 240i) PDFDokument2 Seiten10WR (WR 240i) PDFadrianNoch keine Bewertungen

- ZF GearDokument3 SeitenZF Gearsergio blandon lNoch keine Bewertungen

- John Deere - Parts CatalogDokument84 SeitenJohn Deere - Parts CatalogАлександрNoch keine Bewertungen

- Compresor Mobil Atlas Copco XAS 186 DDDokument4 SeitenCompresor Mobil Atlas Copco XAS 186 DDdiconNoch keine Bewertungen

- Bonfiglioli WinchDokument1 SeiteBonfiglioli WinchJames EddiebondNoch keine Bewertungen

- TIMKEN Maintenance ToolsDokument16 SeitenTIMKEN Maintenance ToolsIgor JuricNoch keine Bewertungen

- Subaru WRX (STi) 07 Lubrication FSMDokument22 SeitenSubaru WRX (STi) 07 Lubrication FSMGustavo RivasNoch keine Bewertungen

- Pneuma 320Dokument1 SeitePneuma 320Zaen SalimNoch keine Bewertungen

- Fittings - ManuliDokument128 SeitenFittings - ManuliImmorthalNoch keine Bewertungen

- Glow Plugs PDFDokument644 SeitenGlow Plugs PDFDevi Sharan PrajapatiNoch keine Bewertungen

- Compresor Mobil Atlas Copco XAVS 287 MDDokument4 SeitenCompresor Mobil Atlas Copco XAVS 287 MDdiconNoch keine Bewertungen

- Benni Mini CatalogDokument6 SeitenBenni Mini CatalogskpppNoch keine Bewertungen

- CNC Notching and Marking Machines: at 820 E CNC - at 820 E HD CNCDokument2 SeitenCNC Notching and Marking Machines: at 820 E CNC - at 820 E HD CNCdesetekNoch keine Bewertungen

- Schaeffler Corporate PresentationDokument9 SeitenSchaeffler Corporate PresentationRyusuke IshikawaNoch keine Bewertungen

- Case Study - BEML Dump TruckDokument1 SeiteCase Study - BEML Dump TrucksupihNoch keine Bewertungen

- OEM - Fuel Manager Brand Cross Reference P/Ns For Service Filter Elements 99642 - January 2006Dokument6 SeitenOEM - Fuel Manager Brand Cross Reference P/Ns For Service Filter Elements 99642 - January 2006Miguel RojasNoch keine Bewertungen

- Planetary Gear CalculatorDokument19 SeitenPlanetary Gear CalculatorDaris M Al-MubarokNoch keine Bewertungen

- Catalogue en 60hzDokument384 SeitenCatalogue en 60hzjuan yenqueNoch keine Bewertungen

- 04 Turbo PDFDokument26 Seiten04 Turbo PDFFabioMacielNoch keine Bewertungen

- Computer Aided Modeling Cost Estimation of A Hand TruckDokument4 SeitenComputer Aided Modeling Cost Estimation of A Hand TruckIJARP PublicationsNoch keine Bewertungen

- Workshop Manual Newage 85m2 GearboxesDokument15 SeitenWorkshop Manual Newage 85m2 Gearboxesdjordjes123Noch keine Bewertungen

- Tridec TP-O Fly ZDE19901902E 09-2010Dokument4 SeitenTridec TP-O Fly ZDE19901902E 09-2010Maximiliano DreyerNoch keine Bewertungen

- Tratores de Esteira Zoomlion PDFDokument10 SeitenTratores de Esteira Zoomlion PDFAbrar Muhammad AbrarNoch keine Bewertungen

- Steering System Repair ManualDokument13 SeitenSteering System Repair Manualsample nameNoch keine Bewertungen

- Agricultural Tractors Brake Performance TestDokument7 SeitenAgricultural Tractors Brake Performance Testniloy_67Noch keine Bewertungen

- BT-50 en OrganizedDokument40 SeitenBT-50 en OrganizedPao RodNoch keine Bewertungen

- Diesel Generator Set: Output RatingsDokument4 SeitenDiesel Generator Set: Output RatingsRick Wright100% (1)

- FSAPE 1 Element Replacement and Maintenance ChecklistsDokument18 SeitenFSAPE 1 Element Replacement and Maintenance ChecklistsJovMac ManzanoNoch keine Bewertungen

- Spare Parts Catalog: Date: 04.12.2023 Language: enDokument1.044 SeitenSpare Parts Catalog: Date: 04.12.2023 Language: enezgiulusoyy07Noch keine Bewertungen

- CAT TonkaDokument24 SeitenCAT TonkaGERSON RAFAEL CUAQUIRA MEDINA100% (1)

- Maintenance ManualDokument78 SeitenMaintenance ManualbannetNoch keine Bewertungen

- Smoce SodecaDokument182 SeitenSmoce SodecaRadoman KuburovicNoch keine Bewertungen

- Flender Sip Catalogue enDokument52 SeitenFlender Sip Catalogue enStone123456789Noch keine Bewertungen

- Pre and Post Heating Glow Plugs For Diesel Engines: Catalogue 2014Dokument92 SeitenPre and Post Heating Glow Plugs For Diesel Engines: Catalogue 2014Gonzalo De CarliNoch keine Bewertungen

- Fleet MaintenanceDokument36 SeitenFleet MaintenanceRery Dwi SNoch keine Bewertungen

- Seal BrochureDokument29 SeitenSeal BrochureAziz AbdullahNoch keine Bewertungen

- Spartan Next Fitting: Digital Test Bench Edx711 Jinny N-Line Cap. 38Dokument28 SeitenSpartan Next Fitting: Digital Test Bench Edx711 Jinny N-Line Cap. 38Vadim BlackNoch keine Bewertungen

- LUBEX - Catalogue - ENG VersionDokument48 SeitenLUBEX - Catalogue - ENG Versionخالد ابووجدانNoch keine Bewertungen

- Baldwin Fuel Dahl PDFDokument27 SeitenBaldwin Fuel Dahl PDFjack sliverNoch keine Bewertungen

- ZQYM Tech Limited: Independent Solution Provider For Diesel Injection Pump ProblemsDokument7 SeitenZQYM Tech Limited: Independent Solution Provider For Diesel Injection Pump ProblemsEU VaNoch keine Bewertungen

- 6 DMDokument3 Seiten6 DMOlivier ORMANNoch keine Bewertungen

- Wankel Engine MainDokument23 SeitenWankel Engine MainAbhay MauryaNoch keine Bewertungen

- RA - 29165 DBET 5xDokument10 SeitenRA - 29165 DBET 5xrafarodrig6Noch keine Bewertungen

- 8FG25 8FD25: Main Vehicle SpecificationsDokument3 Seiten8FG25 8FD25: Main Vehicle SpecificationsNuñez JesusNoch keine Bewertungen

- Portal Axle Design PDFDokument5 SeitenPortal Axle Design PDFUmesh JadhavNoch keine Bewertungen

- Information Service: Cylinder Reconditioning On Aluminium Cylinder BlocksDokument0 SeitenInformation Service: Cylinder Reconditioning On Aluminium Cylinder BlocksMoaed KanbarNoch keine Bewertungen

- Ful Vane Air CompressorsDokument6 SeitenFul Vane Air CompressorsBara BarackNoch keine Bewertungen

- 01 121117 FPTIndustrial NewF36 HIeSCR2Dokument3 Seiten01 121117 FPTIndustrial NewF36 HIeSCR2RasoolKhadibiNoch keine Bewertungen

- Effast Product CatalogueDokument76 SeitenEffast Product CatalogueLynn Selfe0% (2)

- Flaktwoods Plate FanDokument27 SeitenFlaktwoods Plate FanEldin JelecNoch keine Bewertungen

- Formula R1 Racing - Explosionszeichnungen Und Adapter PDFDokument9 SeitenFormula R1 Racing - Explosionszeichnungen Und Adapter PDFIBC_TobiNoch keine Bewertungen

- Operator's Service Book: Tata LP / LPT 613 Euro-IiDokument180 SeitenOperator's Service Book: Tata LP / LPT 613 Euro-IiDamith Nishantha KarunarathnaNoch keine Bewertungen

- CTAPP1845 Ifr 90352Dokument2 SeitenCTAPP1845 Ifr 90352GUSTAVO DA CRUZNoch keine Bewertungen

- 6bta5,9 FR91092 173 HP 2500Dokument2 Seiten6bta5,9 FR91092 173 HP 2500Dany_WallyNoch keine Bewertungen

- Cummins N14Dokument4 SeitenCummins N14GLG100% (1)

- CTPP2060 Ifr 90168Dokument6 SeitenCTPP2060 Ifr 90168GUSTAVO DA CRUZNoch keine Bewertungen

- 6BT5.9-M120 Datasheet ENDokument4 Seiten6BT5.9-M120 Datasheet ENnarisNoch keine Bewertungen

- FR91468 4BT3.9-C100Dokument5 SeitenFR91468 4BT3.9-C100narisNoch keine Bewertungen

- Operation and Maintenance - CP2100 - 2015 - 4812316022Dokument109 SeitenOperation and Maintenance - CP2100 - 2015 - 4812316022Alexander LopezNoch keine Bewertungen

- DRILLCare Hydraulic First Aid KitDokument2 SeitenDRILLCare Hydraulic First Aid KitAlexander LopezNoch keine Bewertungen

- Drillcare: Atlas Copco Drilling SolutionsDokument2 SeitenDrillcare: Atlas Copco Drilling SolutionsAlexander LopezNoch keine Bewertungen

- 2002 Engine Manual J08E-TA, TB - S5UJ08E02BDokument351 Seiten2002 Engine Manual J08E-TA, TB - S5UJ08E02BAlexander LopezNoch keine Bewertungen

- 2011 Tracked PaverDokument24 Seiten2011 Tracked PaverAlexander LopezNoch keine Bewertungen

- Drillcare: Atlas Copco Drilling SolutionsDokument2 SeitenDrillcare: Atlas Copco Drilling SolutionsAlexander Lopez100% (1)

- DML Electric Test Manual 2657868267 - 007Dokument77 SeitenDML Electric Test Manual 2657868267 - 007Alexander Lopez100% (2)

- Item Cds Repair Oper. Parts TrainDokument2 SeitenItem Cds Repair Oper. Parts TrainAlexander LopezNoch keine Bewertungen

- Chapter 03 REV 06 2009Dokument48 SeitenChapter 03 REV 06 2009Alexander LopezNoch keine Bewertungen

- Manual de Instrucciones ICA250-5EN2Dokument111 SeitenManual de Instrucciones ICA250-5EN2Alexander LopezNoch keine Bewertungen

- Drillcare: Atlas Copco Drilling SolutionsDokument2 SeitenDrillcare: Atlas Copco Drilling SolutionsAlexander LopezNoch keine Bewertungen

- Chapter 04 Mark 8 Rev-06Dokument20 SeitenChapter 04 Mark 8 Rev-06Alexander LopezNoch keine Bewertungen

- He 388Dokument27 SeitenHe 388Alexander LopezNoch keine Bewertungen

- Plant Type Model LanguageDokument3 SeitenPlant Type Model LanguageAlexander LopezNoch keine Bewertungen

- Market Information - InternalDokument2 SeitenMarket Information - InternalAlexander LopezNoch keine Bewertungen

- QSB4.5 Curve and Datasheet-FR91611Dokument3 SeitenQSB4.5 Curve and Datasheet-FR91611Alexander Lopez100% (2)

- kOBELCO-POLICY MANUAL ONLYDokument37 SeitenkOBELCO-POLICY MANUAL ONLYAlexander LopezNoch keine Bewertungen

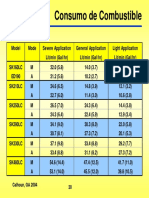

- Consumo de Combustible EXC, KOBELCO)Dokument1 SeiteConsumo de Combustible EXC, KOBELCO)Alexander LopezNoch keine Bewertungen

- Service Bulletin (ECB) Priority - Ii - Iii - : Rebuilding Kit - Parking Brake SwitchDokument2 SeitenService Bulletin (ECB) Priority - Ii - Iii - : Rebuilding Kit - Parking Brake SwitchAlexander LopezNoch keine Bewertungen

- Workshop Manual W3030EN1.pdf Workshop Manual W3030EN1 PDFDokument43 SeitenWorkshop Manual W3030EN1.pdf Workshop Manual W3030EN1 PDFAlexander LopezNoch keine Bewertungen

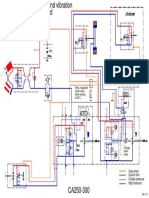

- CA250-300 Steering Vibration Driving Barkes Disengaged PDFDokument1 SeiteCA250-300 Steering Vibration Driving Barkes Disengaged PDFAlexander LopezNoch keine Bewertungen

- Workshop Manual W3015EN2.pdf Workshop Manual W3015EN2 PDFDokument20 SeitenWorkshop Manual W3015EN2.pdf Workshop Manual W3015EN2 PDFAlexander LopezNoch keine Bewertungen

- Workshop Manual W3024EN2.pdf Workshop Manual W3024EN2 PDFDokument64 SeitenWorkshop Manual W3024EN2.pdf Workshop Manual W3024EN2 PDFAlexander LopezNoch keine Bewertungen

- Cho Gsas - Harvard 0084L 11462Dokument503 SeitenCho Gsas - Harvard 0084L 11462Claudemiro costaNoch keine Bewertungen

- Problem-Based Learning ReportDokument24 SeitenProblem-Based Learning Reporterdayu86Noch keine Bewertungen

- Mid Lesson 1 Ethics & Moral PhiloDokument13 SeitenMid Lesson 1 Ethics & Moral PhiloKate EvangelistaNoch keine Bewertungen

- Setting Times of ConcreteDokument3 SeitenSetting Times of ConcreteP DhanunjayaNoch keine Bewertungen

- Neuropsychological Performance in Neurofibromatosis Type 1: Original ArticleDokument5 SeitenNeuropsychological Performance in Neurofibromatosis Type 1: Original ArticleRaquel DuarteNoch keine Bewertungen

- WL4000Dokument1 SeiteWL4000Laser PowerNoch keine Bewertungen

- Prakab Export 20.8.2018 UkDokument260 SeitenPrakab Export 20.8.2018 UkREN JTNNoch keine Bewertungen

- Industrial Revolution OutlineDokument8 SeitenIndustrial Revolution OutlineGeraldine GuarinNoch keine Bewertungen

- Charles Haanel - The Master Key System Cd2 Id1919810777 Size878Dokument214 SeitenCharles Haanel - The Master Key System Cd2 Id1919810777 Size878Hmt Nmsl100% (2)

- Editor: Lalsangliana Jt. Ed.: H.Dokument4 SeitenEditor: Lalsangliana Jt. Ed.: H.bawihpuiapaNoch keine Bewertungen

- Aesa Based Pechay Production - AbdulwahidDokument17 SeitenAesa Based Pechay Production - AbdulwahidAnne Xx100% (1)

- JMO 2023 (7, 8) Question PaperDokument2 SeitenJMO 2023 (7, 8) Question PaperSuryanshu BhardwajNoch keine Bewertungen

- Plaquette - PRECASEM - CIMEC 2019 English VersionDokument18 SeitenPlaquette - PRECASEM - CIMEC 2019 English VersionFranck BertrandNoch keine Bewertungen

- Annie Ovenden Exibition 2017Dokument19 SeitenAnnie Ovenden Exibition 2017Vitaliy ChuenkoNoch keine Bewertungen

- Goal 6 Unesco Water SanatationDokument5 SeitenGoal 6 Unesco Water Sanatationapi-644347009Noch keine Bewertungen

- BRASS Introduction 2012Dokument23 SeitenBRASS Introduction 20121234scr5678Noch keine Bewertungen

- Water Chemistry - An Introduction To The Chemistry of Natural and Engineered Aquatic Systems-Páginas-483-492Dokument10 SeitenWater Chemistry - An Introduction To The Chemistry of Natural and Engineered Aquatic Systems-Páginas-483-492jhonier guevaraNoch keine Bewertungen

- Boundary ScanDokument61 SeitenBoundary ScanGéza HorváthNoch keine Bewertungen

- CM Bu9000 Eng Bushings 3Dokument36 SeitenCM Bu9000 Eng Bushings 3ing.dmanriq27100% (1)

- Foldable HelmetDokument16 SeitenFoldable Helmetharsha kotewarNoch keine Bewertungen

- Brainedema 160314142234Dokument39 SeitenBrainedema 160314142234Lulu LuwiiNoch keine Bewertungen

- Logarithmic Functions Week 7Dokument20 SeitenLogarithmic Functions Week 7gadraNoch keine Bewertungen

- 33 Mpact - of - The - Great - Earthquake-2015 - On - Hospitality PDFDokument30 Seiten33 Mpact - of - The - Great - Earthquake-2015 - On - Hospitality PDFJoannabelNoch keine Bewertungen

- Fo Transfer ProcedureDokument8 SeitenFo Transfer ProcedureadityasahayNoch keine Bewertungen

- NREL Novel Electrolyzer Applications Providing More Than Just Hydrogen PDFDokument35 SeitenNREL Novel Electrolyzer Applications Providing More Than Just Hydrogen PDFJosePPMolinaNoch keine Bewertungen

- Sandvik Saf 31803 Tube and Pipe, Seamless: DatasheetDokument9 SeitenSandvik Saf 31803 Tube and Pipe, Seamless: DatasheetPaul NeedhamNoch keine Bewertungen

- Unit-1 Infancy: S.Dharaneeshwari. 1MSC - Home Science-Food &nutritionDokument16 SeitenUnit-1 Infancy: S.Dharaneeshwari. 1MSC - Home Science-Food &nutritionDharaneeshwari Siva-F&NNoch keine Bewertungen

- DSR Codes - 1Dokument108 SeitenDSR Codes - 1lakkireddy seshireddyNoch keine Bewertungen

- Water Vapor Permeability of Polypropylene: Fusion Science and TechnologyDokument5 SeitenWater Vapor Permeability of Polypropylene: Fusion Science and TechnologyBobNoch keine Bewertungen

- Proknow VersionDokument21 SeitenProknow Versionapi-392523563Noch keine Bewertungen