Beruflich Dokumente

Kultur Dokumente

Sabic: Polybutylene Terephthalate

Hochgeladen von

Akshay BOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sabic: Polybutylene Terephthalate

Hochgeladen von

Akshay BCopyright:

Verfügbare Formate

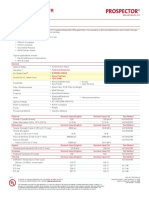

VALOX™ FR Resin 420SE0 -

Americas www.ulprospector.com

Polybutylene Terephthalate

SABIC

Technical Data

Product Description

VALOX 420SE0 Polybutylene Terephthalate (PBT) resin is a 30% glass fiber reinforced, injection moldable grade. This brominated flame

retardant PBT has a UL V0 and 5VA rating. VALOX 420SE0 resin is a general purpose resin that is an excellent candidate for a wide variety of

applications including electrical components, bobbins, switches, stators, commutators and cooling fans.

General

Material Status • Commercial: Active

Literature 1 • Technical Datasheet

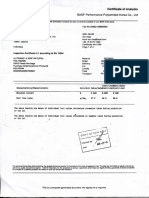

• E121562-101092083

UL Yellow Card 2

• E121562-101513781

Search for UL Yellow Card • SABIC

Availability • Latin America • North America

Filler / Reinforcement • Glass Fiber, 30% Filler by Weight

• Aerospace Applications • Automotive Under the Hood

• Lighting Applications

• Appliances • Construction Applications

• Medical/Healthcare

Uses • Automotive Exterior Parts • Electrical/Electronic Applications

Applications

• Automotive Interior Parts • Non-specific Food Applications

• Electronic Displays

• Automotive Lighting • Sporting Goods

• Industrial Applications

Automotive Specifications • CHRYSLER MS-DB-400 • GM GMP.PBT.005

CPN2253 Color: Black

Processing Method • Injection Molding

• Flexural DMA (ASTM D4065) • Shear DMA (ASTM D4065) • Tensile Fatigue

• Instrumented Impact (Energy) • Specific Heat vs. Temperature • D638)

Tensile Stress vs. Strain (ASTM

Multi-Point Data (ASTM D3763) (ASTM D3417)

• Instrumented Impact (Load) • Tensile Creep (ASTM D2990) •

Viscosity vs. Shear Rate

(ASTM D3763) (ASTM D3835)

Also Available In • Asia Pacific • Europe

Physical Nominal Value (English) Nominal Value (SI) Test Method

Density / Specific Gravity

-- 1.63 1.63 g/cm³ ASTM D792

-- 1.63 g/cm³ 1.63 g/cm³ ISO 1183

Specific Volume 16.9 in³/lb 0.610 cm³/g ASTM D792

Melt Mass-Flow Rate (MFR) (250°C/5.0 kg) 42 g/10 min 42 g/10 min ASTM D1238

Melt Volume-Flow Rate (MVR) (250°C/5.0 kg) 1.77 in³/10min 29.0 cm³/10min ISO 1133

Molding Shrinkage Internal Method

Flow 4 1.0E-3 to 5.0E-3 in/in 0.10 to 0.50 %

Flow : 0.126 in (3.20 mm) 5.0E-3 to 7.0E-3 in/in 0.50 to 0.70 %

Across Flow 4 4.0E-3 to 8.0E-3 in/in 0.40 to 0.80 %

Across Flow : 0.126 in (3.20 mm) 5.0E-3 to 0.010 in/in 0.50 to 1.0 %

Water Absorption ISO 62

Saturation, 73°F (23°C) 0.090 % 0.090 %

Equilibrium, 73°F (23°C), 50% RH 0.070 % 0.070 %

Outdoor Suitability f2 f2 UL 746C

Mechanical Nominal Value (English) Nominal Value (SI) Test Method

Tensile Modulus

-- 5 1.74E+6 psi 12000 MPa ASTM D638

-- 1.45E+6 psi 10000 MPa ISO 527-2/1

Tensile Strength

Yield 6 17400 psi 120 MPa ASTM D638

Yield 17400 psi 120 MPa ISO 527-2/5

Break 6 17400 psi 120 MPa ASTM D638

Break 17400 psi 120 MPa ISO 527-2/5

1 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Mechanical Nominal Value (English) Nominal Value (SI) Test Method

Tensile Elongation

Yield 6 2.0 % 2.0 % ASTM D638

Yield 1.9 % 1.9 % ISO 527-2/5

Break 6 2.0 % 2.0 % ASTM D638

Break 1.9 % 1.9 % ISO 527-2/5

Flexural Modulus

1.97 in (50.0 mm) Span 7 1.42E+6 psi 9800 MPa ASTM D790

-- 8 1.38E+6 psi 9500 MPa ISO 178

Flexural Stress

-- 26100 psi 180 MPa ISO 178

Break, 1.97 in (50.0 mm) Span 7 27000 psi 186 MPa ASTM D790

Taber Abrasion Resistance Internal Method

1000 Cycles, 1000 g, CS-17 Wheel 22.0 mg 22.0 mg

Impact Nominal Value (English) Nominal Value (SI) Test Method

Charpy Notched Impact Strength 9 ISO 179/1eA

-22°F (-30°C) 2.9 ft·lb/in² 6.0 kJ/m²

73°F (23°C) 3.3 ft·lb/in² 7.0 kJ/m²

Charpy Unnotched Impact Strength 9 ISO 179/1eU

-22°F (-30°C) 24 ft·lb/in² 50 kJ/m²

73°F (23°C) 24 ft·lb/in² 50 kJ/m²

Notched Izod Impact

-22°F (-30°C) 1.1 ft·lb/in 57 J/m ASTM D256

73°F (23°C) 1.1 ft·lb/in 60 J/m ASTM D256

-22°F (-30°C) 10 2.9 ft·lb/in² 6.0 kJ/m² ISO 180/1A

73°F (23°C) 10 3.3 ft·lb/in² 7.0 kJ/m² ISO 180/1A

Unnotched Izod Impact

73°F (23°C) 12 ft·lb/in 620 J/m ASTM D4812

-22°F (-30°C) 10 21 ft·lb/in² 45 kJ/m² ISO 180/1U

73°F (23°C) 10 21 ft·lb/in² 45 kJ/m² ISO 180/1U

Instrumented Dart Impact ASTM D3763

73°F (23°C), Total Energy 44.3 in·lb 5.00 J

Hardness Nominal Value (English) Nominal Value (SI) Test Method

ASTM D785

Rockwell Hardness (R-Scale) 119 119

ISO 2039-2

Ball Indentation Hardness (H 358/30) 17100 psi 118 MPa ISO 2039-1

Thermal Nominal Value (English) Nominal Value (SI) Test Method

Deflection Temperature Under Load

66 psi (0.45 MPa), Unannealed, 0.126 in (3.20

414 °F 212 °C ASTM D648

mm)

66 psi (0.45 MPa), Unannealed, 0.157 in (4.00

428 °F 220 °C ISO 75-2/Be

mm), 3.94 in (100 mm) Span 11

264 psi (1.8 MPa), Unannealed, 0.126 in (3.20

392 °F 200 °C ASTM D648

mm)

264 psi (1.8 MPa), Unannealed, 0.157 in (4.00

383 °F 195 °C ISO 75-2/Ae

mm), 3.94 in (100 mm) Span 11

264 psi (1.8 MPa), Unannealed, 0.157 in (4.00

392 °F 200 °C ISO 75-2/Af

mm), 2.52 in (64.0 mm) Span 10

Vicat Softening Temperature

-- 392 °F 200 °C ASTM D1525 12

-- 428 °F 220 °C ISO 306/A50

Ball Pressure Test IEC 60695-10-2

253 to 261°F (123 to 127°C) Pass Pass

2 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Thermal Nominal Value (English) Nominal Value (SI) Test Method

CLTE

ASTM E831

Flow : -40 to 104°F (-40 to 40°C) 1.4E-5 in/in/°F 2.5E-5 cm/cm/°C

ISO 11359-2

Flow : 73 to 176°F (23 to 80°C) 1.4E-5 in/in/°F 2.5E-5 cm/cm/°C ISO 11359-2

Transverse : -40 to 104°F (-40 to 40°C) 4.9E-5 in/in/°F 8.9E-5 cm/cm/°C ASTM E831

Transverse : -40°F (-40°C) 4.9E-5 in/in/°F 8.9E-5 cm/cm/°C ISO 11359-2

Transverse : 73 to 176°F (23 to 80°C) 6.7E-5 in/in/°F 1.2E-4 cm/cm/°C ISO 11359-2

Thermal Conductivity 1.7 Btu·in/hr/ft²/°F 0.25 W/m/K ISO 8302

RTI Elec 266 °F 130 °C UL 746

RTI Imp 266 °F 130 °C UL 746

RTI Str 284 °F 140 °C UL 746

Electrical Nominal Value (English) Nominal Value (SI) Test Method

Surface Resistivity > 1.0E+15 ohms > 1.0E+15 ohms IEC 60093

ASTM D257

Volume Resistivity > 1.0E+15 ohms·cm > 1.0E+15 ohms·cm

IEC 60093

Dielectric Strength

0.0630 in (1.60 mm), in Oil 610 V/mil 24 kV/mm ASTM D149

0.126 in (3.20 mm), in Air 480 V/mil 19 kV/mm ASTM D149

0.0315 in (0.800 mm), in Oil 580 V/mil 23 kV/mm IEC 60243-1

0.0630 in (1.60 mm), in Oil 560 V/mil 22 kV/mm IEC 60243-1

0.126 in (3.20 mm), in Oil 410 V/mil 16 kV/mm IEC 60243-1

Dielectric Constant

ASTM D150

100 Hz 3.80 3.80

IEC 60250

1 MHz 3.70 3.70 ASTM D150

50 Hz 3.30 3.30 IEC 60250

60 Hz 3.30 3.30 IEC 60250

1 MHz 3.30 3.30 IEC 60250

Dissipation Factor

ASTM D150

100 Hz 2.0E-3 2.0E-3

IEC 60250

1 MHz 0.020 0.020 ASTM D150

50 Hz 1.0E-3 1.0E-3 IEC 60250

60 Hz 1.0E-3 1.0E-3 IEC 60250

1 MHz 0.010 0.010 IEC 60250

Arc Resistance 13 PLC 6 PLC 6 ASTM D495

Comparative Tracking Index (CTI) PLC 3 PLC 3 UL 746

Comparative Tracking Index IEC 60112

-- 175 V 175 V

Solution B 125 V 125 V

High Amp Arc Ignition (HAI) 14 PLC 0 PLC 0 UL 746

High Voltage Arc Tracking Rate (HVTR) PLC 4 PLC 4 UL 746

Hot-wire Ignition (HWI) PLC 2 PLC 2 UL 746

Flammability Nominal Value (English) Nominal Value (SI) Test Method

Flame Rating UL 94

0.016 in (0.40 mm) V-2 V-2

0.028 in (0.71 mm) V-0 V-0

0.08 in (2.0 mm) 5VA 5VA

Glow Wire Flammability Index IEC 60695-2-12

0.04 in (1.0 mm) 1760 °F 960 °C

Oxygen Index 32 % 32 % ISO 4589-2

3 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Injection Nominal Value (English) Nominal Value (SI)

Drying Temperature 248 °F 120 °C

Drying Time 3.0 to 4.0 hr 3.0 to 4.0 hr

Suggested Max Moisture 0.020 % 0.020 %

Suggested Shot Size 40 to 80 % 40 to 80 %

Rear Temperature 473 to 509 °F 245 to 265 °C

Middle Temperature 482 to 518 °F 250 to 270 °C

Front Temperature 491 to 527 °F 255 to 275 °C

Nozzle Temperature 482 to 518 °F 250 to 270 °C

Processing (Melt) Temp 491 to 527 °F 255 to 275 °C

Mold Temperature 149 to 194 °F 65 to 90 °C

Back Pressure 43.5 to 102 psi 0.300 to 0.700 MPa

Screw Speed 50 to 80 rpm 50 to 80 rpm

Vent Depth 9.8E-4 to 1.5E-3 in 0.025 to 0.038 mm

Injection Notes

Injection Molding Parameters

• Drying Time (Cumulative): 12 hrs

4 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Flexural DMA (ASTM D4065)

1400000

1300000 6.30 Hz, E´

6.30 Hz, E"

1200000 6.30 Hz, TAN DELTA

1100000

1000000

900000

Pressure (psi)

800000

700000

600000

500000

400000

300000

200000

100000

0

-100 0 100 200 300 400 500

Temperature (°F)

5 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Instrumented Impact (Energy) (ASTM D3763)

5.0

134 in/sec, 73.4°F,

4.5 0.126 in

4.0

3.5

Energy (ft·lb)

3.0

2.5

2.0

1.5

1.0

0.5

0.0

0 200 400 600 800 1000 1200 1400

Deflection (mil)

6 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Instrumented Impact (Load) (ASTM D3763)

240

134 in/sec, 73.4°F,

220

0.126 in

200

180

160

140

Load (lbf)

120

100

80

60

40

20

0

-20

0 200 400 600 800 1000 1200 1400

Deflection (mil)

7 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Shear DMA (ASTM D4065)

350000

6.30 Hz, G´

300000 6.30 Hz, G"

6.30 Hz, TAN DELTA

250000

200000

Pressure (psi)

150000

100000

50000

-50000

-100 0 100 200 300 400 500

Temperature (°F)

8 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Specific Heat vs. Temperature (ASTM D3417)

0.80

HEATING

0.75

COOLING

0.70

0.65

Specific Heat (Btu/lb/°F)

0.60

0.55

0.50

0.45

0.40

0.35

0.30

0.25

0.20

100 200 300 400 500 600 700

Temperature (°F)

9 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Tensile Creep (ASTM D2990)

0.055

71.6°F, 3625.9 psi

0.050 71.6°F, 4206.1 psi

0.045 71.6°F, 4931.3 psi

255°F, 2755.7 psi

0.040 255°F, 3625.9 psi

255°F, 4206.1 psi

0.035 356°F, 1740.5 psi

Strain (in/in)

356°F, 2755.7 psi

0.030

0.025

0.020

0.015

0.010

0.005

0.000

0 20 40 60 80 100

Time (hr)

10 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Tensile Fatigue

15500

73.4°F, 5 Hz (1)

73.4°F, 5 Hz (2)

15000 73.4°F, 5 Hz (3)

73.4°F, 5 Hz (4)

14500

14000

13500

13000

12500

12000

Stress (psi)

11500

11000

10500

10000

9500

9000

8500

8000

7500

7000

100 1000 10000 100000 1000000 10000000

Cycles (Cycles)

11 of 14 Form No. TDS-4726-en

Data Notes

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

(1) - Series

UL Prospector 1

| 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

(2) - Series 2

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

(3) -noSeries

assumes 3 or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

responsibility

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

(4)of- such

content Series 4 sites is not within our control, and we cannot and will not take responsibility for the information or content.

third party

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Tensile Stress vs. Strain (ASTM D638)

19000

-40.0°F, 0.0833 %/sec

18000 (1)

71.6°F, 0.0833 %/sec

17000 71.6°F, 0.0833 %/sec

73.4°F, 0.833 %/sec (1)

16000 151°F, 0.0833 %/sec

151°F, 0.833 %/sec

15000 255°F, 0.0833 %/sec

302°F, 0.0833 %/sec

14000 356°F, 0.0833 %/sec

13000

12000

11000

Stress (psi)

10000

9000

8000

7000

6000

5000

4000

3000

2000

1000

0

-0.01 0.00 0.01 0.02 0.03 0.04

Strain (in/in)

Data Notes

(1) - BREAK

12 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Viscosity vs. Shear Rate (ASTM D3835)

700

482°F

600 482°F (1)

509°F

500 509°F (1)

536°F

536°F (1)

400

300

200

Viscosity (Pa·s)

100

90

80

70

60

50

40

30

100 200 500 1000 2000 5000 10000 20000

Shear Rate (sec^-1)

Data Notes

(1) - Rab. Corrected Data

13 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ FR Resin 420SE0 - Americas

Polybutylene Terephthalate

SABIC www.ulprospector.com

Notes

1 These links provide you with access to supplier literature. We work hard to keep them up to date; however you may find the most current literature

from the supplier.

2 A UL Yellow Card contains UL-verified flammability and electrical characteristics. UL Prospector continually works to link Yellow Cards to

individual plastic materials in Prospector, however this list may not include all of the appropriate links. It is important that you verify the association

between these Yellow Cards and the plastic material found in Prospector. For a complete listing of Yellow Cards, visit the UL Yellow Card Search.

3 Typical properties: these are not to be construed as specifications.

4 Tensile Bar

5 0.20 in/min (5.0 mm/min)

6 Type I, 0.20 in/min (5.0 mm/min)

7 0.051 in/min (1.3 mm/min)

8 0.079 in/min (2.0 mm/min)

9 80*10*4 sp=62mm

10 80*10*4 mm

11 120*10*4 mm

12 Rate A (50°C/h), Loading 2 (50 N)

13 Tungsten Electrode

14 Surface

14 of 14 Form No. TDS-4726-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Thursday, May 3, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 4/11/2018

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

Das könnte Ihnen auch gefallen

- Santoprene 101-73Dokument4 SeitenSantoprene 101-73Ewerthon Brand'sNoch keine Bewertungen

- 3D-Systems DuraForm HST DATASHEET 03.27.17 USEN WEB 0Dokument2 Seiten3D-Systems DuraForm HST DATASHEET 03.27.17 USEN WEB 0sdhgwdNoch keine Bewertungen

- TDS SantopreneT 8211-55B100Dokument3 SeitenTDS SantopreneT 8211-55B100Adi HermawanNoch keine Bewertungen

- Duraform Pa Plastic: General Properties FeaturesDokument2 SeitenDuraform Pa Plastic: General Properties FeaturesMarouane MbarkiNoch keine Bewertungen

- AmodelDokument4 SeitenAmodelPeter EvansNoch keine Bewertungen

- TDS - Acrylic V825 - From PolyOneDokument2 SeitenTDS - Acrylic V825 - From PolyOneVio Amariei0% (1)

- PET Eastar™ Copolyester EN058Dokument2 SeitenPET Eastar™ Copolyester EN058GodesPow. Jose L. Godes: Entrenamiento con potenciaNoch keine Bewertungen

- Santoprene™ 101-64: Thermoplastic VulcanizateDokument4 SeitenSantoprene™ 101-64: Thermoplastic VulcanizateMohitNoch keine Bewertungen

- Lupol® GP3156FDokument3 SeitenLupol® GP3156FYo ANoch keine Bewertungen

- 1072 - Ppo Noryl gfn1720Dokument4 Seiten1072 - Ppo Noryl gfn1720pava16230.meNoch keine Bewertungen

- Santoprene 201 87Dokument4 SeitenSantoprene 201 87AdileneNoch keine Bewertungen

- Product PDF 244478Dokument3 SeitenProduct PDF 244478lorejaz84071127Noch keine Bewertungen

- Santoprene™ 201-87: Thermoplastic VulcanizateDokument4 SeitenSantoprene™ 201-87: Thermoplastic VulcanizateallenNoch keine Bewertungen

- Repol® C015Eg: Reliance Industries LimitedDokument2 SeitenRepol® C015Eg: Reliance Industries LimitedCamilo ObandoNoch keine Bewertungen

- Datenblatt Rohstoff Torlon 4301Dokument4 SeitenDatenblatt Rohstoff Torlon 4301DarkedgeNoch keine Bewertungen

- Kopla Pa6 KNG1015Dokument3 SeitenKopla Pa6 KNG1015agungNoch keine Bewertungen

- Starex GR-4020: Lotte Advanced Materials Co., LTDDokument5 SeitenStarex GR-4020: Lotte Advanced Materials Co., LTDsivalingabeastboy2002Noch keine Bewertungen

- Para - Solvay Ixef 1022Dokument8 SeitenPara - Solvay Ixef 1022armandoNoch keine Bewertungen

- Mada Wall Stud (C-STUD) : Product Description Product CharacteristicsDokument1 SeiteMada Wall Stud (C-STUD) : Product Description Product Characteristicsmichael jan tubongbanuaNoch keine Bewertungen

- Product PDF 66314Dokument1 SeiteProduct PDF 66314rubser05Noch keine Bewertungen

- Tristar® PC-05GFRDokument3 SeitenTristar® PC-05GFRRhekron PlasticsNoch keine Bewertungen

- Pmma Plexigals Hfi7-101Dokument4 SeitenPmma Plexigals Hfi7-101countzeroaslNoch keine Bewertungen

- Technical Data Sheet MarlexDokument2 SeitenTechnical Data Sheet MarlexWilly NursalimNoch keine Bewertungen

- Product PDF 77365Dokument1 SeiteProduct PDF 77365rubser05Noch keine Bewertungen

- Geogrid Standard Material SpecificationDokument2 SeitenGeogrid Standard Material SpecificationBriccioNoch keine Bewertungen

- Para - Solvay Ixef 1032Dokument7 SeitenPara - Solvay Ixef 1032armandoNoch keine Bewertungen

- Kumho ABS 750SWDokument3 SeitenKumho ABS 750SWVu TranNoch keine Bewertungen

- Lustran® 433: INEOS StyrolutionDokument3 SeitenLustran® 433: INEOS StyrolutionJames FaunceNoch keine Bewertungen

- Yuplene™ H360F: SK Global ChemicalDokument2 SeitenYuplene™ H360F: SK Global ChemicalNguyễn Hồng NamNoch keine Bewertungen

- Hanwha Total PP BJ550Dokument2 SeitenHanwha Total PP BJ550Nguyễn Hồng NamNoch keine Bewertungen

- Product PDF 210710Dokument1 SeiteProduct PDF 210710vaibhav ShindeNoch keine Bewertungen

- Mechanical Seals - Mechanical Seals For Pumps - Pusher SealsDokument4 SeitenMechanical Seals - Mechanical Seals For Pumps - Pusher SealsAndré Silva RibeiroNoch keine Bewertungen

- ACRYLITE® Satinice df21 8NDokument3 SeitenACRYLITE® Satinice df21 8NEnriqueNoch keine Bewertungen

- Polylac® Pa-747Dokument3 SeitenPolylac® Pa-747vicenteNoch keine Bewertungen

- Series GT2450: 4-20 Ma Hazardous Location Pressure TransmitterDokument2 SeitenSeries GT2450: 4-20 Ma Hazardous Location Pressure TransmitterLuis Carlos Mora UrriagoNoch keine Bewertungen

- Carlisle - Training Jan 27-10Dokument106 SeitenCarlisle - Training Jan 27-10Dani Susanto100% (1)

- Denyl 6 NDokument2 SeitenDenyl 6 NPhung LucNoch keine Bewertungen

- 3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBDokument1 Seite3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBsdhgwdNoch keine Bewertungen

- 214 - Pei Ultem 1000Dokument4 Seiten214 - Pei Ultem 1000Chandrasekar KrishnamurthyNoch keine Bewertungen

- Lotte sm240 TITANPRO® SM240Dokument2 SeitenLotte sm240 TITANPRO® SM240Truc Thao NguyenNoch keine Bewertungen

- ImpactDokument3 SeitenImpacthyper meshNoch keine Bewertungen

- Elvax® 460 PDFDokument2 SeitenElvax® 460 PDFXuân Giang NguyễnNoch keine Bewertungen

- SCG PP P483Ju: SCG Chemicals Co., LTDDokument2 SeitenSCG PP P483Ju: SCG Chemicals Co., LTDTruc Thao NguyenNoch keine Bewertungen

- Anti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeDokument1 SeiteAnti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeVC KannanNoch keine Bewertungen

- LS PEKK CF HT23 Material Datasheet 201705Dokument1 SeiteLS PEKK CF HT23 Material Datasheet 201705Angel LagrañaNoch keine Bewertungen

- Product PDF 37722Dokument3 SeitenProduct PDF 37722Marcelo VicentiniNoch keine Bewertungen

- Kobelt Tabla de EspecificacionesDokument43 SeitenKobelt Tabla de EspecificacionesWilson CendalesNoch keine Bewertungen

- XENOY™ Resin 1760E - AmericasDokument4 SeitenXENOY™ Resin 1760E - AmericasWellington C. de AraujoNoch keine Bewertungen

- Certene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneDokument1 SeiteCertene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneRoberto De Mesa PNoch keine Bewertungen

- 4.36. Millsheet COUPLER 6P MINI F 32671-KYZ - 9010-Y1 Housing (66 Nylon)Dokument7 Seiten4.36. Millsheet COUPLER 6P MINI F 32671-KYZ - 9010-Y1 Housing (66 Nylon)Rizki Eka SiswantoNoch keine Bewertungen

- PC-ABS Bayblend FR110Dokument3 SeitenPC-ABS Bayblend FR110countzeroaslNoch keine Bewertungen

- GMS0030001 R2Dokument10 SeitenGMS0030001 R2Arlindo CrispimNoch keine Bewertungen

- UmaPET - AODokument1 SeiteUmaPET - AOñeNoch keine Bewertungen

- Exceed™ XP 8346CB: Performance PolymerDokument2 SeitenExceed™ XP 8346CB: Performance PolymerMaram YasserNoch keine Bewertungen

- TGS TDS NBR Dia 6165Dokument1 SeiteTGS TDS NBR Dia 6165Chang MikeNoch keine Bewertungen

- Molex 0002081201 - CRIMP - TERMINALSDokument2 SeitenMolex 0002081201 - CRIMP - TERMINALSSadeq NeiroukhNoch keine Bewertungen

- Tenac C 4520Dokument2 SeitenTenac C 4520Phung LucNoch keine Bewertungen

- Lecture 1 Electrolyte ImbalanceDokument15 SeitenLecture 1 Electrolyte ImbalanceSajib Chandra RoyNoch keine Bewertungen

- Early Christian ArchitectureDokument38 SeitenEarly Christian ArchitectureInspirations & ArchitectureNoch keine Bewertungen

- CP3 - June2019 2Dokument5 SeitenCP3 - June2019 2Sifei ZhangNoch keine Bewertungen

- Medical Equipment Quality Assurance For Healthcare FacilitiesDokument5 SeitenMedical Equipment Quality Assurance For Healthcare FacilitiesJorge LopezNoch keine Bewertungen

- Chapter 2Dokument69 SeitenChapter 2Lizi CasperNoch keine Bewertungen

- Net Pert: Cable QualifierDokument4 SeitenNet Pert: Cable QualifierAndrés Felipe Fandiño MNoch keine Bewertungen

- NCPDokument6 SeitenNCPJoni Lyn Ba-as BayengNoch keine Bewertungen

- Measuring and Modeling Vertical Crosshead Vibration in Api-618 Reciprocating CompressorsDokument18 SeitenMeasuring and Modeling Vertical Crosshead Vibration in Api-618 Reciprocating CompressorshmshawkiNoch keine Bewertungen

- How Muslim Inventors Changed The WorldDokument4 SeitenHow Muslim Inventors Changed The WorldShadab AnjumNoch keine Bewertungen

- Chapter 08 MGT 202 Good GovernanceDokument22 SeitenChapter 08 MGT 202 Good GovernanceTHRISHIA ANN SOLIVANoch keine Bewertungen

- BS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDokument16 SeitenBS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDayan Yasaranga100% (2)

- Coc 1 ExamDokument7 SeitenCoc 1 ExamJelo BioNoch keine Bewertungen

- Family Factors: Its Effect On The Academic Performance of The Grade 6 Pupils of East Bayugan Central Elementary SchoolDokument11 SeitenFamily Factors: Its Effect On The Academic Performance of The Grade 6 Pupils of East Bayugan Central Elementary SchoolGrace Joy AsorNoch keine Bewertungen

- Patricio Gerpe ResumeDokument2 SeitenPatricio Gerpe ResumeAnonymous 3ID4TBNoch keine Bewertungen

- Microbiological Quality Ice CreamDokument9 SeitenMicrobiological Quality Ice CreamocortezlariosNoch keine Bewertungen

- Volcano Lesson PlanDokument5 SeitenVolcano Lesson Planapi-294963286Noch keine Bewertungen

- Assesment Test in English 9Dokument3 SeitenAssesment Test in English 9Chazz SatoNoch keine Bewertungen

- Limestone Standards PDFDokument2 SeitenLimestone Standards PDFJacqueline BerueteNoch keine Bewertungen

- Course Outline Cbmec StratmgtDokument2 SeitenCourse Outline Cbmec StratmgtskyieNoch keine Bewertungen

- Types of Intermolecular ForcesDokument34 SeitenTypes of Intermolecular ForcesRuschan JaraNoch keine Bewertungen

- Steve Jobs TalkDokument3 SeitenSteve Jobs TalkDave CNoch keine Bewertungen

- Ict's - 2022 - Mentorship - Summarized - Thread - by - Trader - Theory - Sep 22, 22 - From - RattibhaDokument11 SeitenIct's - 2022 - Mentorship - Summarized - Thread - by - Trader - Theory - Sep 22, 22 - From - RattibhaChristiana OnyinyeNoch keine Bewertungen

- Edtpa Lesson 3Dokument3 SeitenEdtpa Lesson 3api-299319227Noch keine Bewertungen

- Market EquilibriumDokument36 SeitenMarket EquilibriumLiraOhNoch keine Bewertungen

- OnTime Courier Software System Requirements PDFDokument1 SeiteOnTime Courier Software System Requirements PDFbilalNoch keine Bewertungen

- Model DPR & Application Form For Integrated RAS PDFDokument17 SeitenModel DPR & Application Form For Integrated RAS PDFAnbu BalaNoch keine Bewertungen

- HG32High-Frequency Welded Pipe Mill Line - Pakistan 210224Dokument14 SeitenHG32High-Frequency Welded Pipe Mill Line - Pakistan 210224Arslan AbbasNoch keine Bewertungen

- Adding and Subtracting FractionsDokument4 SeitenAdding and Subtracting Fractionsapi-508898016Noch keine Bewertungen

- Full Download Ebook PDF Introductory Econometrics A Modern Approach 7th Edition by Jeffrey PDFDokument42 SeitenFull Download Ebook PDF Introductory Econometrics A Modern Approach 7th Edition by Jeffrey PDFtimothy.mees27497% (39)

- NHL DB Rulebook ENGLISHDokument6 SeitenNHL DB Rulebook ENGLISHAdhika WidyaparagaNoch keine Bewertungen