Beruflich Dokumente

Kultur Dokumente

By The ASCE Task Committee On Design Criteria For Composite Structures in Steel and Concrete ABSTRACT: This Commentary Complements The "Proposed Specification For Struc

Hochgeladen von

Prapa KaranOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

By The ASCE Task Committee On Design Criteria For Composite Structures in Steel and Concrete ABSTRACT: This Commentary Complements The "Proposed Specification For Struc

Hochgeladen von

Prapa KaranCopyright:

Verfügbare Formate

COMMENTARY ON PROPOSED SPECIFICATION FOR

STRUCTURAL STEEL BEAMS WITH W E B OPENINGS

(WITH DESIGN EXAMPLE)

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

By the ASCE Task Committee on Design Criteria for Composite Structures

in Steel and Concrete

ABSTRACT: This commentary complements the "Proposed Specification for Struc-

tural Steel Beams with Web Openings." The specification follows load and resis-

tance factor design (LRFD) philosophy, and may be adopted as a chapter in a

larger specification. Basic design procedures involve determination of maximum

nominal flexural capacity, maximum nominal shear capacity, and interaction of

flexure and shear. The maximum nominal flexural capacity is calculated using

standard strength procedures for both composite and noncomposite sections, taking

into account the loss of material within the web. The maximum nominal shear

capacity is based on a simplified four-hinge mechanism, with one hinge at each

corner of the opening. The general design approach is identical for composite and

noncomposite members, with or without opening reinforcement. The design pro-

cedures apply only to compact sections. Additional criteria are applied to ensure

ductile behavior and performance in accordance with the design expressions. The

procedures apply to both rectangular and circular openings. Criteria for placement

of concentrated loads and positioning of openings are included, as are detailing

requirements for opening and slab reinforcement.

1.0 SCOPE

This specification (ASCE: "Proposed Specification for Structural Steel

Beams with Web Openings" 1992) is based on the design procedures and

guidelines presented by Darwin (1990) for both composite and noncom-

posite beams with web openings. Darwin (1990) drew heavily on design

guidelines presented by Redwood and Shrivastava (1980) for noncomposite

sections, as well as a wide range of other references, many of which are

cited in this commentary. Steel sections must meet the requirements of a

compact section for reasons explained in section 4.1 of this commentary.

The specification is formulated in terms of load and resistance factor

design because the capacity of beams at web openings can be accurately

expressed in terms of strength, but not in terms of stresses at stages below

ultimate.

2.0 DESIGN

Several design procedures have been developed for structural steel beams

with web openings (Cho and Redwood 1986; Clawson and Darwin 1980;

Darwin and Donahey 1988; Darwin and Lucas 1990; Donoghue 1982; Kuss-

man and Cooper 1976; Redwood 1968, 1971; Redwood and Poumbouras

1984; Redwood and Shrivastava 1980; Redwood and Wong 1982; Wang et

al. 1975). Most of the techniques have been developed for specific types of

members, such as noncomposite beams with reinforced openings (Kussman

and Cooper 1976; Redwood 1971; Redwood and Shrivastava 1980; Wang

et al. 1975) or composite beams with unreinforced openings (Cho and Red-

Note. Discussion open until May 1, 1993. To extend the closing date one month,

a written request must be filed with the A S C E Manager of Journals. The manuscript

for this paper was submitted for review and possible publication on February 11,

1992. This paper is part of the Journal of Structural Engineering, Vol. 118, No. 12,

December, 1992. ©ASCE, ISSN 0733-9445/92/0012-3325/$1.00 + $.15 per page.

Paper No. 3436.

3325

J. Struct. Eng. 1992.118:3325-3348.

wood 1986; Clawson and Darwin 1980; Darwin and Donahey 1988; Red-

wood and Poumbouras 1984; Redwood and Wong 1982). In most cases,

these procedures have proved to be safe and conservative. To be used under

the provisions of this specification, a method must provide strength predic-

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

tions that accurately match experimental results such as detailed for non-

composite beams by Bower (1968), Clawson and Darwin (1980), Congdon

and Redwood (1970), Cooper and Snell (1972), Cooper et al. (1977), Lupien

and Redwood (1978), Redwood et al. (1978), and Redwood and Mc-

Cutcheon (1968), and for composite beams by Cho (1982), Clawson and

Darwin (1982), Donahey and Darwin (1988), Granade (1968), Redwood

and Poumbouras (1983), Redwood and Wong (1982), and "Structural In-

vestigation" (1984). The method must include the required resistance fac-

tors.

The procedure presented next provides a single technique that applies to

all types of structural steel beams with web openings, i.e., composite and

noncomposite members, reinforced and unreinforced openings. These pro-

cedures presented are generally easier to apply than the earlier techniques

and provide for more efficient designs (Lucas and Darwin 1990).

3.0 DESIGN PROCEDURE

3.1 Interaction of Flexure and Shear

The cubic interaction equation for flexure and shear presented in Spec-

ification Eq. (1) (ASCE: "Proposed" 1992) provides a consistent and con-

servative representation of the interaction between flexure and shear at web

openings in both composite and noncomposite beams (Darwin and Donahey

1988; Darwin 1990; Donahey and Darwin 1986; Lucas and Darwin 1990).

The upper limits on Vu and M„, design strengths <j>DV„ and §0Mn, respec-

tively, can be obtained by substituting the design capacities for the factored

loads in Specification Eq. (1) (ASCE: "Proposed" 1992)

-1/3

Mu

cJ>0M„

4>0V„ = W„. + 1 (1)

Vu

4>oV„

" / \3 1 ~Ui

<$>0M„ = $0Vn <$>oMm

ted

7 r-3 + 1 (2)

JO)

The values of 4>0, 0.9 for noncomposite sections and 0.85 for composite

sections (Darwin and Lucas 1990; Lucas and Darwin 1990), happen to

correspond to the values of §b used for bending of noncomposite and com-

posite sections, respectively, in the American Institute of Steel Construc-

tion's (AISC) Load and Resistance Factor Design Specification for Structural

Steel Buildings (1986b).

3.2 Maximum Nominal Flexural Capacity

Expressions for the maximum nominal flexural capacity of members at

an opening, Mm, are developed using the same assumptions as used in plastic

3326

J. Struct. Eng. 1992.118:3325-3348.

design for members without openings. The procedures are limited to mem-

bers that meet the requirements of AISC compact sections (Load 1986b).

Noncomposite Beams

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

Fig. 1 presents stress diagrams for noncomposite sections in pure bending.

Unreinforced Openings. For members with unreinforced openings [Fig.

1(a)], the maximum capacity at the opening is expressed as

Mm = Mp - FyAAs (^ + e (3)

where Mp = plastic bending moment of unperforated section = FyZ;

A A., = n0tw;

h0 = depth of opening;

1 1—*y—H

u 1

t '

0

f /§ Openingi 1

rl h

'04

1 ^q Steel Section t

1

u

\ H/H

(a)

-K-A

2

< Ar

1 •w

(b) (C)

FIG. 1. Noncomposite Sections in Pure Bending: (a) Unreinforced Opening; (b)

Reinforced Opening, e =s Arlt„; (c) Reinforced Opening, e a Arlt„

3327

J. Struct. Eng. 1992.118:3325-3348.

tw = thickness of web;

e = eccentricity of opening = \e\ for noncomposite sections;

Z = plastic section modulus; and

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

Fy = yield strength of steel.

Reinforced Openings. For members with reinforcement of area Ar along

both the top and bottom edge of the opening, and eccentricity e < Arltw

[Fig. 1(b)], the maximum moment may be expressed as

Mm = Mp- Fy K (-f + Ke - e2 ) + Arh0 sMp (4)

In the development of Commentary Eq. (4), the reinforcement is assumed

to be concentrated along the top and bottom edges of the opening, and the

thickness of the reinforcement is assumed to be small. These assumptions

provide a conservative value for Mm and allow these simplified expression

to be used. For e =£ 0, the plastic neutral axis (PNA) will be located within

the reinforcing bar at the edge of the opening closest to the centroid of the

original steel section.

For members with larger eccentricities [Fig. 1(c)], i.e., e > Ar/tw, the

maximum moment capacity is

Mm = MP- FyAAs I ^ + e - ^j < Mp (5)

where AAS = hjw - 1Ar.

Like Commentary Eq. (4), Commentary Eq. (5) is based on the as-

sumptions that the reinforcement is concentrated along the top and bottom

edges of the opening and that the thickness of the reinforcement is small.

In this case, however, the PNA lies in the web of the larger tee.

Commentary Eqs. (3)-(5) provide results that are identical to those ob-

tained for the maximum flexural capacity in "Rectangular, Concentric"

(1981, 1986).

Composite Beams

Fig. 2 illustrates stress diagrams for composite sections in pure bending.

In each case, the force in the concrete Pc, is limited to the lower of the

concrete compressive strength, the shear connector capacity, or the yield

strength of the net steel section

Pc s 0.85/# e f e (6a)

Pc^NQ„ (66)

PcsT = FyAm (6c)

where/c = concrete compressive strength;

be = effective width of concrete slab (Load 1986b);

te = effective thickness of concrete slab ( = ts for solid slab; = t's for

slab with ribs perpendicular to steel beam; = (t's + ts)l2 for slab

with ribs parallel to steel beam);

3328

J. Struct. Eng. 1992.118:3325-3348.

0.85 f e

A_r

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

0.85 fe (a) 0.85/;.

~\ /lHM,

7

— a

• — - ^

(b) (c)

FIG. 2. Composite Sections in Pure Bending: (a) Neutral Axis above Top of Flange;

(b) Neutral Axis in Flange; (c) Neutral Axis in Web

4 = total thickness of concrete slab;

t's = thickness of slab above the rib;

N = number of shear connectors between the high moment end of the

opening and the support;

Qn = individual shear connector capacity, including reduction factor for

ribbed slabs (Load 1986b);

3329

J. Struct. Eng. 1992.118:3325-3348.

T" = maximum tensile force in the net steel section;

Asn = net steel area = As — hjw + 2Ar; and

As = cross sectional area of steel in unperforated member.

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

The maximum moment capacity, Mm, depends on which of the inequalities

in Commentary Eq. (6) governs.

If Pc = T [Commentary Eq. (6c) and Fig. 2(a)]

d AAse

Mm = T - + + ts (7)

2 Asn

where LAS = hj„, - 2Ar;

e = opening eccentricity; for composite sections, positive when the center

line of the opening is above the center line of the steel section; and

a = depth of concrete compression block = Pcl(0.&5f'cbe) for solid slabs

and ribbed slabs for which a < t's.

If a > t's, as it can be for ribbed slabs with longitudinal ribs, the term (r,

- a/2) in Commentary Eq. (7) must be replaced with the appropriate

expression for the distance between the top of the steel flange and the

centroid of the concrete force.

If Pc < T [Commentary Eqs. (6a) or (6b)], the plastic neutral axis (PNA)

is in either the flange or the web of the top tee, based on whether

Pc + 2FyAf \ T (8a)

or

Pc + 2FyAf < T (86)

where Af = the flange area = bftf.

Commentary Eqs. (8a) and (8b) are derived from the inequalities Pc +

FyAf > Fy(Am - Af) and Pc + FyAf < Fy(Asn - Af), respectively, which

determine whether the force in the concrete, Pc, and the force in the flange,

FyAf, is greater than or less than the force that can be developed in the

steel section below the flange.

If Commentary Eq. (8a) governs, the PNA is in the flange (Fig. 2b) at

a distance x = (T — Pc)/(2bfFy) from the top flange. In this case

d k.Ase - bfx'

Mm = V + P, (9)

2 A...

If Commentary Eq. (&b) governs, the PNA is in the web [Fig. 2(c)] at a

distance x = (As„ - 2A/)/(2f,„) - PJ(2Fytw) + tf from the top of the

flange. In this case

&Ase - (bf - Qtj twx2

M„ T + P,\U - (10)

A..

Commentary Eqs. (7), (9), and (10) can be replaced by two simplified

expressions (Darwin 1990; Darwin and Lucas 1990) with little loss in ac-

curacy. For beams in which the PNA in the unperforated member is located

at or above the top of the flange, the value of Mm may be approximated in

3330

J. Struct. Eng. 1992.118:3325-3348.

terms of the nominal capacity of the unperforated composite section at the

location of the opening, Mpc

M =, . M(A,„ +F AA,e\ Mpc

v

(11)

- ^\t ^Cr

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

Commentary Eq. (11) is always conservative for Am < As. The values of

Mpc can be conveniently obtained from part 4 of the AISC Load and Resis-

tance Factor Design Manual (1986a).

For beams in which the PNA in the unperforated member is located below

the top of the flange and Pc > Pcmin = Fy[(3/4)twd - AAS], the value of

Mm may be approximated by Commentary Eq. (12)

Mm = FyAm - + FyAAse + Pc L - ^J < Mpc (12)

where ts = thickness of slab; and

Pc = force in the concrete [Commentary Eq. (6)].

Commentary Eq. (12) is also accurate for members in which the PNA in

the unperforated section is located at or above the top of the flange. If Pc

< Fy[(3/4)twd - AAJ, Commentary Eqs. (9) or (10), as appropriate, should

be used to calculate Mm.

When reinforcement is used, the value of Mm in Commentary Eqs. (7)

and (9) through (12) is limited to M the flexural strength of the unper-

forated composite beam (Darwin 1990; Lucas and Darwin 1990). This re-

quirement, along with a similar limitation for steel beams (Redwood and

Shrivastava 1980), is required to insure safe designs.

3.3 Maximum Nominal Shear Capacity

3.3. a General Equations

The maximum shear capacity at a web opening coincides with the for-

mation of plastic hinges at all four corners of the opening (Fig. 3) (Clawson

and Darwin 1982; Darwin and Donahey 1988). The maximum shear capacity

is calculated assuming that there is no axial force in the tees (regions above

and below the opening). The bending moments that act on the tees are due

to shear at the opening and are often referred to as "secondary bending

moments." The ends of the opening subjected to positive and negative

secondary bending moments are referred to as the high and low moment

ends of the opening (right and left sides of Fig. 3), respectively.

The maximum shear capacity at the opening is equal to the sum of the

shear capacities of the top and bottom tees. The capacity of the individual

tees, as expressed in Specification Eq. (2) (ASCE: "Proposed" 1992), is

obtained by solving the shear-secondary moment equilibrium equations for

the tee and accounting for interaction between shear and axial stresses within

the steel web. Eq. (2) in "Proposed" (ASCE 1992) was developed using a

simplified version of the von Mises yield criterion

Fy = y/2Fy - V 3 T (13)

where Fy = reduced axial strength; and

T = web shear stress,

3331

J. Struct. Eng. 1992.118:3325-3348.

0.85 fc 0.85 fc

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

Top

Tea

Bottom

Tea

High

Moment

End

FIG. 3. Axial Stress Distributions for Opening at Maximum Shear: Fy = Reduced

Axial Strength of Steel in Web Due to Cbmbined Axial Stress and Shear Stress

0.85 fe 0.85 fc

. W, -r Knf,

/ t 4

\ r\ L, dh

Top

TM

Bottom

Tea

High

Moment

End

FIG. 4. Simplified Axial Stress Distributions for Opening at Maximum Shear; Fy

= Reduced Axial Strength of Steel in Web Due to Combined Axial Stress and Shear

Stress

and simplifying the stress distributions illustrated in Fig. 3 to those shown

in Fig. 4, which treat the resultants of the stresses in the flanges as acting

at the outside edges of the respective flanges. The simplifications illustrated

in Fig. 4 are obtained by recognizing that: (1) Under pure shear, the PNA

of the tee is usually in the flange; and (2) the exact nature of the stresses

in the flange do not play an important role in the shear-secondary bending

moment equilibrium equations, if the secondary moments are taken about

3332

J. Struct. Eng. 1992.118:3325-3348.

the outside of the flange. The full details of the derivation are presented

by Donahey and Darwin (1986) and Lucas and Darwin (1990).

The use of a modified tee depth, s„ for the calculation of the aspect ratio

of the tee, v, is used to account for movement of the plastic neutral axis in

the tee due to the presence of reinforcement. As the amount of reinforce-

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

ment increases, the PNA moves further from the outside, thus reducing the

effective moment arm of both the normal stresses in the web and the re-

inforcement. The effect of this movement is handled by modifying s, in the

calculation of v only. The actual value of st should be used to calculate (x

in Specification Eq. (3) (ASCE: "Proposed" 1992).

3.3.b Top Tee in Composite Beams

The force in the concrete at the high moment opening, Pc,„ is limited by

the concrete strength, the shear connector capacity, and the top tee tensile

strength in Specification Eqs. (4a), (4b), and (4c), respectively (ASCE:

"Proposed" 1992); N is taken as the number of shear connectors between

the high moment end of the opening and the support rather than the point

of zero moment, because tests (Donahey and Darwin 1986,1988) show that

shear studs participate, even in negative moment regions, due to lateral

movement of the slab. The force at the low moment end of the opening,

Pci in Specification Eq. (5), is based on Pch and the shear connector capacity

over the opening, N0Q„.

The distances from the top of the flange to the centroid of the concrete

stress blocks at the high and low moment ends of the opening, dh and d,,

respectively, are calculated using Specification Eqs. (6) and (7). The spec-

ification provides guidance for calculating d, for slabs with longitudinal ribs.

Specification Eq. (2) for Vml is based on the assumption that all of the

shear in the tee is carried by the steel web. This assumption may be over-

conservative for top tees in composite beams since the concrete slab also

carries shear. If the term (V6 + \i)/(v + V3) in Specification Eq. (2)

exceeds 1.0, the web has fully yielded in shear. Under this state of stress,

the force in the concrete, Pch, is limited to the combined axial strength of

the flange and the reinforcement in the top tee. In this case, Pch in Speci-

fication Eq. (4c) must be replaced by Specification Eq. (9). Upon checking

the limiting value of Pch, and modifying Pd and u, if necessary, Specification

Eq. (8) is used to calculate the capacity of the tee.

Finally, the capacity of the tee may not exceed the plastic shear capacity

of the cross-section, as given in Specification Eq. (10) (Darwin et al. 1988,

1990). The effective area of the concrete, Avc, used in Specification Eq.

(10) was originally proposed by Clawson and Darwin (1980) and later mod-

ified by Donahey and Darwin (1986) to provide a realistic upper limit on

the contribution of the concrete to shear capacity.

4.0 DESIGN CRITERIA

The design criteria presented in 4.0 are based on both theoretical con-

siderations and experimental observations. Many of the criteria were de-

veloped for noncomposite beams (Redwood and Shrivastava 1980) and ex-

tended as appropriate to composite beams (Darwin 1990). The criteria help

insure that the limit states can be obtained upon which the design formulas

are based.

3333

J. Struct. Eng. 1992.118:3325-3348.

4.1 Steel Section

Steel sections must meet the AISC requirements for compact sections

(Load 1986b) to insure that local instabilities, specifically buckling of the

compression flange, do not occur. The equations presented in 3.0 have been

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

validated experimentally only for compact sections (Darwin and Lucas 1990;

Lucas and Darwin 1990).

4.2 Web Buckling

The criteria to prevent web buckling are based on the work reported by

Redwood and Uenoya (1979) for steel sections. The recommendations are

adopted in whole for noncomposite members and relaxed slightly for com-

posite members to account for the portion of the shear carried by the

concrete slab. The higher limit on the opening parameter, p0, of 6.0 for

composite sections versus 5.6 for steel sections is based on successful test

results (Donahey and Darwin 1986, 1988).

4.3 Buckling of Tee-Shaped Compression Zone

Unreinforced, noncomposite tees in compression must be checked to

insure that buckling does not occur. This is of primary concern for large

openings in regions of high moment (Redwood and Shrivastava 1980). MJ

(Vud) > 20 is used to define a high moment region. Buckling is unlikely to

occur in a reinforced tee (Redwood and Shrivastava 1980).

4.4 Lateral Buckling

The design criteria for lateral buckling are based on the recommendations

in Redwood and Shrivastava (1980) and Suggested Design Guides (Subcom-

mittee 1971, 1973). Openings have little effect on the lateral stability of W-

shaped sections. However, design expressions have not been formulated to

predict the inelastic lateral buckling capacity of a member with an opening,

and to be safe, the strength of the member should be governed by a point

remote from the opening.

The effect of the opening may be accounted for by multiplying the tor-

sional constant of the section, / , by

"l - (Vi —MiT <! (14)

y

\Lb) tw(d + 2bf)\ '

where Lh = unbraced length of compression flange; and

A A, = hatw - 2Ar.

In members reinforced on only one side of the web, use Ar = 0 for the

calculation of AAS in Commentary Eq. (14). Members reinforced on one

side of the web should not be used for long laterally unsupported spans,

and for shorter spans, the lateral bracing closest to the opening should be

designed for an additional load equal to 2% of the force in the compression

flange (Redwood and Shrivastava 1980).

Commentary Eq. (14) is an extension (Darwin 1990) of the recommen-

dations made in Redwood and Shrivastava (1980) and Suggested Design

Guides (Subcommittee 1971, 1973) for use with the lateral buckling pro-

visions of design specifications (Load 1986b). It is recommended that Com-

mentary Eq. (14) be applied only if the value of the expression is less than

0.90 (Redwood and Shrivastava 1980).

3334

J. Struct. Eng. 1992.118:3325-3348.

4.5 Opening Depth

The limitations on opening depth are based on both the practical consid-

eration that opening depths in excess of 70% of the section depth are

unrealistically large and the fact that only two beams out of the 85 used to

establish the (j>-factors in 3.1 of the specification had openings with depths

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

in excess of 0.7d.

4.6 Tee Proportions

The limitations on the depths of the top and bottom tees are based on

the need to transfer some load over the opening and a lack of test data for

shallower tees. The upper limit of 12 on the aspect ratio of the tees, v, is

based on a lack of data with members with greater aspect ratios. These

limits, in conjunction with the limitations onp0, prevent the use of openings

for which Specification Eq. (2) (ASCE: "Proposed" 1992) would provide

unconservative predictions of Vmt (Darwin 1990).

4.7 Corner Radii

The limitations on the corner radii are based on the work reported by

Frost and Leffler (1971), which indicates that radii meeting these require-

ments do not adversely affect the fatigue capacity of a member. In spite of

this point, openings are not recommended for members that will be sub-

jected to significant cyclic or fatigue loading.

4.8 Concentrated Loads

Concentrated loads are not permitted over the opening because the design

formulas do not account for the local bending and shear that would be

caused by a concentrated load on a tee. If a concentrated load must be

placed at an opening, additional analyses will be necessary to determine the

effect of the load on the strength of the member at the opening.

The limitations on the locations of concentrated loads near openings to

prevent web crippling are based on an extension (Darwin 1990) of the criteria

presented by Redwood and Shrivastava (1980).

4.9 Placement of Opening

The requirement that openings be placed no closer than a distance d to

a support limits the horizontal shear stresses that must be transferred by

the web between the opening and the support.

4.10 Spacing Between Openings

The limits on spacing between openings in Specification Eqs. (11) and

(12) (ASCE: "Proposed" 1992) are meant to insure that a plastic mechanism

involving interaction between openings will not develop, instability of the

web posts between openings will not occur, and web posts between openings

will not yield in shear (Redwood and Shrivastava 1980). Guidance for the

design of openings that do not meet the criteria in Specification Eqs. (11)

and (12) may be found in Redwood (1973, 1983). Specification Eqs. (13a)

and (13b) limit the potential problem of slab bridging between adjacent

openings (Darwin 1990).

4.11 Circular Openings

The criteria for converting circular openings to equivalent rectangular

openings for application with the design expressions come from Redwood

and Shrivastava (1980) and are based on an investigation into the location

3335

J. Struct. Eng. 1992.118:3325-3348.

of plastic hinges relative to the center line of openings in steel members

(Redwood 1969). These conversions have been adopted for composite beams

as well (Darwin 1990). The use of D0 for h0 for both shear and bending in

members with reinforced web openings is due to the fact that the reinforce-

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

ment is adjacent to the opening. Treating the reinforcement as if it were

adjacent to a shallower opening would provide an unconservative value for

vm.

4.12 Opening Reinforcement

Reinforcement should be placed as close as possible to the edges of the

opening, leaving adequate clearance for fillet welds, if required, on both

sides of the reinforcement. Continuous welds are required because the de-

sign expressions are based on the assumption that full strain compatibility

exists between the reinforcement and the steel section.

Fillet welds are used most commonly to attach the reinforcement to the

web. If a single size fillet weld is used on one side of the bar within the

length of the opening and both sides of the bar within the extensions, the

reinforcement must be extended beyond the opening by a distance of at

least a0IA. The extension requirement of V3Ar/(2fM,) insures that the shear

strength of the web is not exceeded.

The required strength of the weld within the length of the opening is

Kr = <|>02Pr (15)

where c()0 = 0.90 for steel beams and 0.85 for composite beams;

P = F A < Fy t" a°

r y r

~ 2V3

Ar = cross-sectional area of reinforcement above or below the opening.

The required strength of a weld within each extension is

Rwr = $0FyAr (16)

The factor 2 in Commentary Eq. (15) is used because the reinforcement is

in tension on one side of the opening and in compression on the other end

when the tee is subjected to shear (Figs. 3 and 4). Within the extensions,

the reinforcement must be anchored to provide the full yield strength of

the bars since the expressions for M,n are based on this assumption.

The terms 2Pr in Commentary Eq. (15) and FyAr in Commentary Eq.

(16) are multiplied by (J>0 to convert these forces into equivalent factored

loads. The weld is then designed to resist the factored load, Rwr, with a

value of (J> = 0.75 (Load 1986b). The result is a design that is consistent

with the Load and Resistance Factor Design Specification for Structural Steel

Buildings (1986b).

The criteria for placing the reinforcement on one side of the web limit

the reductions in strength caused by out-of-plane deflections caused by

eccentric loading of the reinforcement (Lupien and Redwood 1978). The

limitations on the area of reinforcement, Ar, and the aspect ratio of the

opening, a0lh0, represent the extreme values that have been tested. The

limitation on sjtw is primarily empirical. The limitation on MJ{Vud) restricts

the use of unsymmetrical reinforcement to regions subject to some shear

loading. For regions subjected to pure bending or negligibly low shear, the

out-of-plane deflections of the web can be severe. Under shear, the lateral

3336

J. Struct. Eng. 1992.118:3325-3348.

deformation mode caused by the unsymmetrical reinforcement changes to

allow a greater capacity to be developed. Additional guidance is given by

Lupien and Redwood (1978) for the use of unsymmetrical reinforcement in

regions of pure bending or very low shear.

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

The provisions of 4.12 should not be construed to restrict the use of flange

cover plates, or a thickened concrete slab in composite beams, which are

considered to be modifications of the unperforated section.

4.13 Composite Members

4.13.a

There is strong experimental evidence to suggest that the concrete slab

improves the shear strength at a web opening, even in regions of negative

bending. However, since no tests have actually been carried out for openings

in negative moment regions, the traditional approach, ignoring the contri-

bution of the concrete slab, is taken for the design of web openings in

negative moment regions of composite members.

4.13.b

Slabs tend to crack both transversely and longitudinally in the vicinity of

web openings. The minimum slab reinforcement ratio of 0.0025 is used to

limit crack width and improve the postcrack strength of the slab in the

vicinity of a web opening (Donahey and Darwin 1986, 1988).

4.13.C

At failure, a significant amount of bridging (lifting of the slab from the

steel section) tends to occur between the low moment end of the opening

and a point past the high moment end of the opening in the direction of

increasing moment (Donahey and Darwin 1986, 1988). The required min-

imum number of shear connectors in the direction of increasing moment

limits bridging, although the studs do not directly enter into the calculation

of member strength at the opening. The minimum of two studs per foot

(0.3 m) applies to the total number of studs. If this criteria is already satisfied

by normal stud requirements, additional shear connectors are not needed.

4.13.d

This requirement recognizes that a composite beam with adequate strength

at a web opening may not provide adequate capacity during construction,

when it must perform as a noncomposite member.

4.14 Fatigue

Web openings are not recommended for members that will be subjected

to significant cyclic or fatigue loading. This is due to both a lack of exper-

imental data and a number of specific considerations. However, most mem-

bers in buildings are not subject to a large enough number of cycles of

sufficient amplitude to require design for fatigue.

A web opening in a steel beam can create severe stress concentrations,

especially near the corners of an opening (Clawson and Darwin 1980). The

magnitude of the stresses are dependent upon several factors, including: (1)

The geometry and location of the opening; (2) workmanship; (3) corner

radius; and (4) loading (Frost and Leffler 1971). Reinforcement of an open-

ing with bars welded to the web can also increase local stresses. High lo-

calized stresses under fatigue (cyclic) load conditions can lead to crack

3337

J. Struct. Eng. 1992.118:3325-3348.

initiation and fracture. Prudent design of web openings for fatigue loading

must include a prediction of stresses in the vicinity of the opening, high-

quality workmanship to reduce stress concentrations due to flame cutting

and welding, and proper detailing of corner geometry and welds.

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

4.15 Deflections

Web openings reduce the local moment of inertia of beams, which results

in an increase in the maximum deflection. Openings also result in a local

decrease in the shear stiffness, which leads to deflections through the length

of the opening. The first effect is often greatest when the opening is located

in a region of high moment, the latter when the opening is in a region of

high shear. The effects of the opening on member deformation must be

considered by the engineer. However, in most cases, the effect of a single

web opening on deflection is small. A review of analysis methods that

account for the effects of web openings on beam deflection is presented by

Darwin (1990).

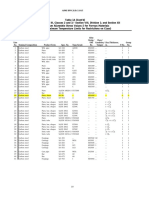

APPENDIX I. DESIGN EXAMPLE

Given

A W16 x 31 composite section with Fy = 36 ksi has been selected to

support a service live load of 1.0 kips/ft and a service dead load of 0.65

kips/ft. The beam span and spacing are 30 ft and 10 ft, respectively. The

total slab thickness is 6.25 in. The slab is placed on a composite metal deck

with a rib depth of 3 in., an average rib width of 6 in., and a rib spacing of

12 in. The ribs are oriented perpendicular to the beam center line {be = 90

in.). Lightweight concrete (f'c = 3.5 ksi [115 pcf]) is used. A total of 26

3/4 in. diameter X 5 in. headed studs (Qn = 19.8 kips) have been selected.

Shored construction is specified. [Note: The basic beam design is identical

to example 1, pages 4-9 through 4-12 of the AISC Load and Resistance

Factor Design Manual (1986a).]

A 10 in. x 20 in. rectangular opening is required at the quarter point of

the span (Fig. 5). Determine if the opening can be placed in the selected

beam. If not, modify the design to allow the same beam depth to be used.

Solution

A. Loads

Factored load = 1.2(0.65) + 1.6(1.0) = 2.38 kips/ft.

n r-\ r\ r\ r\ r\ cxjziu^xjzi^xj^Li, \ n r\ r\ r\j-\

^Opening 4 Support

30'-0"

Ar

FIG. 5. Opening Location

3338

J. Struct. Eng. 1992.118:3325-3348.

B. Moment and Shear at Quarter Point

Mu = 2.38(7.5)(30 - 7.5)/2 = 200.8 ft-kips = 2410 in.-kip and Vu =

2.38(30/2 - 7.5) = 17.9 kips.

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

C. Section Properties

As = 9.12 in.2, d = 15. 1 in., tw = 0.275 in., bf = 5.525 in., tf = 0.440

in., ts = 6.25 in., te = t's -- 3.25 in., andfr„ = 90 in.

D. Preliminary Calculations

Preliminary calculations indicate that the selected beam must be modified

to accept the required opening. It should be noted that a number of options

are available, including: (1) Use of a heavier section; (2) use of higher

strength steel, and (3) use of reinforcement at the opening. For this example,

the second and third options will be investigated. Final selection will be

dependent upon material and fabrication costs.

E. Check the Capacity Using Fy = 50 ksi

Opening and tee properties (see Fig. 6):

hD = 10 in. and a0 = 20 in.

s, = 2.94 in. for both the top and bottom tees

e = 0.0

AAS = hjw - 2Ar = 10(0.275) - 0 = 2.75 in.2

As„ = As - AA = 9.12 - 2.75 = 6.37 in.2

v = ajs, = 20/2.94 = 6.80 for each tee

Check proportioning guidelines:

Compression flange (section 4.1)

Rolled section => compact O.K.

Web limits and limit on Vm (section 4.2)

(d - 2tf) . 420

< O.K.

Opening <5

3.25 in.

/ \ / \ t 7- 3.00 in.

2.94 in.

10 in. _&.

2.94 in.

FIG. 6. Unreinforced Opening Details

3339

J. Struct. Eng. 1992.118:3325-3348.

— = 2 < 3 O.K.

K

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

p c

"' ~ 3 ~ 3\V3 J 3\ V3

+ Vc = 84 + Vc

" - ? „ + ^ = 2 + H-" 8 < 6 » OK '

Opening proportions (sections 4.5 and 4.6)

hjd = 10/15.88 = 0.63 < 0.7 O.K.

st = 2.94 > 0.15d = 0.15(15.88) = 2.38 for top tee O.K.

st = 2.94 > 0.12d = 0.12(15.88) = 1.90 for bottom tee O.K.

v = ajs, = 6.80 < 12 O.K.

Maximum Moment Capacity (Section 3.2). Estimate the number of studs

from the high moment end of the opening to the support, N, to be 7 (specify

one stud per rib for the last 8 ft of the span). Use Commentary Eqs. (6a),

(6b), and (6c) to calculate the force in the concrete:

Pc < 0.85f'cbete = 0.85(3.5)(90)(3.25) = 870 kips

Pc s NQn = 7(19.8) = 139 kips controls

pc s r = FyAm = 50(6.37) = 319 kips

Since Pc < V and Pc + 2FyAf = 139 + 2(50)(5.525)(0.440) = 382 kips

> T' [Commentary Eq. (8a)], the PNA is in the flange and Mm is given by

Commentary Eq. (9):

"- -T' {h ^u^) + '- ('• -1

where x = (J' - Pc)/(2bfFy) = (319 - 139)/[2(5.525)(50)] = 0.326 in.

Therefore

15.88 , 2.75(0.0) - 5.525(0.326)2\

M,„ = 319 | - ^ - + - " v - - ' rn„ ^ "' I

6.37

139

+ 139 | 6.25

1.7(3.5)(90),

= 3336 in.-kip

Maximum Shear Capacity (Section 3.3)

Bottom tee:

Vpt = Fytwst/V3 = 50(0.275)(2.94)/V3 = 23.3 kips

Using Specification Eq. (2) with |x = 0 and v = 6.80:

3340

J. Struct. Eng. 1992.118:3325-3348.

V6 + u. V6 + 0

v

- = T w I y" =

6.80 + v ^ ( 2 3 ' 3 ) = 6 7 kips

-

Top tee:

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

Vp, = Fytws,lV?> = 50(0.275)(2.94)/V3 = 23.3 kips

The value of u, must be calculated for the top tee. The net area of steel in

the top tee is Ast = AJ2 - etw = 6.37/2 - 0.0(0.275) = 3.19 in.2. The

force in the concrete at the high moment end of the opening is obtained

using Specification Eqs. (4a), (4b), and (4c).

Pch < 0.85f'cbete = 0.85(3.5)(90)(3.25) = 870 kips

Pch =s NQ„ = 7(19.8) = 139 kips controls

Pch < FyAsl = 50(3.19) = 159 kips

The force in the concrete at the low moment end of the opening is found

using Specification Eq. (5). Assume the minimum number of ribs over the

opening, N0, is 1 (conservative).

Pc = Pen - N0Qn s 0

= 139 - 1(19.8) = 119 kips

Calculate dh and dt using Specification Eqs. (6) and (7b), respectively:

P 139

d = t = 6 25 _ = 5 in

" ' - hlfbe ' 1.7(3.5)(90) -" -

P 119

d n + 625 3 25 +

' = '- - Tnhr - ' i.7(3.5)(90) = 3 ' 2 2 in

'

Calculate u. using Specification Eq. (3)

2Prdr + Pcndh - Pcld, 0 + 139(5.99) - 119(3.22) _

* Vpts, 23.3(2.94) ^ °

Check (V6 + |x)/(v + V5):

V 6 + \L _ V6 + 6.56

= 1.06 > 1.0

v + V 3 ~ 6.80 + V 3

Therefore, Vm, must be calculated using Specification Eq. (8). The value of

u. to be used in Specification Eq. (8) is now calculated using values for Pch

and Pcl, which are limited by Specification Eqs. (4a), (4b), and (9). Using

Specification Eq. (9):

Pch =£ Fy[tf(bf - tw) + Ar] = 50[0.440(5.525 - 0.275) + 0]

= 116 kips controls

Therefore

Pd = Pch - N0Qn = 116 - 1(19.8) = 96 kips

dh and d, must also be recalculated:

3341

J. Struct. Eng. 1992.118:3325-3348.

?ch 116

dh = ts - = 6.25 - 6.03 in.

l.V'cbe 1.7(3.5)(90)

Pel 96

d, = ts - t's + = 6.25 - 3.25 + = 3.18 in.

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

l-lf'cbe ""~ " • " ' 1.7(3.5)(90)

Recalculate JJL:

The shear capacity is given by Specification Eq. (8):

_ 2Prdr + Pchdh - Pcld, _ 0 + 116(6.03) - 96(3.18) _

= 5.75

Vpts, 23.3(2.94)

5.75

V ,= - V = (23.3) = 19.7 > Vpt = 23.3 kips

6.80

Therefore, Vmt = 2 3 . 3 kips.

Check to see if Vm, s Vmt(sh) [Specification Eq. (10c)]:

Vmt{sh) = Vpt + Q.ll\fcAvc = 23.3 + 0.1lV33(3)(6.25)(3.25)

= 35.8 kips O.K.

Total Shear Capacity

Vm = XVml = 6.7 + 23.3 = 30.0 kips < | Vp + Vc O.K.

Check the interaction [Specification Eq. (1)]:

M„ V„

+ < 1.0

3

2,410 17.9

+ = 0.61 + 0.35 = 0.96 O.K.

0.85(3,336) 0.85(30.0)

F. Check the Capacity Using Fy = 36 ksi and Ar = 0.75 in.2 at

Each Tee

Select reinforcement:

Try a single, 3/8 x 2 bar at each tee. Use a single fillet weld within the

opening length (section 4.12) and place the bars with dr = 2.75 in. for both

tees (Fig. 7).

Check for reinforcement on one side only (section 4.12):

i4p5=0.75<f = ^ ^ = o. 810 .K.

^ = 2 < 2.5 O.K.

K

£, = ^ 9 4 = 10.7 < 1^ = 23.3 o.K.

t„ 0.275

3342

J. Struct. Eng. 1992.118:3325-3348.

Opening and Bar

r

Hr~\ 11 r h tr-A

!

i

"^X^LZ^Z

i

7.

0.25 ia

3.00in.

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

.-ei.. 2.94 in.

3— 12.94 h.

Mil

• \\n » a In. > 30 h. B«r CTyp.)

FIG. 7. Reinforced Opening Details

M„ 2,410

= 8.5 < 20 O.K.

y„rf 17.9(15.88)

Maximum Moment Capacity

AA, = h0tw - 2Ar = 10(0.275) - 2(0.75) = 1.25 in.2

and

As„ = As - M.s = 9.12 - 1.25 = 7.87 in.2

Use Commentary Eqs. (6a), (6b), and (6c) to calculate the force in the

concrete:

Pc < 0.85/^,4 = 0.85(3.5)(90)(3.25) = 870 kips

Pc ^ NQn = 7(19.8) = 139 kips controls

Pc<T' = FyAsn = 36(7.87) = 283 kips

Again, since Pc < T and Pc + 2FyAf = 139 + 2(36)(5.525)(0.440) = 314

kips > T" [Commentary Eq. (8a)], the PNA is in the flange and Mm is given

by Commentary Eq. (9)

M„, = v (d- + AAe

~ b>*2) +PAt.

where

T - Pr 283 - 139

x = = 0.362 in.

2bfFy 2(5.525)(36)

Therefore

* „ - 283 | ' » y » + 1-25(0.0) -gWM&j

139

139 6.25

1.7(3.5)(90)/

3343

J. Struct. Eng. 1992.118:3325-3348.

= 3,053 in.-kip < Mp = 3,385 for the unperforated section O.K.

Maximum Shear Capacity

Per section X3.3, the axial force in the opening reinforcement is given

by

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

Ft a

p r = FA

y r < y 'V-°

~ 2V3

Therefore,

0 2 0

Pr = 36(0.75) = 27.0 kips * ^ C ^ ) = 57.2 kips

Bottom tee:

^ = ^ = 36(0.275^(2.94) = 168k .ps

With reinforcement at the bottom tee, (JL is nonzero (Specification Eq. 3).

_ 2Prdr + Pchdh - Pcldi _ 2(27.0)(2.75) + 0 - 0

^" V^, 16.8(2.94)

For reinforced openings, v is initially given by v = a 0 /s, = a0/[sr - A r /

(26,)]. Therefore, v = 20/{2.94 - 0.75/[2(5.525)]} = 6.96. Using Specifi-

cation Eq. (2) with JJL = 3.00 and v = 6.96:

V6 + (JL V6 4- 3.00

V V

- = VT^ * = 6 * ^ / 3 (16-8^ = 10'5 ^

Top tee:

p = Fytwst =36(0.275)(2.94) = ps

' "W vJ—

As with the unreinforced opening, Pch must be found before calculating \i.

Since Specification Eq. (4c) gives Pch = K,AM = Fy(A„,/2 - etw) = 36(7.87/

2 - 0(0.275)) = 141, Specification Eq. (Ab) again provides the initial limit

on the concrete force with Pch - 139 kips. The value for |x [Specification

Eq. (3)] is therefore

2Prdr + Pchdh - Pc,d, = 2(27.0)(2.75) + 139(5.99) - 119(3.22)

^ Vpts, 16.8(2.94)

= 12.1

Check (V6 + |x)/(v + V3):

V6 + n, V6 + 12.1

£ = -F= = 1.68 > 1.0

v + V3 6.96 + V 3

Fcft is therefore limited by the combined yield capacity of the top flange

and the reinforcement [Specification Eq. (9)]

Pch =£ Fy[tf(bf - tw) + Ar] = 36[0.440(5.525 - 0.275) + 0.75]

= 110 kips

3344

J. Struct. Eng. 1992.118:3325-3348.

Therefore

Pd = Pch - N0Qn = HO - 1(19.8) = 90 kips

dh and d, are given by

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

d = = 6 25 = 6 04in

" '• " ilk ' - 1.7(3.5)(90) - '

di

= '• - < ;+ uKte = 6 - 2 5 -3-25 + UiBjwr3-17 in

-

fx [Specification Eq. (3)] is now given by

= 2Prdr + Pchdh - Pcld, = 2(27.0)(2.75) + 110(6.04) - 90(3.17)

^ Vplst 16.8(2.94)

= 10.7

Finally, v = ajst = 6.80 for use in Specification Eq. (8)

y =

- I^ = S = 26 4kipS

'

Check to see if Vm, < Vm,(sh) [Specification Eq. (10a)]

Vmt{sh) = Vpt + 0.llVfcAvc = 16.8 + 0.1lV53(3)(6.25)(3.25)

= 29.4 kips O.K.

Total Shear Capacity

Vm = 2Vra, = 10.5 + 26.4 = 36.9 kips < | Vp + Vc = 84 + Vc O.K.

Check the interaction [Specification Eq. (1)]

4>0M,J \4>0Vm

2,410 17.9

-- 0.80 + 0.18 = 0.98 O.K.

0.85(3,053) + 0.85(36.9)

Reinforcement details (Section 4.12):

V3A V3(0.75)

Extension a _ _ r = _____ = 2 . 3 6 in.

& a J A = 5.0 in. controls

A 5 in. extension is therefore required at each end of the opening. Use a

3/8 in. x 2 in. x 30 in. bar centered at each tee (see Fig. 7). To develop

the reinforcement, use a single 3/16 in. fillet weld within the length of the

opening and two 3/16 in. fillets within the extensions.

Slab reinforcement and stud details (section 4.13):

Slab reinforcement > 0.0025(12 in.)4 = 0.0025(12)(6.25) = 0.19 in.2/ft

width.

Use No. 4 bars at 12 in. on center.

3345

J. Struct. Eng. 1992.118:3325-3348.

Specify 2 studs per rib in the first two ribs between the opening and the

center line of the span.

ACKNOWLEDGMENTS

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

This Commentary and the accompanying Specification were written by

the ASCE Task Committee on Design Criteria for Composite Structures in

Steel and Concrete. The members are:

David Darwin, Chairman, University of Kansas

Rex C. Donahey, Secretary, Ellerbe Becket

William C. Clawson, Howard Needles Tammen & Bergendoff

Gregory G. Deierlein, Cornell University

Roberto T. Leon, University of Minnesota

APPENDIX II. CONVERSION TO SI CUSTOMARY UNITS

To convert To Multiply by

ft m 0.305

in. mm 25.4

in.-kip m-N 112.98

kip kN 4.448

kip/ft kN/m 14.59

ksi N/mm2 6.895

APPENDIX III. REFERENCES

ASCE Task Committee on Design Criteria for Concrete Structures in Steel and

Concrete. (1992). "Proposed specification for structural steel beams with web

openings." /. Struct. Engrg., ASCE, 118(12), 3315-3324.

Bower, J. E. (1968). "Ultimate strength of beams with rectangular holes." J. Struct.

Div., ASCE, 94(6), 1315-1337.

Cho, S. H. (1982). "An investigation on the strength of composite beams with web

openings." M.S. Arch. Eng. Thesis, Hanyong University, Seoul, Korea.

Cho, S. H., and Redwood, R. G. (1986). "The design of composite beams with web

openings." Struct. Engrg. Series No. 86-2, McGill University, Montreal, Quebec,

Canada.

Clawson, W. C , and Darwin, D. (1980). "Composite beams with web openings."

SM Report No. 4, Univ. of Kansas Ctr. for Res., Univ. of Kansas, Lawrence,

Kans.

Clawson, W. C , and Darwin, D. (1982). "Tests of composite beams with web

openings." J. Struct. Div., ASCE, 108(1), 145-162.

Congdon, J. G., and Redwood, R. G. (1970). "Plastic behavior of beams with

reinforced holes." J. Struct. Div., ASCE, 96(9), 1933-1955.

Cooper, P. B., and Snell, R. R. (1972). "Tests on beams with reinforced web

openings." J. Struct. Div., ASCE, 98(3), 611-632.

Cooper, P. B., Snell, R. R., and Knostman, H. D. (1977). "Failure tests on beams

with eccentric web holes." /. Struct. Div., ASCE, 103(9), 1731-1737.

Darwin, D. (1990). Design of steel and composite beams with web openings. American

Institute of Steel Construction, Chicago, 111.

Darwin, D., and Donahey, R. C. (1988). "LRFD for composite beams with un-

reinforced web openings." /. Struct. Engrg., ASCE, 114(3), 535-552.

Darwin D., and Lucas, W. C. (1990). "LRFD for steel and composite beams with

web openings." /. Struct. Engrg., ASCE, 116(6), 1579-1593.

Donahey, R. C , and Darwin, D. (1986). "Performance and design of composite

beams with web openings." SM Report No. 18, Univ. of Kansas Ctr. for Res.,

Univ. of Kansas, Lawrence, Kans.

3346

J. Struct. Eng. 1992.118:3325-3348.

Donahey, R. C , and Darwin, D. (1988). "Web openings in composite beams with

ribbed slabs." /. Struct. Engrg., ASCE, 114(3), 518-534.

Donoghue, C. M. (1982). "Composite beams with web openings: design." /. Struct.

Div., ASCE, 108(12), 2652-2667.

Frost, R. W., and Leffler, R. E. (1971). "Fatigue tests of beams with rectangular

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

web holes." /. Struct. Div., ASCE, 97(2), 509-527.

Granade, C. J. (1968). "An investigation of composite beams having large rectan-

gular openings in their webs," M.S. thesis, University of Alabama, University,

Alabama.

Kussman, R. L., and Cooper, P. B. (1976). "Design example for beams with web

openings." AISC Engrg. J., 13(2), 48-56.

Load and resistance factor design manual of steel construction. (1986a). 1st Ed.,

American Institute of Steel Construction (AISC), Chicago, 111.

Load and resistance factor design specification for structural steel buildings. (1986b).

American Institute of Steel Construction, Chicago, 111.

Lucas, W. K., and Darwin, D. (1990). "Steel and composite beams with web open-

ings." SM Report No. 23, Univ. of Kansas Ctr. for Res., Univ. of Kansas, Law-

rence, Kans.

Lupien, R., and Redwood, R. G. (1978). "Steel beams with web openings reinforced

on one side." Can. J. Civ. Engrg., 5(4), 451-461.

"Rectangular, concentric and eccentric unreinforced web penetrations in steel beams—

a design aid." (1981). ADUSS27-7108-01, U.S. Steel Corp., Pittsburgh, Pa.

"Rectangular, concentric and eccentric reinforced web penetrations in steel beams—

a design aid." (1986). Rev. Ed., ADUSS27-8482-02, U.S. Steel Corp., Pittsburgh,

Pa.

Redwood, R. G. (1968). "Plastic behavior and design of beams with web openings."

Proc, 1st Canadian Struct. Engrg. Conf, Canadian Steel Industry Construction

Council, 127-138.

Redwood, R. G. (1969). "The strength of steel beams with unreinforced web holes."

Civ. Engrg. and Public Works Review, London, England, 64(755), 559-562.

Redwood, R. G. (1971). "Simplified plastic analysis for reinforced web holes." AISC

Engrg. /.,8(3), 128-131.

Redwood, R. G. (1973). Design of beams with web holes. Canadian Steel Industrial

Construction Council, Don Mills, Ontario, Canada.

Redwood, R. G. (1983). "Design of I-beams with web perforations." Beams and

beam columns: stability and strength, R. Narayanan, ed., Applied Science Publ.,

New York, N.Y., 95-133.

Redwood, R. G., Baranda, H., and Daly, M. J. (1978). "Tests of thin-webbed beams

with unreinforced holes." /. Struct. Div., ASCE, 104(3), 577-595.

Redwood, R. G., and McCutcheon, J. O. (1968). "Beam tests with unreinforced

web openings." /. Struct. Div., ASCE, 94(1), 1-17.

Redwood, R. G., and Poumbouras, G. (1983). "Tests of composite beams with web

holes." Can. J. Civ. Engrg., 10(4), 713-721.

Redwood, R. G., and Poumbouras, G. (1984). "Analysis of composite beams with

web openings." /. Struct. Engrg., ASCE, 110(9), 1949-1958.

Redwood, R. G., and Shrivastava, S. C. (1980). "Design recommendations for steel

beams with web holes." Can. J. Civ. Engrg., 7(4), 642-650.

Redwood, R. G., and Uenoya, M. (1979). "Critical loads for webs with holes." J.

Struct. Div., ASCE, 105(10), 2053-2076.

Redwood, R. G., and Wong, P. K. (1982). "Web holes in composite beams with

steel deck." Proc, 8th Can. Struct. Engrg. Conf, Canadian Steel Construction

Council, Willowdale, Ontario, Canada.

"Structural investigation of a typical floor beam at the 200 West Adams Building,

Chicago, Illinois." (1984). WJE No. 840795, Wiss, Janney, Elstner Associates,

Inc., Northbrook, 111.

Subcommittee on Beams with Web Openings of the Task Committee on Flexure

Members of the Structural Division. (1971). "Suggested design guides for beams

with web holes." /. Struct. Div., ASCE, 97(11), 2707-2728.

Subcommittee on Beams with Web Openings of the Task Committee on Flexure

3347

J. Struct. Eng. 1992.118:3325-3348.

Members of the Structural Division. (1973). "Closure to 'Suggested design guides

for beams with web holes."' J. Struct. Div., ASCE, 99(6), 1312-1315.

Wang, T.-M., Snell, R. R., and Cooper, P. B. (1975). "Strength of beams with

eccentric reinforced holes."/. Struct. Div., ASCE, 101(9), 1783-1799.

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

APPENDIX IV. GLOSSARY

The following terms apply to members with web openings.

bottom tee is the region of a beam below an opening.

high moment end is the edge of an opening subjected to the greater primary

bending moment. The secondary and primary bending moments act in

the same direction.

low moment end is the edge of an opening subjected to the lower primary

bending moment. The secondary and primary bending moments act in

opposite directions.

opening index, p0, is the parameter used to limit opening size and aspect

ratio.

primary bending moment is the bending moment at any point in a beam

caused by external loading.

reinforcement is the longitudinal steel bars welded to the web above and

below an opening to increase section capacity.

secondary bending moment is the bending moment within a tee that is

induced by the shear carried by the tee.

tee is the region of a beam above or below an opening.

top tee is the region of a beam above an opening.

unperforated member is the section without an opening. Refers to properties

of the member at the position of the opening.

APPENDIX V. NOTATION

The notation listed here includes only those symbols used in the Com-

mentary that are not defined in the Nomenclature section of the Specification.

The section number in parentheses after the definition of a symbol refers to

the section in this Commentary where the symbol is first defined.

As = cross-sectional area of steel in unperforated member (3.2);

Am = net area of steel section with opening and reinforcement (3.2);

a = depth of concrete compression block (3.2);

e = eccentricity of opening; distance between the center line of the steel

section and the center line of the opening; for noncomposite sec-

tions—always positive; for composite sections—positive when the

center line of the opening is above the center line of the steel section

. (3.2);

Fy = reduced axial yield strength of steel (3.3);

Lb = unbraced length of compression flange (4.4);

M„ = nominal bending capacity (3.1);

Mp = plastic bending capacity of an unperforated noncomposite beam

(3.2);

Mpc = plastic bending capacity of an unperforated composite beam (3.2);

Pc = axial force in concrete for a section under pure bending (3.2);

Rwr = required strength of a weld (4.12);

7" = maximum tensile force in net steel section (3.2);

3348

J. Struct. Eng. 1992.118:3325-3348.

V„ = nominal shear capacity (3.1);

x = distance from top of flange to plastic neutral axis in flange or web

of a composite beam (3.2);

Z = plastic section modulus (3.2);

AAS = net reduction in area of steel section due to presence of an opening

Downloaded from ascelibrary.org by Universidad Politecnica De Madrid on 12/29/14. Copyright ASCE. For personal use only; all rights reserved.

and reinforcement = h0tw - 2Ar (3.2); and

T = average shear stress (3.3).

3349

J. Struct. Eng. 1992.118:3325-3348.

Das könnte Ihnen auch gefallen

- Design Portal Frame Building - Woolcock - GuideDokument358 SeitenDesign Portal Frame Building - Woolcock - GuidePrapa Karan0% (1)

- Roeder (1999) - Shear Connector Requirements For Embedded Steel Sections PDFDokument10 SeitenRoeder (1999) - Shear Connector Requirements For Embedded Steel Sections PDFTeodora BogdanNoch keine Bewertungen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- LRFD For Steel and Composite BeamsDokument23 SeitenLRFD For Steel and Composite BeamsMunna SheikNoch keine Bewertungen

- Ref 10Dokument15 SeitenRef 10SHEIK MASTANNoch keine Bewertungen

- (Asce) 0733-9445 (1998) 124 12 (1375)Dokument43 Seiten(Asce) 0733-9445 (1998) 124 12 (1375)sepehrNoch keine Bewertungen

- Rational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsDokument13 SeitenRational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsRayan MahgoubNoch keine Bewertungen

- Optimization and Sensitivity of Retaining Structures: by A KM Sarlba L and Fuat ErbaturDokument8 SeitenOptimization and Sensitivity of Retaining Structures: by A KM Sarlba L and Fuat ErbaturIngénieurCivilNoch keine Bewertungen

- 93 S37 PDFDokument7 Seiten93 S37 PDFPaul KohanNoch keine Bewertungen

- Carolin Et Al. (2005) BDokument10 SeitenCarolin Et Al. (2005) BBenzaamia AliNoch keine Bewertungen

- Determination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsDokument3 SeitenDetermination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsklllNoch keine Bewertungen

- (Asce) ST 1943-541X 0001789Dokument11 Seiten(Asce) ST 1943-541X 0001789surafel abebawNoch keine Bewertungen

- Pile Design Practice and Seismic Performance Concerns in TaiwanDokument9 SeitenPile Design Practice and Seismic Performance Concerns in Taiwanhriveroll2Noch keine Bewertungen

- Experimental Study On Shear Strength of High-Strength Concrete BeamsDokument8 SeitenExperimental Study On Shear Strength of High-Strength Concrete BeamsHuda JawadNoch keine Bewertungen

- (2003) Flexural Design of Reinforced Concrete Frames by Genetic AlgorithmDokument13 Seiten(2003) Flexural Design of Reinforced Concrete Frames by Genetic AlgorithmJONATHAN JUSTINO APOS CASSIMIRONoch keine Bewertungen

- Bousselham2010Dokument13 SeitenBousselham2010Hekmatullah NoorzaiNoch keine Bewertungen

- Design Equations For Flexural Capacity of Concrete Beams Reinforced With Glass Fiber-Reinforced Polymer BarsDokument12 SeitenDesign Equations For Flexural Capacity of Concrete Beams Reinforced With Glass Fiber-Reinforced Polymer BarsRikson TandelilinNoch keine Bewertungen

- Modeling, Analysis, and Behavior of Load-Carrying Precast Concrete Sandwich PanelsDokument13 SeitenModeling, Analysis, and Behavior of Load-Carrying Precast Concrete Sandwich PanelsAristotle MedinaNoch keine Bewertungen

- Seu Feb 2022 Serviceability Concrete Slabs Handouts 6ppDokument10 SeitenSeu Feb 2022 Serviceability Concrete Slabs Handouts 6ppÇağatay TahaoğluNoch keine Bewertungen

- Akguzel 2012Dokument14 SeitenAkguzel 2012dewa made adityaNoch keine Bewertungen

- High-Strength Concrete Columns: A Design Guide: Structural Engineer March 2007Dokument9 SeitenHigh-Strength Concrete Columns: A Design Guide: Structural Engineer March 2007nikola1popovi1Noch keine Bewertungen

- Adobe Scan 16 Mar 2022Dokument20 SeitenAdobe Scan 16 Mar 2022Saraj GillNoch keine Bewertungen

- Long SpanDokument16 SeitenLong SpanStructureClassNoch keine Bewertungen

- MINAFO Strenght Evaluation of RC CoumnsDokument8 SeitenMINAFO Strenght Evaluation of RC Coumnsamanh7618Noch keine Bewertungen

- 364.4T-10 Determining The Load Capacity of A Structure When As-Built Drawings Are Unavailable (TechNote)Dokument3 Seiten364.4T-10 Determining The Load Capacity of A Structure When As-Built Drawings Are Unavailable (TechNote)Yaser ShabasyNoch keine Bewertungen

- Design Aspects On Steel Fiber-ReinforcedDokument9 SeitenDesign Aspects On Steel Fiber-ReinforcedjayanthNoch keine Bewertungen

- Analytical MethodDokument10 SeitenAnalytical MethodCHERUKURU BALA VENKATA HAREENNoch keine Bewertungen

- Structural Safety and Serviceability of Concrete Bridges Subject To CorrosionDokument10 SeitenStructural Safety and Serviceability of Concrete Bridges Subject To CorrosionnagarajuNoch keine Bewertungen

- Revisiting The Effect of Axial Force Ratio On The Seismic Behaviour of RC Building ColumnsDokument13 SeitenRevisiting The Effect of Axial Force Ratio On The Seismic Behaviour of RC Building ColumnsTeo Peng KeatNoch keine Bewertungen

- 047 P2 (Asce) 1090 0268 (2005) 9 - 6Dokument10 Seiten047 P2 (Asce) 1090 0268 (2005) 9 - 6Novia MerisaNoch keine Bewertungen

- Performance-Based Seismic Retrofit Strategy For Existing Reinforced Concrete Frame Systems Using Fiber-Reinforced Polymer CompositesDokument16 SeitenPerformance-Based Seismic Retrofit Strategy For Existing Reinforced Concrete Frame Systems Using Fiber-Reinforced Polymer CompositesShreyas AlagundiNoch keine Bewertungen

- 2020 August, Preliminary Design of Post-Tensioned Transfer GirdersDokument7 Seiten2020 August, Preliminary Design of Post-Tensioned Transfer GirdersMonika jainNoch keine Bewertungen

- Numerical Investigation of The Shear Strength of RC DeepDokument13 SeitenNumerical Investigation of The Shear Strength of RC DeepJoão Paulo MendesNoch keine Bewertungen

- Design Optimization of Shear Wall High-Rise Building StructuresDokument11 SeitenDesign Optimization of Shear Wall High-Rise Building StructuresSachintha WijekoonNoch keine Bewertungen

- Finding Neccesary Arrangements in The SystemDokument19 SeitenFinding Neccesary Arrangements in The SystemmohansanjayNoch keine Bewertungen

- S B RCC V T C: Eismic Ehavior of Olumns With Arious IE Onfigurations by Y. L. Mo, Member, ASCE, and S. J. WangDokument9 SeitenS B RCC V T C: Eismic Ehavior of Olumns With Arious IE Onfigurations by Y. L. Mo, Member, ASCE, and S. J. Wangdexter238Noch keine Bewertungen

- Galvanic Cathodic Protection For Power Transmission Tower Grillage FoundationsDokument6 SeitenGalvanic Cathodic Protection For Power Transmission Tower Grillage FoundationsMA100% (1)

- Paultre 2009Dokument15 SeitenPaultre 2009unurNoch keine Bewertungen

- VG0-Pap - (ASCE) - Shear Behaviour of Joints in Segmental BridgesDokument22 SeitenVG0-Pap - (ASCE) - Shear Behaviour of Joints in Segmental BridgesPATHA ADITHSAINoch keine Bewertungen

- One Engineer's Opinion - Bolted SplicesDokument2 SeitenOne Engineer's Opinion - Bolted SplicesDoctoreNoch keine Bewertungen

- Seismic Design Criteria For Slab-Column ConnectionsDokument12 SeitenSeismic Design Criteria For Slab-Column ConnectionsIvan Jansen S.Noch keine Bewertungen

- Bai 1994Dokument17 SeitenBai 1994manish469patidarNoch keine Bewertungen

- Engineering Structures: Nattapat Wongpakdee, Sutat Leelataviwat, Subhash C. Goel, Wen-Cheng LiaoDokument9 SeitenEngineering Structures: Nattapat Wongpakdee, Sutat Leelataviwat, Subhash C. Goel, Wen-Cheng LiaoPhilip Amsal Apriano GintingNoch keine Bewertungen

- Bennett - 2015 - Design Parameters For Masonry Wall - Stiffness PredictionDokument14 SeitenBennett - 2015 - Design Parameters For Masonry Wall - Stiffness PredictionJhon Smit Gonzales UscataNoch keine Bewertungen

- Lecture 7 - MR Aditya Sharma On Chapter 6 PDFDokument68 SeitenLecture 7 - MR Aditya Sharma On Chapter 6 PDFSulabh GuptaNoch keine Bewertungen

- MSC October 2011 PDFDokument8 SeitenMSC October 2011 PDFYan Naung KoNoch keine Bewertungen

- Behavior of Cold-Formed Steel Built-Up Sections With Intermediate Stiffeners Under Bending. II: Parametric Study and DesignDokument11 SeitenBehavior of Cold-Formed Steel Built-Up Sections With Intermediate Stiffeners Under Bending. II: Parametric Study and Designviveksp99Noch keine Bewertungen

- 2022 Capacity Design of Coupled Composite Plate Shear Wall ConcreteDokument18 Seiten2022 Capacity Design of Coupled Composite Plate Shear Wall ConcreteHamid GoodarziNoch keine Bewertungen

- Optimization of Elevated Concrete Foundations For Vibrating MachinesDokument10 SeitenOptimization of Elevated Concrete Foundations For Vibrating Machinesحيدر البصريNoch keine Bewertungen

- Punching Capacity Nguyen-Minh2012Dokument12 SeitenPunching Capacity Nguyen-Minh2012Ashraf Gomah Mohamed ElshamandyNoch keine Bewertungen

- Seismic Retrofit of Low-Rise Reinforced-Concrete Buildings - A Modified Displacement-Based Design Procedure - 2020Dokument10 SeitenSeismic Retrofit of Low-Rise Reinforced-Concrete Buildings - A Modified Displacement-Based Design Procedure - 2020jcarlosgomez546Noch keine Bewertungen

- Full-Scale Testing For Composite Slab/Beam Systems Made With Extended Stud SpacingDokument9 SeitenFull-Scale Testing For Composite Slab/Beam Systems Made With Extended Stud SpacingvardhangargNoch keine Bewertungen

- Evaluation of The Composite Action of Cold Formed Steel Buil - 2023 - Thin WalleDokument21 SeitenEvaluation of The Composite Action of Cold Formed Steel Buil - 2023 - Thin WalleSang NguyenNoch keine Bewertungen

- Numerical Analysis of Composite Steel-Concrete Columns of Arbitrary Cross SectionDokument10 SeitenNumerical Analysis of Composite Steel-Concrete Columns of Arbitrary Cross SectionNasar KhanNoch keine Bewertungen

- PMat 15 BfullDokument7 SeitenPMat 15 Bfullgosiw71340Noch keine Bewertungen

- Materials 15 03827 v2Dokument34 SeitenMaterials 15 03827 v2NguyễnVănToảnNoch keine Bewertungen

- Trahair (2009) - Buckling Analysis Design of Steel FramesDokument5 SeitenTrahair (2009) - Buckling Analysis Design of Steel FramesGogyNoch keine Bewertungen

- Flexural Modeling of Steel Fiber Reinforced Concrete Members Analytical InvestigationsDokument12 SeitenFlexural Modeling of Steel Fiber Reinforced Concrete Members Analytical InvestigationsYury Erick Rosales LeónNoch keine Bewertungen

- Bearing Strength Capacity of Continuous Supported Timber Beams: Unified Approach For Test Methods and Structural Design CodesDokument7 SeitenBearing Strength Capacity of Continuous Supported Timber Beams: Unified Approach For Test Methods and Structural Design CodesRenato OrenseNoch keine Bewertungen

- Urgent Need For A Performance-Based Approach For Seismic Assessment and Design of Fastenings Used in Structural ApplicationsDokument3 SeitenUrgent Need For A Performance-Based Approach For Seismic Assessment and Design of Fastenings Used in Structural ApplicationsakanshuNoch keine Bewertungen

- Improved Seismic Performance of Gusset Plate ConnectionsDokument12 SeitenImproved Seismic Performance of Gusset Plate ConnectionsPrateek PandaNoch keine Bewertungen

- Introducing An Innovative Moment Connect PDFDokument10 SeitenIntroducing An Innovative Moment Connect PDFPrapa KaranNoch keine Bewertungen

- Analysis On Shear Behavior of High-Strength Bolts ConnectionDokument11 SeitenAnalysis On Shear Behavior of High-Strength Bolts ConnectionPrapa KaranNoch keine Bewertungen

- A State of Art - Review of Composite Deck Systems: October 2016Dokument5 SeitenA State of Art - Review of Composite Deck Systems: October 2016Prapa KaranNoch keine Bewertungen

- Objective and Background: J. Struct. Eng. 1986.112:1989-2000Dokument12 SeitenObjective and Background: J. Struct. Eng. 1986.112:1989-2000Prapa KaranNoch keine Bewertungen

- Shear-Bond Capacity of Composite Slabs Made With Profiled SheetingDokument7 SeitenShear-Bond Capacity of Composite Slabs Made With Profiled SheetingPrapa KaranNoch keine Bewertungen

- Journal of Constructional Steel Research: Inas Mahmood Ahmed, Konstantinos Daniel TsavdaridisDokument15 SeitenJournal of Constructional Steel Research: Inas Mahmood Ahmed, Konstantinos Daniel TsavdaridisPrapa KaranNoch keine Bewertungen

- Design of Mega Column With Several Encased Steel Profiles For Combined Compressonand Bending - Plumiecs - Journal PDFDokument27 SeitenDesign of Mega Column With Several Encased Steel Profiles For Combined Compressonand Bending - Plumiecs - Journal PDFPrapa KaranNoch keine Bewertungen

- Local Elastic Buckling Coefficients of Steel Plates in Composite Steel Plate Shear WallsDokument7 SeitenLocal Elastic Buckling Coefficients of Steel Plates in Composite Steel Plate Shear WallsPrapa KaranNoch keine Bewertungen

- The Design and Testing of Connections in Steel Sheeting and SectionsDokument1 SeiteThe Design and Testing of Connections in Steel Sheeting and SectionsPrapa KaranNoch keine Bewertungen

- Design Procedures For Profiled Metal Sheeting and DeckingDokument11 SeitenDesign Procedures For Profiled Metal Sheeting and DeckingPrapa KaranNoch keine Bewertungen

- Journal of Constructional Steel Research: Su-Hee Park, Sung-Mo Choi, Yo-Suk Kim, Young-Wook Park, Jin-Ho KimDokument11 SeitenJournal of Constructional Steel Research: Su-Hee Park, Sung-Mo Choi, Yo-Suk Kim, Young-Wook Park, Jin-Ho KimPrapa KaranNoch keine Bewertungen

- Journal of Constructional Steel Research: Bin Wang, Huanjun Jiang, Xilin LuDokument12 SeitenJournal of Constructional Steel Research: Bin Wang, Huanjun Jiang, Xilin LuPrapa KaranNoch keine Bewertungen

- Journal of Constructional Steel Research Volume 103 Issue 2014 (Doi 10.1016 - j.jcsr.2014.08.006) Hu, Hong-Song Nie, Jian-Guo Eatherton, Matthew R. - Deformation Capacity of Concrete-Filled Steel PDokument11 SeitenJournal of Constructional Steel Research Volume 103 Issue 2014 (Doi 10.1016 - j.jcsr.2014.08.006) Hu, Hong-Song Nie, Jian-Guo Eatherton, Matthew R. - Deformation Capacity of Concrete-Filled Steel PPrapa KaranNoch keine Bewertungen

- Ductility Characteristics of Partially Restrained Beam-to-Column Composite Connections in Concrete Filled Square TubesDokument11 SeitenDuctility Characteristics of Partially Restrained Beam-to-Column Composite Connections in Concrete Filled Square TubesPrapa KaranNoch keine Bewertungen

- Is 14687 Falsework For Concrete Structure GuidelineDokument24 SeitenIs 14687 Falsework For Concrete Structure GuidelineChaitanya Choudhary100% (1)

- Steel Design (Track 2) Beam 2 Check 1: Job No Sheet No RevDokument1 SeiteSteel Design (Track 2) Beam 2 Check 1: Job No Sheet No RevPrapa KaranNoch keine Bewertungen

- BS en 20898-7-1995Dokument10 SeitenBS en 20898-7-1995Prapa KaranNoch keine Bewertungen

- Aci 351.1 R-99 Grouting Bet Foundn & Bases For Support of Equipment & Machinery (PDF - Io)Dokument18 SeitenAci 351.1 R-99 Grouting Bet Foundn & Bases For Support of Equipment & Machinery (PDF - Io)Prapa KaranNoch keine Bewertungen

- Is 13063 - 1991 Structural Safety o Fbuildings On Shallow Foundations On Rocks - Code of PracticeDokument19 SeitenIs 13063 - 1991 Structural Safety o Fbuildings On Shallow Foundations On Rocks - Code of PracticePrapa KaranNoch keine Bewertungen

- Is 15109 (Part 2) - 2002 Iso 11269 - 1995 - Determination of The Effects of Pollutants On Soil Flora - Part 2 Effects of Chemicals On The Emergence and Growth Higher PlantsDokument10 SeitenIs 15109 (Part 2) - 2002 Iso 11269 - 1995 - Determination of The Effects of Pollutants On Soil Flora - Part 2 Effects of Chemicals On The Emergence and Growth Higher PlantsPrapa KaranNoch keine Bewertungen

- Mechanical Engineering Notes: 3-SemesterDokument1 SeiteMechanical Engineering Notes: 3-SemesterAkash AkuNoch keine Bewertungen

- A-36 - Pages From Section II Part D (Customary)Dokument3 SeitenA-36 - Pages From Section II Part D (Customary)siswantoNoch keine Bewertungen

- Exam - April 1997Dokument4 SeitenExam - April 1997Marcial Jr. MilitanteNoch keine Bewertungen

- Ps-Iso 16143 Part 1Dokument51 SeitenPs-Iso 16143 Part 1Shaikh KamaluddinNoch keine Bewertungen

- Concrete Construction Article PDF - Hot Weather Affects Fresh ConcreteDokument2 SeitenConcrete Construction Article PDF - Hot Weather Affects Fresh ConcreteyazedNoch keine Bewertungen

- Data Sheet Schott® Borofloat: Chemical PropertiesDokument2 SeitenData Sheet Schott® Borofloat: Chemical PropertiesDiego SaenzNoch keine Bewertungen

- Catalog Gebo Eng Est E-Catalog 2022Dokument293 SeitenCatalog Gebo Eng Est E-Catalog 2022RO-AM-BDNoch keine Bewertungen

- Duct Bank InformationDokument19 SeitenDuct Bank InformationGaneshNoch keine Bewertungen

- Two Days Hands On Workshop Computational Modelling of Polymeric MaterialsDokument2 SeitenTwo Days Hands On Workshop Computational Modelling of Polymeric MaterialsSrashmiNoch keine Bewertungen

- A Brief Study On Structural Use & High Performance of Jute in Different Applications and Its Prospects in Future UsesDokument66 SeitenA Brief Study On Structural Use & High Performance of Jute in Different Applications and Its Prospects in Future UsesMosharaf HossainNoch keine Bewertungen

- CSA G40.21 Steel SpecificationsDokument4 SeitenCSA G40.21 Steel SpecificationsIshaan RajNoch keine Bewertungen

- BCM Block BoardDokument34 SeitenBCM Block BoardNidhi JoshiNoch keine Bewertungen

- Astm A1008 12aDokument9 SeitenAstm A1008 12aAleks SenaNoch keine Bewertungen

- Control of Cracking Due To End Restraint: Input Parameters Symbol Unit ValueDokument1 SeiteControl of Cracking Due To End Restraint: Input Parameters Symbol Unit ValuedsureshcivilNoch keine Bewertungen

- Slag Interaction With Linings.Dokument32 SeitenSlag Interaction With Linings.edwardbloomcer06Noch keine Bewertungen

- Introduction To Shape Memory Alloys-SpringerDokument31 SeitenIntroduction To Shape Memory Alloys-SpringerYah IratoNoch keine Bewertungen

- Teijin Aramid Ballistic HandbookDokument24 SeitenTeijin Aramid Ballistic Handbookdev soniNoch keine Bewertungen

- ABC Pola Change OrderDokument23 SeitenABC Pola Change OrderELMERNoch keine Bewertungen