Beruflich Dokumente

Kultur Dokumente

(23005319 - Acta Mechanica Et Automatica) Influence of Corrugation Depth On Lateral Stability of Cold-Formed Steel Beams of Corrugated Webs PDF

Hochgeladen von

ci_balaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

(23005319 - Acta Mechanica Et Automatica) Influence of Corrugation Depth On Lateral Stability of Cold-Formed Steel Beams of Corrugated Webs PDF

Hochgeladen von

ci_balaCopyright:

Verfügbare Formate

Viorel Ungureanu, Dan Dubina DOI 10.

1515/ama-2016-0017

Influence of Corrugation Depth on Lateral Stability of Cold-Formed Steel Beams of Corrugated Webs

INFLUENCE OF CORRUGATION DEPTH ON LATERAL STABILITY

OF COLD-FORMED STEEL BEAMS OF CORRUGATED WEBS

Viorel UNGUREANU*, Dan DUBINA*

*Department of Steel Structures and Structural Mechanics, Politehnica University of Timisoara, Romania

Laboratory of Steel Structures, Romanian Academy – Timisoara Branch, Romania

viorel.ungureanu@upt.ro, dan.dubina@upt.ro

received 6 September 2015, revised 10 May 2016, accepted 12 May 2016

Abstract: The beams of thin corrugated web afford a significant weight reduction compared with hot-rolled or welded ones. In the initial so-

lutions, the flanges are made of flat plates, welded to the sinusoidal web sheet, requiring a specific welding technology. A new solution

is proposed by the authors, in which the beam is composed by a web of trapezoidal cold-formed steel sheet and flanges of back-to-back

lipped channel sections. For connecting flanges to the web self-drilling screws are used. The paper summarizes the experimental and nu-

merical investigations carried out at the CEMSIG Research Centre (www.ct.upt.ro/centre/cemsig/) of the Politehnica University

of Timisoara and, at the end, presents the influence of corrugation depth of web on the lateral stability of the beams.

Key words: Corrugated Web Beam, Cold-Formed Steel Solution, Discrete Fasteners, Self-Drilling Screws, Experimental Investigation

1. INTRODUCTION Also, it is easy to be observed that the new solution, as

a whole, is 100% composed by cold-formed steel elements, avoid-

ing the combination of two types of steel products, i.e. cold-formed

Corrugated web girders represent a relatively new structural for webs and hot-rolled for flanges as presented before

system emerged in the past two decades in Europe, particularly

(www.zeman-steel.com). Moreover, high protection to corrosion

in Germany and Austria. Increased interest for this solution was due to the fact that all components are galvanized is a major

observed for the main frames of single-storey steel buildings and advantage.

in steel bridges. The technical solution consists in using a sinusoi-

Thin new solution can be used as roof girders, frame bearing

dal web sheet which is welded to the flat plates used for flanges, structures (also multi-span and multi-storey) and short span pe-

a specific welding technology being applied. destrian bridges. It is expected from this solution to cover medium

The main benefits of this type of elements are that the corru- spans up to 24 m length. They also can be a reliable alternative to

gated webs increase the beam’s stability against local buckling purlins and secondary beams where these have to cover large

and also against lateral-torsional buckling, which may result

bays, instead of using steel trusses.

in a more economical design if compares with flat web with stiff- A beam with corrugated web behaves similarly to a lattice

eners. Furthermore, the use of thinner webs results in lower mate- girder, in which the bending moments and applied forces are

rial cost, with an estimated cost savings of 10-30% in comparison

transferred via flanges only, while the transverse forces are trans-

with conventional fabricated sections and more than 30% com- ferred through the diagonals and verticals of the lattice girder, in

pared with standard hot-rolled beams. The buckling resistance this case the corrugated web. The dimensioning of corrugated

of the sinusoidal corrugated steel sheet used for webs, which web beams is ruled by Annex D of the EN 1993-1-5:2006, togeth-

is very thin (1.5-3 mm), is comparable with plane webs of 12 mm er with specific aspects of EN 1993-1-1 and EN 1993-1-3.

thickness or more.

The main aim of present study is to complete the previous

A new technological solution composed by webs made studies of authors with an investigation of sensitivity of webs to

of trapezoidal cold-formed steel sheets and flanges of built-up distortion of corrugations when the size of corrugations increases.

cold-formed steel profiles (e.g. back-to-back lipped channel sec-

tions or angles with turn lips) has been proposed by the authors

Dubina et al., (2013, 2015). The connections between flanges and 2. LITERATURE REVIEW

web can be done with self-drilling screws or by spot welding.

Compared with the traditional solution, where the sinusoidal web

sheet is continuous, in this case the width of corrugated sheets Several types of built-up cold-formed steel beams prepared

that compose the web is approximately 1000 mm. Consequently, for industrialised fabrication have been experimentally investigat-

ed. For these beams, bolts, screws or spot/laser welding are used

seam connections are needed for providing the continuity of the

web. This ensemble, i.e. seam connections – two overlapped as fastening technologies.

corrugated sheets, acts as web stiffeners, increasing resistance In 2000, BEN-VAUTIER S.P.A., Italy (WO 00/17463), patent-

under transverse loads, of particular interest in the locations ed a modular H-beam comprises one or more modules, each

of purlin supports. formed of two half-structural parts of two pieces of structural steel,

104

Unauthentifiziert | Heruntergeladen 10.11.19 05:25 UTC

DOI 10.1515/ama-2016-0017 acta mechanica et automatica, vol.10 no.2 (2016)

forming each a thin sheet, comprising a central part or core and arc time used while forming the weld. In this case the arc times

lateral half-flanges. The half-flanges form gaps, inside which were broken down into three separate categories. The first cate-

plates are introduced in order to strengthen the flanges of the gory consisted of full-time welds, the second 2/3-time welds, and

beam, which constitute the regions more subjected to bending the third 1/3-time welds. Testing was performed on steel gauge

stresses. sheets of 0.85 mm, 1 mm, 1.3 mm and 1.6 mm. Each gauge

Zhao (2005) at Queensland University of Technology initiated material was tested in single-, double- and four-layer configura-

a research program to investigate the structural behaviour and tions. Two types of diameter arc spot welds were tested. Compar-

design of hollow flange beam sections as compression members. isons were made between shear strength and weld geometry,

He used rectangular hollow flanges and various manufacturing including average diameter, effective diameter and penetration.

methods such as spot welding, self-pierced riveting and screw The research has proven that arc time has a tremendous influ-

fastening to form Rectangular Hollow Flange Beam (RHFB) sec- ence on arc spot weld shear strength.

tions from a single steel strip. It was observed that the type A wide experimental investigation on laser welded connec-

of fastening and spacing does not affect the member compression tions based on both lap-shear and tension tests were performed

capacity significantly. However, the structural behaviour and at the University of Naples (2009). The experimental programme

design of RHFB as flexural members will be different and there- was designed in order to evaluate the effects of different parame-

fore further investigations are needed to identify their failure ters on the strength and ultimate displacement of the selected

modes and develop suitable design rules. connections. The results of the experimental tests were compared

Wanniarachchi (2005) extended the work of Zhao (2005) with the predicted resistance values according to Eurocode 3, with

and developed a new cold-formed steel beam with two rectangu- the aim of validating for laser welding the mechanical models

lar hollow flanges rigid in torsion and a slender web formed using provided for spot welds.

intermittent screw fastening to enhance the flexural capacity while A lot of work has been done to study the shear capacity (Yi et

maintaining a minimum fabrication cost. His research was focused al., 2008; Moon et al., 2008; Sause and Braxtan, 2011) and the

on the flexural behaviour and design of cold-formed steel beams behaviour under patch loading of steel beams with corrugated

with rectangular hollow flanges (RHFB) made of separately web (Abbas et al., 2006, 2007). In what concerns the bending

formed flanges and web connected by simple screw fastening. behaviour it was observed that the contribution of the web to the

He has found that intermittent screw fastening method appears to ultimate moment capacity of a beam with corrugated web is negli-

be structurally adequate and minimises the fabrication cost. gible, and the ultimate moment capacity is based on the flange

Landolfo et al. (2008) evaluated the applicability of built-up yield stress. The effect of the corrugation profiles of the web on

cold-formed steel beams assembled by laser welding and as- the lateral-torsional buckling strength of I-girders was also studied

sessed the load bearing capacity of the assembled beams. The (Kazemi et al., 2010; Jiho et al., 2009; Moon et al., 2013; Kövesdi,

I-section with hollow flanges is fabricated from two back-to-back 2012). Pasternak et al. (2010) presented a new proposal for An-

special C-profiles. The two profiles are joined with connections nex D of EN 1993-1-5:2006.

which are located on the web and on the flanges. Two reinforcing Probably, the first built-up steel girder using corrugated sheets

plates are placed inside the top and bottom hollow flanges of the as web elements and cold-formed sections for flanges is the

I-section, providing an additional connection system between the Macomber Panlweb girder appeared on the market around the

two C-profiles. ’70s. The Macomber Panlweb girder consists of 1.9 mm to 3.8

A very important aspect related to the cold-formed steel is the mm thickness of the corrugated web for depths of 0.51 to 1.02 m

connecting technique. Briskham et al. (2006) performed a com- (US3444664). This solution applies shallow VV-section for flang-

parative study on of self-pierce riveting, resistance spot welding es, which make difficult enough the installing of flange-to-web

and spot friction joining for aluminium automotive sheet. Quantita- fasteners.

tive comparisons have been made on the basis of tensile strength The first attempt of the authors of this paper related to this

(shear and peel), process time, equipment price and running cost. type of beams 100% composed by cold-formed steel elements

The results identified resistance spot welding as a more economi- was a numerical study (Neagoie et al., 2005) in order to prove the

cally favourable option than self-pierce riveting or spot friction efficiency of such solution against cold-formed steel trusses.

joining for the task of producing the majority of the joints. The A similar solution has been proposed and analysed in the

analysis indicates that it is the ongoing cost of the rivets that frame of PRECASTEEL project (RFSR-CT-2007-00038), but

makes self-pierce riveting the most expensive process. For re- using blind rivets as seam fasteners for the corrugated web and

sistance spot welding, the largest cost factors identified were bolts for web-to-flange connections. For flanges, back-to-back

energy consumption and frequency of electrode replacement. lipped channel or two types of hat-sections have been used. Deep

Although the material is aluminium, similar conclusions can be corrugation web sheeting of longitudinal intermediate stiffeners

drawn for steel too. have been applied in this solution. However, looking to the test

Guenfoud et al. (2010) tested welded specimens fabricated results, one observes the sensitivity to distortion of corrugation still

through one, two or four layers of steel sheets with thicknesses remain high.

ranging from 0.76 mm to 1.52 mm. A total of 72 tension tests and

107 shear tests were completed. The idea was the initiation

of a research program on the shear resistance and tension re- 3. EXPERIMENTAL TESTS

sistance of multi-layer arc spot welds. They found that the type

of electrode, high current setting and proper welding technique 3.1. Specimens, test procedure and test results

affect the quality of arc-spot welds in multi-layer connections, and

a lower limit for the net effective weld diameter was proposed.

Snow (2008) conducted a similar research in order to estab- The experimental program was carried out at the CEMSIG

lish a relationship between arc spot weld shear strength and the Research Centre (http://www.ct.upt.ro/en/centre/cemsig) of the

Politehnica University of Timisoara. Five beams with corrugated

105

Unauthentifiziert | Heruntergeladen 10.11.19 05:25 UTC

Viorel Ungureanu, Dan Dubina DOI 10.1515/ama-2016-0017

Influence of Corrugation Depth on Lateral Stability of Cold-Formed Steel Beams of Corrugated Webs

webs (CWB) with a span of 5157 mm and a height of 600 mm Fig. 2 presents the experimental arrangement. Six points

have been tested (see Tab. 1), considering different arrangements bending tests, monotonically conducted, were applied for each

for self-drilling screws and shear panels [1,2]. specimen with a loading velocity of 2 mm/min.

Fig. 1(a) presents the components of the CWB-1 beam with Dubina et al. (2013, 2015) show detailed information related to

corrugated web (standard solution), i.e.: the behaviour of each tested specimen, including the initial stiff-

back-to-back lipped channel sections for flanges 2×C120/2.0; ness, 𝐾0−𝐸𝑥𝑝 and maximum load 𝐹𝑚𝑎𝑥 , as well as the failure

corrugated web with the corrugation depth of 43 mm and the mode. These values are summarised in Tab. 4. Fig. 1 (b,c) show,

thickness of 0.7 mm – A45/0.7; as an exemplification, the deformed shape of the CWB-5 beam at

reinforcing shear panels – plates of 1 mm thickness and 830 collapse and the distortion of the web corrugation in the region

mm length, at the beam ends where the shear force is maxi- with the reduced number of screws.

mum;

reinforcing U150/2.0 profiles used under the load application

points, to avoid excessive local deformations;

self-drilling screws for flange-to-web connection – STP-

6.3×25;

self-drilling screws for shear plates to end support – STP-

5.5×25;

self-drilling screws as seam fasteners for corrugated webs –

STT-4.8×20;

bolts M12 class 8.8 for flanges to the end support connection.

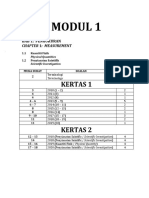

Tab. 1. Types of specimens

Code Description

Standard solution: flange-to-web connection in

CWB-1 every corrugations and uniformly distributed seam

fasteners

Standard solution + supplementary lipped channel

CWB-2

sections under the load application points

Optimized solution by adapting the flange-to-web

connections according to the distribution of shear

CWB-3

stresses (connections at each second corrugations

where the shear force decreases)

Optimized solution by eliminating shear panels and

CWB-4 doubling of corrugated webs in the zones with high

shear forces

Optimized solution by adapting both the flange-to-

CWB-5 web connections and seam fasteners to the distri-

bution of shear stresses

Fig. 2. Experimental arrangement

250

(a)

200

SLS

150

Force [kN]

CWB - 1

(b) CWB - 2

100

CWB - 3

CWB - 4

ULS CWB - 5

50

ULS level

SLS level

0

(c) 0 20 40 60 80 100 120 140 160 180

Fig. 1. (a) Configuration of the specimens; (b) Deformed shape Displacement [mm]

of CWB-5 beam at failure; (c) Distortion of the web corrugation

Fig. 3. Load-displacement curves for the tested specimens

106

Unauthentifiziert | Heruntergeladen 10.11.19 05:25 UTC

DOI 10.1515/ama-2016-0017 acta mechanica et automatica, vol.10 no.2 (2016)

Finally, Fig. 3 shows, comparatively, the load-displacement found in the beam (see Tab. 3 and Fig. 5) (Abbas et al., 2007).

curves for all five specimens, together with the ultimate (ULS) and

serviceability limit state (SLS) levels.

Tab. 3. Types of tested connections

The full-scale testing program was completed with tensile

tests to determine both the material properties for beam compo- t2 No. of dnom

Name t1 [mm] Name

nents and the behaviour of connections. [mm] tests [mm]

T1-1.4 0.7 0.7 6 4.8 T1-1.4

T2-1.7 1.0 0.7 5 4.8 T2-1.7

3.2. Material properties and connections behaviour

T3-3.7 2.0+1.0 0.7 6 6.3 T3-3.7

T4-9.0 1.0 8.0 5 5.5 T4-9.0

In order to determine the mechanical properties of the CWB T5-11.0 2.0+1.0 8.0 5 M12 T5-11.0

components, a set of samples were cut out from the lipped chan- T6-2.7 2.0 0.7 10 6.3 T6-2.7

nels, corrugated sheet, both from the flat regions and corners

and reinforcing shear panels, according to EN ISO 6892-1:2009

specifications, as shown in Fig. 4. Tab. 2 presents the mean 4. NUMERICAL MODEL CALIBRATION AND VALIDATION

values, standard deviations and the characteristic values for yield

and ultimate strengths for the above samples. The following ab-

Numerical models applied to simulate the behaviour of mem-

breviations for coupons have been used: BM-CF coupon cut from

bers experimentally tested have been created using the commer-

the flange of the lipped channel; BM-CW coupon cut from the web

cial FE program ABAQUS/CAE v.6.7.1. Rectangular 4-noded shell

of the lipped channel; CM-CF coupon cut from the flange-web

elements with reduced integration (S4R) were used to model the

corner of the lipped channel; CM-CW coupon cut from the flat

thin-walled components. CONN3D2 element types, with 2 nodes

region of the corrugated web; BM-SP coupon cut from the shear

and 6 DOF per node, have been used to model the self-drilling

panel.

screws and bolts. RB3D2 elements were used as rigid body

for load transfer and multi-point constrain beam (MPC-Beam)

for DOF coupling between groups of specified nodes.

The material behaviour used for numerical modelling was

in accordance with the recorded curves from tensile tests from

coupons cut over the cross-section of component elements (see

Tab. 2). Self-drilling screws and bolts were introduced using

CONN3D2 element type according to the mean values recorded

from tests of each type of connection (see Fig. 5).

General contact with the following parameters have been

used, i.e. (1) on normal direction – hard contact; (2) on transversal

direction – a friction coefficient of 𝜇=0.1. Finally, as initial imper-

fections, the first 3 eigen modes from a linear bucking analysis

have been used.

Fig. 6 presents comparatively the FEM and experimental load-

Fig. 4. Samples cut from flat regions and corners displacement curves for the five beams, while Tab. 4 shows com-

paratively, for each specimen, the initial stiffness and ultimate load

Tab. 2. Yield and ultimate strengths of coupons cut from lipped channels,

obtained experimentally and via numerical simulations. Significant

corrugate sheet and shear panel work on girders with corrugated web has been done. An extended

literature review will be presented on the following.

fyM fuM fyk fuk

Type sfy sf\u

[MPa] [MPa] [MPa] [MPa]

BM-CF 438.74 517.06 5.69 2.46 425.48 511.33 Tab. 4. Initial stiffness and ultimate load: FEM vs. experimental results

BM-CW 441.65 521.86 25.53 3.48 382.16 513.05 Beam K0-Exp K0-FEM Fmax-Exp Fmax-FEM

CM-CF 521.64 585.07 9.89 9.69 498.6 562.49 type (N/mm) (N/mm) (kN) (kN)

CM-CW 358.42 419.59 4.09 2.48 348.9 413.81 CWB-1 6862.2 7721.1 218.9 225.9

BM-SP 349.41 394.75 12.67 10.89 319.89 369.37 CWB-2 7831.5 7834.6 231.3 229.5

CWB-3 7184.9 6819.3 209.5 205.8

CWB-4 3985.0 4932.0 181.9 223.5

Six types of connections were tested according to Publication

124 of ECCS [29], at a loading velocity of 1 mm/min, i.e.: CWB-5 5516.2 6594.9 214.6 216.0

T1-1.4 seam fasteners for corrugated sheets;

T2-1.7, seam fasteners for shear plates and corrugated The results obtained via numerical simulations show that the

sheets; behaviour and maximum load accurately replicate the experi-

T3-3.7, self-drilling screws for shear plates and flanges; mental tests. In case of CWB-4 beam the numerical results are

T4-9.0, self-drilling screws for shear plates and end supports; 23% higher than experimental one. The reason could be the

T5-11.0, bolts for flanges to end-supports; higher contribution of shear in the end panels; in this case there

T6-2.7, self-drilling screws for flanges to corrugated webs are no stiffening shear plates.

at mid-span,

in order to determine the behaviour of all types of connections

107

Unauthentifiziert | Heruntergeladen 10.11.19 05:25 UTC

Viorel Ungureanu, Dan Dubina DOI 10.1515/ama-2016-0017

Influence of Corrugation Depth on Lateral Stability of Cold-Formed Steel Beams of Corrugated Webs

250

FEM vs. Experimental

200

Force [kN]

150

100

50 CWB - 1 - EXP

CWB - 1 - FEM

0

0 20 40 60 80

Displacement [mm]

250

FEM vs. Experimental

200

Force [kN]

150

100

50 CWB - 2 - EXP

CWB - 2 - FEM

0

0 10 20 30 40 50 60

Displacement [mm]

250

FEM vs. Experimental

200

Force [kN]

150

100

50 CWB - 3 - EXP

CWB - 3 - FEM

0

0 20 40 60 80

Displacement [mm]

250

FEM vs. Experimental

200

Force [kN]

150

100

CWB - 4 - EXP

50

CWB - 4 - FEM

0

0 15 30 45 60 75 90 105 120 135 150 165

Displacement [mm]

250

FEM vs. Experimental

200

Force [kN]

150

100

50 CWB - 5 - EXP

CWB - 5 - FEM

0

0 20 40 60 80 100

Displacement [mm]

Fig. 5. Force-displacement curves for the tested connections Fig. 6. FEM / Experimental load – displacement curves

108

Unauthentifiziert | Heruntergeladen 10.11.19 05:25 UTC

DOI 10.1515/ama-2016-0017 acta mechanica et automatica, vol.10 no.2 (2016)

Based on the presented results, the FEM model can be con- corrugated web with the corrugation depth of 43 mm and the

sidered as validated. Further, it has been applied to evaluate the thickness of 0.7 mm – A45/0.7, steel grade S320GD+Z;

behaviour and capacity of a beam of 12 m span, with trapezoidal reinforcing shear panels – plates of 2 mm thickness and 1300

shape, as shown in Fig. 7. The height of the beam at ridge was mm length, at the beam ends (ridge and eaves), steel grade

considered 900 mm, while at eaves 1700 mm. Details concerning S320GD+Z;

the beam components are presented in Dubina et al. (2014). The self-drilling screws for flange-to-web connection – STP-6.3×25

lateral-torsional bucking has been prevented. Similar failure (3 self-drilling screws per height of the profile);

modes have been obtained as in case of the tested beams. Fig 7 self-drilling screws for shear plates to end support with a

presents the stress distribution and the load-displacement curve nominal diameter – STP-5.5×25;

for this beam with trapezoidal shape. The maximum capacity is self-drilling screws as seam fasteners for corrugated webs

achieved at 389.12 kN (i.e. corresponding to 5.4 kN/m2, consider- with a nominal diameter – STT-4.8×20 (16 self-drilling screws

ing a spacing of 6 m) for 35 mm displacement. per height of the profile);

M16 bolts class 8.8 for flanges to the end support connection

(6 bolts for each flange); (8) the height of the beam was con-

stant along the length, i.e. 1000 mm.

Four types of lateral restraints have been considered in the

analysis, i.e.

pinned lateral supports at the top flange in the position

of purlins (PLS);

transversal translational springs at the top flange in the posi-

tion of purlins, corresponding to axial rigidity of a Z200/2 purlin

(TTS);

transversal translational and rotational springs at the top

flange in the position of purlins, corresponding to axial and

bending rigidities of a Z200/2 purlin (TTRS);

Fig. 7. Stress distribution and load-displacement curve for a 12 m case no. 3 including fly bracings corresponding to the first

span beam with corrugated web purlin adjacent to the ridge (TTRS+FB). Fig. 9 presents the

load-displacement curves for this beam with trapezoidal

shape.

Even good capacities can be obtained for larger spans, i.e. The maximum capacity for TTRS+FB beam is achieved at

16-18 m or more, the disadvantage of these trapezoidal beams 270.16 kN (i.e. corresponding to 2.81 kN/m2, considering a frame

is the height at the eaves and the difficulties in tailoring the corru- spacing of 6 m) for 55.51 mm displacement.

gated sheets at the top flanges. In order to overcome these defi-

ciencies, an alternative solution of parallel flanges sloped beams

(e.g. pitched roof beams) was considered. 5. INFLUENCE OF CORRUGATION DEPTH

FEM model, correspondingly adapted, has been applied to ON THE LATERAL STABILITY OF BEAMS

evaluate the behaviour and capacity of these beams, taking as

reference a pitched roof portal frame of 16 m span, with a 10°

Based on the conclusions of the second beam, of 16 m span

slope, as shown in Fig. 8 (Dubina et al., 2014)).

with parallel flanges, on the following, the influence of the depth of

corrugation on the global behaviour is studied. In this sense, three

300

different depths for the corrugated web have been chosen, i.e. 30

mm, 43 mm (presented above) and 85 mm, in all the cases the

250

thickness being 0.7 mm. Case number (4) from the chapter above

has been analysed and presented below. Also, it should be men-

Total Applied Force[kN]

200 tion that in case of screws, the optimized solution used for beam

CWB-5 was adopted, i.e. by adapting both the flange-to-web

150 connections and seam fasteners to the distribution of shear

stresses. Fig. 9 presents the force-displacement curve for the 30

100 mm depth of corrugation and the points 1-2-3 corresponding to

TTS

the appearance of local failures.

50 TTRS

PLS

TTRS+FB Tab. 5. Force and displacements for characteristic points

0

30 mm corr. 45 mm corr. 85 mm corr.

0 50 100 150 200

Mid-span Vertical Displacement [mm] Point Δ Δ Δ

Fig. 8. Stress distribution and load-displacement curve for a 16 m F (kN) F (kN) F (kN)

(mm) (mm) (mm)

span beam with corrugated web 1 258.1 29.5 275.5 32.7 263.4 36.7

2 291.2 41.1 279.8 46.3 293.3 43.4

The beam components are: 3 279.7 53.8 286.7 59.8 287.2 46.5

back-to-back lipped channel sections for flanges –

2×C150/2.0, steel grade S350GD+Z;

109

Unauthentifiziert | Heruntergeladen 10.11.19 05:25 UTC

Viorel Ungureanu, Dan Dubina DOI 10.1515/ama-2016-0017

Influence of Corrugation Depth on Lateral Stability of Cold-Formed Steel Beams of Corrugated Webs

350 350

2 2

300 3 300

3

1

250 1 250

Force[kN]

200

Force [kN]

200

150 1 - Buckling of shear panel 150

1 - Buckling of shear panel

2 - Distortion of web corrugation in the same 2 - Distortion of web corrugation in the

100 time with LTB 100 same time with LTB

3 - Plastic mechanism at the bottom flange 3 - Plastic mechanism at the bottom flange

50 50

A30/0.7 A85/0.7

0 0

0 20 40 60 80 100 120 140 0 20 40 60 80 100 120 140

Displacement [mm] Displacement [mm]

Fig. 9. Force-displacement curve for 30 mm depth of corrugation Fig. 12. Force-displacement curve for 85 mm depth of corrugation

Fig. 10 presents the distribution of stresses for the three char- 350

acteristic points.

300

250

Force[kN]

200

150

A30/0.7

100 A45/0.7

A85/0.7

50

0

0 20 40 60 80 100 120 140

Displacement [mm]

Fig. 13. Force-displacement curve for the three different depths

Fig. 10. Distribution of stresses for the three characteristic points of corrugated web

Fig. 11 and Fig. 12 present the force-displacement curves for Plotting all three curves on the same graph, it is easy to see

the 43 mm and 85 mm depths and the corresponding points 1-2-3. that curve for corrugation A85 has a reduced stiffness compared

The subsequences of appearance are the same as in the first to the other two due to the fact the depth of the corrugations

case, but for different values of force/displacement (see Tab. 5). is more sensible to the end distortion of the corrugations. More,

The distribution of stresses presented in Fig. 10 is almost the after reaching the maximum load the curve drop suddenly and

same as for the beam with 30 mm depth of corrugation. a stable path can be seen due to the buckling coming from in-

plane loading of the web. The curves for corrugation A30 and A45

have the same stiffness, but the maximum force is lower in case

350

of A45 and a “plateau” can be seen between points 1-2-3 (see

Fig. 13 and Tab. 5).

300

1 2 3 Another aspect is related to the optimisation of screws used

250

both as seam fasteners and for connecting the web to the flanges.

A better distribution of self-drilling screws together with reduced

thicknesses for the web will put better in evidence the influence

Force [kN]

200

of the sheeting.

150

1 - Buckling of shear panel

2 - Distortion of web corrugation in the same

100 time with LTB 6. CONCLUSION

3 - Plastic mechanism at the bottom flange

50

A45/0.7 A large experimental program carried out at the CEMSIG Re-

0 search Centre (www.ct.upt.ro/centre/cemsig/) of the Politehnica

0 20 40 60 80 100 120 140 University of Timisoara on five beams with corrugated webs with

Displacement [mm] different arrangements for self-drilling screws and shear panels

Fig. 11. Force-displacement curve for 45 mm depth of corrugation was presented. Very good agreement between numerical models

110

Unauthentifiziert | Heruntergeladen 10.11.19 05:25 UTC

DOI 10.1515/ama-2016-0017 acta mechanica et automatica, vol.10 no.2 (2016)

and experimental ones have been obtained, in both failure modes for built-up cold-formed steel beams, Journal of Constructional Steel

and load-displacement curves. Research, 65, 196–208.

A beam with parallel flanges, coming from a pitched roof por- 12. Landolfo R., Mammana O., Portioli F., Di Lorenzo G., Guerrieri,

tal frame of 16 m span, considering 4 types of lateral restraints M.R. (2008), Laser welded built-up cold-formed steel beams:

Experimental investigations, Thin-Walled Structures. 46(7-9), 781-

have been numerically tested, in order to observe the potential for

791.

practical application of proposed technical solutions. The influence 13. Moon J., Yi J., Choi B.H., Lee H.-E. (2008), Shear strength

of corrugation depth has been particularly investigated in present and design of trapezoidally corrugated steel webs, Journal

study, by using three different depths, i.e. of 30, 45 and 85 mm. of Constructional Steel Research, 65(5), 1198–1205.

It can be observed that the capacity of these beams is almost the 14. Moon, J., Lim, N.H., Lee, H.E. (2013), Moment gradient correction

same, but for deeper corrugations, as effect of distortion, the factor and inelastic flexural–torsional buckling of I-girder with

deflection increases, while stiffness decreases. It is expected for corrugated steel webs, Thin-Walled Structures, 62, 18–27.

thinner sheeting, the differences might be even more significant. 15. Neagoie B., Ungureanu V., Dubina D. (2005), Beams with cold-

The increase of ratios between pitch of seem fasteners and formed steel sections for flanges and corrugated web (in Romanian),

Stability and Ductility of Steel Structures – Recent research,

of flange-to-sheeting connectors vs. thickness of the web must

Academic Days, Timisoara, Romania, 27/05, 57-70.

be other parameters contributing to increase the influence 16. Pasternak H., Robra J., Kubieniec G. (2010), New proposals for

of corrugation depth. On the aim of optimizing the technical solu- EN 1993-1-5, Annex D: Plate girders with corrugated webs, Codes in

tion for a mass production of such beams, the further investiga- Structural Engineering, Joint IABSE-fib Conference, Dubrovnik,

tions will focus on these aspects. Croatia, 2, 1365-1372.

17. Sause R., Braxtan T.N. (2011), Shear strength of trapezoidal

corrugated steel webs, Journal of Constructional Steel Research,

REFERENCES 67(2), 223–236.

18. Snow G. (2008), Strength of arc spot welds made in single and

multiple steel sheets, MSc Thesis, Blacksburg, Virginia, USA.

1. Abbas H.H., Sause R., Driver R.G. (2006), Behavior of corrugated

19. Wanniarachchi S. (2005), Flexural Behaviour of Cold-formed Steel

web I-girders under in-plane loads, Journal of Engineering

Beams with Rectangular Hollow Flanges, PhD Thesis, School of Civ.

Mechanics, ASCE, 132(8), 806-814.

Eng., Queensland University, Brisbane, Australia.

2. Abbas H.H., Sause R., Driver R.G. (2007), Analysis of flange

20. Yi J., Gil H., Youm K., Lee H. (2008), Interactive shear buckling

transverse bending of corrugated web I-girders under in-plane loads,

behavior of trapezoidally corrugated steel webs, Engineering

Journal of Structural Engineering, 133(3), 347-355.

Structures, 30(6), 1659–1666.

3. Briskham P., Blundell N., Han L., Hewitt R., Young K., Boomer D.

21. Zhao W. (2005), Behaviour and design of cold-formed steel hollow

(2006), Comparison of self-pierce riveting, resistance spot welding

flange sections under axial compression, PhD Thesis, School of Civ.

and spot friction joining for aluminium automotive sheet, SAE

Eng., Queensland Univ., Brisbane, Australia.

Technical Paper 2006-01-0774, doi:10.4271/2006-01-0774.

22. ABAQUS/CAE v6.7.1 [Computer software]. ABAQUS Inc.,

4. Dubina D., Ungureanu V. and Gîlia L. (2014), Cold-formed steel

Pawtucket, RI.

beams of corrugated web and built-up section chords, Proceedings

23. ECCS 2008, The Testing of connections with mechanical fasteners in

of the 7th European Conference on Steel and Composite Structures -

steel sheeting and sections, Publication 124, ECCS, Brussels,

EUROSTEEL 2014, 10-12/09, 429-430.

Belgium.

5. Dubina D., Ungureanu V., Gîlia L. (2015), Experimental

24. EN ISO 6892-1:2009. Metallic materials - Tensile testing - Part 1:

investigations of cold-formed steel beams of corrugated web and

Method of test at room temperature. CEN, Brussels.

built-up section for flanges, Thin-Walled Structures, 90, 159–170.

25. EN1993-1-1:2005, Eurocode 3: Design of steel structures – Part 1-1:

6. Dubina D., Ungureanu V., Gîlia, L. (2013), Cold-formed steel

General rules and rules for buildings, CEN, Brussels.

beams with corrugated web and discrete web-to-flange fasteners,

26. EN1993-1-3:2006, Eurocode 3: Design of steel structures. Part 1-3:

Steel Constructions – Design and Research, 6(2), 74–81.

General Rules. Supplementary rules for cold-formed thin gauge

7. Guenfoud N., Tremblay R., Rogers C.A. (2010), Arc-Spot Welds for

members and sheeting, CEN, Brussels.

Multi-Overlap Roof Deck Panels, Twentieth International Specialty

27. EN1993-1-5:2006, Eurocode 3: Design of steel structures – Part 1-5:

Conference on Cold-Formed Steel Structures, 535-549.

Plated structural elements, CEN, Brussels.

8. Jiho M., Jong W., Byung H.C., Hak-Eun L. (2009), Lateral-torsional

28. RFSR-CT-2007-00038, Prefabricated steel structures for low-rise

buckling of I-girder with corrugated webs under uniform bending,

buildings in seismic areas (Precasteel), Final report, Research Fund

Thin Walled Structures, 47(1), 21-30.

for Coal and Steel, 2013.

9. Kazemi Nia Korrani H.R., Molanaei S. (2010), The Effects of the

29. US3444664A Patent, Ribbed web girder, Macomber Inc, Fink Jr. H.

Corrugation Profiles of the Web on the Lateral-Torsional Buckling

R., Scott V. P., http://www.google.com/patents/US3444664, 1967.

Strength of the Inelastic I-Girder, World App. Sci. Journal, 8(5),

30. WO 00/17463, International Patent Classification E04C 3/07 (2000).

527-530.

Modular H-beam, BEN-VAUTIER S.P.A., Italy.

10. Kövesdi B., Jáger B., Dunai L. (2012), Stress distribution in the

31. Zeman & Co GmbH, Corrugated Web Beam, Technical Document,

flanges of girders with corrugated webs, Journal of Constructional

2013 (www.zeman-steel.com/).

Steel Research, 79, 204–215.

11. Landolfo R., Mammana O., Portioli F., Di Lorenzo G., Guerrieri

M.R. (2009), Experimental investigation on laser welded connections

111

Unauthentifiziert | Heruntergeladen 10.11.19 05:25 UTC

Das könnte Ihnen auch gefallen

- Cold-Formed Steel Beams With Corrugated Web and Discrete Web-To-Flange FastenersDokument8 SeitenCold-Formed Steel Beams With Corrugated Web and Discrete Web-To-Flange FastenersAsr FlowerNoch keine Bewertungen

- An Economic Proposal in The Design of The One Storey - Level Steel StructureDokument6 SeitenAn Economic Proposal in The Design of The One Storey - Level Steel StructureKy Visoth SambathNoch keine Bewertungen

- Construction and Building Materials: Christoph Czaderski, Moslem Shahverdi, Julien MichelsDokument16 SeitenConstruction and Building Materials: Christoph Czaderski, Moslem Shahverdi, Julien MichelsSAMUEL ALBERTO ZAMBRANA MALDONADONoch keine Bewertungen

- Uzzaman Etal JCSR 2015 Design of Stainless Steel Sections With Circular Openings in ShearDokument46 SeitenUzzaman Etal JCSR 2015 Design of Stainless Steel Sections With Circular Openings in ShearMatt ThompsonNoch keine Bewertungen

- Dundu 2011Dokument15 SeitenDundu 2011fahmi aballiNoch keine Bewertungen

- 36 2387 1342015 Ijcs A PDFDokument13 Seiten36 2387 1342015 Ijcs A PDFAsr FlowerNoch keine Bewertungen

- Engineering Structures: Zhihua Chen, Xiangyuan Niu, Jiadi Liu, Kashan Khan, Yuecong LiuDokument15 SeitenEngineering Structures: Zhihua Chen, Xiangyuan Niu, Jiadi Liu, Kashan Khan, Yuecong LiuBayuAgungGilangWibowoNoch keine Bewertungen

- Flexural Behaviour of Ferrocement Roof PanelsDokument11 SeitenFlexural Behaviour of Ferrocement Roof PanelsRafael CuaNoch keine Bewertungen

- Materials Today: Proceedings: S. Balaji, P. Manikandan, R. Sruthi, K. LokeshrajDokument6 SeitenMaterials Today: Proceedings: S. Balaji, P. Manikandan, R. Sruthi, K. LokeshrajCaio SantosNoch keine Bewertungen

- CivilBay Steel Connection Brace ConnectionDokument12 SeitenCivilBay Steel Connection Brace ConnectionMichenerparkNoch keine Bewertungen

- Practical Design of Cold-Formed Steel Z Sections With Lapped ConnectionsDokument8 SeitenPractical Design of Cold-Formed Steel Z Sections With Lapped ConnectionsJoseAngelFernandezOrtegaNoch keine Bewertungen

- Innovation in Composite ConstructionDokument6 SeitenInnovation in Composite ConstructionnicholasNoch keine Bewertungen

- Research Proposal F (X)Dokument8 SeitenResearch Proposal F (X)I-Chie PlacidoNoch keine Bewertungen

- Journal of The South African Institution of Civil EngineeringDokument15 SeitenJournal of The South African Institution of Civil Engineeringkranthi142434Noch keine Bewertungen

- Composite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemDokument27 SeitenComposite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemVladimirNoch keine Bewertungen

- 1961 - Structural Problems in The Use of CFS SectionsDokument30 Seiten1961 - Structural Problems in The Use of CFS SectionsYazeed Al-RadhiNoch keine Bewertungen

- Double Skinned Steel Tubular (DSST)Dokument68 SeitenDouble Skinned Steel Tubular (DSST)RkkodiNoch keine Bewertungen

- Stochastic Shear Strength of Plate Girder in Highway BridgeDokument40 SeitenStochastic Shear Strength of Plate Girder in Highway BridgeAbdulrasheed Muhammad KardiNoch keine Bewertungen

- Composites: Part A: Alain Prenleloup, Thomas Gmür, John Botsis, Konstantin O. Papailiou, Kurt ObristDokument9 SeitenComposites: Part A: Alain Prenleloup, Thomas Gmür, John Botsis, Konstantin O. Papailiou, Kurt ObristAdam PrasetyaNoch keine Bewertungen

- Buckling Behavior of Split MullionDokument41 SeitenBuckling Behavior of Split MullionNguyễn SơnNoch keine Bewertungen

- Comp Test On C SectionDokument14 SeitenComp Test On C Sectionrahul_civil22Noch keine Bewertungen

- Seismic Design of Cold Formed Steel Structures in Residential ApplicationsDokument3 SeitenSeismic Design of Cold Formed Steel Structures in Residential ApplicationsKristijanRunevskiNoch keine Bewertungen

- Structural Aspects of Cold-Formed Steel Section Designed As U-Shape Composite BeamDokument12 SeitenStructural Aspects of Cold-Formed Steel Section Designed As U-Shape Composite BeamxavierNoch keine Bewertungen

- Kavya.E, Swedha.TDokument7 SeitenKavya.E, Swedha.TamokeNoch keine Bewertungen

- Modern Seismic Design of Steel Structures and Ec8 DevelopmentsDokument6 SeitenModern Seismic Design of Steel Structures and Ec8 DevelopmentsboyzesNoch keine Bewertungen

- Steel Structures in The New MillenniumDokument16 SeitenSteel Structures in The New MillenniumChris FindlayNoch keine Bewertungen

- 1 s2.0 S014102962300384X MainDokument13 Seiten1 s2.0 S014102962300384X MainmohamedNoch keine Bewertungen

- International Journal of Solids and Structures: Lin Yuan, Stelios KyriakidesDokument13 SeitenInternational Journal of Solids and Structures: Lin Yuan, Stelios KyriakidesAshish GuptaNoch keine Bewertungen

- A Numerical Study On Bolted End-Plate Connection Using Shape Memory Alloys PDFDokument9 SeitenA Numerical Study On Bolted End-Plate Connection Using Shape Memory Alloys PDFmdkmlNoch keine Bewertungen

- Experimental Stress Analysis of Trapezoidal Corrugated Steel Web Beam - A ReviewDokument4 SeitenExperimental Stress Analysis of Trapezoidal Corrugated Steel Web Beam - A ReviewAsr FlowerNoch keine Bewertungen

- SS052a SecureDokument13 SeitenSS052a SecureilovevinaNoch keine Bewertungen

- Web Buckling of High-Strength steelplategirdersinducedbybendingcurvature-S.NascimentoJ - OliveiraPedroA.BiscayaDokument9 SeitenWeb Buckling of High-Strength steelplategirdersinducedbybendingcurvature-S.NascimentoJ - OliveiraPedroA.BiscayaAmadius Sakhiruss SylliussNoch keine Bewertungen

- IEEE PapersDokument12 SeitenIEEE PapersPANNERSELVAMNoch keine Bewertungen

- Structural Performance of Bolted Moment ConnectionDokument10 SeitenStructural Performance of Bolted Moment ConnectionNarasimha DvlNoch keine Bewertungen

- Fatigue in High Strength BoltDokument10 SeitenFatigue in High Strength BoltEgyptian ResearcherNoch keine Bewertungen

- Bondek UWS CompositeBeam ShearConnectionDokument15 SeitenBondek UWS CompositeBeam ShearConnectionRada IoanNoch keine Bewertungen

- Thin-Walled Structures: Kim J.R. Rasmussen, Mani Khezri, Benjamin W. Schafer, Hao ZhangDokument42 SeitenThin-Walled Structures: Kim J.R. Rasmussen, Mani Khezri, Benjamin W. Schafer, Hao ZhangJavedNoch keine Bewertungen

- Recent Advances in Design of Steel and Composite Beams With Web OpeningsDokument16 SeitenRecent Advances in Design of Steel and Composite Beams With Web OpeningsmokhtazulNoch keine Bewertungen

- Aluminum ThesisDokument8 SeitenAluminum Thesisalyssaschultecolumbia100% (2)

- Review Article: Review On Cold-Formed Steel ConnectionsDokument12 SeitenReview Article: Review On Cold-Formed Steel ConnectionsRakeshNoch keine Bewertungen

- Tests of Cold-Formed Channel ColumnsDokument27 SeitenTests of Cold-Formed Channel ColumnsHadeer MohamedNoch keine Bewertungen

- Thin-Walled Structures: Sivakumar Kesawan, Mahen Mahendran, Yomal Dias, Wen-Bin ZhaoDokument14 SeitenThin-Walled Structures: Sivakumar Kesawan, Mahen Mahendran, Yomal Dias, Wen-Bin ZhaoDinesh LakshmananNoch keine Bewertungen

- Dimopoulos2013 Article SeismicDesignModellingAndAssesDokument20 SeitenDimopoulos2013 Article SeismicDesignModellingAndAssesOlaNoch keine Bewertungen

- Libro de Reforzamiento HORMIGON ARMADO 2022-7Dokument25 SeitenLibro de Reforzamiento HORMIGON ARMADO 2022-7David Magne MamaniNoch keine Bewertungen

- Analysis of The Behaviour of Stainless Steel Bolted ConnectionsDokument11 SeitenAnalysis of The Behaviour of Stainless Steel Bolted ConnectionsSam SamouraNoch keine Bewertungen

- Pull Out Resistance of Roof FastenersDokument41 SeitenPull Out Resistance of Roof FastenersChuksbozment100% (1)

- Welded Connections in High Strength Cold-Formed Steels PDFDokument11 SeitenWelded Connections in High Strength Cold-Formed Steels PDFAli KhalafNoch keine Bewertungen

- Optimum Design of Cold-Formed Steel Portal Frame Buildings by Phan 2017Dokument16 SeitenOptimum Design of Cold-Formed Steel Portal Frame Buildings by Phan 2017fahmi aballiNoch keine Bewertungen

- Experimental and Analytical Study of Cold Formed Steel SectionsDokument44 SeitenExperimental and Analytical Study of Cold Formed Steel SectionsAmit SonavaneNoch keine Bewertungen

- The Effect of Infill Steel Plate Thickness On The Cycle Behavior of Steel Plate Shear WallsDokument7 SeitenThe Effect of Infill Steel Plate Thickness On The Cycle Behavior of Steel Plate Shear WallsGogyNoch keine Bewertungen

- Influence of Fastening Systems On The Ultimate CapDokument8 SeitenInfluence of Fastening Systems On The Ultimate Capthelga_899800Noch keine Bewertungen

- Tensile StructuresDokument10 SeitenTensile Structuresaditya2053Noch keine Bewertungen

- Earls, 1999Dokument24 SeitenEarls, 1999carlosNoch keine Bewertungen

- Wang-Salhab2009 Article StructuralBehaviourAndDesignOfDokument11 SeitenWang-Salhab2009 Article StructuralBehaviourAndDesignOfRodyShineNoch keine Bewertungen

- Kim, T., 2020Dokument16 SeitenKim, T., 2020primasukmayuanaNoch keine Bewertungen

- BD C Candidate Handbook 2018 6.12.18 FINALDokument13 SeitenBD C Candidate Handbook 2018 6.12.18 FINALmadhav sreekumarNoch keine Bewertungen

- An in - Built Trial Mechanism of Providing Permanent Sound Proofing and Thermal Insulation' in Buildings Using Steel Shear Bolsters in Sandwiched Reinforced Cement Concrete Slabs and BeamsDokument7 SeitenAn in - Built Trial Mechanism of Providing Permanent Sound Proofing and Thermal Insulation' in Buildings Using Steel Shear Bolsters in Sandwiched Reinforced Cement Concrete Slabs and BeamsvipinNoch keine Bewertungen

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsVon EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNoch keine Bewertungen

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyVon EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNoch keine Bewertungen

- PublicationsDokument1 SeitePublicationsci_balaNoch keine Bewertungen

- Chapter 2Dokument44 SeitenChapter 2ci_balaNoch keine Bewertungen

- 09 Chapter3Dokument15 Seiten09 Chapter3ci_balaNoch keine Bewertungen

- 80 RecommendationDokument5 Seiten80 Recommendationci_balaNoch keine Bewertungen

- 16 Chapter 10Dokument9 Seiten16 Chapter 10ci_balaNoch keine Bewertungen

- Muthumari - ProfromaDokument1 SeiteMuthumari - Profromaci_balaNoch keine Bewertungen

- Title PageDokument3 SeitenTitle Pageci_balaNoch keine Bewertungen

- Structures: Nakisa Haghi, Siamak Epackachi, Mohammad Taghi Kazemi TDokument24 SeitenStructures: Nakisa Haghi, Siamak Epackachi, Mohammad Taghi Kazemi Tci_balaNoch keine Bewertungen

- OML751-Testing of MaterialsDokument13 SeitenOML751-Testing of Materialsci_balaNoch keine Bewertungen

- An Experimental Study For In-Plane Cyclic Behavior of Low Aspect-Ratio Steel-Concrete Composite WallsDokument11 SeitenAn Experimental Study For In-Plane Cyclic Behavior of Low Aspect-Ratio Steel-Concrete Composite Wallsci_balaNoch keine Bewertungen

- Load Carrying Capacity of Clay Brick Masonry Wall Encased by FerrocementDokument10 SeitenLoad Carrying Capacity of Clay Brick Masonry Wall Encased by Ferrocementci_balaNoch keine Bewertungen

- CE - 8702 Internal - 2 - 2020-1Dokument1 SeiteCE - 8702 Internal - 2 - 2020-1ci_balaNoch keine Bewertungen

- 001 Basics of Plastic Analysis 191107085920Dokument61 Seiten001 Basics of Plastic Analysis 191107085920ci_balaNoch keine Bewertungen

- Nonlinear Modeling and Methods of AnalysisDokument29 SeitenNonlinear Modeling and Methods of Analysisci_balaNoch keine Bewertungen

- CE 8601 Internal 2 Answerkey 2021Dokument10 SeitenCE 8601 Internal 2 Answerkey 2021ci_balaNoch keine Bewertungen

- 1.1 General: Chapter 1. IntroductionDokument4 Seiten1.1 General: Chapter 1. Introductionci_balaNoch keine Bewertungen

- FDTP SOM BROCHURE FinalDokument2 SeitenFDTP SOM BROCHURE Finalci_balaNoch keine Bewertungen

- Chapter 2. Review of LiteratureDokument19 SeitenChapter 2. Review of Literatureci_balaNoch keine Bewertungen

- Crack-Free Engineered Cementitious Composites To Overcome Durability Challenges in Construction IndustryDokument12 SeitenCrack-Free Engineered Cementitious Composites To Overcome Durability Challenges in Construction Industryci_balaNoch keine Bewertungen

- Loading History CSP-2: 0.6% Drift 0.9% Drift 1.25% Drift 1.5% Drift 1.8% Drift 2.1% Drift 2.4% DriftDokument12 SeitenLoading History CSP-2: 0.6% Drift 0.9% Drift 1.25% Drift 1.5% Drift 1.8% Drift 2.1% Drift 2.4% Driftci_balaNoch keine Bewertungen

- Pre-Standardisation: 9700/52 AS & A Level - Mark Scheme March 2023Dokument13 SeitenPre-Standardisation: 9700/52 AS & A Level - Mark Scheme March 2023hassan qadir100% (1)

- A Study On Properties of Foamed Concrete With Fly Ash and Marble Sludge PowderDokument4 SeitenA Study On Properties of Foamed Concrete With Fly Ash and Marble Sludge PowderAnuraagNoch keine Bewertungen

- Discovery and InventionsDokument5 SeitenDiscovery and InventionsSymon AngeloNoch keine Bewertungen

- 2.2 Design of Flexural MemberDokument26 Seiten2.2 Design of Flexural MemberNazihah100% (1)

- Methods of Interstellar TravelDokument4 SeitenMethods of Interstellar TravelTimurNoch keine Bewertungen

- Time Price Research Astrofin - Blogspot.in Moon MarketsDokument5 SeitenTime Price Research Astrofin - Blogspot.in Moon MarketsArudra RaoNoch keine Bewertungen

- Maths A 1H 0CT 2020Dokument28 SeitenMaths A 1H 0CT 2020Subaita Azad100% (7)

- Relation Between Difference OperatorsDokument8 SeitenRelation Between Difference OperatorsS AdilakshmiNoch keine Bewertungen

- Anchor Chain Stud RepairsDokument1 SeiteAnchor Chain Stud RepairsAnkush GuptaNoch keine Bewertungen

- Phosphor Bronze Rod, Bar, and Shapes: Standard Specification ForDokument5 SeitenPhosphor Bronze Rod, Bar, and Shapes: Standard Specification FormahfuzNoch keine Bewertungen

- Module 1 Types of Fluid and Its PropertiesDokument11 SeitenModule 1 Types of Fluid and Its PropertiesAragones, Trisha Marie CNoch keine Bewertungen

- Full PaperDokument7 SeitenFull PaperRafique ArisarNoch keine Bewertungen

- Scorched Particle Standards For Dry MilkDokument3 SeitenScorched Particle Standards For Dry MilkArifin R HidayatNoch keine Bewertungen

- Pages From BeerVectorISM - C16P001P164 Problem 16-135, 16-136 PDFDokument8 SeitenPages From BeerVectorISM - C16P001P164 Problem 16-135, 16-136 PDFSerafinNoch keine Bewertungen

- Clark Inflatable Supersonic Tension ConeDokument9 SeitenClark Inflatable Supersonic Tension ConenaraNoch keine Bewertungen

- Lectura de Condensador MLCDokument84 SeitenLectura de Condensador MLCjhon jairo gomez solanoNoch keine Bewertungen

- Installation With Mortar - Umlauf 2015 PDFDokument18 SeitenInstallation With Mortar - Umlauf 2015 PDFvũ minh tâmNoch keine Bewertungen

- Calibration of Direction Finding Antennas in Complex EnvironmentDokument4 SeitenCalibration of Direction Finding Antennas in Complex EnvironmentNorozKhanNoch keine Bewertungen

- Температура ЕЕАDokument13 SeitenТемпература ЕЕААнастасия ФилимоненкоNoch keine Bewertungen

- Practice Test 01 - Physics - Arjuna JEE 2024Dokument2 SeitenPractice Test 01 - Physics - Arjuna JEE 2024kochharmadhav0Noch keine Bewertungen

- 6.5 Solving Exponential EquationsDokument9 Seiten6.5 Solving Exponential EquationsAshan KhanNoch keine Bewertungen

- P 6Dokument4 SeitenP 6Mark Joseph MalaluanNoch keine Bewertungen

- First Bimonthly Examination Mathematics Grade Vii Paper 2Dokument7 SeitenFirst Bimonthly Examination Mathematics Grade Vii Paper 2maeveNoch keine Bewertungen

- M1 PengukuranDokument18 SeitenM1 PengukuranMUHAMMAD HARIZ IKHWAN BIN JAFRI MoeNoch keine Bewertungen

- Guide Ragnarok X Next GenerationDokument6 SeitenGuide Ragnarok X Next GenerationDavid BrianNoch keine Bewertungen

- School Year - : No Physical Labs at HomeDokument4 SeitenSchool Year - : No Physical Labs at HomeJoshua WhiteNoch keine Bewertungen

- FIGURE 10-17: Vapor and Combined Power CyclesDokument8 SeitenFIGURE 10-17: Vapor and Combined Power CyclesBengü MNoch keine Bewertungen

- Q An Ab Initio Exciton Model Including Charge-Transfer Excited StatesDokument12 SeitenQ An Ab Initio Exciton Model Including Charge-Transfer Excited StatesdebmallyNoch keine Bewertungen

- Chapter III A Equilibrium 2D: Engineering MechanicsDokument85 SeitenChapter III A Equilibrium 2D: Engineering MechanicsYue FeiNoch keine Bewertungen

- Catalogue From Shandong Tianren New Material Co. LTDDokument37 SeitenCatalogue From Shandong Tianren New Material Co. LTDChrestella InggrianiNoch keine Bewertungen