Beruflich Dokumente

Kultur Dokumente

Non Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent Repair

Hochgeladen von

Akhmad RamdaniOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Non Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent Repair

Hochgeladen von

Akhmad RamdaniCopyright:

Verfügbare Formate

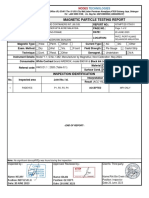

NON DESTRUCTIVE TESTING

REPORT

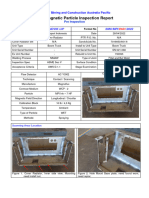

JOB NO : 2024 MODEL / TYPE : N/A

CUSTOMER : PT. ETSI P/N : N/A

EQUIPMENT : ROTOR TURBINE S/N : N/A

OEM : ELLIOTT TAG NUMBER : N/A

Inspector/level : Dadang Hermawan / II Report No. : 213 /NDT/ 04 20

No Id. No Qty. Description Status of Part

1 .--. 201 Blade LP As Recieve Repair

Final

Surface Preparation

Solvent Cleaning

Others

PENETRANT TEST MAGNETIC PARTICLE TEST ULTRASONIC TEST EDDY CURRENT TEST

RED DYE BLACK INK Freq./Gain/Angle/Range Freq./Gain/Probe

FLUORESCENT FLUORESCENT 5-10 / 55- 65 / 0 / 50 2.25 / 60- 72/Abbs

Mnf. Magnetizer Mnf. Mnf.

Krautkramer Branson Olympus Other

: Magnaflux Mobil Unit

Other

Type Yoke : RIGOR RFD1000 :

SOLVENT Media-wet Std.block Std.block

WATER WASH MAGNAFLUX 14 A V1 V2 NFE FE

Dweel time-minute ARDROX SY 8000 Step Wedge Block :

10 30 Amp AC DC

References: References: References: References:

ASTM-1417/API-687 ASTM E-1444/API-687 ASTM-114/API-687/Mil.Std.2183 MIL STD 271/API-687

Witness by : Customer

Test Result :

Part Name NDT Method Remark

Blade LP

Found No Relevant Indications. Found No Crack and other

Blade #1 - #201 MPI

Indications.

QA/NDT L.III/Eng.

Comment :

THE PARTS ABOVE ARE ACCEPTED AND FREE OF CRACK IN ACC TO THE TEHNIQUE AS BELOW BY

MAGNETIC PARTICLE INSPECTION.

NOTE : INSPECTED BY : APPROVED BY :

Dadang Hermawan Customer :

DATE : April 29, 2020 DATE :

ATACHMENT OF REPORT NO. : 213 /NDT/ 04 20

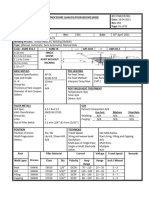

NON DESTRUCTIVE TESTING

REPORT

JOB NO : 2024 MODEL / TYPE : N/A

CUSTOMER : PT. ETSI P/N : N/A

EQUIPMENT : ROTOR TURBINE S/N : N/A

OEM : ELLIOTT TAG NUMBER : N/A

QUALITY VERIFICATION OF PARTS BY MAGNETIC PARTICLE TESTING BASIC

TECHNIQUE

When a bar magnet is broken in the center of its

length, two complete bar magnets with magnetic

poles on each end of each piece will result. If the

magnet is just cracked but not broken completely

in two, a north and south pole will form at each

edge of the crack. The magnetic field exits the

north pole and reenters at the south pole. The

magnetic field spreads out when it encounters the

small air gap created by the crack because the air

cannot support as much magnetic field per unit

volume as the magnet can. When the field spreads

out, it appears to leak out of the material and, thus

is called a flux leakage field.

If iron particles are sprinkled on a cracked magnet,

the particles will be attracted to and cluster not

only at the poles at the ends of the magnet, but

also at the poles at the edges of the crack. This

cluster of particles is much easier to see than the

actual crack and this is the basis for magnetic

particle inspection

Steps to do the MPI Test - Method by Portable Yoke

ATACHMENT OF REPORT NO. : 213 /NDT/ 04 20

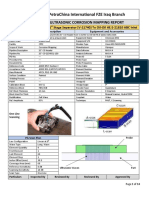

NON DESTRUCTIVE TESTING

REPORT

JOB NO : 2024 MODEL / TYPE : N/A

CUSTOMER : PT. ETSI P/N : N/A

EQUIPMENT : ROTOR TURBINE S/N : N/A

OEM : ELLIOTT TAG NUMBER : N/A

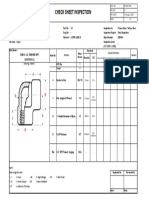

MAGNETIC PARTICLE INSPECTIOIN ON BLADE

Fig 1.Before Magnetization Process on Part, 0 Gauss Fig 2. Magnetic Field orientation on Pie Gauge

Fig 3. After Magnetization Process on Part, 5 Gauss, Fig 4. MPI Inspection on Blade LP Under UV Black

Ready to Inspect Light

Fig 5. MPI Inspection on Blade LP Under UV Black Fig 6. MPI Inspection Under UV Black Light

Light

Fig 7. After Demagnetize Process, 0 Gauss ready

to assembly

Das könnte Ihnen auch gefallen

- En Iso 9606 1 GDokument2 SeitenEn Iso 9606 1 GAnonymous dziHEjc7Y100% (1)

- Final Report UT Inspection BearingDokument5 SeitenFinal Report UT Inspection BearingEko PurwantoNoch keine Bewertungen

- Liquid Penetrant Examination Report: PO No.&Dokument2 SeitenLiquid Penetrant Examination Report: PO No.&Samir Chaudhary100% (2)

- Daily Lrut Report: Lrut Instrument Lrut Probe TechniqueDokument1 SeiteDaily Lrut Report: Lrut Instrument Lrut Probe TechniqueSang Nguyen QuangNoch keine Bewertungen

- 1 Paut ReportDokument1 Seite1 Paut ReportAhmedNoch keine Bewertungen

- 109.8181.MPI - Pre.Unit.730395.Cover RadiatorDokument2 Seiten109.8181.MPI - Pre.Unit.730395.Cover RadiatorHerr Ddiman100% (1)

- Insulator and Conductor Fittings For Overhead Power Lines - : Part 1: Performance and General RequirementsDokument26 SeitenInsulator and Conductor Fittings For Overhead Power Lines - : Part 1: Performance and General RequirementsMohamed Ahmed Afifi100% (1)

- Journal BeringDokument8 SeitenJournal BeringpelakupasarNoch keine Bewertungen

- En Iso 9606 1 ADokument2 SeitenEn Iso 9606 1 AvitharvanNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Ir - L1904-32 17apr19-Mt (Sfjt-E)Dokument5 SeitenIr - L1904-32 17apr19-Mt (Sfjt-E)Alleyson Akin100% (1)

- Temperature MeasurementDokument50 SeitenTemperature MeasurementKubenKrishNoch keine Bewertungen

- DPT of PropellerDokument3 SeitenDPT of Propellersushanto.mtbdNoch keine Bewertungen

- NDT Report - Old.Turbine BearingsDokument3 SeitenNDT Report - Old.Turbine BearingsOm Ar TanNoch keine Bewertungen

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Dokument1 Seite75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNoch keine Bewertungen

- Installation of Padeyes Ad Load Test: Front CoverDokument40 SeitenInstallation of Padeyes Ad Load Test: Front CoverAhmedA.HassanNoch keine Bewertungen

- NDT Report - Dovetail WheelsDokument4 SeitenNDT Report - Dovetail WheelsOm Ar TanNoch keine Bewertungen

- Reporte Hdpe 2Dokument2 SeitenReporte Hdpe 2Woodrow FoxNoch keine Bewertungen

- UT Report BlankDokument1 SeiteUT Report BlankGilang AdiNoch keine Bewertungen

- Inspection: AIR Winch Ingersoll RandDokument19 SeitenInspection: AIR Winch Ingersoll RandAbdou BoucheritNoch keine Bewertungen

- Checklist Fire StopDokument9 SeitenChecklist Fire StopAnonymous DMdGdsOENoch keine Bewertungen

- WO1831 - Arabtec 09.02.2020.Dokument1 SeiteWO1831 - Arabtec 09.02.2020.Pradeep ManivannanNoch keine Bewertungen

- CAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Dokument3 SeitenCAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Komang Triwahyudi100% (1)

- Elbow 0,5-3000 NPT - OKDokument1 SeiteElbow 0,5-3000 NPT - OKJovianto PrisilaNoch keine Bewertungen

- 107.8182.MPI - Pre.Unit.730395.Fuel TankDokument2 Seiten107.8182.MPI - Pre.Unit.730395.Fuel TankHerr DdimanNoch keine Bewertungen

- CB-043 Mpi Exp-02 Apr 2024Dokument1 SeiteCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNoch keine Bewertungen

- Annual Vg7076Dokument2 SeitenAnnual Vg7076Emmanuel SanthanasamyNoch keine Bewertungen

- Client:: Olectra Greentech LTDDokument1 SeiteClient:: Olectra Greentech LTDnareshNoch keine Bewertungen

- Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Dokument2 SeitenMagnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Khalil ChabbouhNoch keine Bewertungen

- Hex Bushing 0,75 X 0,5Dokument1 SeiteHex Bushing 0,75 X 0,5Jovianto PrisilaNoch keine Bewertungen

- Gpti Qicl 032Dokument2 SeitenGpti Qicl 032uselessinstaid52Noch keine Bewertungen

- 106.8180.MPI - Pre.Unit.730395.Hydraulic TankDokument3 Seiten106.8180.MPI - Pre.Unit.730395.Hydraulic TankHerr DdimanNoch keine Bewertungen

- IRM3427 Ensco Ensco5002 Installation of Padeyes Ad Load TestDokument40 SeitenIRM3427 Ensco Ensco5002 Installation of Padeyes Ad Load TestAfzaalUmairNoch keine Bewertungen

- Gpti Qicl J931 Mut 041Dokument3 SeitenGpti Qicl J931 Mut 041uselessinstaid52Noch keine Bewertungen

- Example Report TOFD 2 INT-GP1186-09-70 PDFDokument1 SeiteExample Report TOFD 2 INT-GP1186-09-70 PDFEMTC EMTCNoch keine Bewertungen

- Example Report TOFD 2 INT-GP1186!09!70Dokument1 SeiteExample Report TOFD 2 INT-GP1186!09!70EMTC EMTC100% (1)

- Penetrant Test Report: PT DegremontDokument14 SeitenPenetrant Test Report: PT DegremontMuhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- MPI Report SWL 5 Ton BoxDokument2 SeitenMPI Report SWL 5 Ton BoxYusuf bagewadiNoch keine Bewertungen

- PQR FLow LineDokument2 SeitenPQR FLow Linesar sarNoch keine Bewertungen

- MT ReportDokument11 SeitenMT Reportel_sharkawy2011100% (1)

- CPF1 - PAUT-2023-636-20" CO Header From V-21740 To Oil-Oil HE (E-21810 ABC) Inlet (Abnormal Points)Dokument14 SeitenCPF1 - PAUT-2023-636-20" CO Header From V-21740 To Oil-Oil HE (E-21810 ABC) Inlet (Abnormal Points)Vignesh PanchabakesanNoch keine Bewertungen

- SAMPLE Defect SheetDokument2 SeitenSAMPLE Defect SheetshafanyNoch keine Bewertungen

- Procedure Qualification Record (PQR) Khewari Development ProjectDokument2 SeitenProcedure Qualification Record (PQR) Khewari Development Projectsar sarNoch keine Bewertungen

- 1.wash Pipe 8-1-8 SN NNDokument1 Seite1.wash Pipe 8-1-8 SN NNMuhammad Rijal sembiringNoch keine Bewertungen

- DPT ReportDokument3 SeitenDPT ReportMANIMARAN QCNoch keine Bewertungen

- Threadolet 0,5 X 3 - 4 3000Dokument1 SeiteThreadolet 0,5 X 3 - 4 3000Jovianto PrisilaNoch keine Bewertungen

- Bao Cao PT Ba Ria-04Dokument4 SeitenBao Cao PT Ba Ria-04Sang Nguyen QuangNoch keine Bewertungen

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDokument1 SeitePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNoch keine Bewertungen

- Magnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceDokument4 SeitenMagnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceSulthan HanifNoch keine Bewertungen

- 65.4 Leg Web Sling V 170584Dokument1 Seite65.4 Leg Web Sling V 170584Upi BraderNoch keine Bewertungen

- Int Aim 231787 PT 14 1302&03Dokument1 SeiteInt Aim 231787 PT 14 1302&03Joshua ClaytonNoch keine Bewertungen

- MT PipaDokument70 SeitenMT PipaDani Madrid12Noch keine Bewertungen

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Dokument2 SeitenNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNoch keine Bewertungen

- 23-01-24. Comp MTA 6 Plant SignDokument4 Seiten23-01-24. Comp MTA 6 Plant Signwahyudi140417Noch keine Bewertungen

- Welding Penetration Reports ITLDokument31 SeitenWelding Penetration Reports ITLHarminder KumarNoch keine Bewertungen

- VIR Hot TapDokument2 SeitenVIR Hot TapCak NhassNoch keine Bewertungen

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Dokument2 SeitenNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNoch keine Bewertungen

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Dokument2 SeitenNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNoch keine Bewertungen

- Doosan Power Systems Indai PVT Limited: System CalibrationDokument3 SeitenDoosan Power Systems Indai PVT Limited: System CalibrationBalkishan DyavanapellyNoch keine Bewertungen

- Mpi 44444286 ..Dokument1 SeiteMpi 44444286 ..Khalil ChabbouhNoch keine Bewertungen

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Dokument2 SeitenNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNoch keine Bewertungen

- WPS PQR FormulirDokument2 SeitenWPS PQR FormulirAZaiNoch keine Bewertungen

- MoM and ETSI Request - Lu2205.rev.1Dokument3 SeitenMoM and ETSI Request - Lu2205.rev.1Akhmad RamdaniNoch keine Bewertungen

- PT Horiguchi Engineering Indonesia: General CatalogueDokument24 SeitenPT Horiguchi Engineering Indonesia: General CatalogueAkhmad RamdaniNoch keine Bewertungen

- Audit Form - SalesDokument1 SeiteAudit Form - SalesAkhmad RamdaniNoch keine Bewertungen

- ID-Mxd2005-21-0035-Quotation-PT. - Masrin Damanik - R0-2021-004-26-0016Dokument8 SeitenID-Mxd2005-21-0035-Quotation-PT. - Masrin Damanik - R0-2021-004-26-0016Akhmad Ramdani0% (1)

- The FPL Playbook 201920Dokument63 SeitenThe FPL Playbook 201920Akhmad RamdaniNoch keine Bewertungen

- BronzeLG2LeadedGunmetalBronze PDFDokument2 SeitenBronzeLG2LeadedGunmetalBronze PDFAnthonyNoch keine Bewertungen

- (Hyundai I10 2007-) (Kia Morning 2011-, Picanto 2009-, Ray 2012-, Suria 2006-2011) 4 SPEED FWD With Lock Up (Electronic Control)Dokument4 Seiten(Hyundai I10 2007-) (Kia Morning 2011-, Picanto 2009-, Ray 2012-, Suria 2006-2011) 4 SPEED FWD With Lock Up (Electronic Control)EduRoiNoch keine Bewertungen

- Quotation: Dynamic AttributesDokument3 SeitenQuotation: Dynamic AttributesAkhmad RamdaniNoch keine Bewertungen

- NCP1399AA, NCP1399BA, NCP1399AC, NCP1399AF High Performance Current Mode Resonant Controller With Integrated High-Voltage DriversDokument44 SeitenNCP1399AA, NCP1399BA, NCP1399AC, NCP1399AF High Performance Current Mode Resonant Controller With Integrated High-Voltage DriversGoensNoch keine Bewertungen

- Shaping High-Power IGBT Switching Transitions by Active Voltage Control For Reduced EMI GenerationDokument9 SeitenShaping High-Power IGBT Switching Transitions by Active Voltage Control For Reduced EMI GenerationOsman T.Noch keine Bewertungen

- Kathrein Antennen 1998Dokument161 SeitenKathrein Antennen 1998Sebastian Schille100% (1)

- The Jumping Ring ExperimentDokument6 SeitenThe Jumping Ring ExperimentDaniel McknightNoch keine Bewertungen

- SlideDokument76 SeitenSlideAnamiya BhattacharyaNoch keine Bewertungen

- Literature ReviewDokument18 SeitenLiterature Reviewroyal1979Noch keine Bewertungen

- OSI Op To Electronics CatalogDokument118 SeitenOSI Op To Electronics Catalogshantanu142Noch keine Bewertungen

- Model Questions of SWITCHGEAR & PROTECTIONDokument2 SeitenModel Questions of SWITCHGEAR & PROTECTIONSaroj kumar BiswasNoch keine Bewertungen

- Sanyo - SAP-CRV243GJH - SAP-KCRV243-303 Service ManualDokument78 SeitenSanyo - SAP-CRV243GJH - SAP-KCRV243-303 Service ManualRoberto BottiniNoch keine Bewertungen

- Electrical CalloutsDokument9 SeitenElectrical CalloutsJason d HernandezNoch keine Bewertungen

- LG W1943SSDokument32 SeitenLG W1943SSRuben RiveroNoch keine Bewertungen

- Box Fan ®Dokument5 SeitenBox Fan ®pukymottoNoch keine Bewertungen

- GR 874-GA Operation Manual, Applications, SpecificationsDokument8 SeitenGR 874-GA Operation Manual, Applications, Specifications240GL guyNoch keine Bewertungen

- Zxdu68 B201 DC PDFDokument42 SeitenZxdu68 B201 DC PDFronnymareNoch keine Bewertungen

- Fences. Specification For Electric Security Fences. Design, Installation and Maintenance - Libgen - LiDokument26 SeitenFences. Specification For Electric Security Fences. Design, Installation and Maintenance - Libgen - LiMichael EkubaselasieNoch keine Bewertungen

- BAGAY JUNEE C1 Exp4Dokument17 SeitenBAGAY JUNEE C1 Exp4Dylan CosepNoch keine Bewertungen

- Submission+07+-+copyedited V2+Dokument13 SeitenSubmission+07+-+copyedited V2+Sơn Phạm ThanhNoch keine Bewertungen

- TS1935BCX5: Taiwan SemiconductorDokument9 SeitenTS1935BCX5: Taiwan Semiconductorn tanevarNoch keine Bewertungen

- Type Rechargeable Battery Powered AC Line PoweredDokument2 SeitenType Rechargeable Battery Powered AC Line PoweredMohsin LatifNoch keine Bewertungen

- 13 - IRIS - NV - Error CodeDokument53 Seiten13 - IRIS - NV - Error Codesteve niereNoch keine Bewertungen

- Micromaster 420: 0.12 KW - 11 KWDokument190 SeitenMicromaster 420: 0.12 KW - 11 KWCristian SilvaNoch keine Bewertungen

- Temperature Controller PDFDokument3 SeitenTemperature Controller PDFAhtesham KhanNoch keine Bewertungen

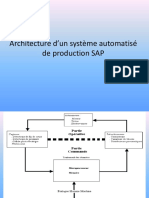

- Architecture D'un Système Automatisé de Production SAPDokument61 SeitenArchitecture D'un Système Automatisé de Production SAPRO S TomNoch keine Bewertungen

- ELECTROCHEMISTRY - Practice Sheet & Solution - Vijeta 2023Dokument4 SeitenELECTROCHEMISTRY - Practice Sheet & Solution - Vijeta 2023Yasir Karim100% (1)

- Materi 210422Dokument7 SeitenMateri 210422Hari YadiNoch keine Bewertungen

- Tube Liquid Sensor: OPB350 / OCB350 Series (Calibration Circuit Available)Dokument8 SeitenTube Liquid Sensor: OPB350 / OCB350 Series (Calibration Circuit Available)Oscar Javier Alvarado ZarabandaNoch keine Bewertungen

- DP 85 Train PackDokument112 SeitenDP 85 Train Packdann222Noch keine Bewertungen

- Part 5 - Electroacoustic Devices - HandoutDokument17 SeitenPart 5 - Electroacoustic Devices - HandoutJade Mark RamosNoch keine Bewertungen