Beruflich Dokumente

Kultur Dokumente

Testing Application Standard 203-94

Hochgeladen von

Shawn DeolOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Testing Application Standard 203-94

Hochgeladen von

Shawn DeolCopyright:

Verfügbare Formate

TESTING APPLICATION STANDARD (TAS) 203-94

CRITERIA FOR TESTING PRODUCTS SUBJECT TO

CYCLIC WIND PRESSURE LOADING

1. Scope 3.8 Maximum Deflection - The maximum dis-

placement measured to the nearest 1/8 inch

1.1 This protocol covers procedures for conduct- attained from an original position while the

ing the cyclic wind pressure loading test maximum load is being applied.

required by the Florida Building Code,

Building and TAS 201-94. 3.9 Permanent Deformation - The permanent dis-

placement measured to the nearest 1/8 inch

2. Referenced Documents from an original position that remains after

the applied test load has been removed.

2.1 The Florida Building Code, Building.

3.10 Specimen Failure - A change in condition of

3. Terminology the specimen indicative of deterioration under

repeated load or incipient failure, such as

3.1 Definitions - For definitions of terms used in

cracking, fastener loosening, local yielding, or

this protocol, refer to the Florida Building

loss of adhesive bond.

Code, Building.

4. Significance and Use

3.2 Description of Terms Specific to This

Protocol

4.1 This test method is a standard procedure for

determining compliance with Sections 1625

3.3 Specimen - The entire assembled, unit sub-

Table 1625.4 and Table 1626 of the Florida

mitted for test, including anchorage devices

Building Code, Building. This test method is

and structure to which product is to be mount-

intended to be used for installations of exteri-

ed. or windows, glazing, wall cladding, exterior

doors, skylights, glass block, storm shutters,

3.4 Positive (Negative) Cyclic Load - the speci- and other similar device used as external pro-

fied differential in static air pressure, creating tection of the building envelope. This test

an inward (outward) loading, for which the method consists of supplying air to and

specimen is to be tested under repeated condi- exhausting air from the chamber in accor-

tions, expressed in pounds per square foot. dance with a specific test loading program at

the rate required to maintain the test pressure

3.5 One Cycle - Beginning at the specified static differential across the specimen, and observ-

air pressure, the application of positive cyclic ing, measuring, and recording the deflection,

test load, and returning to the specified static deformations, and nature of any distress or

air pressure, followed by the application of failures of the specimen.

negative cyclic test load.

5. Test Specimen

3.6 Design Wind Load - The uniform static air

pressure difference, inward or outward, for

which the specimen would be designed under 5.1 Test specimen - All parts of the test specimen

service load conditions using the Florida shall be full size, using the same materials,

Building Code, Building Section 1606. details, methods of construction and methods

of attachment as proposed for actual use. The

3.7 Test Chamber - An airtight enclosure of suffi- specimen shall consist of the entire assembled

unit attached to a given type of structural

cient depth to allow unobstructed deflection

framing of the building, and shall contain all

of the specimen during pressure cycling,

devices used to resist wind forces and wind-

including ports for air supply and removal,

borne debris. When testing glazed products,

and equipped with a device to measure test

the material used to make such glazed product

pressure differentials.

FLORIDA BUILDING CODE — TEST PROTOCOL HVHZ (TAS) 203-94.1

(TAS) NO. 203-94

windborne debris resistant (i.e. fillers, film 5.1.3 Specimen and fasteners, when used,

and similar), shall be an integral part, factory shall not become disengaged during

applied, of such glazed product. test procedure.

In the case of windows, doors, and sliding 5.2 If the impact test is to be performed on the test

glass doors, a pressure treated nominal 2 x 4 specimen, such test shall be conducted prior

wood buck #3 Southern Pine shall be used for to performing the test described in this proto-

attachment of the specimen to the test col.

frame/stand/chamber. Such wood buck will

become part of the approval. 5.3 All locking mechanisms should be in place

when performing this test.

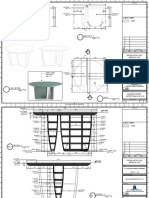

In the case of storm panels, they must be test-

ed in worst case scenarios where attachments 5.4 Doors and windows must be operable after

are directly to CBS block. Figure 1 shows the this test.

basic three (3) configurations that shall be

required; one per each of the three (3) 5.5 Manufacturers of any specimen with width of

required specimens. Each storm panel speci- more than 20 ft and/or a height of more than 8

men shall consist of minimum three (3) pan- ft, must submit for approval a proposed com-

els. parative test criteria to the Authority Having

Jurisdiction prior to testing.

6. Procedure

6.1 Preparation - Remove from the test specimen

any sealing or construction material that is not

normally used when installed in or on a build-

ing. Fit the specimen with its structural fram-

ing into or against the chamber opening. The

outdoor side of the specimen shall face the

higher pressure side for positive loads; the

indoor side shall face the higher pressure side

FIGURE 1 for negative loads. Support and secure the

THREE (3) BASIC STORM PANEL ATTACHMENTS specimen by the same number and type of

FOR TESTING.

anchors to be approved for normal installation

of the specimen in the building.

5.1.1 Locking mechanisms shall be perma-

nently mounted on the specimen. Such

locking mechanism shall require no 6.2 Support and secure the test specimen by the

tools to be latched in the locked posi- same number and type of anchors normally

tion. Devices such as pins shall be per- used in installing the unit in the building.

manently secured to the specimen

through the use of chains or wires which 6.3 Load the specimen using the cycles specified

must be of corrosion resistant material. in section Table 1625.4 and/or Table 1626 of

This section does not apply to speci- the Florida Building Code, Building whichev-

mens referenced in Section 2422 of the er of these apply.

Florida Building Code, Building.

6.4 In the case of Table 1625.4 of the Florida

5.1.2 Products that are not categorized as Building Code, Building Section 6.3 of this

means of egress/escape and are pro- protocol must be repeated for negative pres-

vided with more than one single action sures.

locking mechanism, shall be provided

with permanently posted instructions 6.5 Assemblies shall be tested with no resultant

on latching for high wind pressures. failure or distress and shall have a recovery of

at least 90% over maximum deflection.

(TAS) 203-94.2 FLORIDA BUILDING CODE — TEST PROTOCOL HVHZ

(TAS) No. 203-94

7. Apparatus 8. Hazards

7.1 The description of the apparatus is general in 8.1 Testing facilities must take all necessary pre-

nature. Any equipment, properly certified, cal- cautions to protect the observers during the

ibrated, and approved by Authority Having entire test procedure. All observers shall

Jurisdiction capable of performing this test always be at a safe distance away from speci-

within the allowable tolerance is permitted. men and apparatus. Safety regulations must

be followed in order to avoid any injuries to

7.2 Major Components

any and all observers.

7.2.1 Test Chamber - The test chamber, to

9. Testing Facilities (For a more detailed descrip-

which the specimen is mounted, shall

tion see TAS 301-94)

be provided with pressure tabs to mea-

sure the pressure difference across the

9.1 Any testing facility wishing to perform this

test specimen and shall be so located

test must first obtain the approval of the

that the reading is unaffected by the

Authority Having Jurisdiction. Such approval

velocity of air supplied to or from the

shall only be given to those facilities which

chamber. The specimen mounting

show that they are properly equipped to per-

frame must not deflect under test load

form the complete test. Testing facilities shall

in such manner that the performance

request, in writing, approval of their facilities.

of the specimen will be affected.

Such request shall contain the ability of the

facility to perform all aspects of the test, all

7.2.2 Pressure-Measuring Apparatus - The

equipment used in the performance of the test,

pressure-measuring apparatus shall name of independent agency calibrating their

measure the test pressure difference equipment, location of facilities, personnel

within a tolerance of ±2% involved in the testing, a quality control pro-

gram, a safety program and any other perti-

7.2.3 Deflection-Measuring System - The nent information which will clearly indicate

deflection-measuring system shall that such facility is in the business of per-

measure the deflection within a toler- forming independent testing. The Authority

ance of 0.01 inch. Having Jurisdiction will visit the site and

reserve the right to order any changes neces-

7.2.4 Air System - A controllable blower, a sary to accept the facility for testing.

compressed-air supply, an exhaust sys-

tem, or reversible controllable blower

9.2 Approval of facilities to perform the test

designed to provide the required max-

described in this protocol, does not constitute

imum air pressure difference across

an approval of such facilities to perform other

the specimen. The system shall pro-

tests not specifically mentioned in this proto-

vide an essentially cyclic static air-

col.

pressure difference for the required

test period.

9.3 Fee for testing facilities shall be determined

per TAS 301-94.

7.3 Calibration of Equipment - The pressure-mea-

suring apparatus and the deflection-measuring

10. Format of Test

system shall be calibrated and certified by an

independent qualified agency approved by the

The manufacturer shall notify the Authority Having

Authority Having Jurisdiction, at two-year

Jurisdiction seven (7) working days prior to the per-

intervals.

forming of the test. The Authority Having

Jurisdiction reserves the right to observe the test.

7.3.1 The calibration report shall include:

The Authority Having Jurisdiction must be notified

the date of the calibration, the name of

of the place and time the test will take place. The

the agency conducting the calibration,

test must be recorded on video (VHS) and submit-

methods and equipment used in the

ted along with test report.

calibration process, the equipment

being calibrated and any pertinent

comments.

FLORIDA BUILDING CODE — TEST PROTOCOL HVHZ (TAS) 203-94.3

(TAS) No. 203-94

11. Test Reports 11.13 A statement that the tests were conducted

in accordance with this test method.

The following minimum information shall be

included in the submitted report: 11.14 A statement of whether or not, upon comple-

tion of all testing, the specimens meet the

11.1 Date of the test and the report, and report requirements of Section 1606 of the Florida

number. Building Code, Building and this protocol.

11.2 Name and location of facilities performing the 11.15 A statement as to whether or not tape or

test. film, or both were used to seal against air

leakage, and whether in the judgment of

11.3 Name and address of requester of the test. the test engineer, the tape or film influ-

enced the results of the test.

11.4 Identification of the specimen (manufacturer,

source of supply, dimension, model types, 11.16 Signatures of persons responsible for

material, procedure of selection and any other supervision of the tests and a list of official

pertinent information). observers.

11.5 Detailed drawings of the specimen showing 11.17 All data not required herein, but useful to a

dimensioned section profiles, type of framing better understanding of the test results,

specimen was attached to, panel arrangement, conclusions or recommendations, should

installation and spacing of anchorage, locking be appended to the report.

arrangement, sealant, hardware, product

markings and their location, and any other 12. Recording Deflections

pertinent construction details. Any deviation

from the drawings or any modifications made Maximum Deflection

to the specimen to obtain the reported values

shall be noted on the drawings and in the Permanent Deformation

report.

13. Additional Testing

11.6 Maximum deflection recorded and mecha-

nism used to make such determination. 13.1 Prior to conducting the test described in this

protocol, all specimen must have successfully

11.7 Permanent deformation (provide cross section completed the test specified in protocol TAS

diagram to show where it occurred). 201-94.

11.8 Name, address, signature and seal of Florida 13.2 Any product when installed that is subjected

professional engineer, witnessing the test and to weathering, where such weathering can

preparing the report. Engineer shall be part of affect the integrity of the product, the manu-

the laboratory's permanent staff or under lab- facturer shall contact the Authority Having

oratory's contract. (See TAS 301-94.) Jurisdiction for additional testing require-

11.9 A tabulation of pressure differences exerted ments such as but not limited to moisture,

across the specimen during the test and their U.V., accelerated aging, and other similar

duration. tests.

11.10 Maximum positive and negative pressures 13.3 The Authority Having Jurisdiction reserves

used in the test. the right to require any additional testing nec-

essary to assure full compliance with the

11.11 A description of the condition of the test spec- intent of the Florida Building Code, Building.

imens after testing, including details of any

damage and any other pertinent observations. 13.4 Some products, such as exterior doors, exteri-

11.12 When the tests are made to check conformity or windows, skylights, and wall cladding shall

of the specimen to a particular specification, be required to be successfully tested under

an identification or description of that specifi- TAS 202-94 prior to conducting tests under

cation. this protocol.

(TAS) 203-94.4 FLORIDA BUILDING CODE —TEST PROTOCOL HVHZ

(TAS) No. 203-94

14. Product Marking

14.1 Any and all approved products shall be per-

manently labeled with the manufacturer's

name, city, state, and the following statement:

"Product Control Approved."

14.2 Permanently labeled shall be a metallic label

fixed permanently to the frame of the speci-

men by rivets or permanent adhesive. See

Section 14.2.1 of this protocol for storm pan-

els.

14.2.1 Permanent label on storm panels could

be printed directly on each panel at

intervals not to exceed 24 inches with

non removable paint or ink.

14.3 Any instructions for operations shall be per-

manently mounted on the specimen in an area

not subject to be painted or concealed. Storm

panels may be excluded from this section.

FLORIDA BUILDING CODE —TEST PROTOCOL HVHZ (TAS) 203-94.5

(TAS) 203-94.6 FLORIDA BUILDING CODE — TEST PROTOCOL HVHZ

Das könnte Ihnen auch gefallen

- American National Standard: ANSI/BHMA A156.115 W 2006Dokument18 SeitenAmerican National Standard: ANSI/BHMA A156.115 W 2006Shawn DeolNoch keine Bewertungen

- Astm F476 - 14Dokument15 SeitenAstm F476 - 14Shawn Deol100% (2)

- Surface Vehicle Standard: Laboratory Cyclic Corrosion TestDokument10 SeitenSurface Vehicle Standard: Laboratory Cyclic Corrosion TestShawn Deol100% (1)

- Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across The SpecimenDokument5 SeitenDetermining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across The SpecimenLuis Luna100% (1)

- DD Cen TS 00772-22-2006Dokument20 SeitenDD Cen TS 00772-22-2006Jorge Salasën100% (1)

- f906 PDFDokument3 Seitenf906 PDFαlιf GamersNoch keine Bewertungen

- F 2247 - 03Dokument14 SeitenF 2247 - 03Francisco GuerraNoch keine Bewertungen

- AAMA 501.2 - Hose Nozzle Water Spray TestingDokument4 SeitenAAMA 501.2 - Hose Nozzle Water Spray TestingNoz KiNoch keine Bewertungen

- In-Plant Testing Guidelines For Manufacturers and Independent Laboratories AAMA 205-01Dokument4 SeitenIn-Plant Testing Guidelines For Manufacturers and Independent Laboratories AAMA 205-01DavidNoch keine Bewertungen

- C1032 - 06Dokument2 SeitenC1032 - 06Black GokuNoch keine Bewertungen

- Ansi Bhma A156.115 2006 PDFDokument22 SeitenAnsi Bhma A156.115 2006 PDFShawn Deol100% (1)

- Astm F1941-F1941MDokument14 SeitenAstm F1941-F1941MShawn Deol100% (2)

- Testing Application Standard 202 94Dokument6 SeitenTesting Application Standard 202 94maikelc1Noch keine Bewertungen

- Astm e 331Dokument4 SeitenAstm e 331Zahoor Ahmed MohsanNoch keine Bewertungen

- Astm C 1201-09Dokument4 SeitenAstm C 1201-09kishor150688Noch keine Bewertungen

- D 6672 - 01 Rdy2nziDokument6 SeitenD 6672 - 01 Rdy2nziJuanNoch keine Bewertungen

- Ufgs 13 34 19Dokument45 SeitenUfgs 13 34 19sharandeep1112Noch keine Bewertungen

- 2015 1 9 PDFDokument9 Seiten2015 1 9 PDFచిమ్ముల సందీప్ రెడ్డిNoch keine Bewertungen

- Styrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using Glass Fiber ReinforcementsDokument3 SeitenStyrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using Glass Fiber ReinforcementsLuigi HernándezNoch keine Bewertungen

- As 1191-2002 Acoustics - Method For Laboratory Measurement of Airborne Sound Transmission Insulation of BuildDokument7 SeitenAs 1191-2002 Acoustics - Method For Laboratory Measurement of Airborne Sound Transmission Insulation of BuildSAI Global - APACNoch keine Bewertungen

- Astm E1105 Water Intrusion TestDokument21 SeitenAstm E1105 Water Intrusion TestCristian DandresNoch keine Bewertungen

- Astm / Aama Water TestingDokument3 SeitenAstm / Aama Water Testingy2kareinNoch keine Bewertungen

- Hot-Formed Welded and Seamless Carbon Steel Structural TubingDokument6 SeitenHot-Formed Welded and Seamless Carbon Steel Structural TubingVenreplast PueblaNoch keine Bewertungen

- NFPA 31 Fuel Oil Piping, Installation and Testing Chapter 8 Fuel Piping Systems and ComponentsDokument5 SeitenNFPA 31 Fuel Oil Piping, Installation and Testing Chapter 8 Fuel Piping Systems and ComponentsprokjongNoch keine Bewertungen

- Ea230 - Astm E2357 - E331Dokument11 SeitenEa230 - Astm E2357 - E331Deco DluxeNoch keine Bewertungen

- Astm c1048Dokument10 SeitenAstm c1048Michael LimNoch keine Bewertungen

- SDI - 108 - Standard Steel Doors and FramesDokument4 SeitenSDI - 108 - Standard Steel Doors and FramesPangit BertNoch keine Bewertungen

- SPEC-89 - DuPont Tyvek StuccoWrap Product Specifications BEFORE WindowsDokument8 SeitenSPEC-89 - DuPont Tyvek StuccoWrap Product Specifications BEFORE WindowsSujanto WidjajaNoch keine Bewertungen

- Test Procedure and Acceptance Criteria For - Physical Endurance For Steel Doors, Frames and Frame AnchorsDokument14 SeitenTest Procedure and Acceptance Criteria For - Physical Endurance For Steel Doors, Frames and Frame AnchorsYel DGNoch keine Bewertungen

- Mechanical Fixings: Fixing CountriesDokument3 SeitenMechanical Fixings: Fixing CountriesAlejandro MoralesNoch keine Bewertungen

- Molded Glass Fiber Reinforced Gypsum Parts: Standard Specification ForDokument2 SeitenMolded Glass Fiber Reinforced Gypsum Parts: Standard Specification ForJesús Luis Arce Guillermo100% (1)

- SMD Technical Manual-2011Dokument20 SeitenSMD Technical Manual-2011karfire1982Noch keine Bewertungen

- C 1002 - 00 QzewmditmdaDokument4 SeitenC 1002 - 00 QzewmditmdaHumberto GutierrezNoch keine Bewertungen

- Renderoc TgxtraDokument2 SeitenRenderoc TgxtratalatzahoorNoch keine Bewertungen

- 07270-Fire StoppingDokument4 Seiten07270-Fire StoppingEfz EfzNoch keine Bewertungen

- 0693 Bs2752 c50 50 Shore Specification Neoprene Chloroprene CR Rubber SheetDokument2 Seiten0693 Bs2752 c50 50 Shore Specification Neoprene Chloroprene CR Rubber SheetSerboNoch keine Bewertungen

- Hilti OST - KSA Pull Out Test PDFDokument1 SeiteHilti OST - KSA Pull Out Test PDFPraneshNoch keine Bewertungen

- Wind Load Analysis by ASCE 7-02Dokument8 SeitenWind Load Analysis by ASCE 7-02Afzal Waseem100% (1)

- Aama910 93Dokument10 SeitenAama910 93hasan jouranNoch keine Bewertungen

- 2011 03 Mccowan Kivela PDFDokument11 Seiten2011 03 Mccowan Kivela PDFFranklyn GenoveNoch keine Bewertungen

- Previews ANSI BHMA A156.4 2013 PreDokument5 SeitenPreviews ANSI BHMA A156.4 2013 PreNatalia Diaz100% (1)

- ANSI/AAMA/NWWDA 101/I.S.2-97 Test Report Rendered To: Earthwise Group LLC SERIES/MODEL: 143.191CA Product Type: PVC CasementsDokument24 SeitenANSI/AAMA/NWWDA 101/I.S.2-97 Test Report Rendered To: Earthwise Group LLC SERIES/MODEL: 143.191CA Product Type: PVC Casementszahee007Noch keine Bewertungen

- Is 1642Dokument20 SeitenIs 1642JGD123Noch keine Bewertungen

- A156.4 - 2008 Door Control-Closers Hardware HighlightsDokument1 SeiteA156.4 - 2008 Door Control-Closers Hardware HighlightsteramodNoch keine Bewertungen

- Astm F 1643 - 01Dokument9 SeitenAstm F 1643 - 01Francisco GuerraNoch keine Bewertungen

- Nut & Bolt ScienceDokument3 SeitenNut & Bolt SciencetanujaayerNoch keine Bewertungen

- D 6207-97 Test Method For Dimensional Stability of Fabrics TDokument6 SeitenD 6207-97 Test Method For Dimensional Stability of Fabrics TAnonymous UoRu4s0% (1)

- SIFS Product Submision PDFDokument72 SeitenSIFS Product Submision PDFmahmoud IbrahemNoch keine Bewertungen

- Repair Manual 06-09-10Dokument30 SeitenRepair Manual 06-09-10MaruskLuluNoch keine Bewertungen

- Echnical Eport: FWPRDC Project No: 02.1209Dokument9 SeitenEchnical Eport: FWPRDC Project No: 02.1209aboodjNoch keine Bewertungen

- Aama 450-06Dokument26 SeitenAama 450-06samuelNoch keine Bewertungen

- 11654Dokument8 Seiten11654Wildo-aprizaNoch keine Bewertungen

- Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement PanelsDokument7 SeitenAbuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement PanelsAlejandroNoch keine Bewertungen

- D3492.20048-1 - Vol. 09.02Dokument14 SeitenD3492.20048-1 - Vol. 09.02Jignesh TrivediNoch keine Bewertungen

- Kingspan Lo-Pitch Roof Panel KS1000 LP-CR Datasheet 112013 NZ enDokument8 SeitenKingspan Lo-Pitch Roof Panel KS1000 LP-CR Datasheet 112013 NZ enadnan53Noch keine Bewertungen

- Air BarrierDokument12 SeitenAir Barrierthinker_Noch keine Bewertungen

- Astm C-1178-1 PDFDokument3 SeitenAstm C-1178-1 PDFibrahim0% (1)

- G.james Installation InstructionsDokument44 SeitenG.james Installation InstructionsAymeeenNoch keine Bewertungen

- ASTMDokument7 SeitenASTMMarko's Brazon'Noch keine Bewertungen

- SIDERISEDokument22 SeitenSIDERISENajib KiwanNoch keine Bewertungen

- Astm C954Dokument3 SeitenAstm C954Cj Elamparo100% (1)

- Esr 1308Dokument21 SeitenEsr 1308dkimNoch keine Bewertungen

- As 4118.1.4-1994 Fire Sprinkler Systems Components - Valve MonitorsDokument7 SeitenAs 4118.1.4-1994 Fire Sprinkler Systems Components - Valve MonitorsSAI Global - APACNoch keine Bewertungen

- Impact Test Procedures: Testing Application Standard (Tas) 201-94Dokument6 SeitenImpact Test Procedures: Testing Application Standard (Tas) 201-94MehdiNoch keine Bewertungen

- Ansi Bhma A156.40 2015 PDFDokument34 SeitenAnsi Bhma A156.40 2015 PDFShawn DeolNoch keine Bewertungen

- Testing Application Standard TAS 201-94Dokument6 SeitenTesting Application Standard TAS 201-94Shawn DeolNoch keine Bewertungen

- IP66-IK10 For CB-PI3030XDokument11 SeitenIP66-IK10 For CB-PI3030XShawn DeolNoch keine Bewertungen

- ASTM B240 - Zinc and Zinc-Aluminum (ZA) AlloysDokument4 SeitenASTM B240 - Zinc and Zinc-Aluminum (ZA) AlloysShawn Deol100% (1)

- Special Communication: Force Treadmill For Measuring Vertical and Horizontal Ground Reaction ForcesDokument6 SeitenSpecial Communication: Force Treadmill For Measuring Vertical and Horizontal Ground Reaction ForcesShawn DeolNoch keine Bewertungen

- Cavagna 1997 ResonantfreqrunningDokument8 SeitenCavagna 1997 ResonantfreqrunningShawn DeolNoch keine Bewertungen

- Pixel Standards Environmentaleffectsand Murastandardsfor All Raven ModelsDokument4 SeitenPixel Standards Environmentaleffectsand Murastandardsfor All Raven ModelsShawn DeolNoch keine Bewertungen

- Example UL Installation ManualDokument2 SeitenExample UL Installation ManualShawn DeolNoch keine Bewertungen

- Rotated 61000-4-11 Immunity To Ac Supply Dips Dropouts InterruptionsDokument13 SeitenRotated 61000-4-11 Immunity To Ac Supply Dips Dropouts InterruptionsShawn DeolNoch keine Bewertungen

- The Implementation of NUD Process - Joe Powell - FINAL - REVIEWEDDokument39 SeitenThe Implementation of NUD Process - Joe Powell - FINAL - REVIEWEDShawn DeolNoch keine Bewertungen

- Assignment 9Dokument12 SeitenAssignment 9Shawn DeolNoch keine Bewertungen

- Assignment 8Dokument17 SeitenAssignment 8Shawn DeolNoch keine Bewertungen

- Assignment 3Dokument11 SeitenAssignment 3Shawn DeolNoch keine Bewertungen

- English EssayDokument11 SeitenEnglish EssayShawn DeolNoch keine Bewertungen

- Formula Monitoring Masonry Work DaysDokument5 SeitenFormula Monitoring Masonry Work DaysRizaldy EstebanNoch keine Bewertungen

- Construction Project Engineering and Administration: Unit1Dokument14 SeitenConstruction Project Engineering and Administration: Unit1Joseph Rana SangpangNoch keine Bewertungen

- Beam Section Details: Typical Gravity Reinforced Concrete Beam DetailDokument1 SeiteBeam Section Details: Typical Gravity Reinforced Concrete Beam DetailMARKCHRISTMASNoch keine Bewertungen

- PRELIM EXAM BSD LAB Part 2Dokument5 SeitenPRELIM EXAM BSD LAB Part 2Rico DumlaoNoch keine Bewertungen

- 1.3 General Principles of ConstructionDokument4 Seiten1.3 General Principles of ConstructionJENNY WAI F18SP1371100% (1)

- Types of Steel Roof Trusses Trusses: Sheela Malik AP (Civil) GITAM KablanaDokument29 SeitenTypes of Steel Roof Trusses Trusses: Sheela Malik AP (Civil) GITAM KablanavictorNoch keine Bewertungen

- Method Statement For WMMDokument6 SeitenMethod Statement For WMMRabnawaz Imam100% (1)

- NAPA PCR AsphaltMixtures v2Dokument67 SeitenNAPA PCR AsphaltMixtures v2Fernando MolinasNoch keine Bewertungen

- Santhakumar A R and Uma Rao Santhakumar A R and Uma RaoDokument6 SeitenSanthakumar A R and Uma Rao Santhakumar A R and Uma RaoVirat DesaiNoch keine Bewertungen

- Lexsha's BoqDokument81 SeitenLexsha's BoqJan Lawrence AlbertoNoch keine Bewertungen

- Translucent ConcreteDokument22 SeitenTranslucent ConcreteRicha ShahNoch keine Bewertungen

- Black and Decker - The Book of Home Improvement (2017)Dokument563 SeitenBlack and Decker - The Book of Home Improvement (2017)john carter88% (8)

- Diósgyőri Stadion: A Case StudyDokument13 SeitenDiósgyőri Stadion: A Case StudyKarthikeyan JagathesanNoch keine Bewertungen

- Testing of Double Deck Floating Roofs: GeneralDokument2 SeitenTesting of Double Deck Floating Roofs: GeneralVishvjeet Prakash TiwariNoch keine Bewertungen

- Embedded Retaining Walls - A European Perspective OnDokument18 SeitenEmbedded Retaining Walls - A European Perspective OnElizhabet Flores PaucarNoch keine Bewertungen

- MECH REC49 Ceiling Closure ChecklistDokument1 SeiteMECH REC49 Ceiling Closure ChecklisttinzarmoeNoch keine Bewertungen

- Brutalistic Architecture A RetrospectDokument14 SeitenBrutalistic Architecture A RetrospectKathiresan ManoharanNoch keine Bewertungen

- LF-51-100 (Coffe Table) - Shop DrawingDokument2 SeitenLF-51-100 (Coffe Table) - Shop DrawingAgung SetiawanNoch keine Bewertungen

- Grove 120t Load Chart CW 28.5t-40.1t Outrigger 7.5mDokument1 SeiteGrove 120t Load Chart CW 28.5t-40.1t Outrigger 7.5mAbdul Majid ZulkarnainNoch keine Bewertungen

- Zeeshan AliDokument14 SeitenZeeshan AliVICKY SHAIKHNoch keine Bewertungen

- Gambar Kerja PondasiDokument8 SeitenGambar Kerja PondasixcfNoch keine Bewertungen

- Fire-Dampers 2019 Eng WebDokument214 SeitenFire-Dampers 2019 Eng WebnuqNoch keine Bewertungen

- Cengiz Karakose: Welding/Piping/Tank InspectorDokument4 SeitenCengiz Karakose: Welding/Piping/Tank Inspectorcengiz88Noch keine Bewertungen

- Group-10 (XII) Singapore Tunnel REPORTDokument10 SeitenGroup-10 (XII) Singapore Tunnel REPORTSandeepNoch keine Bewertungen

- L&T - PBQ - 8 L Bengaluru Ring Road Project - HighwaysDokument12 SeitenL&T - PBQ - 8 L Bengaluru Ring Road Project - HighwayskanagarajodishaNoch keine Bewertungen

- Rigid PavementDokument20 SeitenRigid PavementsknagarNoch keine Bewertungen

- Construction of Museum For The Buddhist Monastery at Jagjibanpur, Malda Under Malda Division, PWD During The Year 2018-19 (Balance Work)Dokument5 SeitenConstruction of Museum For The Buddhist Monastery at Jagjibanpur, Malda Under Malda Division, PWD During The Year 2018-19 (Balance Work)matiur rahamanNoch keine Bewertungen

- 2 LN562 - Topic 1 BUILDING MorphologyDokument32 Seiten2 LN562 - Topic 1 BUILDING Morphologyaremyul100% (1)

- Methods To Find Slope and DeflectionDokument10 SeitenMethods To Find Slope and DeflectionDhrumil PatelNoch keine Bewertungen

- Emer Procedures PlanDokument36 SeitenEmer Procedures PlanSungano MashangeNoch keine Bewertungen