Beruflich Dokumente

Kultur Dokumente

HVAC Basic Formulae-1

Hochgeladen von

imtiyaz94Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HVAC Basic Formulae-1

Hochgeladen von

imtiyaz94Copyright:

Verfügbare Formate

SENSIBLE HEAT FACTOR or RATIO (SHR)

SHR = Hs / Ht = Hs / (Hs + HL )

1. SHR from 0.95 - 1.00 for Precision air conditioning (computers and data centres)

2. SHR from 0.65 - 0.75 for Comfort cooling (people)

3. SHR from 0.50 - 0.60 for Dehumidification (pools and outside air)

Lower SHR value indicates that the dehumidification requirement will be high and the supply air leaving the cooling coil shall be at lower temperature

to meet the dehumidification needs. The supply airflow rate will be less.

COOLING & HEATING EQUATIONS

Roofs, External Walls & Conduction through Glass

The equation used for sensible loads from the opaque elements such as walls, roof, partitions and the conduction through glass is:

H = U * A * CLTD (Refer basic Conduction heat formula below)

Where

• H describes Sensible heat flow (Btu/Hr)

• U = Thermal Transmittance for roof or wall or glass. See 1997 ASHRAE Fundamentals, Chapter 24 or 2001 ASHRAE Fundamentals, chapter 25.

(Unit- Btu/Hr Sq-ft °F)

• A = area of roof, wall or glass calculated from building plans (sqft)

• CLTD = Cooling Load Temperature Difference (in °F) for roof,wall or glass. For winter months CLTD is ( Ti - T0 ) which is temperature difference

between inside and outside. For Summer cooling load, this temperature differential is affected by thermal mass, daily temperature range, orientation,

tilt, month, day, hour,latitude, solar absorbance, wall facing direction and other variables and therefore adjusted CLTD values are used. Refer 1997

ASHRAE Fundamentals, Chapter 28, tables 30, 31, 32, 33 and 34.

Solar Load through Glass, Skylights and Plastic Sheets

Heat transfer through glazing is both conductive and transmission. It is calculated in two steps:

Step # 1

The equation used for sensible loads from the conduction through glass is:

H = U * A * (CLTD)

Where

• H = Sensible heat gain (Btu/Hr)

• U = Thermal Transmittance for roof or wall or glass. See 1997 ASHRAE Fundamentals, Chapter 24 or 2001 ASHRAE Fundamentals, chapter 25.

(Unit- Btu/Hr Sq-ft °F)

• A = area of roof, wall or glass calculated from building plans (sqft)

• CLTD = Cooling Load Temperature Difference (in °F) for glass.Refer 1997 ASHRAE Fundamentals, Chapter 28, tables 30, 31, 32, 33 and 34.

Step # 2

The equation used for radiant sensible loads from the transparent/translucent elements such as window glass, skylights

and plastic sheets is:

H = A*(SHGC)*(SC)*(CLF)

Where

• H = Sensible heat gain (Btu/Hr)

• A = area of roof, wall or glass calculated from building plans (sqft)

• SHGC = Solar Heat Gain Coefficient. See 1997 ASHRAE Fundamentals, Chapter 28, table 35

• CLF = Solar Cooling Load Factor. See 1997 ASHRAE Fundamentals, Chapter 28, table 36.

Partitions, Ceilings & Floors

The equation used for sensible loads from the partitions, ceilings and floors:

H = U * A * (Ta - Tr)

Where

• H = Sensible heat gain (Btu/Hr)

• U = Thermal Transmittance for roof or wall or glass. See 1997 ASHRAE Fundamentals, Chapter 24 or 2001 ASHRAE Fundamentals, and Chapter

25. (Unit- Btu/Hr Sq-ft °F)

• A = area of partition, ceiling or floor calculated from building plans (sq-ft)

• Ta = Temperature of adjacent space in °F (Note: If adjacent space is not conditioned and temperature is not available, use outdoor air temperature

less 5 ° F)

• Tr = Inside room design temperature of conditioned space in °F (assumed constant usually 75°F)

Ventilation & Infiltration Air

Ventilation air is the amount of outdoor air required to maintain Indoor Air Quality for the occupants (refer ASHRAE Standard 62 for minimum

ventilation requirements) and makeup for air leaving the space due to equipment exhaust, exfiltration and pressurization.

Hsensible = 1.08 * CFM * (T0 – Tc)

Realize that 1.085 is not a constant! It is the product of density, the specific heat of air and the conversion factor of 60 minutes per hour. These

properties of air at “standard” conditions (69.5°F DB dry air at sea level) result in the value 1.085. Air at other conditions and elevations will cause this

factor to change. Density = 0.075 lb/ft3 Specific Heat = 0.24 Btu/lb°F .(Specific heat is the measure of heat or thermal energy required to increase or

decrease the temperature of a unit quantity of a substance by one unit. For example, at a temperature of 15 °C, the heat required to raise the

temperature of 1 kg of water by 1 K (equivalent to 1 °C) is 4186 joules, meaning that the specific heat of water is 4.186 kJ·kg−1·K−1). When you know

volume of a fluid and the temperature difference it has to go through, then you need to know its specific heat at that temperature and

convert volumetric flow to mass flow as the specific heat is in terms of per pound.

0.075 x 0.24 x 60 min/hr = 1.085

Hlatent = 0.68 x CFM x ▲WGR

Hlatent = 4840 x CFM x▲W Lb

Htotal = 4.5 * CFM * (ho – hc) Realize that 4.5 is not a constant! It is the product of density of air and the conversion factor of 60 minutes per hour. The

density of air at “standard” conditions (69.5°F DB dry air at sea level) results in the value 4.5. Air at other conditions and elevations will cause this factor

to change.

Density = 0.075 lb/ft3 , 0.075 x 60 min/hr = 4.5

Htotal = H sensible + H latent

Where

• H sensible = Sensible heat gain (Btu/hr)

• Hlatent = Latent heat gain (Btu/hr)

• Htotal = Total heat gain (Btu/hr)

• CFM = Ventilation airflow rate in cubic feet per minute

• To = Outside dry bulb temperature, °F

• Tc = Dry bulb temperature of air leaving the cooling coil, °F

• ▲WGR = Humidity Ratio Difference (Gr H02O/Lb of dry air) =(WO – WC)

• ▲WLB = Humidity Ratio Difference (Lb H2O /Lb of dry air) and= (WO – WC)

• WO = Outside humidity ratio, Lb H2O per Lb (dry air)

• WC = Humidity ratio of air leaving the cooling coil, Lb H2O per Lb (dry air)

• hO = Outside/Inside air enthalpy, Btu per lb (dry air)

• hC = Enthalpy of air leaving the cooling c oil Btu per lb (dry air)

Refer to 1997 ASHRAE Fundamentals , Chapter 25, for determining infiltration

People

The heat load from people is both sensible load and the latent load. Sensible heat is transferred through conduction, convection and radiation while

latent heat from persons is transferred through water vapour released in breathing and/or perspiration. The total heat transferred depends on the

activity, clothing, air temperature and the number of persons in the building.

H se ns ib le = N * (H S ) * (CLF)

H la t en t = N * (H L)

Where

• H se ns ib le = Total Sensible heat gain (Btu/hr)

• H la t en t = Total latent heat gain (Btu/hr)

• N = number of people in space.

• HS, HL = Sensible and Latent heat gain from occupancy is given in 1997 ASHRAE Fundamentals Chapter 28, Table 3 (Btu/hr per person depending

on nature of activity)

• CLF = Cooling Load Factor, by hour of occupancy. See 1997 ASHRAE Fundamentals,Chapter 28, table 37.

Note: CLF = 1.0, if operation is 24 hours or of cooling is off at night or during weekends.

The sensible heat influence on the air temperature and latent heat influence the moisture content of indoor space.

Lights

The lights result in sensible heat gain.

H = 3.41 * W * F UT * F BF * (CLF)

Where

• H = Sensible heat gain (Btu/hr)

• W = Installed lamp watts input from electrical lighting plan or lighting load data

• F BF = Lighting use factor, as appropriate

• F BF = Blast factor allowance, as appropriate

• CLF = Cooling Load Factor, by hour of occupancy. See 1997 ASHRAE Fundamentals, Chapter 28, Table 38.

Note: CLF = 1.0, if operation is 24 hours or if cooling is off at night or during weekends.

Power Loads & Motors

Three different equations are used under different scenarios:

a. Heat gain of power driven equipment and motor when both are located inside the space to be conditioned

H = 2545 * (P / Eff) * F UM * F L M

Where

• H = Sensible heat gain (Btu/hr)

• P = Horsepower rating from electrical power plans or manufacturer’s data (HP)

• Eff = Equipment motor efficiency, as decimal fraction

• F UM = Motor us e factor (normally = 1.0)

• F UM = Motor load factor (normally = 1.0)

• Note: F UM = 1.0, if operation is 24 hours

b. Heat gain of when driven equipment is located inside the space to be conditioned space and the motor is outside the space or air

stream

H = 2545 * P * F UM * F L M

Where

• H = Sensible heat gain (Btu/hr)

• P = Horsepower rating from electrical power plans or manufacturer’s data (in HP)

• Eff = Equipment motor efficiency, as decimal fraction

• F U M = Motor us e factor

• F L M = Motor load factor

• Note: F UM = 1.0, if operation is 24 hours

c. Heat gain of when driven equipment is located outside the space to be conditioned space and the motor is inside the space or air stream

H = 2545 * P * [(1.0-Eff)/Eff] * F UM * F L M

Where

• H = Sensible heat gain (Btu/hr)

• P = Horsepower rating from electrical power plans or manufacturer’s data (HP)

• Eff = Equipment motor efficiency, as decimal fraction

• F U M = Motor us e factor

• F L M = Motor load factor

• Note: F UM = 1.0, if operation is 24 hours

Appliances

H = 3.41 * W * F u * F r * (CLF)

Where

• H = Sensible heat gain (Btu/hr)

• W = Installed rating of appliances in watts. See 1997 ASHRAE Fundamentals, Chapter 28; Table 5 thru 9 or use manufacturer’s data. For computers,

monitors, printers and miscellaneous office equipment, see 2001 ASHRAE Fundamentals, Chapter 29, Tables 8,9 & 10.

• F u = Usage factor. See 1997 ASHRAE Fundamentals, Chapter 28, Table 6 and 7

• F r = Radiation factor. See 1997 ASHRAE Fundamentals, Chapter 28, Table 6 and 7

• CLF = Cooling Load Factor, by hour of occupancy. See 1997 ASHRAE Fundamentals, Chapter 28, Table 37 and 39. Note: CLF = 1.0, if operation is

24 hours or of cooling is off at night or during weekends.

Conductive Heat Transfer

Conductive heat flow occurs in the direction of decreasing temperature and takes place when a temperature gradient exists in a solid (or stationary

fluid) medium. The equation used to express heat transfer by conduction is known as Fourier’s Law

and is expressed as:

H = k x A x ▲T / t

Where

• H (or Q) = Hat transferred per unit time (Btu/hr)

• A = Heat transfer area (ft2)

• k = Thermal conductivity of the material (Btu/ (hr0F ft2/ft))

• ▲T = Temperature difference across the material (°F)

• t (or x)= material thickness (ft)

This above formula is the basic formula for heat transfer by conduction, wherez` as this H = U * A * (CLTD) formula is derived from the basic formula

where the overall thermal heat transfer co-efficient U is nothing but k/t (k/t is nothing but Conductance), since in a wall we will have several materials

with different k and t (thickness)

Values we use U as overall heat transfer co-efficient which is a sum of k1/t1+k2/t2+ k3/t3 +…… also since we have properties of of air in terms of

resistance we inverse this a t/k+Rair )

Thermal conductivity is defined as the quantity of heat (Q) transmitted through a unit thickness (t) in a direction normal to a surface of unit area (A) due

to a unit temperature gradient (ΔT) under steady state conditions and when the heat transfer is dependent only on the temperature gradient. In

equation form this becomes the following:

Thermal Conductivity = heat × distance / (area × temperature gradient)

k = Q × t / (A × ΔT) .

The reciprocal of thermal conductivity is thermal resistivity. When dealing with a known amount of material, its thermal conductance and the reciprocal

property, thermal resistance, can be described.

Thermal conductance is k/x the quantity of heat that passes in unit time through a plate of particular area and thickness when its opposite faces differ in

temperature by one Kelvin.

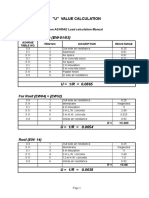

R-Values/U-Values

R = 1/ C = 1/(K / t)

U = 1/ ΣR

Where

• R = R-Value (Hr Sq-ft °F/Btu)

• U = U-Value (Btu/Hr Sq-ft °F)

• C = Conductance (Btu/hr Sq-ft °F)

• K = Conductivity (Btu in/ hr Sq-ft °F)

• ΣR = Sum of the thermal resistances for each component used in the construction of the wall or roof section.

• t = thickness (ft)

Notes: The lower the U-factor, the greater the material's resistance to heat flow and the better is the insulating value. U-value is the inverse of R-value

(hr sq-ft °F /Btu).

Heat Loss by Conduction & Convection through Roof & Walls

Heat loss by conduction and convection heat transfer through any surface is given by:

H sensible = A * U * (Ti – To)

Where

• H = heat transfer through walls, roof, glass, etc. (Btu/hr)

• A = surface areas (sq-ft)

• U = air-to-air heat transfer coefficient (Unit- Btu/Hr Sq-ft °F)

• Ti = indoor air temperature (°F)

• To = outdoor air temperature (°F)

Heat Loss through Floors on Slab

The slab heat loss is calculated by using the following equation:

H = F* P * (T i -T o)

Where:

• H = Sensible heat loss (Btu/hr)

• F = Heat Los s Coefficient for the particular construction and is a function of the degree days of heating. (Unit- Btu/Hr Sq-ft °F)

• P = Perimeter of slab (ft)

• T i = Inside temperature (°F)

• T o = Outside temperature (°F)

Heat loss from slab-on- grade foundations is a function of the slab perimeter rather than the floor area. The losses are from the edges of the slab and

insulation on these edges will significantly reduce the heat losses.

Heat loss through Infiltration and Ventilation

The heat loss due to infiltration and controlled natural ventilation is divided into sensible and latent losses. The energy associated with having to raise

the temperature of infiltrating or ventilating air up to indoor air temperature is the sensible heat loss, which is estimated by:

H sensible = V * рair * Cp * (Ti – To)

Where:

• H sensible = Sensible heat loss

• V = volumetric air flow rate

• рair is the density of the air

• Cp = specific heat capacity of air at constant pressure

• Ti = indoor air temperature

• To = outdoor air temperature

The energy quantity associated with net loss of moisture from the space is latent heat loss which is given by:

Hlatent = V * рair * hfg * (Wi – Wo)

Where

• Hlatent = Latent heat loss

• V = volumetric air flow rate

• рair is the density of the air

• Wi = humidity ratio of indoor air

• Wo = humidity ratio of outdoor air

• hfg = latent heat of evaporation at indoor air temperature

WATTS (POWER) = volts x amps or P = E x I

VA (how the secondary of a transformer is rated) = volts X amps

Example: 24V x .41A = 10 VA

RPM of motor = 60Hz x 120 / No. of Poles

1800 RPM Motor – slippage makes it about 1750

3600 RPM Motor – slippage makes it about 3450

SPECIFIC DENSITY = 1/Specific Volume

CHILLER HEAT LOAD & WATER FLOW

The flow rate necessary to deliver the full output of the heat source at a specific temperature drop can be found using

equation

below:

H = Q (8.01 x ρ x c x ▲T)

Where:

• Q= Water volume flow rate (GPM)

• H = Heat load (Btu/hr)

• ▲T = Intended temperature drop (°F)

• ρ = Fluid's density at the average system temperature (lb/ft3)

• c = the fluid's specific heat at the average system temperature (Btu/lb/°F)

• 8.01 = a constant

In small to medium size hydronic systems, the product of (8.01 x ρ x c) can be taken as 500 for water, 479 for 30%

glycol, and 450 for 50% glycol. The total heat removed by air condition chilled water installation can thus be

expressed as

H = 500 x Q x ▲T

Where

• H = total heat removed (Btu/h)

• Q = water flow rate (gal/min)

• ▲T = temperature difference ( 0F)

Evaporator Flow Rate

The evaporator water flow rate can be expressed as

Qe = Htons x 24 / T

CONDENSATE GENERATION

Condensate generation in an air condition system where specific humidity before and after are known can be

expressed as

Q Cond = Q air x W Lb / (SpV x 8.33)

Q Cond = Q air x W GR / (SpV x 8.33 x 7000)

Where

• Q Cond = Air Conditioning condensate generated (GPM)

• Q air = Air Flow Rate through the air-handling unit cooling coil (Cu-ft / minute)

• SpV = Specific Volume of Air (Cu-ft per lb of dry air)

• W Lb = Specific Humidity diff. between inlet and outlet of air stream across coil (lb-H2O perlb of dry air)

• W GR = Specific Humidity diff. between inlet and outlet of air stream acros s coil (Gr. H2O per lb of dry air)

Cooling Tower Tons

A cooling tower ton is defined as:

1 cooling tower ton = 15,000 Btu/hr (3782 kCal /hr)

This is roughly 25% more than chiller ton because the heat of compress ion of the refrigeration compressor is added

to the condenser/cooling tower.

The lowest practical temperature for refrigeration, considering the freezing point and economics, is about 40°F ( 4.4C)

.(Expansion tank cal sheet)

A saturated liquid contains as much thermal energy as it can without boiling (or conversely a saturated vapor contains

as little thermal energy as it can without condensing). Saturation temperature means boiling point.

The saturation temperature is the temperature for a corresponding saturation pressure at which a liquid boils into its

vapor phase. The liquid can be said to be saturated with thermal energy. Any addition of thermal energy results in a

phase transition.

If the pressure in a system remains constant (isobaric), a vapor at saturation temperature will begin to condense into

its liquid phase as thermal energy (heat) is removed. Similarly, a liquid at saturation temperature and pressure will

boil into its vapor phase as additional thermal energy is applied.

The boiling point corresponds to the temperature at which the vapor pressure of the liquid equals the surrounding

environmental pressure. Thus, the boiling point is dependent on the pressure. Usually, boiling points are published

with respect to atmospheric pressure (101.325 kilopascals or 1 atm). At higher elevations, where the atmospheric

pressure is much lower, the boiling point is also lower. The boiling point increases with increased pressure.

Saturation pressure is the pressure for a corresponding saturation temperature at which a liquid boils into its vapor

phase. Saturation pressure and saturation temperature have a direct relationship: as saturation pressure is increased

so is saturation temperature.

If the temperature in a system remains constant (an isothermal system), vapor at saturation pressure and

temperature will begin to condense into its liquid phase as the system pressure is increased. Similarly, a liquid at

saturation pressure and temperature will tend to flash into its vapor phase as system pressure is decreased.

The boiling point of water is 100 °C (212 °F) at standard pressure. On top of Mount Everest, at 8,848 m elevation, the

pressure is about 260 mbar (26.39 kPa) and the boiling point of water is 69 °C. (156.2 °F). The boiling point decreases

1°C every 285 m of elevation

Das könnte Ihnen auch gefallen

- HVAC Equations, Data, and Rules of Thumb, Third EditionVon EverandHVAC Equations, Data, and Rules of Thumb, Third EditionNoch keine Bewertungen

- HAP Thermal Load Cal - FormulaDokument19 SeitenHAP Thermal Load Cal - Formulamajortay100% (1)

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideVon EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNoch keine Bewertungen

- Design of Ventilation SystemsDokument5 SeitenDesign of Ventilation SystemsSimon LaurentNoch keine Bewertungen

- Air Master CatalogDokument191 SeitenAir Master CatalogNeal Johnson100% (1)

- Heat Load Estimation E20 FormDokument1 SeiteHeat Load Estimation E20 Formkahwooi88Noch keine Bewertungen

- SKM Fan Coil Series: Chilled WaterDokument33 SeitenSKM Fan Coil Series: Chilled WaterHewa AkreyNoch keine Bewertungen

- AHRI Standard 1230 - 2010 PDFDokument184 SeitenAHRI Standard 1230 - 2010 PDFDaud Simon ANoch keine Bewertungen

- Static Regain Method NEWDokument6 SeitenStatic Regain Method NEWMarzookNoch keine Bewertungen

- Ashrae 15-34-Rev 3 MitsubishiDokument7 SeitenAshrae 15-34-Rev 3 MitsubishiJosho SandovalNoch keine Bewertungen

- AIA DHHS Ventilation Requirements For Areas Affecting Patient Care in HospitalsDokument4 SeitenAIA DHHS Ventilation Requirements For Areas Affecting Patient Care in HospitalsMahipal Singh RaoNoch keine Bewertungen

- RTS Example Montreal ASHRAE Chapter 6oct2003Dokument26 SeitenRTS Example Montreal ASHRAE Chapter 6oct2003Sid KherNoch keine Bewertungen

- YCM Series - Catalog PUBL-8441 (0418)Dokument36 SeitenYCM Series - Catalog PUBL-8441 (0418)jotace469Noch keine Bewertungen

- Pan Humidifier CalculaitonDokument1 SeitePan Humidifier CalculaitonAshok KrishnamurthyNoch keine Bewertungen

- AL HVAC Contractor Comprehensive Tutorial 10Dokument278 SeitenAL HVAC Contractor Comprehensive Tutorial 10William Worrell100% (1)

- As 2254-1988 Acoustics - Recommended Noise Levels For Various Areas of Occupancy in Vessels and OffshoreDokument5 SeitenAs 2254-1988 Acoustics - Recommended Noise Levels For Various Areas of Occupancy in Vessels and OffshoreSAI Global - APACNoch keine Bewertungen

- Grease Filter Equipped Kitchen Exhaust System Calculation SheetDokument2 SeitenGrease Filter Equipped Kitchen Exhaust System Calculation SheetMahmoud Anwer100% (1)

- Calculo de CFM Pump Room Ventilation Calculation PDFDokument1 SeiteCalculo de CFM Pump Room Ventilation Calculation PDFsusansue50% (2)

- ACCA Reaffirms HVAC Design For Pool and Spa Manual 1Dokument2 SeitenACCA Reaffirms HVAC Design For Pool and Spa Manual 1mefaisal75Noch keine Bewertungen

- Advanced Air Duct Design Part 2Dokument29 SeitenAdvanced Air Duct Design Part 2Timothy Bryant100% (1)

- ASHRAE Example Room - Cooling LoadsDokument14 SeitenASHRAE Example Room - Cooling LoadsSaiful Islam100% (2)

- How Do You Calculate Airflow Required For Maintaining The Building at 50 PA Positive Pressure - Bayt - Com SpecialtiesDokument3 SeitenHow Do You Calculate Airflow Required For Maintaining The Building at 50 PA Positive Pressure - Bayt - Com Specialtieshadi jamshidiNoch keine Bewertungen

- HVAC Ventilation Residential Building Code OfficialsDokument1 SeiteHVAC Ventilation Residential Building Code Officialsbcap-oceanNoch keine Bewertungen

- Hap Free CoolingDokument2 SeitenHap Free CoolingHnin PwintNoch keine Bewertungen

- Cooling Load Calculation DetailDokument2 SeitenCooling Load Calculation DetailNikita SinhaNoch keine Bewertungen

- SKM FCU High Static DetailDokument28 SeitenSKM FCU High Static DetailInzamamNoch keine Bewertungen

- Condensadora TTB TraneDokument24 SeitenCondensadora TTB TraneRoberto Reyes Lara100% (1)

- Ashrae Pocket Guide I P PDFDokument36 SeitenAshrae Pocket Guide I P PDFMUKESH DAYMANoch keine Bewertungen

- Air Distribution SystemDokument21 SeitenAir Distribution SystemRohit JainNoch keine Bewertungen

- 1922Dokument301 Seiten1922Rafael Leonardo GomezNoch keine Bewertungen

- PDFDokument46 SeitenPDFLidijaSpaseskaNoch keine Bewertungen

- Buffer Tank Hydraulic SeparatorDokument4 SeitenBuffer Tank Hydraulic SeparatorJohn MoreNoch keine Bewertungen

- 38.unit and Conversion PDFDokument2 Seiten38.unit and Conversion PDFEdwinIriantoNoch keine Bewertungen

- ASHRAE Fundamentals Handbook (2009)Dokument2 SeitenASHRAE Fundamentals Handbook (2009)Luís Fernando Ferreira Silva50% (2)

- Equal Friction Method For Duct DesignDokument8 SeitenEqual Friction Method For Duct Designimo konsensya100% (1)

- Ductwork DesignDokument26 SeitenDuctwork DesignHafiz Hassan100% (1)

- Dehumidification Equipment Advance ASHRAE Journal PDFDokument6 SeitenDehumidification Equipment Advance ASHRAE Journal PDFThomás ArévaloNoch keine Bewertungen

- ASHRAE Climatic Data Activities PDFDokument22 SeitenASHRAE Climatic Data Activities PDFsunilpatil.043827Noch keine Bewertungen

- Carrier E20-II Design Software Hourly Analysis Program v4.60 Release SheetDokument2 SeitenCarrier E20-II Design Software Hourly Analysis Program v4.60 Release SheetZeeshan HasanNoch keine Bewertungen

- AHRI Standard 550-590 (I-P) - 2011 PDFDokument74 SeitenAHRI Standard 550-590 (I-P) - 2011 PDFaashiqueo2Noch keine Bewertungen

- Hunter GP100 08-2003 PDFDokument1 SeiteHunter GP100 08-2003 PDFaymanmkNoch keine Bewertungen

- VFD Domestic Water Booster Standard Sequence of Operation PDFDokument13 SeitenVFD Domestic Water Booster Standard Sequence of Operation PDFCristianDumitruNoch keine Bewertungen

- People/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMDokument8 SeitenPeople/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMPola OsamaNoch keine Bewertungen

- Ashrae ChartDokument1 SeiteAshrae Chartalone160162lNoch keine Bewertungen

- Prima Usaha ACMV Duct Sizing Table 2017 LockedDokument1 SeitePrima Usaha ACMV Duct Sizing Table 2017 LockedShaikh Tauseef100% (2)

- Ashrae 90.1-2013 Performance-ExplainedDokument20 SeitenAshrae 90.1-2013 Performance-ExplainedjamesNoch keine Bewertungen

- Redline Ashrae 41.1 2013-1986R2006Dokument64 SeitenRedline Ashrae 41.1 2013-1986R2006Huzaifah Bin YounusNoch keine Bewertungen

- U Value CalculationDokument4 SeitenU Value CalculationSatish Kumar Maurya100% (1)

- A Theoretical and Practical Guide To The Basics of Designing Air Flow SystemsDokument3 SeitenA Theoretical and Practical Guide To The Basics of Designing Air Flow Systemsmarcoo8Noch keine Bewertungen

- ASHRAE Journal - VAV System Duct Main DesignDokument5 SeitenASHRAE Journal - VAV System Duct Main DesignJhoNoch keine Bewertungen

- MAKRO MYANMAR ACMV PDF DWG PDFDokument21 SeitenMAKRO MYANMAR ACMV PDF DWG PDFHnin Pwint100% (1)

- 25hp 4p 284tpa Wpi Bf37 AuDokument15 Seiten25hp 4p 284tpa Wpi Bf37 Aurhusseinpos4765Noch keine Bewertungen

- Cold Air Distribution SystemDokument11 SeitenCold Air Distribution Systemsushant_jhawerNoch keine Bewertungen

- ACCA 6 QR HVAC System Cleanliness RA 2021Dokument28 SeitenACCA 6 QR HVAC System Cleanliness RA 2021ridNoch keine Bewertungen

- Fahu CalculationDokument1 SeiteFahu CalculationArul SankaranNoch keine Bewertungen

- Plumbing Interview Questions by Prosen SirDokument10 SeitenPlumbing Interview Questions by Prosen SirBlue Eye'sNoch keine Bewertungen

- AHRI Standard 885-2008 Duct Discharge Calculation SpreadsheetDokument17 SeitenAHRI Standard 885-2008 Duct Discharge Calculation SpreadsheetJagatjeetMNoch keine Bewertungen

- Hvac Formulas PDFDokument3 SeitenHvac Formulas PDFdasmechNoch keine Bewertungen

- Cooling Loads Classified by Kinds of Heat PDFDokument5 SeitenCooling Loads Classified by Kinds of Heat PDFKanaga Raj0% (1)

- Cooling Load Calculations: Edgardo C. OchavilloDokument34 SeitenCooling Load Calculations: Edgardo C. OchavilloJiggy Lawrence Bathan100% (1)

- HVAC Handbook New Edition Part 6 Air Handling EquipmentDokument75 SeitenHVAC Handbook New Edition Part 6 Air Handling EquipmentAbdul Nabi100% (9)

- Belimo BalancersDokument11 SeitenBelimo BalancersAbdul NabiNoch keine Bewertungen

- Chiller FormulasDokument1 SeiteChiller FormulasAbdul NabiNoch keine Bewertungen

- Hydraulic Calculation For Dry & Wet RiserDokument51 SeitenHydraulic Calculation For Dry & Wet RiserAzeem BashaNoch keine Bewertungen

- Chilled Water Pipe SizingDokument2 SeitenChilled Water Pipe SizingLarry Bea77% (13)

- Manual For The Design of Pipe Systems and Pumps - GEADokument56 SeitenManual For The Design of Pipe Systems and Pumps - GEABeomHee LeeNoch keine Bewertungen

- Exterior Mechanical Utitlity DistributionDokument101 SeitenExterior Mechanical Utitlity DistributionAbdul NabiNoch keine Bewertungen

- ZOne Control Riser Valve (Fire Fighting)Dokument10 SeitenZOne Control Riser Valve (Fire Fighting)Abdul NabiNoch keine Bewertungen

- HVAC Handbook CARRIER New Edition Part 12 Water and DX System PDFDokument23 SeitenHVAC Handbook CARRIER New Edition Part 12 Water and DX System PDFalejandro100% (1)

- Material ScienceDokument368 SeitenMaterial Sciencechethan_n75% (4)

- Around The World in 80 DaysDokument140 SeitenAround The World in 80 Dayssamia2105Noch keine Bewertungen

- FlowRatesDokument3 SeitenFlowRatesbharadwaj037Noch keine Bewertungen

- Steam TableDokument1 SeiteSteam TableotezgidenNoch keine Bewertungen

- Material ScienceDokument368 SeitenMaterial Sciencechethan_n75% (4)

- Wade Floor GulliesDokument79 SeitenWade Floor GulliesAbdul NabiNoch keine Bewertungen

- DOE Fundamentals Handbook, Mathematics Volume 1 of 2Dokument206 SeitenDOE Fundamentals Handbook, Mathematics Volume 1 of 2Bob Vines100% (1)

- Doe Mathematics Volume 2 of 2 Doe-Hdbk-10141-92Dokument112 SeitenDoe Mathematics Volume 2 of 2 Doe-Hdbk-10141-92Titer100% (1)

- Material ScienceDokument368 SeitenMaterial Sciencechethan_n75% (4)

- Heating and PyrophoricityDokument87 SeitenHeating and PyrophoricityAbdul NabiNoch keine Bewertungen

- Essential MATLAB For Engineers and Scientists - Brian D. Hahn & Daniel T. ValentineDokument102 SeitenEssential MATLAB For Engineers and Scientists - Brian D. Hahn & Daniel T. Valentinegagansingh87Noch keine Bewertungen

- Control Valves and AccessoriesDokument39 SeitenControl Valves and AccessoriesAbdul NabiNoch keine Bewertungen

- Wade ChannelDokument24 SeitenWade ChannelAbdul NabiNoch keine Bewertungen

- Pressure Relief Valve Engineering HandbookDokument93 SeitenPressure Relief Valve Engineering Handbookakrouti92% (12)

- Materials Science 2 - DOEDokument112 SeitenMaterials Science 2 - DOEshiv_1987Noch keine Bewertungen

- Ductile IronDokument8 SeitenDuctile IronAbdul NabiNoch keine Bewertungen

- Refrigeration FormulasDokument3 SeitenRefrigeration FormulasAbdul Nabi0% (1)

- Chiller FormulasDokument1 SeiteChiller FormulasAbdul NabiNoch keine Bewertungen

- ACO BrochureDokument20 SeitenACO BrochureAbdul NabiNoch keine Bewertungen

- Ductile IronDokument8 SeitenDuctile IronAbdul NabiNoch keine Bewertungen

- Injection Nozzle Opening Pressure: Lmbo QFKD Fkpqor'qflkDokument1 SeiteInjection Nozzle Opening Pressure: Lmbo QFKD Fkpqor'qflkAlexanderNoch keine Bewertungen

- Industrial Training ReportDokument19 SeitenIndustrial Training ReportKapil Prajapati33% (3)

- Engineering ChemistryDokument21 SeitenEngineering Chemistryjai kumarNoch keine Bewertungen

- Esp-2000 BSDokument6 SeitenEsp-2000 BSByron LopezNoch keine Bewertungen

- Law MCQ 25Dokument3 SeitenLaw MCQ 25nonoNoch keine Bewertungen

- Inclusions in Gross IncomeDokument2 SeitenInclusions in Gross Incomeloonie tunesNoch keine Bewertungen

- Lesson Plan Cot1Dokument9 SeitenLesson Plan Cot1Paglinawan Al KimNoch keine Bewertungen

- Topic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)Dokument8 SeitenTopic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)millerNoch keine Bewertungen

- UN Layout Key For Trade DocumentsDokument92 SeitenUN Layout Key For Trade DocumentsСтоян ТитевNoch keine Bewertungen

- Tesla - Electric Railway SystemDokument3 SeitenTesla - Electric Railway SystemMihai CroitoruNoch keine Bewertungen

- Amplifier Frequency ResponseDokument28 SeitenAmplifier Frequency ResponseBenj MendozaNoch keine Bewertungen

- Eat Something DifferentDokument3 SeitenEat Something Differentsrajendr200100% (1)

- Bai Tap Avtc2 PrepositionsDokument5 SeitenBai Tap Avtc2 PrepositionsShy NotNoch keine Bewertungen

- Standards Guide 1021 1407Dokument8 SeitenStandards Guide 1021 1407Anjur SiNoch keine Bewertungen

- Software Requirements SpecificationDokument9 SeitenSoftware Requirements SpecificationSu-kEm Tech LabNoch keine Bewertungen

- 15-3-2020 Chapter 4 Forward Kinematics Lecture 1Dokument29 Seiten15-3-2020 Chapter 4 Forward Kinematics Lecture 1MoathNoch keine Bewertungen

- Bajaj Allianz General Insurance CompanyDokument4 SeitenBajaj Allianz General Insurance Companysarath potnuriNoch keine Bewertungen

- Araldite 2020 + XW 396 - XW 397Dokument6 SeitenAraldite 2020 + XW 396 - XW 397Paul Dan OctavianNoch keine Bewertungen

- 2018 International Swimming Pool and Spa CodeDokument104 Seiten2018 International Swimming Pool and Spa CodeEngFaisal Alrai100% (3)

- GRADE 1 MUSIC Week 1 Learning PacketsDokument16 SeitenGRADE 1 MUSIC Week 1 Learning PacketsQuennie Rose EderNoch keine Bewertungen

- Game Audio - Tales of A Technical Sound Designer Volume 02Dokument154 SeitenGame Audio - Tales of A Technical Sound Designer Volume 02Joshua HuNoch keine Bewertungen

- S L Dixon Fluid Mechanics and Thermodynamics of TurbomachineryDokument4 SeitenS L Dixon Fluid Mechanics and Thermodynamics of Turbomachinerykuma alemayehuNoch keine Bewertungen

- Put Them Into A Big Bowl. Serve The Salad in Small Bowls. Squeeze Some Lemon Juice. Cut The Fruits Into Small Pieces. Wash The Fruits. Mix The FruitsDokument2 SeitenPut Them Into A Big Bowl. Serve The Salad in Small Bowls. Squeeze Some Lemon Juice. Cut The Fruits Into Small Pieces. Wash The Fruits. Mix The FruitsNithya SweetieNoch keine Bewertungen

- Digital-To-Analog Converter - Wikipedia, The Free EncyclopediaDokument8 SeitenDigital-To-Analog Converter - Wikipedia, The Free EncyclopediaAnilkumar KubasadNoch keine Bewertungen

- Copy - of - Commonlit - Meet The Fearless Cook Who Secretly Fed and Funded The Civil Rights Movement - StudentDokument6 SeitenCopy - of - Commonlit - Meet The Fearless Cook Who Secretly Fed and Funded The Civil Rights Movement - Studentlilywright08Noch keine Bewertungen

- BCSS Sec Unit 1 Listening and Speaking SkillsDokument16 SeitenBCSS Sec Unit 1 Listening and Speaking Skillsjiny benNoch keine Bewertungen

- HOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckDokument3 SeitenHOWO SERVICE AND MAINTENANCE SCHEDULE SinotruckRPaivaNoch keine Bewertungen

- 0apageo Catalogue Uk 2022Dokument144 Seiten0apageo Catalogue Uk 2022Kouassi JaurèsNoch keine Bewertungen

- Financial/ Accounting Ratios: Sebi Grade A & Rbi Grade BDokument10 SeitenFinancial/ Accounting Ratios: Sebi Grade A & Rbi Grade Bneevedita tiwariNoch keine Bewertungen

- Chiba International, IncDokument15 SeitenChiba International, IncMiklós SzerdahelyiNoch keine Bewertungen

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionVon EverandThe Laws of Thermodynamics: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsVon EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNoch keine Bewertungen

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseVon EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseBewertung: 4.5 von 5 Sternen4.5/5 (51)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CVon EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNoch keine Bewertungen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Handbook of Mechanical and Materials EngineeringVon EverandHandbook of Mechanical and Materials EngineeringBewertung: 5 von 5 Sternen5/5 (4)

- Aerodynamics for Engineering StudentsVon EverandAerodynamics for Engineering StudentsBewertung: 5 von 5 Sternen5/5 (5)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsVon EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNoch keine Bewertungen

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchVon EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchBewertung: 4 von 5 Sternen4/5 (10)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsVon EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNoch keine Bewertungen

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyVon EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsVon EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNoch keine Bewertungen

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersVon EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersBewertung: 4 von 5 Sternen4/5 (13)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionVon EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Airplane Flying Handbook: FAA-H-8083-3C (2024)Von EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Bewertung: 4 von 5 Sternen4/5 (12)

- The Galactic Federation: Discovering the Unknown Can Be Stranger Than FictionVon EverandThe Galactic Federation: Discovering the Unknown Can Be Stranger Than FictionNoch keine Bewertungen

- Practical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansVon EverandPractical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansBewertung: 4 von 5 Sternen4/5 (8)

- Oil and Gas Pipelines: Integrity and Safety HandbookVon EverandOil and Gas Pipelines: Integrity and Safety HandbookNoch keine Bewertungen