Beruflich Dokumente

Kultur Dokumente

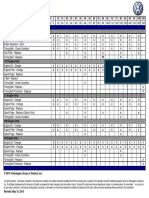

Fuel and maintenance check

Hochgeladen von

DPOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fuel and maintenance check

Hochgeladen von

DPCopyright:

Verfügbare Formate

358 All types of fuel

Always check manual for special jobs

12,000 hrs

24,000 hrs

36,000 hrs

1000 hrs

1500 hrs

2000 hrs

3000 hrs

4000 hrs

5000 hrs

6000 hrs

8000 hrs

250 hrs

500 hrs

Periodic Maintenance Jobs

Engine as a whole 1 x Check monitoring system

structural and 2 x x x x x x Check crankweb deflection

motion parts 3 x x x x x x inspect engine mounting

4 x x x x Inspect pistons and liners

5 x x x Inpect main bearings first removing central one

6 x x x x Inspect gears of valve and auxiliary drives

7 x Replace holset vibration damper

8 x x x x Inspect cooling water jackets and clean as necessary

Inlet/ exhaust 9 x x x x x x Check valve clearance and adjust as necessary

valve drive 10 x x x x x Remove exhaust valves without rotators and inspect. Through resultant apertures in cylinderhead

11 inspect combustion chambers

12 x x x x Remove exhaust valves with rotators and inspect. Through resultant apertures in cylinderhead

13 inspect combustion chambers

14 x x x x x x Check valve rotators

15 x x x x When inspecting pistons and liners, remove inlet valves and inspect. If bad shape, check further

16 Inlet valve

inlet/ exhaust valve 17 x x x Inpect camshaft bearings as well as inlet, exhaust and injection cams

Turbocharger 18 Change oil, inspect water chambers, replace bearings (see BBC instructions)

19 x x x x x x x x x x Clean air cleaner and rewet with oil

Fuel system 20 x Overhaul injection pump, replacing bearings, cam rollers and camshaft

Speed control 21 x x x x Replace bearing of governor (mechanical)

Lubricating system 22 x x x x x x x x x x x x Clean duplex filter

23 x x x x x x x x x x Test an oil sample

24 x x x x Check delivery of cylinders lubricator

25 x x x Clean circuit oil and fresh oil tanks

26 x x x x x x x x x x x x Check injection pump oil dilution by fuel. If necessary, change oil and clean filter

27 x x x x x x x x x x x x Service greasing points; charge air thermostat starting valves and master valves

28 x x x Inspect circuit oil pumps

Cooling system 29 x x x x Inspect charge air cooler for corrosion and soling. Clean tubing inside with a soft cylindrical bruch.

30 If necessary, use Vecom B 85, a hot P3 solution of trichlorethylene and finally flush with water

31 x x x x Inspect coolers for water, lube oil and injectors and clean as necessary

32 Attend to protective screen ahead of starting air master valves

33 (remove after 200 hrs (unless still heavily soilet)

34 x x x x x Service cleaner for starting pilot air distributor

35 x x x x Clean system and test functioning, especially of valves

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

D358 maintenance schedule.xls maintenance schedule

Das könnte Ihnen auch gefallen

- Man NR20Dokument68 SeitenMan NR20DP75% (8)

- Scania Generator Maintenance Interval: Daily Interval (Hours) Minimum R S M L L XLDokument3 SeitenScania Generator Maintenance Interval: Daily Interval (Hours) Minimum R S M L L XLramsey2220% (1)

- Interpretation of Arterial Blood Gases (ABGs)Dokument6 SeitenInterpretation of Arterial Blood Gases (ABGs)afalfitraNoch keine Bewertungen

- York Chiller Log SheetDokument4 SeitenYork Chiller Log SheetEngr Fazal AkbarNoch keine Bewertungen

- Know and Understand Centrifugal PumpsVon EverandKnow and Understand Centrifugal PumpsL. BachusBewertung: 4 von 5 Sternen4/5 (1)

- STAT100 Fall19 Test 2 ANSWERS Practice Problems PDFDokument23 SeitenSTAT100 Fall19 Test 2 ANSWERS Practice Problems PDFabutiNoch keine Bewertungen

- D528 Maintenance Schedule - Xls Maintenance ScheduleDokument1 SeiteD528 Maintenance Schedule - Xls Maintenance ScheduleDPNoch keine Bewertungen

- D540 D640 Maintenance ScheduleDokument2 SeitenD540 D640 Maintenance ScheduleDPNoch keine Bewertungen

- Maintenance Schedule Bauer CompressorsDokument1 SeiteMaintenance Schedule Bauer CompressorsCristel_DC100% (3)

- DG Maintenance PlanDokument2 SeitenDG Maintenance PlanYasir Mehmood100% (1)

- Preventative Maintenance Activity A B C D E: Type of Visit For Each Specific Year, Running Hours Per Year 8000 HRSDokument1 SeitePreventative Maintenance Activity A B C D E: Type of Visit For Each Specific Year, Running Hours Per Year 8000 HRSSeif AlbaghdadyNoch keine Bewertungen

- 2010 Prius Maintenance Schedule (Canadian, Based On Owner's Manual Supplement)Dokument1 Seite2010 Prius Maintenance Schedule (Canadian, Based On Owner's Manual Supplement)Raihan GrimuflihinNoch keine Bewertungen

- Atlas Copco Xrvs 476 Manual (050 054)Dokument5 SeitenAtlas Copco Xrvs 476 Manual (050 054)joseNoch keine Bewertungen

- Standard Service Oil Injected Compressor Atlas CopcoDokument1 SeiteStandard Service Oil Injected Compressor Atlas CopcoAhmad FauzieNoch keine Bewertungen

- ML1812R Maintenance ScheduleDokument6 SeitenML1812R Maintenance ScheduleGioeNoch keine Bewertungen

- Equipment GA132 75 Bar (W) PackDokument1 SeiteEquipment GA132 75 Bar (W) Packsurendra SinghNoch keine Bewertungen

- 2-Stroke Rotax Maintenance Schedule: Cylinder Head Temperature (Reading at Spark Plug Seat) : CHTDokument1 Seite2-Stroke Rotax Maintenance Schedule: Cylinder Head Temperature (Reading at Spark Plug Seat) : CHTLeonardo PachecoNoch keine Bewertungen

- Basic Barrier Maintenance Guide: Tasks Hydraulic ElectricDokument2 SeitenBasic Barrier Maintenance Guide: Tasks Hydraulic Electricbaguspermana7Noch keine Bewertungen

- MaintenanceOfIndUnits2019V001 Industrial UnitsDokument2 SeitenMaintenanceOfIndUnits2019V001 Industrial UnitsMiguel Angel Flores MojicaNoch keine Bewertungen

- Repair Options FOR 950G/H/M Wheel LoadersDokument2 SeitenRepair Options FOR 950G/H/M Wheel LoadersАдыль БабировNoch keine Bewertungen

- Procedimiento de Carga de Horas Hombre y Reporte de MantenimientoDokument23 SeitenProcedimiento de Carga de Horas Hombre y Reporte de Mantenimientoebonilla88Noch keine Bewertungen

- 60,0000 Mile MaintDokument2 Seiten60,0000 Mile MaintjaguarrrrNoch keine Bewertungen

- Scania TerexDokument126 SeitenScania TerexzoeNoch keine Bewertungen

- 2 Stroke Maintenance SchedulesDokument3 Seiten2 Stroke Maintenance SchedulesGeo PalNoch keine Bewertungen

- Santa Fe 3.5 2010 2012 Jan 2014Dokument1 SeiteSanta Fe 3.5 2010 2012 Jan 2014Mohammed AldaffaieNoch keine Bewertungen

- 160.81-MR1 (Log Sheet)Dokument4 Seiten160.81-MR1 (Log Sheet)dhcastanoNoch keine Bewertungen

- 160 54-MR1 PDFDokument1 Seite160 54-MR1 PDFghilesNoch keine Bewertungen

- 36 Series Gear BoxDokument1 Seite36 Series Gear BoxD.V.S.S Ram PrasadNoch keine Bewertungen

- NH L218 - Maintenance ChartDokument2 SeitenNH L218 - Maintenance ChartKristomiDerMarine-IngenieurNoch keine Bewertungen

- 8D100 10 PDFDokument5 Seiten8D100 10 PDFChristian BedoyaNoch keine Bewertungen

- ... An Energy-Saving Approach To Your Service Needs..Dokument4 Seiten... An Energy-Saving Approach To Your Service Needs..Robert sherrodNoch keine Bewertungen

- 设备保养维修指南 Instructions of Equipment Maintenance and repairDokument12 Seiten设备保养维修指南 Instructions of Equipment Maintenance and repairarman emamianNoch keine Bewertungen

- Maintain Your Sportster's Peak PerformanceDokument2 SeitenMaintain Your Sportster's Peak PerformanceÉder Oliveira NicolletiNoch keine Bewertungen

- 460E - ADT - Uptime Maintenance PlannerDokument3 Seiten460E - ADT - Uptime Maintenance PlannerBassieNoch keine Bewertungen

- Maintenance Lists: (3A) Preventive Maintenance ScheduleDokument4 SeitenMaintenance Lists: (3A) Preventive Maintenance Scheduleyoucef tecNoch keine Bewertungen

- 913-SAT ING - Scheduled Maintenance - Testastretta 11° - Ed.08-14Dokument1 Seite913-SAT ING - Scheduled Maintenance - Testastretta 11° - Ed.08-14P JNoch keine Bewertungen

- Annex 2 Maintenance OHB 1013Dokument2 SeitenAnnex 2 Maintenance OHB 1013Project SinhaNoch keine Bewertungen

- D628 Maintenance ScheduleDokument3 SeitenD628 Maintenance ScheduleDPNoch keine Bewertungen

- Mitsubishi Lancer Ralliart / Evolution 10 2015 Maintenance SectionDokument18 SeitenMitsubishi Lancer Ralliart / Evolution 10 2015 Maintenance SectionZafriNoch keine Bewertungen

- HL Owners Manual 2021Dokument2 SeitenHL Owners Manual 2021Dutchie169Noch keine Bewertungen

- 260E PIN 1DW260EX F677827 708124 310E PIN 1DW310EX F677827 708124 Uptime Maintenance PlannerDokument4 Seiten260E PIN 1DW260EX F677827 708124 310E PIN 1DW310EX F677827 708124 Uptime Maintenance PlannerNelson Andrade VelasquezNoch keine Bewertungen

- Overhaul Recommendadtion 28 - 32Dokument2 SeitenOverhaul Recommendadtion 28 - 32Felipe RibasNoch keine Bewertungen

- 160 54-MR1Dokument3 Seiten160 54-MR1Areeb FizaNoch keine Bewertungen

- Regular Service Intervals for Harley-Davidson Softail ModelsDokument5 SeitenRegular Service Intervals for Harley-Davidson Softail Modelsdneprmt1Noch keine Bewertungen

- Kilometers: 2001 Volkswagen Maintenance Schedule by Miles / KilometersDokument2 SeitenKilometers: 2001 Volkswagen Maintenance Schedule by Miles / KilometersaleksandarlaskovNoch keine Bewertungen

- DUCATI Panigale Scheduled Service Maintenance Superquadro Ed 02-13 INGDokument1 SeiteDUCATI Panigale Scheduled Service Maintenance Superquadro Ed 02-13 INGCristian BurbanoNoch keine Bewertungen

- Yamaha Nmax 155 - Engine Oil StrainerDokument1 SeiteYamaha Nmax 155 - Engine Oil Strainermotley crewzNoch keine Bewertungen

- 470GLC (PIN: 1FF470GX - E470001-) : As RequiredDokument2 Seiten470GLC (PIN: 1FF470GX - E470001-) : As RequiredBrian CareelNoch keine Bewertungen

- 923-SAT ING - Scheduled Maintenance - Scrambler - Ed.01-15Dokument1 Seite923-SAT ING - Scheduled Maintenance - Scrambler - Ed.01-15P JNoch keine Bewertungen

- Vol.2-8 PM-MEDokument3 SeitenVol.2-8 PM-MEwwcengNoch keine Bewertungen

- 2010 HD Buell Service IntervalsDokument20 Seiten2010 HD Buell Service IntervalsEugenio CandrevaNoch keine Bewertungen

- 2006 HD Buell Service IntervalsDokument12 Seiten2006 HD Buell Service IntervalsAdrián CasarrubiasNoch keine Bewertungen

- P&G SOWDokument4 SeitenP&G SOWsigmaintipurnamaNoch keine Bewertungen

- 2007 HD Buell Service IntervalsDokument14 Seiten2007 HD Buell Service IntervalsCleverson SantosNoch keine Bewertungen

- Maintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesDokument2 SeitenMaintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesCristiano DellazariNoch keine Bewertungen

- Mixer Preventive Maintenance ScheduleDokument1 SeiteMixer Preventive Maintenance ScheduleTuti SusilawatiNoch keine Bewertungen

- Harley-Davidson: and Buell Service IntervalsDokument16 SeitenHarley-Davidson: and Buell Service IntervalsPeluzitaNoch keine Bewertungen

- DUCATI Scheduled Maintenance Testastretta 11 821 CC Ed 04-13 INGDokument1 SeiteDUCATI Scheduled Maintenance Testastretta 11 821 CC Ed 04-13 INGAnderson HasselmannNoch keine Bewertungen

- Uploads Media Document BAC Rigging-VXI RVXIv15ENDokument28 SeitenUploads Media Document BAC Rigging-VXI RVXIv15ENsidsaleemNoch keine Bewertungen

- Centrifugal Pump ChecklistDokument1 SeiteCentrifugal Pump ChecklistApneryanus LepingNoch keine Bewertungen

- 644K PIN 1DW644K D658218 PIN 1DW644K C658218 Uptime Maintenance PlannerDokument2 Seiten644K PIN 1DW644K D658218 PIN 1DW644K C658218 Uptime Maintenance Plannererick huancaya bartraNoch keine Bewertungen

- Filter: No. Cilt Description D 2W M 6M YDokument2 SeitenFilter: No. Cilt Description D 2W M 6M YkeduseNoch keine Bewertungen

- Periodic Maintenance of Yamaha YZF R15 PDFDokument2 SeitenPeriodic Maintenance of Yamaha YZF R15 PDFPraveen CNNoch keine Bewertungen

- Connecting RodDokument1 SeiteConnecting RodDPNoch keine Bewertungen

- WS A25 Specifications of Plungers TB00-5501-07Dokument5 SeitenWS A25 Specifications of Plungers TB00-5501-07DPNoch keine Bewertungen

- D540 Service and Maintenance of Lube Oil FiltersDokument2 SeitenD540 Service and Maintenance of Lube Oil FiltersDPNoch keine Bewertungen

- Connecting RodDokument1 SeiteConnecting RodDPNoch keine Bewertungen

- W46 Assessment of Bearings 4610Q002 - 01gbDokument8 SeitenW46 Assessment of Bearings 4610Q002 - 01gbDP100% (1)

- Technical Bulletin on Sulzer S20 Cylinder Head RepairsDokument6 SeitenTechnical Bulletin on Sulzer S20 Cylinder Head RepairsDP100% (2)

- WS S20 Undersized Bearings and Reconditioning of Crankshafts TB00-3101-01Dokument7 SeitenWS S20 Undersized Bearings and Reconditioning of Crankshafts TB00-3101-01DP100% (1)

- Eestinova MV Emi Proud: I and II: 19.95 (MM) IiiDokument1 SeiteEestinova MV Emi Proud: I and II: 19.95 (MM) IiiDPNoch keine Bewertungen

- WS S20 New Fuel Pump Element TBS20-5501-03Dokument2 SeitenWS S20 New Fuel Pump Element TBS20-5501-03DP100% (1)

- W46 Turbine Side Water Washing of The Turbochargers 4615Q002 - 03gbDokument3 SeitenW46 Turbine Side Water Washing of The Turbochargers 4615Q002 - 03gbDPNoch keine Bewertungen

- WS A25 Connecting Rod Types Guidelines For Assessment at Bottom End TB00-3301-16Dokument4 SeitenWS A25 Connecting Rod Types Guidelines For Assessment at Bottom End TB00-3301-16DPNoch keine Bewertungen

- W46 Adjustment of Fuel Valve Opening Pressure 4616Q006 - 01gbDokument2 SeitenW46 Adjustment of Fuel Valve Opening Pressure 4616Q006 - 01gbDP100% (1)

- D628 Maintenance Schedule PartsDokument2 SeitenD628 Maintenance Schedule PartsDPNoch keine Bewertungen

- D628 Maintenance ScheduleDokument3 SeitenD628 Maintenance ScheduleDPNoch keine Bewertungen

- Maintenance Schedule and Parts for D232 EngineDokument21 SeitenMaintenance Schedule and Parts for D232 EngineDP100% (1)

- Survey Course OverviewDokument3 SeitenSurvey Course OverviewAnil MarsaniNoch keine Bewertungen

- DECA IMP GuidelinesDokument6 SeitenDECA IMP GuidelinesVuNguyen313Noch keine Bewertungen

- Striedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsDokument22 SeitenStriedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsOsny SillasNoch keine Bewertungen

- Difference Between Text and Discourse: The Agent FactorDokument4 SeitenDifference Between Text and Discourse: The Agent FactorBenjamin Paner100% (1)

- Memo Roll Out Workplace and Monitoring Apps Monitoring Apps 1Dokument6 SeitenMemo Roll Out Workplace and Monitoring Apps Monitoring Apps 1MigaeaNoch keine Bewertungen

- GlastonburyDokument4 SeitenGlastonburyfatimazahrarahmani02Noch keine Bewertungen

- IoT BASED HEALTH MONITORING SYSTEMDokument18 SeitenIoT BASED HEALTH MONITORING SYSTEMArunkumar Kuti100% (2)

- GIS Multi-Criteria Analysis by Ordered Weighted Averaging (OWA) : Toward An Integrated Citrus Management StrategyDokument17 SeitenGIS Multi-Criteria Analysis by Ordered Weighted Averaging (OWA) : Toward An Integrated Citrus Management StrategyJames DeanNoch keine Bewertungen

- PROF ED 10-ACTIVITY #1 (Chapter 1)Dokument4 SeitenPROF ED 10-ACTIVITY #1 (Chapter 1)Nizelle Arevalo100% (1)

- The European Journal of Applied Economics - Vol. 16 #2Dokument180 SeitenThe European Journal of Applied Economics - Vol. 16 #2Aleksandar MihajlovićNoch keine Bewertungen

- Philippine Coastal Management Guidebook Series No. 8Dokument182 SeitenPhilippine Coastal Management Guidebook Series No. 8Carl100% (1)

- IGCSE Chemistry Section 5 Lesson 3Dokument43 SeitenIGCSE Chemistry Section 5 Lesson 3Bhawana SinghNoch keine Bewertungen

- 4 Wheel ThunderDokument9 Seiten4 Wheel ThunderOlga Lucia Zapata SavaresseNoch keine Bewertungen

- Modified Syllabus of Control SystemDokument2 SeitenModified Syllabus of Control SystemDigambar PatilNoch keine Bewertungen

- Unit 3 Computer ScienceDokument3 SeitenUnit 3 Computer ScienceradNoch keine Bewertungen

- Wasserman Chest 1997Dokument13 SeitenWasserman Chest 1997Filip BreskvarNoch keine Bewertungen

- Complete Guide To Sports Training PDFDokument105 SeitenComplete Guide To Sports Training PDFShahana ShahNoch keine Bewertungen

- Good Ethics Is Good BusinessDokument9 SeitenGood Ethics Is Good BusinesssumeetpatnaikNoch keine Bewertungen

- Water Jet CuttingDokument15 SeitenWater Jet CuttingDevendar YadavNoch keine Bewertungen

- Algorithms For Image Processing and Computer Vision: J.R. ParkerDokument8 SeitenAlgorithms For Image Processing and Computer Vision: J.R. ParkerJiaqian NingNoch keine Bewertungen

- Agricultural Engineering Comprehensive Board Exam Reviewer: Agricultural Processing, Structures, and Allied SubjectsDokument84 SeitenAgricultural Engineering Comprehensive Board Exam Reviewer: Agricultural Processing, Structures, and Allied SubjectsRachel vNoch keine Bewertungen

- Oxford Digital Marketing Programme ProspectusDokument12 SeitenOxford Digital Marketing Programme ProspectusLeonard AbellaNoch keine Bewertungen

- Report Emerging TechnologiesDokument97 SeitenReport Emerging Technologiesa10b11Noch keine Bewertungen

- Sewage Pumping StationDokument35 SeitenSewage Pumping StationOrchie DavidNoch keine Bewertungen

- ServiceDokument47 SeitenServiceMarko KoširNoch keine Bewertungen

- Take This LoveDokument2 SeitenTake This LoveRicardo Saul LaRosaNoch keine Bewertungen

- Guidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016Dokument76 SeitenGuidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016kofafa100% (1)

- PRODUCTDokument82 SeitenPRODUCTSrishti AggarwalNoch keine Bewertungen