Beruflich Dokumente

Kultur Dokumente

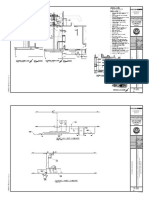

Pipe Supports and Hangars Details

Hochgeladen von

Viswanathan Krish0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten5 SeitenPipe Supports and hangars details

Originaltitel

Pipe Supports and hangars details

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenPipe Supports and hangars details

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten5 SeitenPipe Supports and Hangars Details

Hochgeladen von

Viswanathan KrishPipe Supports and hangars details

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

oO

oO

GENERAL REGULATIONS

314.8 Waterproofing of Openings. Joints at the roof

around pipes, ducts, or other a shall be

made water-tight by the use of lead, copper, galva-

nized iron, or other approved flashings or flashing

material. Exterior wall openings shall be made

water-tight. Counterflashing shall not restrict the

required internal cross-sectional area of the vent.

814.9 Plastic and copper piping penetrating framing

members to within tenty-fve and four-enthy (25.9

‘of a millimeter (1 in.) of the exposed framing shall be

protected by steel nail plates not less than one and

three-tenths (1.3) of a millimeter (0.0478 in, [18

euge]) in thickness. The steel nail plate shall extend

along the framing member not less than thirty-eight

(G8) mullimeters (I-1/2 in.) beyond the outside diam-

eter of the pipe or tubing,

314.10 Sleeves.

314.10. Sleeves shall be provided to protect

piping through concrete and masonry wails and

concrete floors.

Exception: Sleeves shall not be required

where openings are drilled or bored.

314.10.2 Piping through concrete or masonry

walls shall not be subject to any load from

building construction.

814.10.3 In exterior walls, annular space

between sleeves and pipes shall be sealed and

made watertight, as approved by the Authority

Having Jurisdiction. Any penetration through

fire-resistive construction shall be in accordance

with Section 314.7,

314.10.4 Any pipe sleeve through a firewall

«shall have the space around the pipe completely

sealed. with an approved fire-resistive material

in accordance with other codes.

814.11 Any structural member that has been weak-

‘ened or impaired by cutting, notching, or otherwise,

shall be reinforced, repaired, or replaced 60 as to be

left in a safe structural condition in accordance with

the requirements of the applicable Building Codes or

as required by the Authority Having Jurisdiction.

914,12 Ratproofing,

314.121 Strainer plates on drain inlets shall be

designed and installed so that no opening is

exceeding twelve and seven-tenths (12.7) of a

millimeter (0.5 in.) in the least dimension.

914.12.2 Meter boxes shall be constructed in

such a manner that rats cannot enter a building

by following the service pipes from the box into

the building.

314.12.3 In or on buildings where openings

have been made in walls, floors, or ceilings for

the passage of pipes, such openings shall be

closed and protected by the installation of

approved metal collars securely fastened to the

adjoining structure.

314.8 - 316.2

314.12.4 Tub waste openings in framed cons-

truction to craw! spaces at or below the first floor

shall be protected by the installation of approved

‘metal collars or metal screens securely fastened

to the adjoining structure with no opening excee-

ding twelve and seven-tenths (12.7) of a milli-

meter (0.5 in.) in the least dimension.

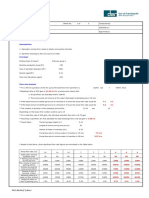

915.0 Hangers and Supports.

916.1 Suspended piping shall be supported at inter-

vals not to exceed those shown in Table 3-2.

316.2 Piping shall be supported in such a manner as

to maintain its alignment and prevent sagging.

‘918.3 Piping in the ground shall be laid on a firm

bed for its entire length; where other support is

otherwise provided, it shall be approved per Section

301.0 of this code.

316.4 Hangers and anchors shall be of sufficient

strength fo support the weight of the pipe and its

contents. Piping shall be isolated from incompatible

materials,

316.5 Piping, fixtures, appliances, and appurtenances

shall be adequately supported in accordance with this

code, the manufacturer's installation instructions, and

8 required by the Authority Having Jurisdiction.

915.6 Hanger rod sizes shall be no smaller than

those shown in Table 3-1.

318.7 Piping for manifold systems shall be

supported in accordance with the manufacturer's

instructions. Hot and cold water distribution piping

shall maintain separation at all points within the

system.

—

TABLE S-1

Hanger Rod Sizes

Pipe and Tube Size Rod Size

mm (in) mm (in)

B7-12 05-4) 95 (0374)

127-203 6-8) 127 05)

254-905 (10-12) 159 (0.625)

816.0 Trenching, Excavation, and Backfill.

816.1 Trenches deeper than the footing of any

building or structure and paralleling the same shail

be not less than seventy-nine hundredths (0.79) of a

radian (45 degrees) therefrom, or as approved per

Section 301.0 of this code.

916.2 Tunneling and driving shall be permitted to be

done in yards, courts, or driveways of any building

site, Where sufficient depth is available to permit,

23

3i6.2-317.1

tunnels shall be permitted to be used between open-

cut trenches. Tunnels shall have a clear height of six-

hundred and ten (610) millimeters (2 ft. above the

pipe and shall be limited in length to one-half (1/2)

the depth of the trench, with a maximum length of

two-thousand, four-hundred and thirty-eight (2438)

millimeters (8 ft). When pipes are driven, the drive

pipe shall be not less than one (1) size larger than the

pipe to be laid.

316.3 Open Trenches. Excavations required to be

made for the installation of a building drainage

system or any part thereof, within the walls of a

building, shall be open trench work and shall be kept

‘open until the piping has been inspected, tested, and

accepted.

316.4 Excavations shall be completely backfilled as

soon after inspection as practicable. Adequate

precaution shall be taken to ensure proper compact-

ness of backfill around piping without damage to

such piping. Trenches shall be backfilled in thin

layers to three-hundred and five (305) millimeters (1

ft.) above the top of the piping with clean earth,

which shall not contain stones, boulders, cinderfill,

frozen earth, construction debris, or other materials

that would damage or break the piping or cause

corrosive action. Mechanical devices such as bull-

dozers, graders, etc,, shall be permitted to then be

used to complete backfill to grade. Fill shall be prop-

erly compacted. Suitable precautions shall be taken

to ensure permanent stability for pipe laid in filled or

made ground.

817.0 Joints and Connections.

317.1 Types of Joints.

3171.4 Threaded Joints. Threads on iron pipe

size (IPS) pipe and fittings shall be standard

taper pipe threads in accordance with standards

listed in Table 14-1. Threads on tubing shall be

approved types. Threads on plastic pipe shall be

factory cut or molded. Threaded plastic pipe

shall be Schedule 80 minimum wall thickness.

Tubing threads shall conform to fine tubing

thread standards. When a pipe joint material is

used, it shall be applied only on male threads,

and such materials shall be approved types,

insoluble in water and nontoxic. Cleanout plugs

and caps shall be lubricated with water-insol-

uble, nonhardening material or tape. Thread

tape or thread lubricants and sealants specifi-

cally intended for use with plastics shall be used

on plastic threads. Conventional pipe thread

compounds, putty, linseed-oil-based products,

and unknown lubricants and sealants shall not

be used on plastic threads. .

24

UNIFORM PLUMBING CODE - INDIA

317.1.2 Soldered Joints. Joints in copper

tubing shall be made by the appropriate use of

approved copper or copper alloy fittings. The

tubing shall be reamed to the full inside diam-

eter. Surfaces to be joined by soldering shall be

cleaned bright by manual or mechanical means.

The joints shall be properly fluxed with an

approved-type flux and made up with approved

solder. Solder and fluxes shall be manufactured

to approved standards. Solders and fluxes with a

ead content that exceeds two-tenths-(0.2) of 1

percent shall be prohibited in piping systems

‘used to convey potable water

317.1.3 Flared Joints. Flared joints for soft

copper tubing shall be made with fittings

‘meeting approved standards. The tubing shall

be reamed to the full inside diameter, resized to

round, and expanded with a proper flaring tool.

317.1.4 Mechanical Joints, When pipe is joined

by means of flexible compression joints, such

joints shall conform to approved standards

and shall not be considered as slip joints.

Mechanical joints shall be installed in accor-

dance with the manufacturer's instructions.

317.1. Solvent Cement Plastic Pipe Joints.

Plastic pipe and fittings designed to be joined by

solvent cementing shall comply with applicable

UPC Instellation Standards.

‘ABS pipe and fittings shall be cleaned and

then joined with solvent cement(s).

CPVC pipe and fittings shall be cleaned and

then joined with listed primer(s) and solvent

cement(s).

Exception: Listed solvent cements that do

not require the use of primer shall be

permitted for use with CPVC pipe and

fittings, manufactured in accordance with

ASTM D2846, twelve and seven-tenths

(12.7) of a millimeter through fifty-one (1)

rillimeters (05 in, -2in.) in diameter,

PVC pipe and fittings shall be cleaned and

joined with primer(s) and solvent cements).

‘A solvent cement transition joint between

ABS and PVC building drain and building sewer

shall be made using a listed transition solvent

cement.

317.1.6 Brazing and Welding. Brazing and

welding shall conform to the applicable stan-

dard(s) in Table 14-1. Only brazing alloys having

a liquid temperature above 536°C (1,000°F) shall

be used. Brazing on medical gas systems shall be

performed by certified installers meeting the

requirements of ASME Boiler and Pressure Vessel

Code, Section IX, Welding and Brazing Qualifen-

tions, or AWS B22, Standard for Brazing Procedure

sand Performance Qualifications.

oO

oO

©

C)

QO

oy

QO

GENERAL REGULATIONS

‘817.1.7 Pressure-Lock-Type Connection. This

is a mechanical connection that depends on an

internal retention device t6 prevent pipe or

tubing separation. Connection is made by

inserting the pipe or tubirig into the fitting to a

prescribed depth.

917.1.8 Pressed Fitting. This is a mechanical

connection for joining copper tubing that uses a

crimping tool to affix the O-ring seal and copper

alloy fitting to the tubing. The tubing shall be

inserted into the fitting, and the crimp shall be

made using the tool recommended by the manu-

facturer.

817.1.9 Push-Fit Fitting. This is a mechanical

connection for joining copper, PEX and CPVC

tubing. The connection is hand assembled by

pushing the tubing into the fitting. The connec

tion seals with an ”O” ring.

317.1.10 Heat Fusion Weld Joints. This type of

joining method involves the preparation of

surfaces to be fused, heating of the surfaces. to

proper fusion temperatures, and bringing the

surfaces together in a manner to form the fusion

bond. Plastic pipe and fittings designed to be

joined by heat-fusion shall comply with one of

the specific methods'as follows:

2) A butt heat-fusion joint shall be joined by a

device that holds the heater element square

to the ends of the piping, compresses the

heated ends together, and holds the pipe in

proper alignment while the plastic hardens.

2) A socket heat-fusion joint shall be joined by

a device that heats the mating surfaces of

the joint uniformly and simultaneously to

essentially the same temperature. Proper

alignment devices shall be used to hold the

pipe and socket fitting together during the

joining process.

@) An electro-fusion joint shall be joined,

utilizing the equipment and techniques of

the fitting manufacturer's equipment. This

technique involves the resistance wire that is

‘embedded in the fitting. This resistance wire

supplies the heat source necessary for

fasion.

317.2 Special Joints.

‘917.2.1 Copper Tubing to Screw Pipe Joints.

Joints from copper tubing to threaded pipe shall

be made by the use of DZR (Dezincification

Resistant) adapter fittings. The joint between the

copper tubing and the fitting shall be a soldered

brazed flared, or pressed joint and the connec-

tion between the threaded pipe and the fitting

shall be made with a standard pipe size screw

317.1-318.0

joint, Solder shall conform to the requirements of

Section 317.1.2, Brazed joints shall conform to

the requirements of Section 317.1.6. Flared joints

shall conform to the requirements of Section

317.1.3. Pressed joints shall conform to the

requirements of 317.1.8.

317.2.2 Plastic Pipe to Other Materials. When

connecting plastic pipe to other types of piping,

only approved types of fittings and adapters

designed for the specific transition intended

shall be used.

317.3 Flanged Fixture Connections.

317.8.1 Fixture connections between drainage

Pipes and water closets, floor outlet service sinks

and urinals shall be made by means of approved

brass, hard lead, ABS, PVC, or iron flanges

caulked, soldered, solvent cemented; rubber

compression gaskets; or screwed to the drai

pipe. The connection shall be bolted with an

approved gasket, washer, or setting compound

between the fixture and the connection. The

bottom of the flange shall be set on an approved

firm base.

817.3.2 Closet bends or stubs shall be cut off so

as to present a smooth surface even with the top

of the closet ring before rough inspection is

called

817.3.3 Wall-mounted water closet fixtures shall

be securely bolted to an approved carrier fitting

The connecting pipe between the carrier fitting

and the fixture shall be an approved material

and designed to accommodate an adequately

sized gasket. Gasket material shall be neoprene,

felt, or similar approved types.

317.4 Prohibited Joints and Connections.

317.4.1 Drainage System. Any-fitting or

connection that has an enlargement, chamber, or

recess with a ledge, shoulder, or reduction of

pipe area that offers an obstruction to flow

through the drain shall be prohibited.

817.4.2 No fitting or connection that offers

abnormal obstruction to flow shall be used. The

enlargement of a seventy-six (76) millimeter (3

in, closet bend or stub to one-hundred and two

(102) millimeters (4 in.) shall not be considered

an obstruction.

318.0 Increasers and Reducers.

Where different sizes of pipes and fittings are to be

connected, the proper size increasers or reducers or

reducing fittings shall be used between the two (2)

sizes. Brass of cast-iron body cleanouts shall not be

used as a reducer or adapter from cast-iron drainage

pipe to iron pipe size (IPS) pipe.

25

319.0-921.0

819.0 Food-Handling Establishments.

Food or drinks shall not be stored, prepared, or

displayed beneath soil or drain pipes, unless those

areas are protected against leakage or condensation

from such pipes reaching the food or drink as

described below. Where building design requires

that soil or drain pipes be located over such areas,

the installation shall be made with the least possible

number of joints and shall be installed so as to

connect to the nearest adequately sized vertical stack

with the provisions as follows:

819.1 Openings through floors over such areas shall

be sealed water-tight to the floor construction.

919.2 Floor and shower drains installed above such

areas shall be equipped with integral seepage pans.

319.3 Soil or drain pipes shall be of an approved

material as listed in Table 14-1 and Section 701.

Materials shall conform to established standards.

Cleanouts shail be extended through the floor

construction above.

319.4 Piping subject to operation at temperatures

‘that will form condensation on the exterior of the

pipe shall be thermally insulated.

319.8 Where pipes are installed in ceilings above

such areas, the ceiling shall be of the removable

Aype, or shall be provided with access panels in order

to form a ready access for inspection of piping.

320.0 Test Gauges.

Tests required by this code, which are performed

ulilizing dial gauges, shall be limited to gauges

having the following pressure graduations oF incte-

mentations.

320.1 Required pressure tests of sixty-nine (69) kilo-

Pascals (10 psi) or less shall be performed with

‘gauges of seven-tenths (0.7) of a kiloPascal (0.10 psi)

incrementation or less.

320.2 Required pressure tests exceeding sixty-nine

(@) kiloPascals (10 psi) but less than or equal to six:

‘hundred and eighty-nine (689) kiloPascals (100 psi)

shall be performed with gauges of six and nine-tenths

(69) of a kiloPascal (1 psi) incrementation or less.

320.3 Required pressure tests exceeding sixchundred

and eighty-nine (689) kiloPascals (100 psi) shall be

performed with gauges incremented for 2 percent or

less of the required test pressure.

320.4 Test gauges shall have a pressure range not

exceeding twice the test pressure applied.

921.0 Medical Gas and Vacuum Systems.

Such piping shall be installed, tested, and verified in

compliance with the applicable standards referenced

26

UNIFORM PLUMBING CODE — INDIA

in Table 14-1 and the requirements of Chapter 13. The

‘Authority Having Jurisdiction shall require evidence

‘of the competency of the installers and verifiers,

GENERAL REGULATIONS Table 3-2

TABLE 32

Pipe Material Spacing and Supports

‘Woniinal Pipe Copper Stainless Stoo! PVCIABEE®

ize Horlzontal Verteal Woitzontal Vertical Horizontal ~~ Vartieat

mm dn) | im (ty) | om ty | om tty |. om ety | om tt) (t)

15 (3%) [18 G9) | 24 Gay | 18 G9) [24 Gan | O68 a96, 08)

20 (0767 | 24 @sn | 30 (a) | 24 G8 | 24 Gan | 06 0196) eat)

25 (0s) | 24 an | 30 as] 24 87 | 27 Gas) | 06 56) 8)

32 (1259) | 27 665) | 30 @as) | 27 a5) | 30 Ga) | 12 G53) om)

4 57) | 30 08) | 36 ats) |) 30 oa) | 30 Ga) | 12 G99) (034)

50 (195) ; 30 6 | 36 ars) | 30 @s) | 30 oa) | 12 G9 34)

6 @5 | 30 ©) | 36 are)! 30 8) | 30 8 | 12 G59) 84)

8 G0) 30 ea) | 36 (us) | 30 Ga) | 30 8) | 12, B93) 54)

109 0 | 37 G2 |} 36 ais) | 30 es) | 30 oa | 12° G99 (88)

43 cao) | 42 G4 | 30 @8 | 30 08 | 14 59) ox)

T oPvet T PEX

Size Horizontal” | —Vertieal | —~-Hevizontal”™ | —Veitcal —}

mm (in) mt) | im ty | mt) | om ty | mt) | mt

(059) “05” Gist) | “10 G2 | OS ei) | 10 G26] aS —Wh.ss) | “1.07 ae)

20 0787) 05 (164) | 10 Gas) | 05 Co | 10 G2 | 05 Gop | 10 28)

2 @98) 05 Gs) 10a) | 05 cues) | 10 (2 | os Co) | 10 (328)

32 25) 08 @a) | 14 ass) | 08 a) | 14 459 | 08 Gor) | 14 (A

49 057) | 08 Ga) | 20 (56 | 08 (262 | 20 65) | a8 m2) | 20 (654

50 09) 12, G53) | 22 G2 | 12 G93 | 22 ~2y | 12 B99) | 22 G21)

6 @) 15 as) 22 Gat) | 15 as) | 22 Gay | 15 asy | 22 Gay

s GD | 15 4m) | 24 GH | 15 Gm | 24 GSN | 15 G9 | 24 CBD

Joo 4) | 18 5) | 24 C8) | 18 G8) | 24 Ga | 18 Gs) | 24 (EN

180 (60) | 18 69 | 24 ca | 18 69 | 24 oy | 18 6% | 24 G87

Nominal Pips | PEK ALPEX PEX-ALPE POLYPROPYLENE

Size Harlzontal” | ~ Vartleal J Horizontal [~ Vertical —|~Hartzontalj — Vertleat~—

mm (in) | om i) | im ty | om dt) | my | mt) | mt

15 (ss) | 05 (6s) | 19 B28) | 05 es) | 10 G28 | OS™ Ge) [10 G28)

20 0787) | 05 C6) | 19 G2) | 05 cs) | 10 G2) | 05 G6) | 10 G2

25 098) | 05 cis) | 19 2H | 05 ass | 10 G2) | 05 cs | 20 G2

32 (125) | 08 @e) | 14 5) | 08 22} | 14 59 | 08 Ga | 14 C58)

40 057) | 08 62) | 20 (655) | 08 ej | 20 56 | 08 Qe | 20 656)

so 96) | 12 9) | 22 gay | 12 ss | 22 ga | 12 @s | 22 gay

6 @s) | 15 4m | 22 gay | 15 fs) | 22 G2) | 15 @s.| 22 oH

© GO | 15 49 | 24 Gary | 15 as) | 24 oan | 15 9a | 24 Can

10 4 | 18 69 | 24 van | 18 9 18 6) | 24 os

150 6 | 18 69 | 24 7a | 18 69 1e_69)_| 24 759)

~ Nominal Pipe Cast-iron Huble

Se izontal |

mm (in) (ft)

B59) | SEES

2 77 | - - - + - - tee

2 (09) | - ~ - - - = - -

32_ (125) | - -_- - - -_-

‘0 (157) ~jBveryotherjoin, [Base and cach [Every other jolt, [Base and cach

50 (195) funlessover ” [oor not to exceed less over oF not to exceed

© @5) [2bmaR, srmasn) f2vman, ksemase)

80 leah schon

100 (40)

ey brane very BRAGS

15060) _lepeningerchange sping arene

er

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Irrigation Design ManualDokument140 SeitenIrrigation Design Manualabinet100% (8)

- Sump Pit CalculationDokument4 SeitenSump Pit CalculationEng Mahmoud Hamdy33% (3)

- NPSH SimplifiedDokument4 SeitenNPSH Simplifiedtexwan_Noch keine Bewertungen

- Plumbing DwgsDokument3 SeitenPlumbing DwgsViswanathan Krish100% (1)

- @water & Drainage Equipement DesignDokument46 Seiten@water & Drainage Equipement DesignDesigner ForeverNoch keine Bewertungen

- Office Population Count Population Count No's: Water Demand Calculation & Water Balance ChartDokument7 SeitenOffice Population Count Population Count No's: Water Demand Calculation & Water Balance ChartViswanathan KrishNoch keine Bewertungen

- Tamil Nadu Fire Rescue Licence AppDokument3 SeitenTamil Nadu Fire Rescue Licence AppViswanathan Krish0% (1)

- Fire Alarm Manual: Training GuideDokument34 SeitenFire Alarm Manual: Training Guideganeshakce100% (1)

- Water hammer design criteria and analysisDokument3 SeitenWater hammer design criteria and analysisNghiaNoch keine Bewertungen

- Thevaram 2.085 Kolaru Thiru PathigamDokument14 SeitenThevaram 2.085 Kolaru Thiru Pathigamrskcad100% (1)

- Astral PVC Pipes Price ListDokument4 SeitenAstral PVC Pipes Price ListKaranjit Sigot75% (4)

- Fire Fighting Calculation BOM (Warehouse)Dokument2 SeitenFire Fighting Calculation BOM (Warehouse)arbindNoch keine Bewertungen

- Rec Storm DrainDokument4 SeitenRec Storm DrainViswanathan KrishNoch keine Bewertungen

- Larsen & Toubro Limited: MIOT International BlockDokument3 SeitenLarsen & Toubro Limited: MIOT International BlockViswanathan KrishNoch keine Bewertungen

- Telangana Fire Service Act 1999 PDFDokument111 SeitenTelangana Fire Service Act 1999 PDFMunnangi NagendrareddyNoch keine Bewertungen

- TlenDokument1 SeiteTlenViswanathan KrishNoch keine Bewertungen

- Astral Price ListDokument4 SeitenAstral Price ListViswanathan KrishNoch keine Bewertungen

- Drainage Scheme-Waste MarkupDokument1 SeiteDrainage Scheme-Waste MarkupViswanathan KrishNoch keine Bewertungen

- CMWS Online Water Payment ReceiptDokument1 SeiteCMWS Online Water Payment ReceiptViswanathan KrishNoch keine Bewertungen

- Terrace floor plan layoutDokument1 SeiteTerrace floor plan layoutViswanathan KrishNoch keine Bewertungen

- Tata PipesDokument16 SeitenTata PipesViswanathan KrishNoch keine Bewertungen

- Holiday Calendar 2019-9632Dokument1 SeiteHoliday Calendar 2019-9632Viswanathan KrishNoch keine Bewertungen

- AspiratingSmokeDetectors AppGuide ASAG442Dokument88 SeitenAspiratingSmokeDetectors AppGuide ASAG442farooq929Noch keine Bewertungen

- Fire Sprinkler DesignDokument19 SeitenFire Sprinkler DesignViswanathan Krish0% (1)

- Index: Sr. No Item Description Makes REVDokument4 SeitenIndex: Sr. No Item Description Makes REVViswanathan KrishNoch keine Bewertungen

- NOC Fire Licence Ease of Doing BusinessDokument3 SeitenNOC Fire Licence Ease of Doing BusinessViswanathan KrishNoch keine Bewertungen

- REVISIONS TO FIRE & LIFE SAFETY CODE IN NBC 2016Dokument4 SeitenREVISIONS TO FIRE & LIFE SAFETY CODE IN NBC 2016JanakiRam BabuNoch keine Bewertungen

- TerraceDokument1 SeiteTerraceViswanathan KrishNoch keine Bewertungen

- Soap Dispenser JaquarDokument2 SeitenSoap Dispenser JaquarViswanathan KrishNoch keine Bewertungen